Landfill gas is unpredictable, hazardous, and tightly regulated—ignoring it risks environmental damage and compliance failure. The solution? Accurate, real-time gas analysis.

Effective landfill gas monitoring requires high-precision gas analyzers to detect methane, CO₂, and other hazardous compounds. These devices ensure environmental compliance, site safety, and energy recovery efficiency.

Even if you already know gas analyzers are important, do you know how they work, what features truly matter, or which brand leads in innovation? Let’s dive into why ESEGAS stands out and what makes landfill gas monitoring truly effective.

What Gases Are Produced In Landfills, And Why Must They Be Monitored?

Landfill gas is a complex and potentially dangerous compound mixture requiring constant observation.

When organic waste decomposes in an anaerobic (oxygen-free) environment, it produces a variety of gases, the most prevalent being methane (CH₄) and carbon dioxide (CO₂), which together account for over 90% of landfill gas composition. Methane is highly flammable and poses explosion risks when accumulating in enclosed areas. It is also a potent greenhouse gas—over 25 times more impactful than CO₂ over 100 years—making its release a significant environmental concern.

In addition to methane and carbon dioxide, landfills also emit trace amounts of hydrogen sulfide (H₂S), ammonia (NH₃), nitrogen (N₂), oxygen (O₂), and volatile organic compounds (VOCs) such as benzene, toluene, and xylene. Hydrogen sulfide is corrosive and toxic even at low concentrations, and VOCs contribute to air pollution and potential health risks for nearby communities.

Monitoring these gases is not optional—it’s a regulatory, safety, and environmental imperative. Fluctuations in gas concentrations can signal changes in waste composition, microbial activity, or system integrity. Continuous monitoring allows for early detection of hazardous conditions, enabling preventive action before they escalate.

Advanced gas analyzers, such as those designed by ESEGAS, are engineered to detect and measure these diverse compounds accurately in real-time. Their multi-gas sensing technology helps operators track site emissions, manage energy recovery systems, and comply with environmental legislation. By using ESEGAS equipment, landfill operators gain peace of mind and operational control in one of the most challenging atmospheric monitoring environments.

How Do Gas Analyzers Improve Landfill Gas Monitoring?

Modern gas analyzers transform landfill monitoring from a reactive task into a proactive, data-driven process.

In the past, landfill gas monitoring often relied on manual sampling and laboratory analysis, which involved delays, data gaps, and significant labor. Such methods provide only a snapshot in time, leaving operators unaware of sudden gas surges, equipment failures, or regulatory breaches.

Gas analyzers eliminate these weaknesses by delivering continuous, real-time data on gas concentrations and flow. These instruments use advanced sensor technologies—such as non-dispersive infrared (NDIR) for methane and CO₂, and electrochemical sensors for hydrogen sulfide and oxygen—to provide precise and stable measurements. This live data enables rapid responses to dangerous gas build-ups, optimization of gas extraction systems, and informed decision-making for operational planning.

Additionally, integrated data logging and remote communication features allow facility managers to access and analyze historical trends, set alarms for threshold violations, and generate compliance reports with minimal manual intervention. This not only enhances safety but also significantly reduces maintenance costs and regulatory risks.

ESEGAS gas analyzers are engineered specifically for landfill applications, combining rugged design with laboratory-grade precision. Their systems can monitor multiple gases simultaneously and withstand the harsh, corrosive environments typical of landfill gas wells. With automatic calibration and low maintenance requirements, ESEGASolutions delivers long-term reliability and cost-efficiency, making them a cornerstone of modern landfill gas management strategies.

What Key Features Make A Gas Analyzer Effective For Landfill Use?

A landfill gas analyzer must do more than measure—it must endure, adapt, and deliver actionable insights in extreme conditions.

Landfill environments are inherently challenging: high humidity, fluctuating temperatures, corrosive gases, and unstable terrain all pose risks to sensitive equipment. To be truly effective, a gas analyzer must be engineered with features tailored specifically for these operational realities. Here are the most critical ones:

1. Multi-Gas Detection Capability

A landfill gas stream typically contains methane (CH₄), carbon dioxide (CO₂), oxygen (O₂), hydrogen sulfide (H₂S), and volatile organic compounds (VOCs).

✔ An effective analyzer—like those from ESEGAS—must be capable of detecting and measuring all relevant gases simultaneously, ensuring a complete understanding of site conditions.

2. Robust Sensor Technology

Accurate readings depend on sensor stability and precision under harsh conditions.

✔ ESEGAS devices integrate high-performance sensors, including:

- NDIR sensors for stable CH₄ and CO₂ monitoring.

- Electrochemical cells for low-range toxic gas detection like H₂S and O₂.

3. Corrosion-Resistant Design

Landfill gases are chemically aggressive, especially with the presence of H₂S.

✔ ESEGAS analyzers feature corrosion-proof enclosures (e.g., stainless steel or reinforced polymer) and gas-path materials designed to resist chemical damage, ensuring durability.

4. Real-Time Data Logging and Remote Access

Monitoring systems must enable not only onsite visibility but also remote control and data retrieval.

✔ ESEGAS equipment includes integrated data loggers and IoT modules for remote access, alerts, and cloud-based analytics—allowing operators to manage multiple landfill sites from a central hub.

5. Automatic Calibration and Self-Diagnostics

Gas sensors drift over time, especially in volatile environments.

