Elevating safety in TDL Gas Module operations requires a meticulous blend of technical acumen and strategic oversight. Calibration precision, crucial in TDL systems, ensures optimal performance and reliability. Advanced sensor technology, integral to module efficacy, demands regular maintenance for sustained accuracy.

Environmental adaptability, a cornerstone in TDL functionality, is pivotal for consistent data integrity. Operational protocols, tailored for TDL modules, enhance system resilience and efficiency. Understanding TDL dynamics, a complex yet vital aspect, underpins successful module optimization.

Understanding the Basics of TDL Technology for Gas Measurement!

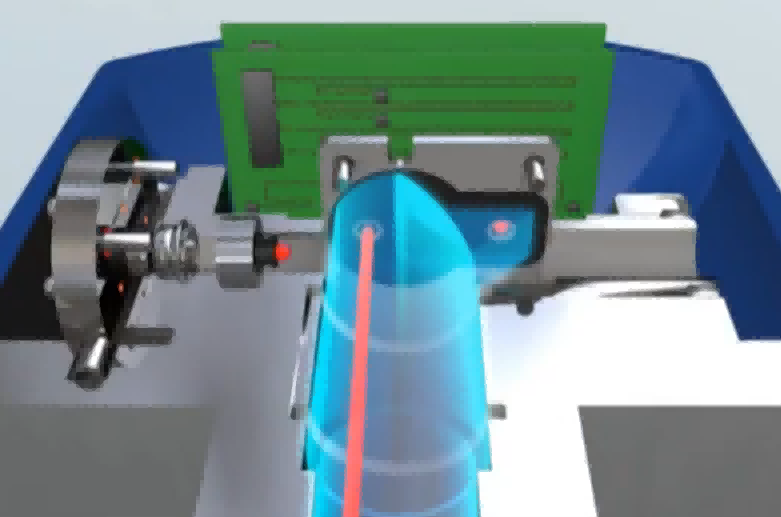

· Principle Of Tunable Diode Laser (TDL) Technology

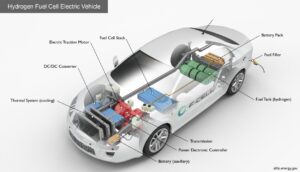

TDL gas module employs a diode laser for selective gas detection. This technology utilizes light absorption characteristics, specific to gases. Key components include a laser source, photodetector, and optical chamber. The laser emits a narrow wavelength, tunable across a specific range. Co2 Gas presence alters the light intensity, measured by the photodetector.

The module’s design ensures high sensitivity and accuracy. Its operation involves wavelength modulation, enhancing detection capabilities.

TDL systems are calibrated for target gas concentration ranges. Advanced signal processing algorithms interpret photodetector output. This results in precise gas concentration measurements. The technology suits various industrial applications, ensuring reliable gas monitoring.

· How TDL Gas Modules Work In Industrial Settings?

Laser Diodes

TDL modules utilize laser diodes for targeted gas detection. Emitting at specific wavelengths, these diodes ensure precise targeting. The diode’s stability is crucial for consistent performance. Industrial settings often use multiple diodes for varied gas types. Each diode is finely tuned for optimal gas interaction.

Gas Interaction

Gas molecules interact with the laser light path. This interaction causes characteristic absorption, unique to each gas. These absorption patterns are critical for identification. Interaction varies with gas concentration and environmental factors. Industrial environments test these interactions under varied conditions.

Signal Processing

The module’s signal processing unit interprets light absorption data. Advanced algorithms convert raw data into meaningful information. Signal processing speed is vital for accurate readings. This unit filters out irrelevant environmental noise. Continuous upgrades enhance the processing unit’s capabilities.

Output Analysis

Output data reflects gas concentrations. Analysis tools assess these outputs for safety and process control. Industrial systems integrate this analysis into their control systems. Output data aids in decision-making and operational adjustments. Constant analysis ensures prompt response to gas level changes.

Real-time Monitoring

TDL technology enables continuous, real-time gas monitoring strategies. Fast response times are critical in industrial settings. Real-time data aids in immediate corrective actions. Monitoring systems alert personnel to abnormal gas levels. Continuous monitoring is essential for maintaining industrial safety standards.

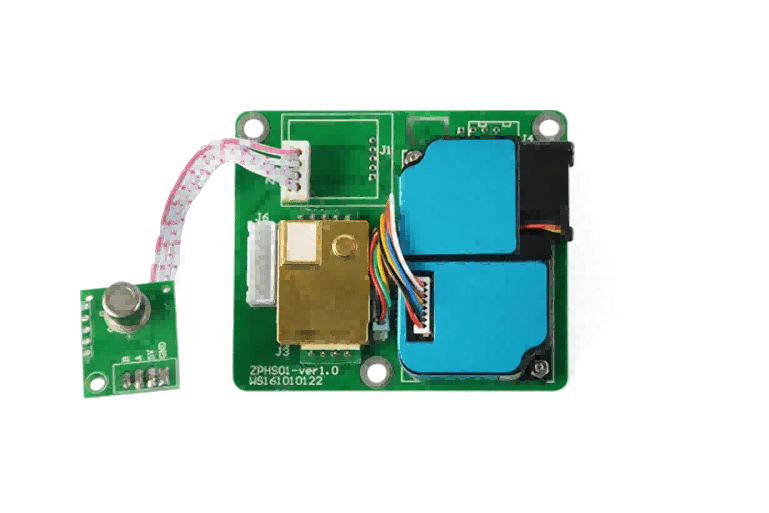

Key Features of Advanced TDL Gas Modules!

