The principle of an online Fourier Transform Infrared (FTIR) gas analyzer is based on the unique absorption characteristics of gases in the infrared (IR) region of the electromagnetic spectrum. Each gas has a unique “fingerprint” in the IR spectrum, allowing for the identification and quantification of various gas components in a mixture. Here’s how the online FTIR gas analyzer works:

- Infrared Light Source: The FTIR analyzer uses an infrared light source to emit a broad spectrum of IR radiation.

- Sample Cell or Path: The IR light passes through a sample cell where the gas mixture to be analyzed is present. Alternatively, the IR beam may pass through an open path in the atmosphere for environmental monitoring.

- Absorption of IR Radiation: As the IR light passes through the gas sample, specific wavelengths of the light are absorbed by the gases present. Each type of gas absorbs IR light at specific and characteristic wavelengths corresponding to the vibrational and rotational transitions of its molecules.

- Interferometer: A key component of the FTIR analyzer is the interferometer. It modifies the incoming IR light into an interference pattern. This pattern changes as the path difference between two beams of light (created by the interferometer) changes.

- Detector: The interfered light then reaches a detector, which records the intensity of the IR radiation at different wavelengths.

- Fourier Transform: The recorded interference pattern (known as an interferogram) is mathematically transformed using a Fourier transform algorithm. This transformation converts the complex interferogram into a more interpretable spectrum, showing the intensity of IR radiation as a function of wavelength or wavenumber.

- Spectral Analysis: The resulting spectrum is analyzed to determine which wavelengths were absorbed by the sample. By comparing these absorption features to known spectra of different gases, the analyzer identifies the gases present and determines their concentrations.

- Continuous Monitoring: In an online FTIR system, this process occurs continuously, allowing for real-time monitoring and analysis of the gas composition.

The strength of online FTIR analyzers lies in their ability to simultaneously detect and quantify multiple gas components, their high sensitivity and accuracy, and their applicability to a wide range of gases. This makes them invaluable tools in environmental monitoring, industrial process control, emissions monitoring, and various research applications.

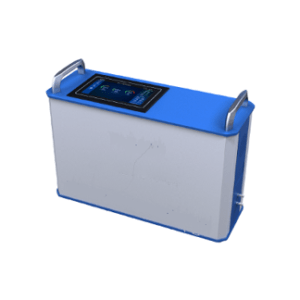

An online FTIR (Fourier Transform Infrared) gas analyzer is a sophisticated instrument used for continuous monitoring and analysis of gas compositions. This type of analyzer is particularly useful in industrial and environmental applications where real-time monitoring of various gases is critical.