Continuous Emission Monitoring Systems (CEMS) play a vital role in industrial emission control. Especially in the steel and metallurgical industries, the application of CEMS is not only to meet the requirements of environmental protection regulations but also to achieve sustainable development and improve production efficiency and economic benefits. This Blog will explore in depth Application of CEMS in the steel and metallurgical industries, including its working principle, application cases, advantages, and challenges.

Overview of the Development of the Steel and Metallurgical Industry

As an important pillar industry for industrialization and modernization, the steel and metallurgical industries are currently in an important period of transformation and upgrading. With the recovery of the global economy and the acceleration of infrastructure construction, steel demand has rebounded, but the industry is also facing the dual challenges of resource and environmental constraints, intensified market competition, and technological progress.

Environmental protection and sustainable development have become important issues that the steel and metallurgical industries must face. Governments around the world are increasingly stringent in their requirements for environmental protection, and companies need to increase investment in environmental protection, reduce pollution emissions, and promote the development of green production technologies. For example, many companies are actively adopting efficient and energy-saving ironmaking and steelmaking processes, promoting the recycling of scrap steel, improving energy efficiency, and reducing carbon emissions.

Emission Characteristics of the Steel and Metallurgical Industries

As a traditional high-energy consumption and high-pollution industry, the steel and metallurgical industry involves numerous complex chemical reactions and mechanical operations in its production process and emits a wide variety of pollutants with high concentrations and large emissions. These emissions not only cause serious pollution to the environment but also have adverse effects on human health. Understanding the emission characteristics of the industry is a prerequisite for taking effective control measures. Below, we analyze in detail the main emission characteristics of the steel and metallurgical industry.

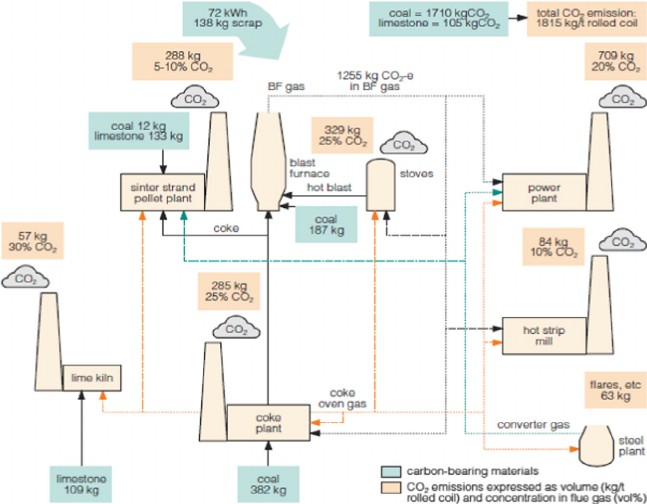

A comprehensive review on energy efficient CO2 breakthrough technologies for sustainable green iron and steel manufacturing – Scientific Figure on ResearchGate.

The picture Available from here

1. Particulate matter (PM)

1.1 Sources of particulate matter

Particulate matter is one of the main pollutants emitted by the steel and metallurgical industries. The main sources include:

- Combustion process: smoke produced by incomplete combustion of fuel at high temperature.

- Mechanical processing: dust generated by processes such as crushing, grinding, and screening.

- Smelting and refining: smoke and dust produced during the smelting process of blast furnaces, converters, electric furnaces, etc.

1.2 Hazards of particulate matter

Particulate matter not only has a serious impact on ambient air quality, but also has a great harm to human health. Fine particulate matter (PM2.5) can penetrate deep into the respiratory tract and lungs, and long-term exposure may cause respiratory and cardiovascular diseases.

2. Sulfur dioxide (SO2)

2.1 Sources of sulfur dioxide

Sulfur dioxide mainly comes from the combustion of sulfur-containing fuels (such as coal, oil, coke, etc.). In the steel and metallurgical industries, sulfur dioxide emissions are mainly concentrated in the following processes:

- Sintering and pelletizing process: SO2 produced by fuel combustion and decomposition of sulfur in ore.

- Blast furnace process: SO2 produced by fuel combustion and decomposition of sulfur-containing ores.

- Coking process: SO2 produced during the combustion of coke ovens.

2.2 Hazards of sulfur dioxide

Sulfur dioxide is a colorless gas with a pungent odor. It has a strong irritating effect on the human respiratory system. Long-term exposure can cause respiratory diseases. At the same time, sulfur dioxide will combine with moisture in the atmosphere to form acid rain, causing soil and water acidification and damaging the ecological environment.

