NDIR CO Gas Sensors are reshaping air quality monitoring. These sensors offer unparalleled precision. They’re changing how we detect CO levels. It’s a blend of technology and environmental care.

Their sensitivity makes a huge difference. They’re easy to integrate into existing setups. A leap towards are safer environment. This is modern monitoring at its best.

The Basics of NDIR CO Gas Sensors

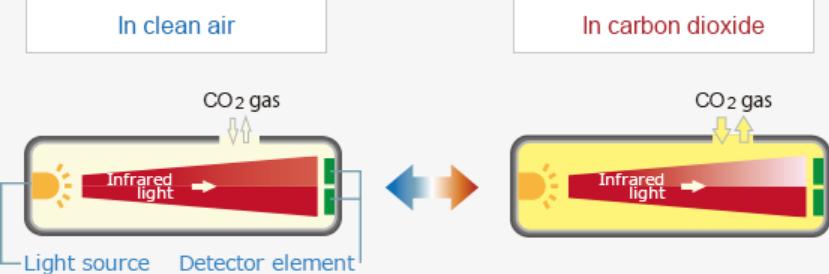

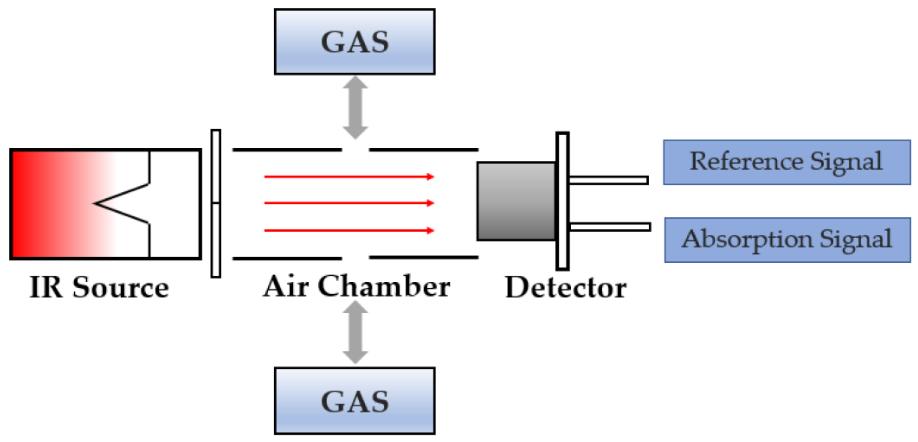

· Explanation of NDIR technology

NDIR CO Gas Sensors operate on a simple principle. These sensors use Infrared (IR) light to detect gas. CO molecules absorb specific IR wavelengths. When CO is present, IR light diminishes. This reduction signals CO levels. NDIR sensors are known for stability. They offer precise CO detection.

Key components include IR sources, detectors, and filters. This setup ensures accurate gas measurement. NDIR technology suits various applications. It’s used in industrial safety and air quality control monitoring. These sensors are reliable over time. They require minimal maintenance. NDIR CO sensors are a preferred choice for gas detection.

· Key components of NDIR CO gas sensors

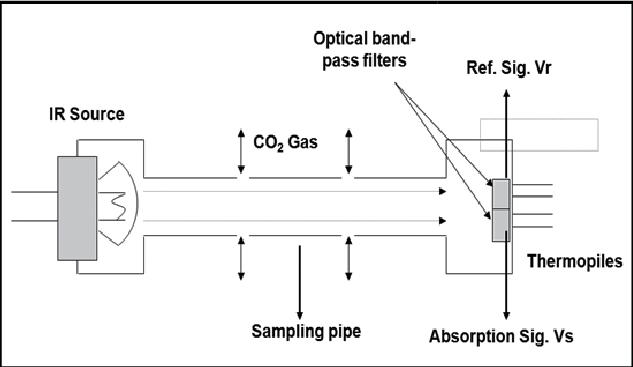

Optical Filters

In NDIR CO sensors, the optical gas filter is crucial. They refine light to specific wavelengths. This ensures accurate gas detection. These filters block unwanted light, enhancing sensor precision.

They’re tailored for CO’s unique absorption. This leads to reliable readings. Optical filters sustain sensor longevity too.

