Fundamental Working Mechanism of NDIR Sensors!

· Infrared Absorption

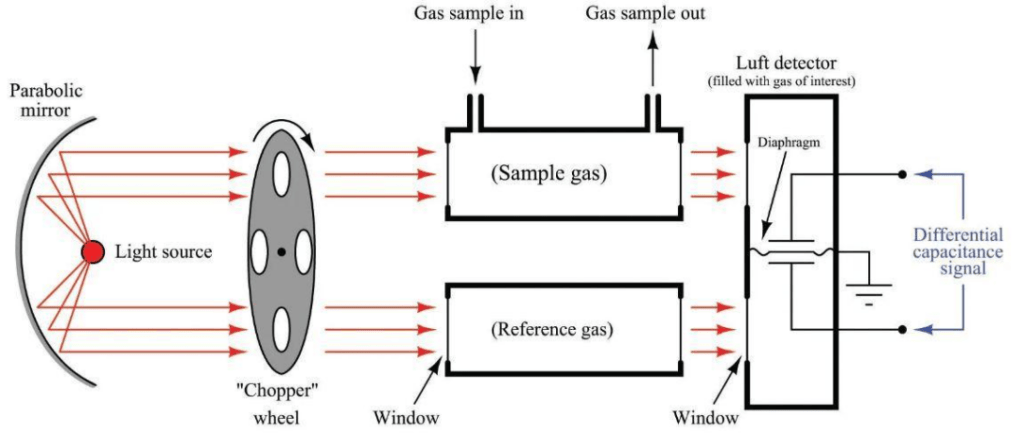

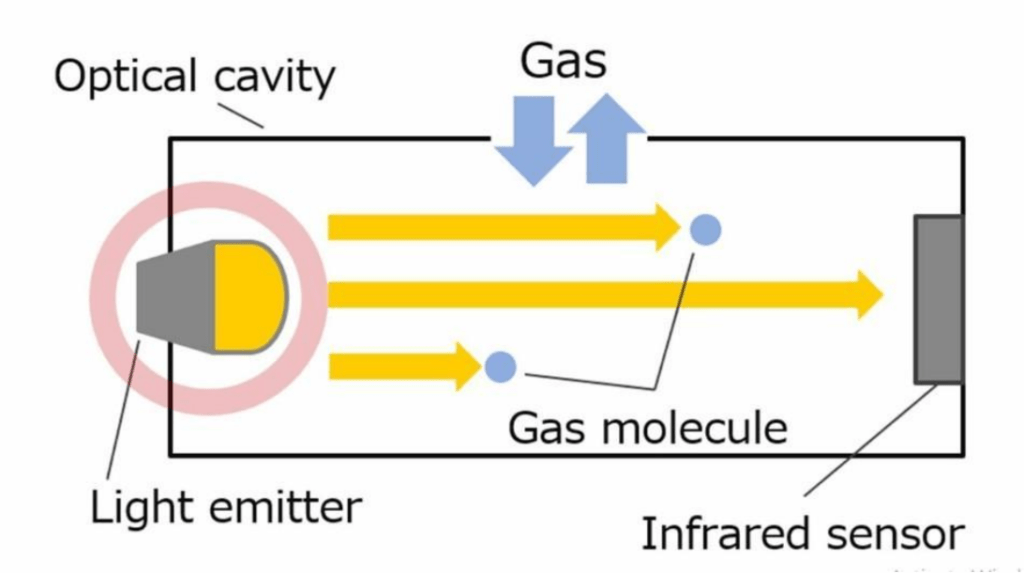

NDIR CO Gas Sensors rely on infrared absorption, a pivotal method. IR light traverses the gas chamber, encountering CO molecules. Absorption fluctuates with CO concentration, a critical factor. Detectors gauge this variance, converting it into electrical signals.

