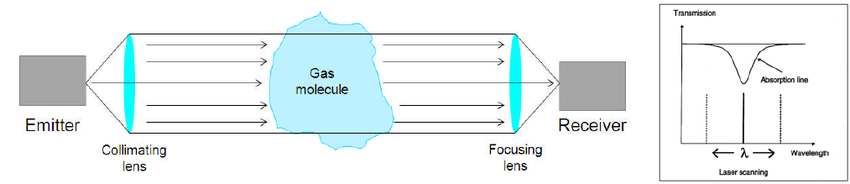

Using the premise of “frequency-selective” molecule absorption to create an absorption spectrum and provide a high-resolution quantitative analysis of molecular concentration, Tunable Diode Laser Absorption Spectroscopy (TDLAS) is an infrared absorption spectrum analysis method. TDLAS possesses high precision and great selectivity, and it can do in-situ non-contact measurements.

TDLAS has transformed numerous disciplines by providing high-sensitivity, real-time measurements of gas concentrations in areas where conventional approaches are inadequate. The gas module, a small, multipurpose device that makes accurate gas analysis possible, is one of the main factors TDLAS’s success is based on. This article examines the revolutionary uses of TDLAS gas modules in many industries.

The Principle of TDLAS Gas Analyzer

The foundation of TDL (Tunable Diode Laser) measurements is absorption spectroscopy. A TDL system called the TruePeak Analyzer measures the quantity of laser light absorbed—or lost—as it passes through the gas under investigation.

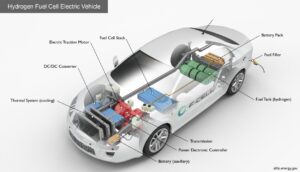

The most basic configuration of a TDL analyzer includes an infrared laser, optical lenses to direct the laser light through the gas to be measured and onto a detector, the detector itself, and electronics to regulate the laser and convert the signal from the detector into a signal that indicates the concentration of the gas.

As the name suggests, Tunable Diode Laser Absorption Spectroscopy relies on the absorption spectroscopy principle. This extensively used analytical approach includes observing the interactions between light at different wavelengths and molecules in a sample gas as the light travels through or reacts with the sample. Absorption spectroscopy uses various measurement technologies, including fluorescence, Raman, X-ray, UV visible, and nuclear magnetic resonance. Every one of them has a specific application.

Infrared spectroscopy is the technology most useful for identifying and quantifying certain compounds in gas samples. This is because of the way that gas molecules are made; each gas has a different combination of resonance frequencies that cause it to vibrate continuously at those particular frequencies. Between 2.5um and 750nm in wavelength, the near-infrared region of the electromagnetic spectrum is where a large number of gases of importance for industrial purposes absorb light.

Gas analysis has found a new leader in Tunable Diode Laser Absorption Spectroscopy (TDLAS), which provides great sensitivity, selectivity, and real-time measurement capabilities. Utilizing the special qualities of lasers and molecular absorption spectra, a complex principle forms the basis of TDLAS gas analyzers. This article delves into the fundamentals of TDLAS gas analyzers, examining their operation and the reasons that make them essential instruments for various sectors.

Let’s explore the revolutionary uses of TDLAS gas modules in many industries.

The Typical Application of TDLAS Gas Module

Environmental monitoring

By making it possible to identify and measure air pollutants, TDLAS gas modules precisely are essential to environmental monitoring. TDLAS gas modules provide unmatched sensitivity and selectivity for tracking volatile organic compounds (VOCs) released from industrial operations as well as monitoring greenhouse gases including CO2 and CH4. These modules are used in air quality monitoring networks, assisting environmental agencies and governments in making defensible decisions to reduce pollution and safeguard public health.

Industrial gas analysis

TDLAS gas modules are frequently used for process control and optimization in industrial environments. Through constant monitoring of gas concentrations in factory settings, these devices improve safety, reduce emissions, and guarantee product quality. TDLAS gas modules provide real-time feedback on gas composition to industries like semiconductor manufacturing, petrochemicals, and pharmaceuticals. This feedback allows for quick modifications to production parameters and minimizes downtime.