3. Nitrogen oxides (NOx)

3.1 Sources of nitrogen oxides

Nitrogen oxides are mainly produced by high-temperature combustion processes. In the steel and metallurgical industries, the sources of nitrogen oxide emissions include:

- Sintering and pelletizing process: NOx produced by high temperature combustion.

- Blast furnace and converter processes: NOx generated during fuel combustion and smelting.

- Coking process: NOx emissions during high temperature cracking and combustion.

3.2 Hazards of nitrogen oxides

Nitrogen oxides are the precursors of photochemical smog and ozone pollution, which have a significant polluting effect on the atmospheric environment. In addition, NOx will react with water vapor to produce nitric acid, forming acid rain, which damages the ecosystem.

4. Carbon monoxide (CO)

4.1 Sources of Carbon Monoxide

Carbon monoxide is mainly produced when fuel is not completely burned. In the steel and metallurgical industry, the main sources of carbon monoxide emissions include:

- Blast furnace process: Blast furnace gas contains a large amount of carbon monoxide.

- Converter and electric furnace processes: CO produced by incomplete combustion of fuel during the steelmaking process.

4.2 Hazards of Carbon Monoxide

Carbon monoxide is a colorless, odorless, highly toxic gas. It can bind to hemoglobin and prevent the blood from carrying oxygen. In severe cases, it can cause carbon monoxide poisoning or even death. Long-term exposure to low concentrations of carbon monoxide can also cause chronic health problems.

5. Volatile organic compounds (VOCs)

5.1 Sources of Volatile Organic Compounds

VOCs refer to a class of organic compounds that are easily volatile at room temperature. In the steel and metallurgical industries, VOCs mainly come from the following aspects:

- Raw materials and fuels: VOCs produced by the volatilization of organic matter such as coal and coke.

- Coking process: VOCs produced by the evaporation of coke oven gas and tar.

- Paints and coatings: VOCs emitted from paints and coatings used in the steel surface treatment process.

5.2 Hazards of Volatile Organic Compounds

VOCs are harmful to human health and the environment. Some VOCs are carcinogenic, mutagenic and reproductively toxic. VOCs also participate in atmospheric photochemical reactions to form ozone and fine particulate matter (PM2.5), further exacerbating air pollution.

6. Other hazardous substances

6.1 Heavy Metals

The production process of the steel and metallurgical industries also produces some heavy metal pollutants, such as lead, cadmium, mercury, etc. These heavy metals mainly come from impurities in raw materials and by-products in the smelting process.

6.2 Dioxins

Dioxins are a class of highly toxic organic pollutants, mainly produced during high-temperature combustion and smelting processes. Dioxin emissions from the steel and metallurgical industries are mainly concentrated in waste incineration and certain special smelting processes.

6.3 Fluoride

Some fluxes used in the steel production process may contain fluorides, which are easily volatilized under high temperature conditions and discharged into the atmosphere, causing harm to the environment and human health.

The emission characteristics of the steel and metallurgical industries determine their huge impact on the environment and health. By understanding these emission characteristics in detail, we can provide a scientific basis for taking targeted emission reduction measures.The CEMS system plays an important role in this processThrough real-time monitoring and data analysis, it helps enterprises better control pollutant emissions and achieve green development goals. In the future, with the advancement of technology and the improvement of environmental protection requirements, the steel and metallurgical industries will gradually achieve cleaner and more efficient production methods.

Specific Applications of CEMS in the Steel and Metallurgical Industries

The application of continuous emission monitoring system (CEMS) in the steel and metallurgical industry is an important means to ensure emission control and environmental protection.

Due to the complexity and diversity of the production process of the steel and metallurgical industry and the wide variety of pollutant emissions, the application of CEMS in different processes is also different. The following is the specific application of CEMS in the main processes of this industry.

1. Sintering process

1.1 Introduction to sintering process

The sintering process is a process of mixing iron ore powder, flux and fuel, partially melting them at high temperatures, and forming a lump material suitable for blast furnace ironmaking. The sintering process produces a large amount of flue gas, which contains pollutants such as particulate matter, sulfur dioxide (SO2) and nitrogen oxides (NOx).

1.2 Application of CEMS in sintering process

During the sintering process, the CEMS system is mainly used to monitor the following parameters:

- Particle concentration: The particle concentration in the flue gas is monitored in real time through laser scattering or beta-ray absorption to ensure that the particle emission meets environmental protection standards.