Infrared Source

NDIR CO sensors use an infrared source. It emits light absorbed by CO. This source is the heart of detection. It’s designed for consistent output. This ensures stable sensor performance. The infrared’s interaction with CO is key. It helps in determining gas concentration accurately.

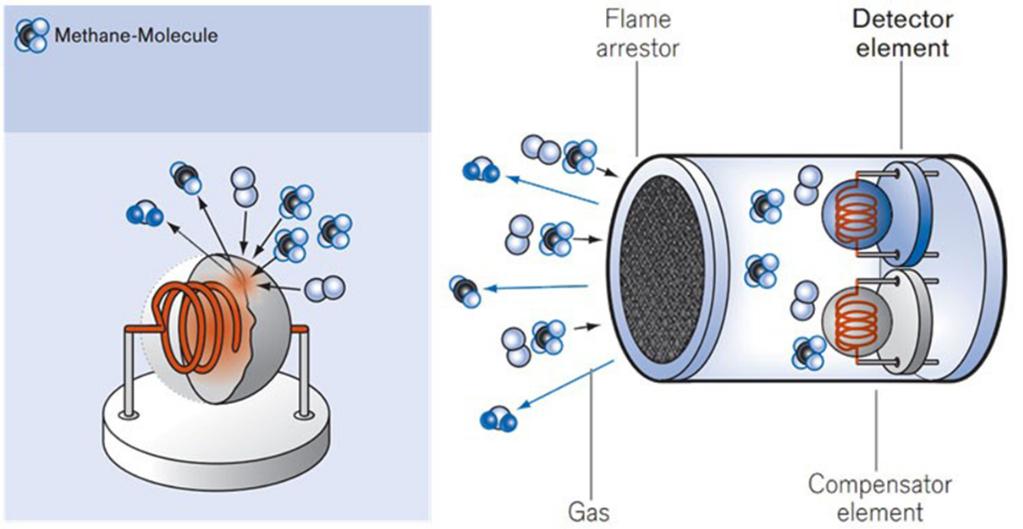

Detector

The detector in NDIR CO sensors is vital. It captures light after CO absorption. This component translates light into electrical signals. These signals indicate CO levels. The detector’s sensitivity is paramount.

It ensures accurate gas measurement. Advanced detectors provide quicker responses. This improves overall sensor efficiency.

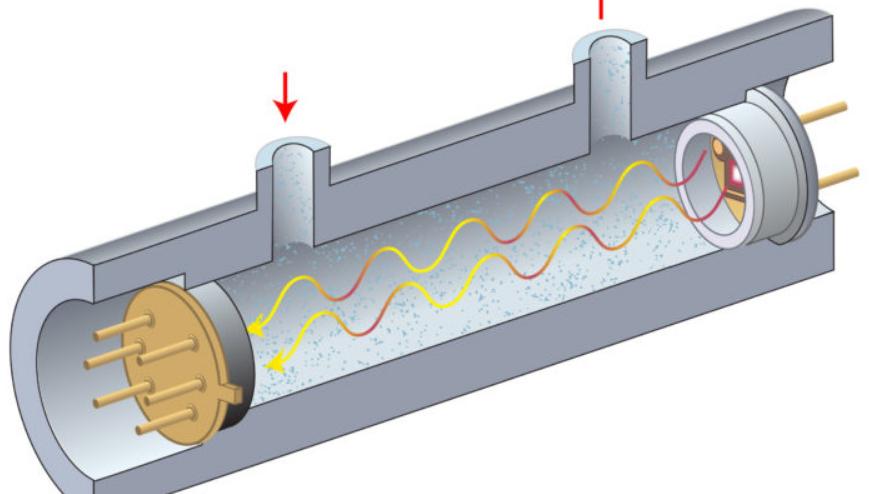

Waveguide

Waveguides in NDIR CO sensors are essential. They direct infrared light precisely. This ensures optimal path for light. Their design affects sensor accuracy. Waveguides are made for specific light wavelengths. They maintain light intensity for detection. Proper waveguide function is crucial for sensor reliability.

