Methane, CH4, a molecule both simple and complex demands precise monitoring. Enter the realm of CH4 sensors, where variety and specificity reign. Among these, the TDL CH4 Gas Sensor stands as a pinnacle of technological prowess. Its brethren, varying in sensitivity, range, and application, present a spectrum for selection. Choosing the right TDL CH4 Gas Sensor hinges on understanding these nuances.

Factors like environment, application precision, and operational longevity guide this crucial decision. It’s a journey through a forest of parameters, where each sensor type beckons with unique capabilities.

Understanding CH4 Sensors!

· Explanation Of CH4 Sensors And Their Significance

TDL CH4 sensors are vital in gas detection and offer precision in methane tracking. These devices, crucial in various industries, ensure safety by monitoring CH4 levels. Their technology, based on tunable diode laser absorption spectroscopy, provides reliable readings.

Key in preventing gas leaks, they’re essential for environmental protection. TDL sensors, with their advanced detection capabilities, play a pivotal role in safety systems. They are indispensable tools in modern industry, safeguarding against methane-related hazards.

· Overview Of Different Types Of CH4 Sensors.

PID Sensors

In the PID sensor domain, precision is paramount. They utilize photon-induced ionization for operation. Ideal for sensing volatile organic compounds, these sensors have a broad detection scope.

Rapid response times set them apart. Environmental factors like humidity and temperature affect them. Maintenance, especially lamp replacement, is crucial. They are often used in industrial safety environments.

Electrochemical

Electrochemical sensors for CH4 detection stand out for efficiency. They operate via chemical reactions generating electrical signals. Known for compactness and low power needs, they deliver accurate low concentration readings. Environmental factors can influence their performance. Regular calibration is key for accuracy. These are suitable for portable devices due to their size.

NDIR Sensors

NDIR sensors use non-dispersive infrared technology for CH4 detection. They identify gases through light wavelength absorption. Their long-term stability and minimal maintenance are significant.

These sensors work independently of oxygen levels. They are less sensitive at lower gas concentrations. Predominantly, they are used in fixed installations for continuous monitoring.

TDLAS Sensors

TDLAS sensors offer high accuracy in CH4 measurement. They function by laser light absorption at specific wavelengths. Their rapid, precise measurements are commendable. Suitable for harsh conditions, they resist interference well. They are commonly used in real-time industrial monitoring. Their cost can be higher compared to others.

Infrared Sensors

Infrared sensors detect CH4 through infrared light absorption. They are known for their long lifespan and resistance to toxins. Ideal for explosive gas environments, they are reliable and robust.

Accuracy can be affected by other gases. These sensors are typically used in safety systems for detecting leaks.

The Technology Behind TDL CH4 Gas Sensors!

· Principles Of Tunable Diode Laser Absorption Spectroscopy (TDLAS)

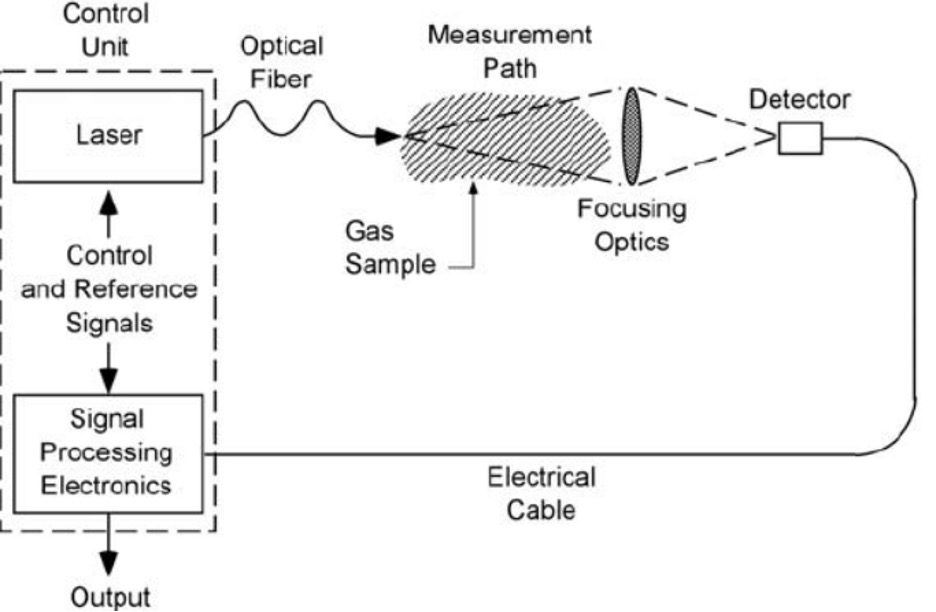

Laser Spectroscopy

In the world of TDL CH4 Gas Sensors, laser spectroscopy stands as a cornerstone. It’s where a tiny diode laser plays a big role, shining light that mingles with methane’s essence. This light is carefully chosen for its methane-friendly wavelength, journeys through a gas sample.