- Sulfur dioxide (SO2): Use ultraviolet absorption or infrared absorption method to monitor the SO2 concentration in sintering flue gas, adjust the ratio of fuel and flux in time, and reduce SO2 emissions.

- Nitrogen oxides (NOx): Use chemiluminescence or non-dispersive infrared absorption to monitor NOx concentration, optimize combustion temperature and air supply, and reduce NOx emissions.

2. Blast furnace process

2.1 Introduction to blast furnace process

Blast furnace smelting is the core process of steel production. It produces pig iron and blast furnace gas by reacting iron ore, coke and flux at high temperatures. The main pollutants emitted by the blast furnace process include particulate matter, carbon monoxide (CO) and sulfur dioxide (SO2).

2.2 Application of CEMS in blast furnace process

The application of CEMS in blast furnace process mainly includes:

- Particle concentration: Monitor the particulate matter in the flue gas emitted by the blast furnace and control it through electrostatic precipitators and bag filters to ensure that the emission meets the standards.

- Carbon Monoxide (CO): Use non-dispersive infrared (NDIR) analysis technology to monitor CO concentration, optimize the combustion process, reduce CO emissions, and improve energy efficiency.

- Sulfur dioxide (SO2): Monitor the SO2 content in blast furnace gas and remove SO2 through desulfurization equipment to prevent the formation of acid rain.

3. Steelmaking process

3.1 Introduction to Steelmaking Process

The steelmaking process includes converter steelmaking and electric furnace steelmaking, which produces molten steel by reacting pig iron and scrap steel at high temperatures. The steelmaking process produces a large amount of flue gas containing pollutants such as particulate matter, nitrogen oxides (NOx), and sulfur dioxide (SO2).

3.2 Application of CEMS in steelmaking process

In the steelmaking process, CEMS is mainly used in the following aspects:

- Particle concentration: Real-time monitoring of particulate matter in flue gas emitted by converters and electric furnaces, and reduction of particulate matter emissions through high-efficiency dust removal devices.

- Nitrogen Oxides (NOx): Monitor NOx concentration and reduce NOx generation by optimizing oxygen blowing and combustion control.

- Sulfur dioxide (SO2): Monitor SO2 emissions and reduce SO2 emissions by adjusting raw material ratios and using desulfurization technology.

4. Coking process

4.1 Introduction to coking process

The coking process is the process of pyrolyzing coal at high temperatures to produce coke and coke oven gas. The pollutants emitted in this process mainly include volatile organic compounds (VOCs), particulate matter, sulfur dioxide (SO2) and nitrogen oxides (NOx).

4.2 Application of CEMS in coking process

The applications of CEMS in the coking process include:

- Volatile organic compounds (VOCs): Monitor VOCs using gas chromatography or mass spectrometry and reduce VOC emissions through closed operations and recovery systems.

- Particle concentration: Monitor particulate matter in coke oven flue gas and use dust removal equipment to control emissions.

- Sulfur Dioxide (SO2) and Nitrogen Oxides (NOx): Monitor SO2 and NOx concentrations and reduce emissions through combustion optimization and exhaust gas treatment technologies.

5. Auxiliary processes and waste gas treatment

5.1 Auxiliary Processes

Auxiliary processes in the steel and metallurgical industries include limestone calcination, waste treatment, etc. These processes also generate a certain amount of pollutants.

5.2 Waste gas treatment

The application of CEMS in waste gas treatment is mainly reflected in the monitoring of the treated waste gas to ensure that the emissions meet environmental protection standards.

Multi-pollutant monitoring: Comprehensively monitor multiple pollutants such as particulate matter, SO2, NOx, CO, etc. to fully understand the emission situation.

Data analysis and feedback: Through data analysis, timely feedback and adjustment of production and environmental protection measures are provided to continuously improve emission control effects.