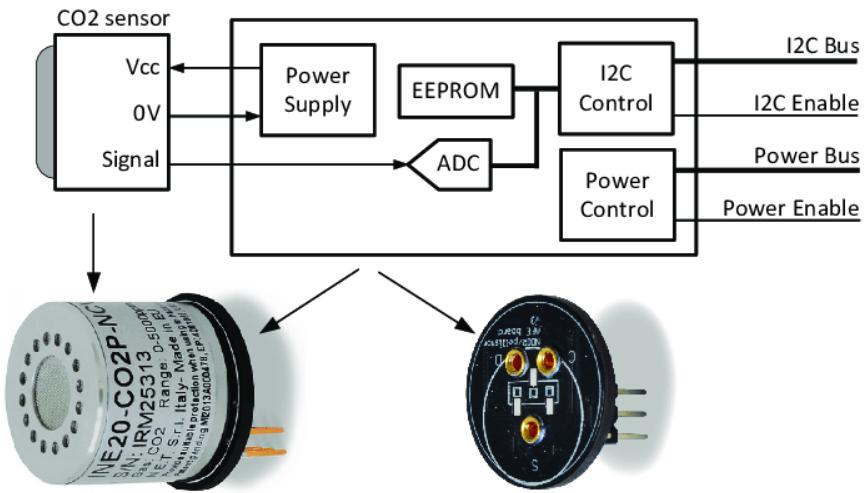

Electronics

Electronics in NDIR CO sensors control operations. They process signals from the detector. This includes signal amplification and analysis. Electronics determine gas concentration.

They are programmed for accuracy. Advanced electronics adapt to environmental changes. This maintains sensor precision in different conditions. Electronics are key for consistent sensor performance.

How do NDIR Sensors Differ From Other Gas Sensing Technologies?

· Specificity

NDIR sensors excel in specificity compared to other technologies. They’re finely tuned to detect specific gases like CO. This is due to their unique light absorption method. Other sensors may react to multiple gases, reducing accuracy. NDIR’s selectivity helps in precise gas detection. This is crucial in environments with various gases.

· Stability

NDIR sensors showcase superior stability. Their readings remain consistent over time. This contrasts with other sensors that may drift. Drift leads to frequent recalibrations. NDIR’s stable output reduces this need. It’s due to their non-reactive detection method. This stability is key for reliable long-term use.

· Sensitivity

NDIR sensors are susceptible. They detect even low levels of gases like CO. This sensitivity is higher than many other technologies. It’s because of their specialized infrared absorption.

Other sensors might miss low concentrations. NDIR’s ability to detect subtle changes is a major advantage. It ensures early detection of hazardous gases.

· Longevity

NDIR sensors often have a longer lifespan. They don’t degrade like chemical-based sensors. Chemical sensors can exhaust their reactive materials. NDIR uses light, which doesn’t wear out. This leads to a longer, more reliable service life. A longer lifespan means less frequent replacements, saving costs.

· Calibration

Calibration in NDIR sensors is less frequent. Other technologies might need regular recalibration. This is due to their sensitivity to environmental factors. NDIR sensors, however, remain calibrated for longer. External conditions less influence their method of detection. This reduces maintenance time and effort significantly.

| Criteria | NDIR Sensors | Electrochemical Sensors | Catalytic Sensors | Semiconductor Sensors | Infrared Absorption Sensors | Photoionization Detectors |

| Specificity | High (selective to CO2) | Moderate | Low | Low to Moderate | High | Moderate to High |

| Stability | Excellent (over years) | Good (some degradation) | Moderate | Sensitive to environment | Good | Sensitive to humidity |

| Sensitivity | High (ppm levels) | Very High (ppb levels) | High (percent levels) | Moderate to High | High (ppm levels) | Very High (ppb levels) |

| Longevity | Long (5-10 years) | Moderate (1-3 years) | Moderate to Low (1-2 years) | Moderate (2-5 years) | Long (5+ years) | Moderate (1-3 years) |

| Calibration | Infrequent (annual) | Frequent (monthly) | Frequent (3-6 months) | Frequent (monthly) | Infrequent (annual) | Frequent (monthly) |

| Cost Efficiency | Moderate to High | Low to Moderate | Low | Low | High | Moderate |

| Environmental Impact | Low (non-consumptive) | Moderate (chemical use) | High (catalyst degradation) | Moderate (sensitive to pollutants) | Low (non-consumptive) | Moderate (chemical use) |

