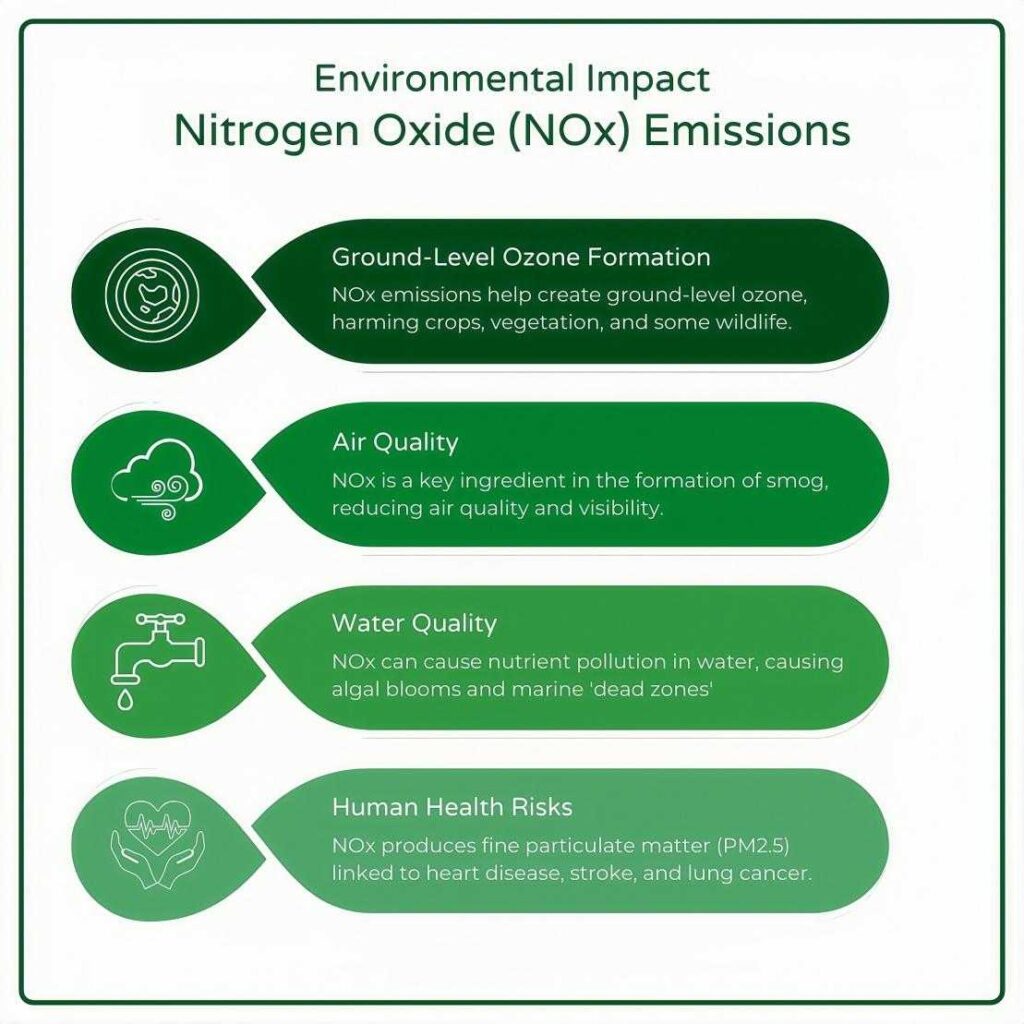

Environmental regulations are tightening globally, especially concerning nitrogen oxides (NOx) emissions. Industries such as coal-fired power plants, cement factories, steel mills, waste incinerators, and chemical manufacturing facilities face stricter NOx limits, often below 50 mg/Nm³. Compliance with these standards necessitates the implementation of Continuous Emissions Monitoring Systems (CEMS) to provide accurate, real-time data on pollutant levels. Failure to meet these requirements can result in significant fines, operational restrictions, or even plant shutdowns.

Many facilities continue to rely on legacy analyzers like chemiluminescence and Non-Dispersive Infrared (NDIR) systems. These traditional technologies often require frequent calibrations, use of NO₂-to-NO converters, and are susceptible to inaccuracies in high-dust or high-moisture environments. Such limitations lead to increased maintenance demands, unexpected downtimes, and escalated operational costs. Moreover, analyzers with optical moving parts are prone to mechanical failures, further compromising measurement reliability and system availability.

Engineering, Procurement, and Construction (EPC) contractors, along with system integrators, seek solutions that are not only accurate but also easy to install and maintain. Ideal analyzers should have a compact footprint, integrate seamlessly with existing sample conditioning systems, and offer predictable maintenance schedules. Additionally, minimizing the need for consumables and reducing calibration requirements are critical factors that influence procurement decisions, aiming to lower the total cost of ownership over the analyzer’s lifespan.