Optical filters enhance accuracy, selectively admitting specific IR wavelengths. Mirrors inside the chamber direct the IR path; maximizing interaction with CO. Sensor response times are swift, vital for real-time monitoring. Calibration ensures precision, essential for reliable readings.

· Gas Sampling

In NDIR CO Gas Sensors, gas sampling is a meticulous process. Ambient air enters through a designated inlet, crucial for sample integrity. A pump system, often miniaturized, circulates the air into the sensor chamber. Flow rate control is paramount, ensuring consistent sample volume.

Moisture filters are employed, removing potential interference. Temperature regulation within the chamber maintains measurement stability. Exhaust vents expel the analyzed sample, a necessary step. Periodic system purging prevents residue buildup, maintaining sensor efficacy.

· Light Emission

Light emission in NDIR CO Gas Sensors is a fine-tuned operation. An IR source, typically an LED or laser, emits controlled light pulses. Wavelength specificity is key, aligning with CO absorption peaks. Modulation of light intensity aids in distinguishing signal from noise.

Thermal management of the IR source preserves its longevity. Reflector placement optimizes light path, crucial for effective sensing. The light source’s stability over time ensures consistent sensor performance. Regular testing verifies the emission quality, maintaining sensor reliability.

· Signal Processing

Signal processing in NDIR CO Gas Sensors involves advanced techniques. Initial signal capture is critical, requiring high-sensitivity detectors. Noise reduction algorithms are applied, enhancing signal clarity. Amplification stages boost the signal, pivotal for accurate analysis.

Digital conversion of the analog signal is a crucial step. Microprocessors interpret these signals, applying calibration data. Software algorithms compensate for environmental variables, ensuring accurate readings. Real-time data processing enables prompt response to CO changes. Ongoing software updates refine processing accuracy.

· Concentration Calculation

Concentration calculation in NDIR CO Gas Sensors is a complex process. The Beer-Lambert Law is fundamental, relating IR absorption to CO concentration. Algorithmic interpretation of signal strength determines CO levels. Cross-sensitivity compensation adjusts for other gases’ presence.

Calibration curves are essential, providing reference points. Temperature and pressure corrections ensure accuracy under varying conditions. Data logging captures concentration over time, vital for trend analysis. Continuous monitoring allows for immediate hazard detection.

Specificity To Different Gas Types!

· CO2 Detection

NDIR CO Gas Sensors excel in CO2 identification. Specific IR wavelengths correlate to CO2’s unique absorption characteristics. Tailored optical filters isolate these wavelengths, ensuring CO2 detection accuracy. Advanced algorithms differentiate CO2 from other gases, a crucial aspect.

Calibration against known CO2 concentrations guarantees precision. Continuous monitoring enables tracking CO2 levels, vital for various applications. Sensor design focuses on CO2’s specific IR absorption spectrum, a key feature.

· Methane Sensing

Methane detection in NDIR CO Gas Sensors involves distinct approaches. Methane’s absorption spectrum differs from CO’s, necessitating specialized IR wavelengths. Sensors employ unique filters for methane’s IR signature. Algorithmic adjustments are made for methane’s specific properties.

Rapid response to methane’s presence is crucial, given its flammability. Calibration with methane standards ensures accuracy. Methane sensing aids in leak detection, a safety imperative. Sensor technology adapts to methane’s lower IR absorption efficiency.

· Hydrocarbon Analysis

Hydrocarbon analysis via NDIR CO Gas Sensors is multifaceted. Diverse hydrocarbons exhibit varied IR absorption patterns. Sensor calibration aligns with these unique signatures. Real-time analysis distinguishes between different hydrocarbons.

Sensitivity adjustments cater to hydrocarbons’ varying concentrations. Data interpretation algorithms are fine-tuned for hydrocarbon specifics. Regular recalibration maintains sensor precision. Hydrocarbon analysis is crucial for environmental and industrial applications. Sensor versatility allows for broad hydrocarbon detection.