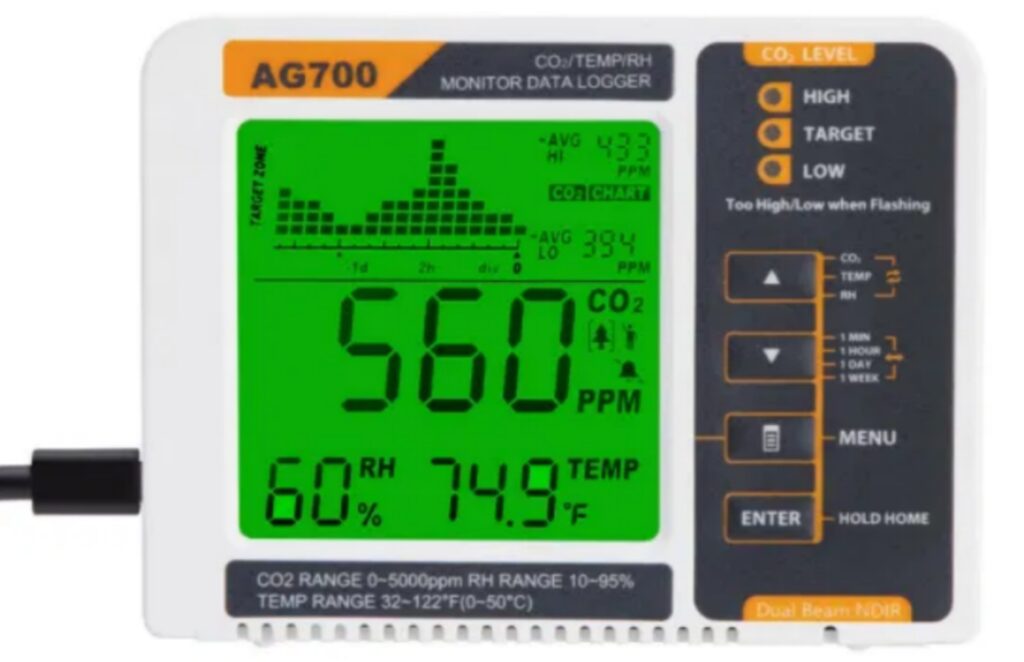

Application of NDIR CO Gas Sensors in Air Quality Monitoring!

· Industrial Use

NDIR CO sensors are crucial in industries. They detect gas leaks promptly. This ensures safety in factories. Industries benefit from their high accuracy. Downtime is reduced, thanks to these sensors. They monitor air quality constantly. Sensor durability is a key advantage.

It leads to cost savings in maintenance. Reliable readings are essential. These sensors provide just that. Their integration into industrial systems is seamless. NDIR technology enhances operational efficiency.

· Environmental Monitoring

NDIR CO sensors play a vital role outdoors. They track air pollution levels. This helps in environmental protection. Data from these sensors inform policy decisions. They are widely used in urban areas.

Their precision in measuring CO levels is unmatched. Continuous monitoring supports ecological research. These sensors are resistant to weather changes. They provide consistent performance. This makes them ideal for long-term environmental studies.

· HVAC Systems

In HVAC, NDIR CO sensors are essential. They ensure air quality indoors. These sensors control ventilation effectively. This leads to energy savings. They detect CO levels accurately. It’s vital for healthy indoor environments. Integration in HVAC systems is straightforward.

These sensors help in maintaining comfort. They adjust ventilation based on CO levels. This creates a safer indoor atmosphere. Their reliability is crucial for HVAC efficiency.

· Health Safety

NDIR CO sensors are key for health. They detect harmful CO levels. This helps in preventing health hazards. Their use in public spaces is growing. Timely detection can save lives.

These sensors are compact and unobtrusive. They fit easily in various settings. Detection accuracy is critical. NDIR sensors provide this accuracy. They help in creating safer environments. Continuous monitoring is their major advantage.