Why Should High-Emission Plants Choose UV-DOAS Continuous Gas Analyzer?

(Environmental impact of NOx emission)

To address the challenges of stringent NOx regulations and the limitations of traditional analyzers, adopting UV-DOAS (Ultraviolet Differential Optical Absorption Spectroscopy) technology offers a compelling solution.

Simultaneous NO and NO₂ Measurement Without Converters

UV-DOAS continuous gas analyzers, such as the UV-GAS-500s, utilize ultraviolet absorption spectroscopy to simultaneously measure NO and NO₂ concentrations directly, eliminating the need for NO₂-to-NO converters. This direct measurement approach enhances accuracy and simplifies the system design.

Lower Capital Expenditure (CapEx)

The UV-DOAS system’s simpler optical design reduces initial investment costs. Unlike hybrid Quantum Cascade Laser (QCL) and Tunable Diode Laser (TDL) systems that require expensive laser diodes and optical cryostats, UV-DOAS continuous gas analyzers use a pulse xenon light source, which is more cost-effective and has a longer lifespan.

Reduced Operational Expenditure (OpEx)

Operational costs are minimized due to the UV-DOAS continuous gas analyzer’s robust design:

- Long-Lifetime Light Source: The pulse xenon lamp has a service life of up to 10 years, reducing the frequency and cost of replacements.

- No Optical Moving Parts: The absence of moving components enhances reliability and reduces maintenance requirements.

- Minimal Drift: The system exhibits low zero and span drift, ensuring stable long-term operation.

Robust Performance in Harsh Conditions

UV-DOAS continuous gas analyzers maintain high accuracy even in challenging environments:

- Resistance to Particulates and Moisture: The measurement accuracy is not affected by water or dust, making it suitable for high-dust and high-moisture conditions.

- Temperature Stability: The system exhibits small temperature drift, ensuring consistent performance across varying temperatures.

Practical Applications Across Industries

The ESEGAS UV-GAS-500 UV-DOAS continuous gas analyzer is versatile and applicable in various high-emission industries, including:

- Power Plants: Continuous flue gas emission monitoring for SO₂, NO, NO₂, and O₂.

- Cement and Steel Plants: Monitoring of DeSOX and DeNOX processes.

- Waste Incineration: Emission monitoring of SO₂, NO, NO₂, and O₂.

- Chemical Industry: Trace analysis of Cl₂, H₂S, NOx, and other gases in various processes.

By integrating UV-DOAS technology, facilities can achieve precise NOx measurements, ensure regulatory compliance, and significantly reduce both capital and operational expenditures.

How Does UV-DOAS Technology Work, and Why Does It Matter for NOx Continuous Gas Analyzer?

(ESEGAS UV-DOAS sensor UV-GAS-100M)

Understanding the Fundamentals of UV-DOAS for NOx Measurement

UV-DOAS (Ultraviolet Differential Optical Absorption Spectroscopy) stands out for its unique approach to NOx detection. Instead of relying on chemical converters or narrowband lasers, it uses a broad-spectrum UV light source—typically a high-stability pulse xenon lamp—to transmit light through a long-path absorption chamber. Each gas absorbs light at specific UV wavelengths. In the 200–400 nm range, both NO and NO₂ have distinct absorption features, allowing the continuous gas analyzer to capture both simultaneously and calculate total NOx directly—no converter required. This direct reading improves both accuracy and response time.

Key Features That Deliver Real-World Value

The ESEGAS UV-DOAS continuous gas analyzer doesn’t just sound good on paper—it performs in the field:

- Outstanding Accuracy: Linearity error ≤ ±2% FS; repeatability ≤ 0.5%; zero/span drift within ±2% FS over 7 days.

- Fast & Compact: Response time is <25 seconds; the unit weighs only 3.2 kg and fits into tight spaces (420 × 160 × 80 mm).

- Long-Lasting & Low Maintenance: Its pulse xenon lamp lasts over 10 years, requires no preheating, and demands little attention.

- Solid-State Stability: With no moving optical parts, it resists vibration and harsh environments better than many competitors.

- Direct NOx Measurement: It captures NO and NO₂ in one go, making real-time NOx tracking simpler and more reliable.

Why This Matters for You

For power plants, cement kilns, steel mills, and incinerators, every maintenance hour and sensor drift adds risk. UV-DOAS offers a plug-and-play, low-maintenance path to compliance—one that’s easier to install, cheaper to run, and built to last. It bridges the gap between precision and practicality.

Which NOx Continuous Gas Analyzer Offers the Best Value: UV-DOAS, QCL, or TDL?

Choosing the right NOx continuous gas analyzer often comes down to balancing accuracy, maintenance, and cost. Let’s break it down clearly.