· Environmental Monitoring

Environmental monitoring with NDIR CO Gas Sensors is crucial. Sensors detect gases indicative of pollution levels. Customized IR wavelengths target specific environmental contaminants.

Real-time data aids in tracking air quality changes. Algorithms account for environmental factors like humidity and temperature. Calibration against environmental standards ensures data reliability. Data helps in assessing compliance with environmental regulations. Sensor deployment in diverse environments showcases their adaptability. Continuous monitoring enables proactive environmental management.

· Industrial Safety

In industrial safety, NDIR CO Gas Sensors play a pivotal role. Gases like CO are common in industrial settings. Sensors provide real-time detection of hazardous gas levels. Custom calibration caters to industry-specific gas concentrations.

Alarm systems integrate with sensors for immediate hazard alerts. Regular testing ensures sensor responsiveness. Durable designs withstand industrial environments. Data aids in safety protocol development. Sensor technology contributes significantly to workplace safety.

| Feature/Spec | CO₂ Detection | Methane Sensing | Hydrocarbon Analysis | Environmental Monitoring | Industrial Safety |

| Sensitivity (ppm) | ≤ 400 | ≤ 5 | ≤ 10 | ≤ 15 | ≤ 20 |

| Detection Range (meters) | 0-30 | 0-50 | 0-100 | 0-80 | 0-60 |

| Response Time (seconds) | ≤ 10 | ≤ 8 | ≤ 6 | ≤ 12 | ≤ 15 |

| Operating Temp. Range (°C) | -10 to 50 | -20 to 40 | -15 to 45 | -5 to 55 | -10 to 60 |

| Alarm Thresholds (levels) | 2 | 3 | 4 | 3 | 5 |

| Calibration Frequency | Biannual | Annual | Quarterly | Semi-Annual | Annual |

| Data Logging Capability | Yes | Yes | Advanced | Standard | Essential |

Key Components of NDIR CO Gas Sensors!

· Infrared Source

NDIR CO Gas Sensors‘ core is the IR source. It emits specific wavelengths, aligning with CO’s absorption. LED or laser options vary based on application needs. Pulse modulation enhances detection capabilities.

IR source longevity impacts overall sensor performance. Optimal power management ensures stable IR emission. Regular maintenance checks preserve IR source efficiency. Replacement schedules depend on usage intensity. IR source quality directly influences sensor accuracy. Sensor designers prioritize this component’s reliability.

· Sample Chamber

The sample chamber is pivotal in NDIR CO Gas Sensors. It houses the gas for analysis. Design ensures uniform gas distribution, key for accurate readings. Materials used resist corrosive gases, extending chamber life. Size correlates with sensor sensitivity. Seals prevent external air contamination.

Chamber cleaning protocols maintain measurement precision. Temperature control within the chamber stabilizes readings. Chamber’s reflective surfaces enhance IR light path. Design innovations focus on maximizing gas and IR interaction.

· Gas Filter

Gas filters in NDIR CO Gas Sensors are crucial. They selectively allow specific IR wavelengths, matching CO’s absorption spectrum. Filter durability affects long-term sensor performance.

Advanced materials enhance filter lifespan. Regular testing confirms filter efficacy. Design aims for minimal IR attenuation. Filters help mitigate effects of interfering gases. Replacement intervals vary based on environmental conditions. Filter precision directly impacts sensor accuracy. Innovations in filter technology continuously improve sensor specificity.

· IR Detector

The IR detector is essential in NDIR CO Gas Sensors. It captures IR light after gas interaction. Detector sensitivity dictates overall sensor accuracy. Noise reduction technologies are integrated for clearer readings. Calibration aligns detector response with known CO levels.

Advanced materials enhance detector responsiveness. Regular checks ensure detector stability. Detector design balances sensitivity and durability. Data from the detector is key for CO concentration analysis. Detector advancements continually enhance sensor performance.