· Compliance Monitoring

Compliance with regulations requires NDIR CO sensors. They ensure adherence to safety standards. Monitoring CO levels is a legal necessity in many sectors. These sensors aid in maintaining compliance.

They provide detailed data logs. This is important for regulatory audits. Their reliability is key in legal contexts. Accurate readings support compliance efforts. They are an essential tool for regulatory bodies. Their use simplifies the compliance process.

Accuracy and Reliability of NDIR CO Gas Sensors!

· Industrial Use

In factories, NDIR CO sensors are key players. They keep tabs on carbon monoxide levels. This ensures a safer workspace. Industrial processes emit CO. These sensors are crucial for monitoring. They help maintain air quality. This protects workers’ health. Factories rely on them for safety. NDIR tech is vital in this setting.

· Environmental Monitoring

NDIR sensors play a huge role outdoors. They track air emerging pollutants. CO levels are important for environmental health. These sensors offer precise readings. They’re used in various locations. This helps in studying air quality trends. They provide valuable data for researchers. Environmentalists use this info. It’s key for sustainable practices.

· HVAC Systems

In HVAC, NDIR sensors are essential. They monitor air quality indoors. These sensors detect CO levels. This helps maintain a healthy environment. They’re used in offices, homes, and more.

HVAC systems rely on this tech. It ensures air circulated is clean. This is crucial for occupant health. NDIR sensors enhance HVAC efficiency.

· Health Safety

For health safety, NDIR sensors are crucial. They detect harmful CO levels. This prevents health risks. CO exposure can be dangerous. These sensors offer early warnings. They’re used in public spaces.

This includes malls, schools, and hospitals. They help in emergency response. It’s vital for public safety. NDIR sensors are a health safeguard.

· Compliance Monitoring

NDIR sensors aid in compliance. They ensure regulations are met. CO levels must be within safe limits. These sensors monitor this constantly. They’re used by regulatory bodies.

This helps in policy enforcement. They provide accurate data. This is key for environmental laws. Compliance is crucial for public safety. NDIR sensors play a vital role here.

Installation and Operational Aspects of NDIR Sensors!

· Mounting Procedures

Mounting Procedures for NDIR CO Gas Sensors entail several critical steps. Firstly, choose the right point for installation with consideration to airflow and temperature. Mount the sensor firmly such that it does not vibrate, hence hindering accuracy.

Ensure that the sensor is away from direct sunlight and other forms of moisture as this may tamper with its performance. Checking of the mounting hardware should be done regularly to create stability and enhance performance. By adhering to these guidelines, the sensor can operate effectively and provide reliable readings.

· Power Requirements

Specific Power Requirements for NDIR CO Gas Sensors must be carefully considered. These sensors operate, if not between low power consumption so they are relatively power-saving. They therefore require a semi-constant power supply order to avoid excessive spiking in the transference of power that may disrupt the performance of the sensor.

Power fluctuations can interrupt power and set inconsistencies in readings. In most cases, it is prudent to check on the state of the power supply as this will help point out the cautionary signs for any prospective problems. This involves checking such things as wear on the power cables and connections. Proper power management ensures the sensor functions optimally for accurate and reliable CO detection.

· Data Interfaces

Data Interfaces for NDIR CO Gas Sensors are essential in providing for their efficient operation. Through the standard communication protocols, it is usual that sensors should have to connect with the data systems. A safe and secure connection at all times has to be provided so that conveyed data is trustworthy.

There is a regular check done for these interconnections; data loss or corruption may be avoided. The feature of compatibility of the gadget over a range of data systems makes this really simple sensor, versatile. With all technological advancements and versions updating continuously into software and firmware, the gadget also has to receive such updates in time to keep it updated against all odds.

This ensures the sensor remains efficient and accurate in its readings and integration with other systems.

· Environmental Adaptation

Environmental Adaptation for the NDIR CO Gas Sensors is important so as to ensure proper working conditions exist for such sensors. The sensor should be adjusted to adapt to changing environmental conditions. This could be changes in ambient temperature, humidity, and atmospheric pressure.

The sensors should be calibrated on a timely basis to ensure that the levels of accuracy are upheld. There are additional environmental factors including dust and various pollutants that can impact the performances of sensors as well.