It’s a path of discovery, as some light gets absorbed, leaving clues about the methane’s presence. Essential bits like optical lenses lend a hand, sharpening the sensor’s methane-spotting skills.

Gas Absorption

Gas absorption, the heart of TDL CH4 sensors, is all about methane’s dance with laser light. Here, methane particles in the air embrace specific wavelengths of this light. The sensor, like a keen observer, notes this absorption, unraveling the story of methane levels.

It’s a blend of innovation, with ultra-sensitive detectors and specialized optics, all joining forces for that precise methane narrative. This method cleverly tells methane apart from its gaseous peers, offering trustworthy insights for environmental watch.

Diode Tunability

Diode tunability in TDL CH4 sensors is like having a fine-tuned instrument in a grand orchestra. It’s the art of tweaking the laser’s wavelength, making the sensor a dedicated methane seeker.

This fine-tuning cuts through the noise of other gases. The sensor’s smart circuitry keeps the laser performance steady, ready to adapt to the whims of the environment. This trait makes the sensor a versatile hero in various scenarios.

Optical Feedback

Optical feedback in TDL CH4 sensors is akin to a masterful calibration. It employs the laser light’s echo to perfect the beam’s aim and power. Key components within the sensor uphold this feedback loop, vital for unwavering performance. This technology is the sensor’s promise for ongoing vigilance and swift response to methane shifts, a guardian for environmental safety.

Signal Processing

In the realm of TDL CH4 sensors, signal processing is the bridge from optical data to actionable methane insights. Advanced algorithms play the role of a skilled filter, isolating the methane signal from the noise.

Digital processors take the helm, steering this data with efficiency, leading to prompt and precise methane readings. The sensor’s software stands guard, detecting and rectifying any oddities, ensuring steadfast methane detection in diverse conditions. This processing prowess is the sensor’s key to real-time monitoring excellence.

· Advantages Of TDLAS In CH4 Detection

High Sensitivity

TDL CH4 Gas Sensors shine in their sensitivity. They’re like hawks, spotting methane with laser precision. Every part, from diodes to detectors, works in harmony.

It’s like a symphony, each note hitting the right wavelength. This sensitivity is not just impressive, it’s vital. It allows for the subtle detection of methane, often missed by less sensitive devices.

Rapid Response

When it comes to speed, these sensors are sprinters. They detect methane faster than you can snap your fingers. This rapid response is crucial, especially in emergencies. Imagine a gas leak – every second counts. These sensors act swiftly, providing data in a blink. It’s not just fast; it’s lightning-fast, making it indispensable for safety.

Selective Detection

The true power of TDL CH4 sensors lies in their selectivity. It’s like they have a sixth sense for methane. Amidst a cocktail of gases, they find methane with unerring accuracy. This selectivity is their superpower distinguishes methane in complex environments. It’s not just detection; it’s detection with precision.

Low Interference

Interference is a common problem in gas detection, but not for these sensors. They stand strong, unaffected by external factors. It’s like they’re in a bubble, focused only on methane. This low interference ensures data integrity, a cornerstone for reliable measurements. It’s not just robust; it’s a fortress against false readings.

Long-Term Stability

The endurance of TDL CH4 sensors is remarkable. They’re like marathon runners, maintaining consistency over time. This long-term stability is crucial for ongoing monitoring. They don’t just last; they endure, providing reliable data year after year. It’s not just stability; it’s a commitment to long-term performance.

· Key Technical Specifications Of TDL CH4 Sensors

Measurement Range

The TDL CH4 Gas Sensor’s measurement range is striking. It efficiently identifies the low to high methane concentration. This range is critical in a wide variety of fields from small gas leak detection to dense concentrations measurement required for industrial processes.