· Calibration Unit

Calibration units are fundamental in NDIR CO Gas Sensors. They ensure readings match actual CO levels. Regular calibration checks maintain sensor accuracy. Use of known gas concentrations for calibration is standard. Automated calibration routines offer convenience.

Calibration data logs provide historical accuracy records. User-accessible calibration options enhance maintenance efficiency. Environmental changes prompt recalibration needs. Calibration technology evolves with sensor advancements. Accurate calibration is crucial for reliable gas detection.

How to Choose the Right NDIR CO Gas Sensor?

· Sensitivity Level

Selecting NDIR CO Gas Sensors necessitates evaluating sensitivity. Higher sensitivity detects lower CO concentrations. Application needs dictate sensitivity requirements. Industrial settings might need ultra-sensitive sensors. Sensitivity variance affects detection thresholds.

Balancing sensitivity with environmental noise is key. Overly sensitive sensors might trigger false alarms. Regular sensitivity checks ensure consistent performance. Sensitivity aligns with safety standards in various industries. Sensor selection starts with understanding sensitivity needs.

· Measurement Range

Measurement range is crucial in NDIR CO Gas Sensor selection. Wide ranges suit diverse environments. Industrial applications often require broader ranges. Precision across the entire range is vital. Range limitations can affect application suitability.

Calibration ensures accuracy across all ranges. Range selection impacts sensor utility. Environmental conditions influence the optimal range choice. Consistency at extreme ranges is a quality indicator. Range adaptability enhances sensor versatility in different settings.

· Environmental Adaptability

Environmental adaptability is key for NDIR CO Gas Sensors. Sensors must withstand diverse conditions. Humidity, temperature, and pressure variations affect performance. Robust designs endure harsh environments. Sensor housing materials are selected for durability.

Adaptability extends sensor lifespan. Industrial and outdoor settings demand high adaptability. Regular environmental testing maintains sensor accuracy. Adaptability features vary among sensor models. Sensor choice depends on specific environmental challenges.

· Response Speed

Response speed is a defining factor for NDIR CO Gas Sensors. Rapid detection is crucial in emergency situations. Delayed responses can lead to safety risks. Speed varies among sensor models. Faster sensors are essential in dynamic environments. Trade-off between speed and accuracy is considered.

Regular testing verifies response speed. High-speed sensors are prioritized in critical applications. Speed requirements depend on the specific use case. Sensor technology advancements continually improve response times.

· Calibration Stability

Calibration stability is essential in NDIR CO Gas Sensors. Stable calibration ensures consistent accuracy. Fluctuations in calibration affect reliability. Regular recalibration maintains performance. Sensors with long-term calibration stability are preferred. Calibration frequency varies with sensor quality.

Industrial standards often dictate calibration stability requirements. Advanced sensors offer automated calibration features. Calibration stability is a sign of sensor quality. Stable calibration supports dependable gas detection.