Medical gas sensing

TDLAS gas modules are very beneficial to the medical field, especially for applications involving patient monitoring and breath analysis. The non-invasive assessment of exhaled gases made possible by TDLAS technology makes it easier to identify diseases like diabetes, lung cancer, and asthma in their early stages. Furthermore, precise respiratory gas monitoring is made possible by TDLAS gas modules that are connected to ventilators and anesthetic machines. This ensures that patients receive the best care possible through critical care interventions and surgical procedures.

Automobile emissions testing

TDLAS gas modules are quickly becoming a necessary instrument for automotive emissions testing due to growing concerns about vehicle emissions and their effects on air quality. These modules make it possible to analyze exhaust emissions in a lab and while driving, which helps scientists and government agencies determine how well catalytic converters work and how effective pollution control methods are. Emission testing with TDLAS offers important information for enhancing vehicle design and cutting hazardous emissions.

Monitoring of greenhouse gas emissions

TDLAS gas modules are essential for tracking greenhouse gas emissions from natural sources, agricultural practices, and industrial sites. These modules assist organizations in tracking their carbon footprint, adhering to emissions standards, and implementing plans for carbon mitigation and offsetting by correctly quantifying CO2, CH4, and other greenhouse gases. A low-carbon economy and the fight against climate change depend on TDLAS-based greenhouse gas monitoring.

Applications for safety and security

TDLAS gas modules are also used in safety and security applications to identify dangerous gases and chemical hazards. TDLAS technology delivers quick and accurate gas detection for a variety of applications, including border security, industrial facility leak detection, and defense. TDLAS gas modules protect vital infrastructure, improve worker safety, and preserve public health by offering early notice of potential threats.

The TDLAS Gas Analyzer’s Working Principle

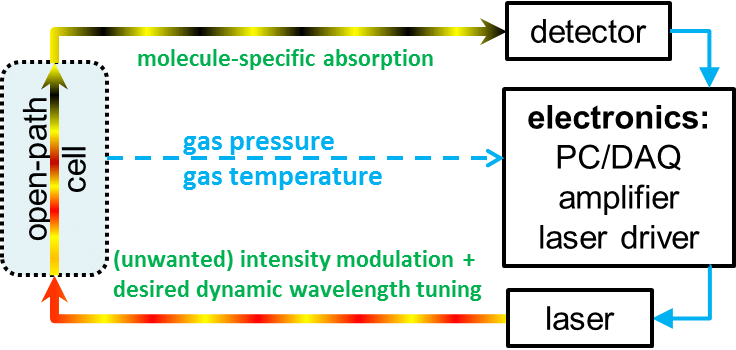

The basis for TDLAS gas analyzers’ operation is absorption spectroscopy, which measures the light that gas molecules absorb at particular wavelengths. A gas cell or sample chamber, a detector, and a tunable diode laser are the essential parts of a TDLAS gas analyzer.

1. The Lambert-Beer Law

A high-resolution spectral absorption technique is TDLAS. The Lambert-Beer law can be used to express the light intensity attenuation of the semiconductor laser as it passes through the gas under measurement. The laser with frequency V is represented in the formula by IV, 0, and IV, respectively. The light intensity both at the incident and exit points from the gas, which have pressure P, concentration X, and optical path L; the intensity of the gas absorption line is represented by S (T); the absorption line’s shape is represented by the linear function g (v-v0). Since gas absorption is typically low, these connections suggest that light is attenuated more when the gas concentration is higher. As a result, the attenuation of the laser caused by a gas can be used to determine its concentration.

2. Linear Spectral Line Intensity

The energy level change within a molecule from a low-energy state to a high-energy state is always connected to the absorption of gas molecules. During the transition phase, the net effect of the intensities of stimulated absorption, stimulated emission, and spontaneous emission is represented by line intensity S (T). It is the absorption spectrum line’s most fundamental characteristic. The transition probability at the upper and lower energy levels as well as between energy levels, determines it. based on the quantity of molecules.