The much large range is proof of the sensor’s versatility and accuracy under different circumstances.

Accuracy Levels

The TDL CH4 Gas Sensor is a mark of accuracy. It has high methane detection precision, which is an important factor in achieving safety and compliance with regulation. This accuracy is consistent throughout the entire measurement range, which has only been made possible through cutting-edge sensor technology and careful calibration procedures.

Response Time

The short response time of the TDL CH4 Gas Sensor is remarkable. With instant methane changes identification it becomes irreplaceable in emergencies when the response can be fast. This speed realizes the use of advanced sensor design and on-time data processing abilities that guarantee timely and accurate readings.

Environmental Durability

The TDL CH4 Gas Sensor is resistant to various types of environments. It is resistant to high temperatures, humidity as well as other unfriendly weather conditions. This toughness ensures high performance under severe industrial environments in continuous, long-term monitoring.

Power Efficiency

Power efficiency is one of the main features in TDL CH4 Gas Sensor. It runs efficiently using very little energy hence ideal for continuous monitoring. This efficiency lowers the operating costs and facilitates environmentally friendly practices without sacrificing performance or reliability.

How to Choose the Right TDL CH4 Gas Sensor?

· Application Relevance

The choice of the TDL CH4 gas sensor requires knowing its working conditions. Industrial environments require robust sensors. The laboratory setting answers sensitivity and precision.

Before making a decision, assess the application’s unique requirements. Different settings require different sensor attributes. From the oil fields to various research labs, having a correct sensor guarantees best performance.

· Sensitivity Needs

A TDL CH4 gas sensor needs to be sensitive. Accurate methane detection is guaranteed with high sensitivity. In less demanding applications, lower sensitivity may be sufficient.

Assess your environment’s methane concentrations. Sensitivity of a sensor matches these needs. Reliable measurements are based on sensitivity. Select according to your methane detection requirements.

· Environmental Adaptability

Environmental variations significantly impact the selection of TDL CH4 gas sensor. Harsh conditions demand durable sensors. Performance is influenced by humidity, temperature and atmospheric pressure. Better choose sensors that proved to be effective in similar environments.

No matter how diverse the conditions, reliability is essential. Make sure the sensor can endure your particular weather problems.

· Measurement Range

When choosing a TDL CH4 gas sensor, take the measurement range into account. Ranges with many values are crucial for different uses. Limited ranges suit controlled environments. Evaluate the usual methane concentrations. Select a sensor capable of measuring within this limit. For effective monitoring, accuracy throughout the entire range is very important.

· Installation Ease

Installability is important for TDL CH4 gas sensors. Complex setups require more resources. User-friendly designs speed up processes and minimize mistakes. Go for sensors with less complicated installation processes. With easier installation of sensors, setup becomes faster. Make things as simple to install them.

· Maintenance Requirements

One of the main elements for TDL CH4 gas sensors is maintenance. Time and cost are saved with low-maintenance sensors. Regular maintenance is often resource demanding.

Analyze the sensor maintenance requirements before choosing it. Durable designs are usually low on maintenance. Opteimum performance is achieved by balancing balance maintenance demands with efficiency in operations.

| Factor | TDL CH4 Gas Sensor Model A | TDL CH4 Gas Sensor Model B | TDL CH4 Gas Sensor Model C | TDL CH4 Gas Sensor Model D | TDL CH4 Gas Sensor Model E | TDL CH4 Gas Sensor Model F |

| Application Relevance | Industrial, Mining | Urban Monitoring, HVAC | Lab Research, Medical | Environmental, Agriculture | Petrochemical, Refinery | Aerospace, Aviation |

| Sensitivity (ppm) | 0.1 – 1000 | 1 – 500 | 0.05 – 800 | 2 – 1000 | 0.5 – 750 | 0.2 – 900 |

| Environmental Adaptability | -20°C to 60°C, IP65 | -10°C to 50°C, IP54 | -30°C to 70°C, IP68 | -15°C to 55°C, IP67 | -25°C to 65°C, IP60 | -20°C to 60°C, IP66 |

| Measurement Range (CH4 %) | 0-5%, ±1% | 0-10%, ±2% | 0-2%, ±0.5% | 0-15%, ±1.5% | 0-8%, ±1% | 0-6%, ±0.8% |

| Installation (Mounting/Space) | Wall, Compact | Ceiling, Modular | Benchtop, Small | Ground, Spacious | Wall, Medium | Portable, Miniature |

| Maintenance (Calibration/Service) | Biannual, Self-Check | Annual, Technician | Quarterly, Auto-Calibrate | Yearly, Manual | 18-Months, Semi-Auto | 6-Months, On-Demand |

Applications of TDL CH4 Gas Sensors in Industry!