✔ With ESEGAS auto-calibration and self-check features, maintenance cycles are reduced, and operational uptime is maximized. These functions also ensure long-term measurement accuracy and regulatory compliance.

6. Portability and Deployment Flexibility

In many landfills, monitoring points are spread out and difficult to access.

✔ Portable options from ESEGAS allow technicians to perform spot checks, while fixed units can be deployed at extraction wells or perimeter boundaries for continuous monitoring.

In summary, the effectiveness of a gas analyzer in landfill applications depends on ruggedness, versatility, and intelligence. ESEGAS brings all these attributes together, delivering monitoring systems that operators can trust in the most demanding environments.

Do Gas Analyzers Help Meet Environmental And Regulatory Standards?

Landfill gas emissions are closely regulated worldwide due to their environmental, health, and safety implications. Authorities such as the U.S. Environmental Protection Agency (EPA), the European Environment Agency (EEA), and various national environmental ministries impose strict requirements on how landfill gas is monitored, reported, and controlled.

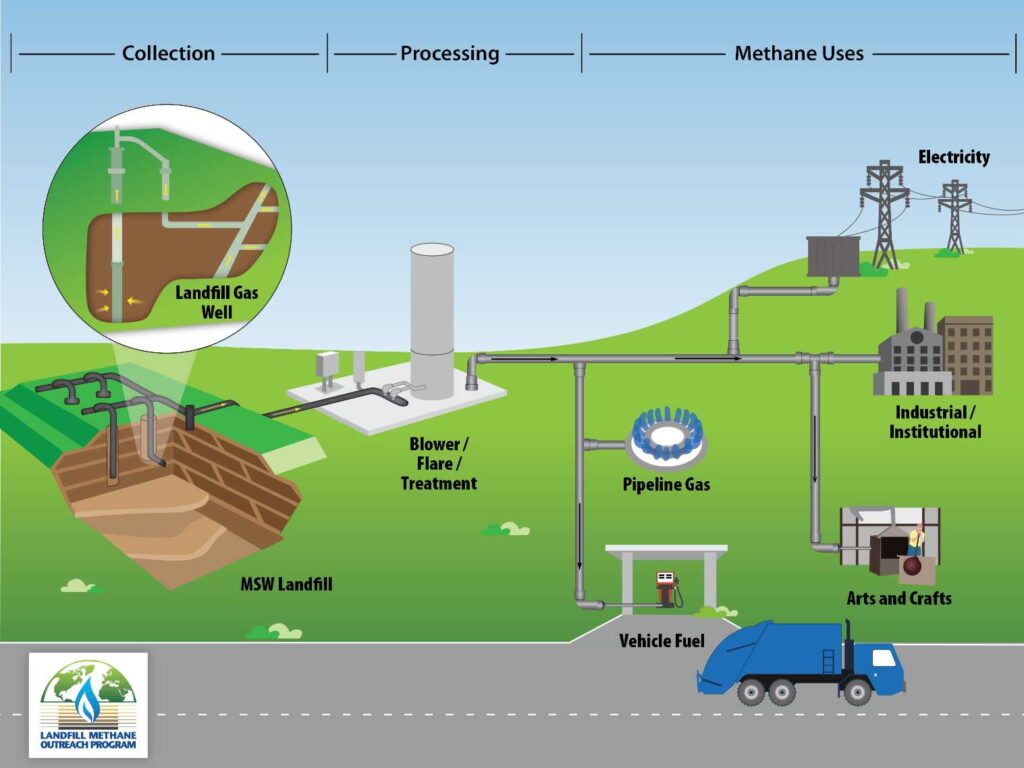

For instance, the EPA’s New Source Performance Standards (NSPS) and Landfill Methane Outreach Program (LMOP) mandate the continuous monitoring of methane levels, flare efficiency, and gas collection system performance. In the EU, Directive 1999/31/EC on the landfill of waste requires regular measurement of landfill gas composition to prevent groundwater contamination and air pollution.

Meeting these standards isn’t just about compliance—it also ensures safe operations and enables landfill operators to participate in carbon credit programs, biogas recovery projects, or energy resale initiatives.

ESEGAS analyzers are specifically engineered to align with international compliance frameworks. Their systems are:

- Certifiable and traceable, supporting calibration with reference gases as required by regulators.

- Equipped with detailed logging functions, storing time-stamped gas concentration data for months or years.

- Compatible with digital reporting protocols, making it easy to export compliance-ready reports.

Moreover, ESEGAS devices support alarm threshold settings, enabling immediate alerts if gas concentrations approach regulatory limits—helping sites avoid penalties and respond proactively to risk.

By integrating ESEGAS solutions into landfill operations, site managers can ensure that their gas monitoring practices not only meet but often exceed regulatory expectations. This builds trust with environmental auditors, local communities, and energy partners alike.

How Can You Choose The Right Gas Analyzer For Landfill Applications?

The right analyzer depends on your site’s size, gas composition, and compliance needs.

Selecting an analyzer isn’t just about price—it’s about reliability, ease of use, and compatibility with site operations. ESEGAS offers tailored solutions for small, medium, and industrial-scale landfill sites. Factors to consider include sensor type, gas range, portability, and connectivity. Consult with ESEGAS specialists to match the analyzer to your site’s specific monitoring demands.

Conclusion

Landfill gas monitoring is a high-stakes task. A reliable gas analyzer—especially from ESEGAS—ensures safety, compliance, and environmental stewardship with precision and confidence.

If you have any questions, please get in touch with us!