Temperature affects the distribution of molecules across various energy levels; thus, temperature affects the line intensity of spectral lines.

- Tunable diode laser: In TDLAS gas analyzers, the light source is a tunable diode laser. Tunable diode lasers can emit light at many wavelengths within a small spectral range, in contrast to conventional lasers that only emit light at fixed wavelengths. Because of this tunability, TDLAS analyzers can focus on particular absorption lines of the gas molecules they are looking into.

- Gas cell or sample chamber: The gas sample for analysis is kept in the gas cell or sample chamber. Usually, optical windows are installed in this chamber to let laser light through. Because of the interaction between the gas molecules in the sample and the laser beam, light at specific wavelengths is absorbed, which is dependent on the molecular makeup of the gas species.

- Detector: The light intensity passing through the gas cell is measured by the detector in a TDLAS gas analyzer. The amount of absorption brought on by the gas molecules can be ascertained by the analyzer by comparing the intensity of the transmitted light with the intensity of the incident laser light. The concentration of the target gas species in the sample is then determined using this information.

Working Principle: The following is a summary of how a TDLAS gas analyzer operates

At a certain wavelength, a narrow beam of light is produced by the tunable diode laser.

The target gas’s molecules are exposed to the laser light as it travels through the gas sample in the gas cell.

Photons are absorbed by gas molecules whose absorption lines coincide with the laser’s

wavelength. This lowers the transmitted light’s intensity. By measuring the transmitted light’s intensity, the detector enables the analyzer to calculate how much light is absorbed by the gas molecules. The analyzer determines the gas concentration in the sample by calibrating the device and using the target gas’s known absorption characteristics.

Our TDLAS Gas Analyzer

ESE-LASER-100M TDL gas module adopts the principle of Tunable Diode Laser Absorption Spectroscopy (TDLAS) to measure the concentration of specific gases in process gas components, including NH3, HCL, HF, H2S, CH4, CO, CO2, O2, etc. The gas analysis module has the characteristics of high sensitivity, fast response, no interference from background gas, non-contact optical measurement, etc. It can be used in gas emission monitoring, process control, and trace gas monitoring of air stations in many industrial fields, such as coal-fired power plants, waste incineration power plants, and chemical plants, in combination with appropriate gas pretreatment systems, providing a reliable guarantee for real-time and accurate reflection of gas concentration changes.

Features: Compared with other gas analyzers, this laser gas analysis module has the following main features:

- High selectivity. TDLAS is a high-resolution spectral technology. Due to the “fingerprint” feature of the molecular spectrum, the measurement is not interfered by other gases, which has obvious advantages over other analytical methods.

- Wide universality. TDLAS technology can effectively measure all active molecules that have absorption in the near-infrared region, basically covering the main engineering analysis gases.

- Strong applicability. TDLAS technology has the advantages of fast speed and high sensitivity. In practical application, its time resolution can reach ms level, and its sensitivity can reach ppb level.

Working Principle

ESE-LASER-100M laser gas analysis module utilizes the tunability of laser wavelength to make the laser emission wavelength change with the change of working temperature and current. By periodically modulating the current, the laser wavelength can be changed periodically in a small range, and the “single-line absorption line” data of the measured gas can be obtained in each cycle. At present, TDLAS technology has developed into a gas detection technology with high sensitivity, high resolution, high selectivity and fast response, which is widely used in molecular spectrum research, industrial process monitoring and control, combustion process diagnosis and analysis, engine efficiency and motor vehicle exhaust Measurement, safety control, monitoring of trace pollutant gases in the atmosphere and other fields.

TDLAS Gas Analyzer Benefits

The analyzer can detect water content accurately without interference from hydrogen sulfide, methanol, glycol, or amine. The foundational ideas of physics underpin this ability.

Because TDLAS analyzers do not easily drift and do not have problems with chemical contamination that could influence the sensor itself, they are naturally stable and only need to be calibrated occasionally.