· Emission Monitoring

The TDL CH4 Gas Sensor is the best in sensing emissions. Key features: real-time data, rapid response. Industries like power plant use it for emission control. It accurately measures CH4 levels, helping to ensure compliance with environmental standards. Its resilient engineering can survive the toughest industrial conditions.

· Industrial Safety

The TDL CH4 Gas Sensor is a must-have in industrial safety. It measures methane, a potential risk of its factories. By warning workers in advance, it avoids accidents. The reliability of the sensor is attributed to its sensitivity and zero maintenance requirements. A necessity towards are ensuring safety in the workplace.

· Process Control

Process control needs TDL CH4 Gas Sensors. In manufacturing, they ensure optimal conditions by tracking methane levels. This control is essential for quality and safety of the product. Its accuracy and sturdiness are beneficial to industries. Integration of the sensor within control systems provides smooth operations.

· Environmental Testing

The TDL CH4 Gas Sensor is the one that occupies a place of primary importance in environmental testing. It is accurate in detecting methane that is a pollutant to the environment.

This assists in air quality evaluation. Environmental organizations depend on its accurate measures for surveillance and studies. Its high-tech nature also explains why this product is a favorite for many environmental professionals.

· Gas Leakage Detection

Gas sensors by TDL CH4 are required to detect leaks of gas. They act as early indicators and help in averting potential disasters. Sensors used by industries detect even trace amounts of methane leaks. The rapidity and high sensitivity play a crucial role in ensuring safety.

· Combustion Efficiency

The TDL CH4 Gas Sensor is a powerful tool for improving combustion efficiency. It maximizes the use of fuel through monitoring of methane levels. This results in cost efficiency and low emission levels.

Its accurate data helps power plants and industrial facilities. It contributes towards effective combustion processes.

Installation and Maintenance of TDL CH4 Gas Sensors!

· Proper Placement

Installing TDL CH4 Gas Sensors demands strategic placement. Ideal locations: near potential leak sources, away from direct sunlight. Ensure unobstructed airflow for accurate readings.

Mounting height and position are critical for optimal performance. Consult the manual for specific site recommendations. Proper positioning enhances sensor efficacy significantly.

· Regular Calibration

Calibration of TDL CH4 Gas Sensors is crucial for precision. Use standard methane samples for calibration. Monitor calibration logs for any drifts in sensor readings. Regular calibration ensures the sensor’s reliability and longevity in various industrial settings.

· Environmental Protection

Environmental factors impact TDL CH4 Gas Sensors. Protect sensors from extreme temperatures, humidity, and dust. Use protective casings if necessary. Environmental shields enhance sensor durability. Check environmental compatibility in the product specifications. Adapting to environmental conditions extends the sensor’s operational life.

· Sensor Cleaning

It is vital to keep TDL CH4 Gas Sensors clean. Sensor accuracy is affected by dust and debris. Schedule regular cleaning sessions. Apply recommended cleaning products. Prevent strong chemicals from damaging the sensor. Proper cleaning ensures repeatability of performance and a longer sensor life.

· Software Updates

The functionality in TDL CH4 Gas Sensors is increased through software updates. Check for updates regularly. New firmware typically incorporates better algorithms and bug corrections. Update via the sensor’s interface or remotely if applicable. The sensor works with the latest advances and attributes as long as software is constantly updated.

· Technical Support

Technical support for TDL CH4 Gas Sensors is critical to access. Ask for help with installation, debugging and maintenance. Manufacturing support teams provide technical guidance. Use online tools such as forums and tutorials. Good technical support ensures continued functioning and quick resolution of any problems.

Conclusion

In the intricate dance of CH4 detection, the TDL CH4 Gas Sensor emerges as a symphony of precision and reliability. Different types cater to varied requirements, each with its own technical symphony. Selecting the right one intertwines understanding of specific needs with sensor capabilities.

As the curtain falls on this exploration, we invite you to continue your journey at ESEGAS where the perfect TDL CH4 Gas Sensor awaits, ready to transform your challenges into solutions.