The specific applications of CEMS in the steel and metallurgical industries are wide and varied.Through real-time monitoring and data analysis of each production process, CEMS helps enterprises optimize production processes, reduce pollutant emissions, and ensure compliance with environmental regulations. At the same time, CEMS also provides scientific data support, providing an important basis for enterprises’ environmental management and decision-making. With the continuous advancement of technology and the improvement of environmental protection requirements, the application prospects of CEMS in the steel and metallurgical industries will be broader.

| Process | Pollutants | Monitoring Technology | effect |

| Sintering process | Particulate matter, sulfur dioxide (SO2), nitrogen oxides (NOx) | Laser scattering method, β-ray absorption method, ultraviolet absorption method, infrared absorption method | Monitor particulate matter, SO2, and NOx concentrations, optimize fuel and sintering parameters, and reduce pollutant emissions |

| Blast furnace process | Particulate matter, carbon monoxide (CO), sulfur dioxide (SO2) | Laser scattering, beta-ray absorption, non-dispersive infrared (NDIR) analysis technology | Monitor particulate matter, CO, SO2 concentrations, optimize combustion processes and desulfurization devices, and reduce emissions |

| Steelmaking process | Particulate matter, nitrogen oxides (NOx), sulfur dioxide (SO2) | Laser scattering method, β-ray absorption method, chemiluminescence method, non-dispersive infrared absorption method | Monitor particulate matter, NOx, SO2 concentrations, optimize oxygen blowing and combustion control, and reduce emissions |

| Coking process | Volatile organic compounds (VOCs), particulate matter, sulfur dioxide (SO2), nitrogen oxides (NOx) | Gas chromatography, mass spectrometry, laser scattering, ultraviolet absorption, infrared absorption | Monitor VOCs, particulate matter, SO2, NOx concentrations, and control volatile matter and flue gas emissions |

| Auxiliary processes and waste gas treatment | Various pollutants (particulate matter, SO2, NOx, CO, etc.) | Comprehensive monitoring of multiple pollutants, data analysis and feedback | Comprehensively monitor and manage emissions to ensure that emissions meet environmental standards and continuously improve emission control effects |

Advantages of CEMS in the Steel and Metallurgical Industries

Improve environmental management

Through real-time monitoring and data analysis, CEMS helps enterprises to promptly detect emission anomalies and take corresponding measures to adjust and control them, thereby improving environmental management levels and ensuring that emissions meet standards.

Reduce environmental costs

Through the application of CEMS, enterprises can reduce fines due to excessive emissions and frequent maintenance costs of environmental protection facilities. At the same time, optimizing production processes and reducing energy consumption can also help reduce environmental protection costs.

Enhance corporate image

As environmental protection requirements become increasingly stringent, companies can demonstrate their emphasis on environmental protection and enhance their social responsibility image and market competitiveness by using advanced CEMS technology.

Support decision making

The continuous and reliable emission data provided by CEMS provides an important basis for the decision-making of enterprise management. Through data analysis, problems and optimization space in the production process can be discovered, and more scientific and reasonable production plans and environmental protection measures can be formulated.

Challenges of CEMS Application in Steel and Metallurgical Industry

Technical complexity

The installation and maintenance of CEMS systems require a high level of technical support. Especially in the steel and metallurgical industries, the complex production environment and variable emission sources place higher demands on the stability and accuracy of CEMS.

High initial investment

The equipment and installation costs of CEMS systems are relatively high, which may bring certain economic pressure, especially for small and medium-sized enterprises. However, in the long run, the application of CEMS can reduce environmental protection costs and improve economic benefits.

Data Management and Analysis

The amount of data generated by CEMS is huge, requiring effective data management and analysis tools. How to transform this data into valuable information is a major challenge facing enterprises.

Case Analysis

- CEMS application case of a steel enterprise

Take a large steel company as an example. The company installed CEMS systems in multiple links such as sintering, ironmaking, steelmaking and coking, and realized continuous monitoring of major pollutants. Through data analysis, the company discovered some key problems in the production process and carried out corresponding process optimization, ultimately achieving a significant reduction in emissions and reducing environmental protection costs.

- Successful experience of industry benchmark companies

Some benchmark companies in the industry have accumulated rich experience in CEMS applications. They have not only realized the automation and intelligence of emission monitoring, but also improved the environmental protection level and economic benefits of the entire industry through data sharing and collaborative management.

Conclusion

The application of CEMS in the steel and metallurgical industries is of great significance. It not only helps enterprises meet the requirements of environmental protection regulations, but also optimizes production processes, reduces emissions and environmental protection costs, and enhances the market competitiveness and social responsibility image of enterprises. Although the application of CEMS faces some challenges, with the continuous advancement of technology and the promotion of policies, CEMS will be more widely and deeply used in the steel and metallurgical industries in the future. Enterprises should actively explore and adopt CEMS technology to achieve sustainable development goals.

If you have any questions please contact us!