In comparison to conventional gas analysis methods, TDLAS gas analyzers have several benefits, such as:

- High sensitivity and selectivity: The method is based on the way that water molecules absorb infrared light, which makes it possible to measure the moisture content precisely. Because TDLAS can detect moisture levels down to parts per million (ppm), it is a good fit for situations where precise moisture control is needed. Moreover, reliable readings are guaranteed even in the presence of interfering chemicals since TDLAS can distinguish between water vapor and other gases. Because of its great sensitivity and selectivity, TDLAS is the best option for moisture analysis in a variety of challenging situations and samples.

- Real-time and non-intrusive measurements: One important benefit of TDLAS is its capacity for non-intrusive measurements. The method minimizes sample contamination and disturbance by enabling moisture analysis without the need for physical contact. TDLAS also makes real-time measurements possible by offering immediate input for process management and optimization. Applications requiring constant monitoring and adjustment of moisture levels benefit greatly from these real-time capabilities. When moisture variations arise, TDLAS can help operators make decisions quickly and take prompt remedial action, preventing problems with product quality and minimizing downtime.

- Broad dynamic range: TDLAS is capable of precisely measuring moisture levels over a wide range of concentrations, regardless of the moisture content, from low to high. This adaptability is especially useful in applications like environmental monitoring and drying processes where the moisture content might change greatly. TDLAS simplifies the measuring process and lowers overall expenses by doing away with the need for additional instruments or calibration adjustments due to its wide dynamic range coverage.

- Sturdy and low maintenance: TDLAS analyzers’ lack of moving components reduces the possibility of mechanical problems, assuring their long-term dependability. Moreover, sample conditioning is not required thanks to the non-contact measuring method, which lowers maintenance requirements and related expenses. Furthermore, self-diagnostic features are frequently built into TDLAS analyzers, allowing for proactive maintenance and troubleshooting. Thanks to these characteristics, TDLAS is a more affordable option for measuring moisture than other technologies, with less downtime and lower total costs of ownership.

When compared to alternative methods, Tunable Diode Laser Absorption Spectroscopy (TDLAS) has many advantages for measuring moisture. When compared to alternative methods, its high sensitivity, selectivity, robustness, wide dynamic range, and non-intrusive nature make it the method of choice for accurate and trustworthy moisture analysis across a variety of sectors.

By utilizing the concepts of absorption spectroscopy and laser technology, Tunable Diode Laser Absorption Spectroscopy (TDLAS) gas analyzers provide a potent method for gas analysis. High sensitivity, selectivity, and real-time measurement capabilities have made TDLAS analyzers precious instruments in a variety of industries where accurate gas analysis is crucial. As technology develops, TDLAS systems will become increasingly important for tackling challenging issues in public health, industrial process optimization, and environmental monitoring.

Industry Gas Analysis Solutions and Environmental Emissions

The ESE-LASER series laser gas analyzers, which are based on TDLAS technology, use a variety of cutting-edge key technology applications to offer high-performance instrument solutions for clients with various testing needs.

Technology for Multi-line Scanning

Based on wavelength modulation (WMS), a conventional laser light source technique. To minimize background gas interference, choose the suitable laser type and use the multi-line scanning processing approach based on the spectrum absorption characteristics of various test objects. Dust and water vapor fluctuate

Long Optical Path Gas Cell Technology

The gas’s absorption path length is more important to consider when monitoring low concentrations. The extraction test apparatus often uses a specially made Heliott cell, which may achieve a measurement optical path of three to thirty meters. A small amount of air chamber emptying volume and good thermal stability are guaranteed by the compact structure’s optimal design.

Harmonic Detection Technology

The second harmonic of the test signal is collected and amplified using a fully digital lock-in amplifier, which effectively suppresses low-frequency noise in the measurement and enhances test sensitivity and anti-interference.

Conclusion

The laser gas analyzer is an extensively utilized instrument in numerous fields for gas analysis due to its exceptional accuracy, sensitivity, and selectivity. Its ability to precisely detect the concentration of gas components stems from its foundation in the concepts of laser spectroscopy and optical absorption. For many applications, laser gas analyzers are the preferred instrument due to their distinct benefits over other varieties of gas analyzers.more information pls visit www.esegas.com