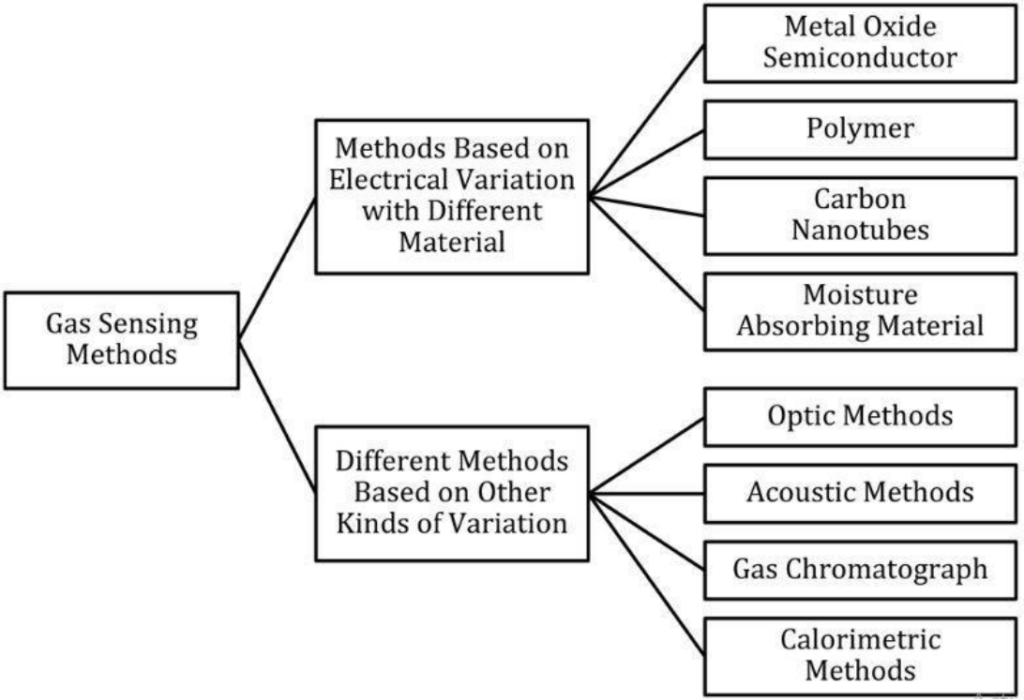

Advantages of NDIR Technology Over Other Gas Sensing Methods!

· High Accuracy

NDIR CO Gas Sensors excel in precision. Advanced optical components ensure accurate gas detection. Calibration techniques enhance accuracy further. IR absorption specificity contributes to precise measurements. Sensor algorithms interpret signals with high fidelity.

Accuracy remains consistent over varied conditions. High accuracy benefits critical applications. Sensor technology advancements continually improve accuracy. Accurate readings are crucial for safety and environmental monitoring.

· Longevity

Longevity is a hallmark of NDIR CO Gas Sensors. Durable components withstand extensive use. Sensor design minimizes wear and tear. Long lifespan reduces replacement frequency.

Regular maintenance extends sensor life. Robust construction suits challenging environments. Longevity supports cost-effective operation. Sensors maintain performance over years. Long-term reliability is a key advantage. Sensor technology focuses on maximizing lifespan.

· Low Maintenance

NDIR CO Gas Sensors require minimal upkeep. Simple cleaning routines suffice for maintenance. Sensor stability reduces calibration needs. Durable design lessens repair frequency. Low maintenance is cost-effective over time. User-friendly interfaces facilitate easy checks.

Maintenance simplicity aids in widespread sensor adoption. Sensors retain functionality with minimal intervention. Low maintenance demands appeal to various sectors. Sensor design prioritizes ease of maintenance.

· Fast Response

Fast response is critical in NDIR CO Gas Sensors. Quick detection enables timely action. Rapid response aids in emergency situations. Sensor technology ensures swift gas analysis. Speed is vital in dynamic environments. Immediate readings facilitate prompt decision-making.

Sensor responsiveness is key in safety applications. Fast response enhances monitoring efficiency. Sensors quickly adapt to changing gas levels. Response speed is continuously optimized.

· Specific Detection

Specific detection sets NDIR CO Gas Sensors apart. Tailored IR wavelengths target specific gases. Optical filtering enhances gas specificity. Cross-sensitivity is minimized in sensor design.

Specific detection aids in accurate analysis. Sensors distinguish target gases in complex environments. Specificity is crucial for reliable readings. Sensor development focuses on refining detection. Specific detection capabilities are essential in varied applications.

Conclusion

With this expert guide, we have discussed the essential aspects of NDIR CO Gas Sensors highlighting their role in precise gas measurement. We have taken you through their principles of operation, special features and many uses that will help one make informed decisions. Go to ESEGAS for more advanced research and niche services Begin your journey to master NDIR CO Gas Sensors today, for accurate and safe gas analysis.