The product adopts advanced online analysis technology with high accuracy; low lower limit and small temperature drift

● Adopt Ultraviolet Absorption Spectrum Gas Analysis Technology and Chemometrics Algorithms. The measurement accuracy is not affected by water or dust. With low detection lower limit and small temperature drift.

● High range ratio (the maximum is 10:1).

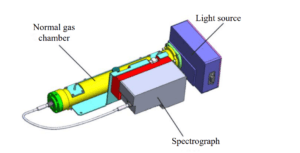

Strong gas chamber, low operation and maintenance cost.

● The gas chamber of module is made of stainless steel and the internal part is not required for mirror polish and gold plating. The gas chamber is very strong, with low cost and little effect by water and dust.

● The detector is connected to the gas chamber via the optical fiber, which is convenient for replacement and achieves low maintenance cost.

The service life of the light source is up to 10 years

● The light source adopts the pulse xenon lamp, with long service life, good stability and no preheating time.

Achieve simultaneous measurement of NO and NO2

● Carry out simultaneous measurement of NO and NO2, and then obtain NOX by the accumulation method, dispensing with NO2→NO converter

No optical moving parts, strong vibration resistance and high measurement reliability,Modular design, good expansibility and convenient maintenance

● Configured to produce diversified and customized products to meet all kinds of requirements.

Applications

☑ Continuous flue gas emission monitoring (CEMS) for power plants (analyze SO2, NO, NO2 and O2)

☑ DeSOX process monitoring (analyze SO2 and O2)

☑ DeNOX process monitoring (analyze NO, NO2, NH3 and O2)

☑ Continuous flue gas emission monitoring of waste incineration (analyze SO2, NO, NO2 and O2)

☑ Trace Cl2 analysis in PVC process and titanium dioxide production process in chlor-alkali plants (analyze Cl2)

☑ Gas analysis in sulfur recovery process (analyze SO2 and H2S)

☑ Gas analysis in natural gas purification process (analyze trace H2S)

☑ Methyl iodide analysis in coal chemical industry (analyze CH3I)

☑ On-line atmospheric air monitoring (analyze SO2, NO2 and O3), etc