1. Hybrid QCL (Quantum Cascade Laser)

Hybrid QCL analyzers use mid-infrared lasers to achieve ultra-low detection limits, even below 1 ppb. They’re ideal for precision-critical applications like ambient air monitoring. But that level of sensitivity comes at a price. These systems require expensive optical components, active thermal control, and sometimes even cryogenic cooling. CapEx is high, and maintenance is not trivial.

2. TDL (Tunable Diode Laser)

TDL systems operate in the near-IR range and offer strong selectivity for NO or NO₂ lines. They’re more affordable than QCLs but still require regular calibration and clean gas samples. Dust, moisture, and temperature swings can cause interference, so sample conditioning is often needed. That means additional cost, space, and complexity.

3. UV-DOAS: Balanced and Practical

UV-DOAS strikes a sweet spot. It delivers ppm to low-ppb sensitivity without moving parts or laser cooling. Its broadband UV light source, simple design, and rugged optics mean minimal sample prep, no gas converters, and nearly zero drift. For plants needing reliable CEMS data without breaking the budget, this is the most cost-effective solution.

Technology Comparison: Performance vs. Cost

| Parameter | Ultraviolet Differential Optical Absorption Spectroscopy (UV-DOAS) | Hybrid Quantum Cascade Laser (QCL) | Tunable Diode Laser (TDL) |

| Measuring Principle | UV differential absorption (200–400 nm) | Mid-IR quantum cascade laser absorption | Near-IR/IR tunable diode laser absorption |

| NOx Detection Range | 0 – 3000 ppm (standard); 0 – 100 ppm (low-range); 0 – 20 ppm (ultra-low) | < 1 ppm down to ppb levels (dependent on path length) | < 1 ppm down to low-ppb (dependent on path length) |

| Linearity & Repeatability | ≤ ±2% FS (linearity); ≤ ±0.5% FS (repeatability) | ≤ ±1% FS (typical) | ≤ ±1% FS (typical) |

| Optical Moving Parts | None (pulse xenon lamp + fiber optics) | Often none; uses single-mode QC laser with scanning optics | May include scanning gratings or tuning elements |

| Maintenance Interval | 10+ years for light source; annual check, minimal recalibration | Laser module: ~5 years life; periodic alignment; active cooling servicing | Laser diode: ~5 – 7 years; may require optics realignment |

| Sample ConditioningRequirements | Simple particulate filter; tolerant to moisture/dust | High-purity, dry sample; desiccant + filtration; avoids IR scattering | Clean, dry gas; filtration; sometimes need heated sample line |

| Power Consumption | ~100 – 200 W (no preheating) | ~200 – 300 W (active cooling) | ~150 – 250 W (temperature control) |

| Estimated CapEx (Analyzer Only) | $40k – $60k USD (varies by path length and range) | $80k – $120k USD (laser module + cooler + optics) | $60k – $90k USD (laser + optics + sampling) |

| Estimated 5-Year OpEx(Maintenance & Spares) | $10k – $15k (lamp replacement, annual calibration) | $20k – $30k (cooler service, alignment, frequent calibrations) | $15k – $20k (diode replacement, optics cleaning, calibrations) |

| Typical Total Cost ofOwnership (5 yrs) | $50k – $75k USD | $100k – $150k USD | $75k – $110k USD |

| Typical Accuracy (NOx) | ± 2% FS (ppm) | ± 1% FS (ppb) | ± 1% FS (ppb) |

| Environmental Robustness | Highly resistant to dust,moisture; no converter required | Sensitive to dust; sample must be dried; may require heated optics | Sensitive to dust/moisture; must purge; optical alignment sensitive |

UV-DOAS doesn’t try to outperform QCL or TDL in raw sensitivity. Instead, it offers what most plants actually need: accurate, stable, and cost-controlled NOx monitoring—without the engineering headaches. For operations and maintenance teams, instrumentation engineers, and procurement specialists, that’s a win.

Conclusion: UV-DOAS Continuous Gas Analyzer—A Practical Solution for Modern Emissions Monitoring

(Plant operation and maintenance)

In industries where precision, reliability, and cost-efficiency are paramount, UV-DOAS continuous gas analyzers emerge as a compelling choice for NOx monitoring. By leveraging ultraviolet differential optical absorption spectroscopy, these continuous gas analyzers offer accurate, real-time measurements of NO and NO₂ without the need for converters or complex sample conditioning.

For plant operations and maintenance teams, instrumentation engineers, procurement specialists, and environmental monitoring integrators, UV-DOAS continuous gas analyzers provide a dependable and economical solution for continuous emissions monitoring.

Explore the capabilities of UV-DOAS technology and consider how it can enhance your emissions monitoring strategy. Learn more at ESEGAS UV-DOAS NOx Continuous Gas Analyzer.