There have to be protective measures against any type of environmental influence. Proper care by regular cleaning and maintenance can only ensure the durability and reliability of the sensor. This adaptability allows the sensors to provide precise readings in varying environmental conditions.

· Maintenance Protocols

Maintenance Protocols for NDIR CO Gas Sensors are being called for to ensure that they last longer and give accurate results. The sensors need regular checking and cleaning so that the sensors are not degraded. This includes visual inspection for any physical defects or obstructions that may prevent the sensor from giving accurate results.

The sensor’s calibration needs to be kept so that it continues to read accurately. The parts may need to be changed and software updates would help proper functioning. A log of all, that was done, regarding maintenance, could help track whether the sensor, with its age, is becoming sluggish or not.

By following these maintenance protocols, the sensor will last considerably longer and go on giving dependable readings.

NDIR Sensors and IoT Integration!

· Data Analytics

NDIR CO gas sensors are game changers in data analytics. They collect vital readings efficiently. This data guides crucial decisions. Businesses rely on these insights. Real-time analysis becomes possible. Enhanced decision-making is the result. It’s all about precision and accuracy. Smart tech is smarter decisions.

· Remote Monitoring

Imagine monitoring gas levels from afar. That’s what NDIR CO sensors enable. Remote control is now a reality. It’s like having eyes everywhere. Safety increases manifold. The quick response given to danger zones. Constant vigilance, all thanks to these sensors. Effortless monitoring is enormous peace of mind.

· Automated Alerts

NDIR CO sensors are your silent guardians. They detect gas levels and react. Automated alerts save the day. They’re like vigilant watchmen. Quick alerts mean quick actions. Safety is not compromised. It’s technology working for us. We stay safe, sensors stay alert.

· System Integration

Integrating NDIR CO sensors is a breeze. They fit into existing systems smoothly. It’s like adding a brain to the machine. Enhanced functionality follows. They communicate seamlessly. Data flows, and systems respond. It’s a symphony of technology. Integration that spells efficiency and safety.

· Scalability

Growing with NDIR CO sensors? Absolutely. They scale with your needs. Small setup or large, they adapt. They’re like chameleons in technology. Expand your operations, sensors follow suit. It’s about being flexible yet robust. Growing pains? Not with these sensors.

How to Optimize Air Quality Monitoring with NDIR CO Gas Sensors?

· System Calibration

Calibrating NDIR CO sensors is a key step. It’s like tuning an instrument before a concert. Accuracy is the goal here. Precise calibration equals reliable results. It’s a routine yet crucial task. Regular check-ups ensure peak performance. Think of it as a health check for sensors.

· Data Analysis

Data from NDIR CO sensors is a goldmine. Analyzing this data uncovers patterns. It’s like decoding a secret language. From raw data to valuable insights both are crucial. This analysis drives smart decisions. We’re talking about improved air quality management. It’s data telling a story, loud and clear.

· Sensor Placement

Where do you place NDIR CO sensors matters? It’s about finding the perfect spot. Placing a camera is the best view. Strategic placement captures accurate data. Think of high-traffic or risk-prone areas. It’s all about location, location, location. Optimal placement is for optimal data.

· Integration Techniques

Integrating NDIR CO sensors is an art. They need to sync with other systems. It’s like adding a new member to a team. Seamless integration is crucial. They should work together, effortlessly. Integration that spells harmony and efficiency.

· Monitoring Strategies

Effective monitoring with NDIR CO sensors requires strategy. It’s not just about watching; it’s about understanding. Think of it as a game plan. Continuous monitoring keeps us ahead. Anticipating issues before they arise. Always alert is prepared. That’s smart monitoring for you.

Conclusion

In wrapping up, NDIR CO gas sensors are pivotal in transforming air quality monitoring, providing precision and reliability crucial for environmental health. These devices, with their complex components and advanced algorithms, accurately detect CO levels, an important factor in air quality.

Their integration into air quality systems signifies a significant step in identifying and controlling air pollutants, thereby protecting public health and the environment. Discover more about how these sensors are changing the landscape of air quality monitoring at ESEGAS.