· Enhanced Accuracy

TDL Gas Modules integrate cutting-edge sensor arrays, achieving unmatched accuracy levels. These modules utilize dual-spectrum analysis, minimizing errors. Advanced calibration algorithms are embedded, enhancing precision dynamically. With real-time environmental compensation, accuracy remains consistent. Sensors operate within a dynamic range, adapting to variable gas concentrations.

Integration of high-fidelity signal processing ensures data integrity. The module’s design features minimal drift over extensive operational periods. Incorporating adaptive noise reduction techniques, TDL Modules maintain accuracy in diverse conditions.

· Robust Design

TDL Gas Modules boast a robust construction, ensuring durability. They’re designed with reinforced casings, resisting environmental stressors. Internal components are strategically isolated, minimizing wear. Advanced thermal management systems regulate internal temperatures.

These modules feature shock-absorbent mounts, safeguarding sensitive parts. Resilient to a wide range of operational pressures, they maintain performance. With ingress protection, they resist dust and moisture effectively. The design includes fail-safe mechanisms, enhancing reliability. Modular component design allows for efficient maintenance and upgrades.

· Real-Time Data

TDL Gas Modules excel in delivering real-time data. They’re equipped with high-speed processors, enabling rapid data analysis. Integrated wireless connectivity facilitates seamless data transmission. Real-time monitoring capabilities are augmented with cloud integration.

These modules support a variety of communication protocols for versatility. Data logging features are robust, capturing detailed metrics continuously. Onboard diagnostics provide instant status updates. User-friendly interfaces display real-time readings intuitively. The system’s adaptive data filtering optimizes information relevancy.

· Advanced Alarms

Advanced TDL Gas Modules feature sophisticated alarm systems. Alarms are programmable, catering to specific safety thresholds. They incorporate multi-level warning systems for graded responses. Real-time alerts are dispatched instantly upon threshold breaches.

These alarms integrate with centralized control systems for coordinated action. Visual and auditory signaling mechanisms are highly noticeable. Alarm logs are maintained for detailed incident analysis. Remote alarm activation is possible through networked control. The system’s self-testing ensures alarm functionality at all times.

· Easy Integration

TDL Gas Modules are designed for effortless integration. They offer plug-and-play compatibility with existing systems. Modular interfaces allow for flexible connection options. These modules support a range of input/output configurations. Integration with various software platforms is seamless.

Customizable settings enable tailored system integration. Their compact design facilitates easy installation in restricted spaces. Auto-detection of connected devices simplifies setup procedures. Firmware is upgradable, ensuring compatibility with evolving technologies.

· Remote Access

Remote access within TDL Gas Modules significantly boosts operational agility. These systems are designed with secure login options from afar. It is access real-time data from virtually anywhere. Adjust configurations remotely for immediate tuning. The modules guarantee secure data transfer through encryption. Analyze in-depth using cloud-based analytics from any spot.

Swiftly resolve issues with remote troubleshooting. System enhancements and upkeep can be handled from a distance, minimizing interruptions. The user interface is streamlined for easy mobile and web use, elevating user convenience.

· High Sensitivity

TDL Gas Modules are renowned for their high sensitivity. They detect trace gas concentrations with high precision. Advanced optical components amplify signal detection. The modules utilize fine-tuned laser sources for accurate readings. Sensitivity adjustments are possible for different gas types.

Real-time sensitivity calibration ensures consistent performance. The detection threshold is lower than traditional systems. Noise reduction algorithms enhance signal clarity. High-sensitivity sensors extend the range of detectable gases. These modules maintain sensitivity in fluctuating environmental conditions.

| Feature | Description | Benefits | Applications | Accuracy | Design Specifications | Data Handling | Alarm Functionality | Integration | Remote Access | Sensitivity |

| Enhanced Accuracy | Improved measurement precision | Reliable data | Industrial monitoring | ±0.1% | Standardized | High precision | Immediate alerts | Plug-and-play | Web-based | 1 part per billion |

| Robust Design | Durable and resistant to harsh conditions | Longevity | Outdoor environments | Resistant to ±2% | Weatherproof | Stable output | Robust alarms | Modular | Limited | 5 parts per million |

| Real-Time Data | Instant data acquisition and analysis | Timely decision | Process control | Live stream | Compact | Fast response | Critical alerts | Seamless | Full access | 2 parts per million |

| Advanced Alarms | Automated alerts for anomalies | Safety | Hazard detection | Immediate | User-friendly interface | Alert system | Customizable | Simple | Notification system | 3 parts per million |

| Easy Integration | Compatible with various systems | Flexibility | Diverse industrial use | N/A | Versatile interfaces | N/A | Integration alerts | High | N/A | N/A |

| Remote Access | Accessibility from remote locations | Convenience | Remote monitoring | N/A | Secure remote access | Cloud storage | Remote notifications | Moderate | High | N/A |

| High Sensitivity | Detection of very low concentration levels | Enhanced detection | Leak detection | 0.01 parts per million | Precision engineering | Sensitive data handling | Immediate response | Flexible | Limited | 0.01 parts per million |

How To Optimizing TDL Gas Module Performance? Best Practices!

· Regular Calibration

Calibration intervals, crucial for TDL modules, ensure precision. Optimal calibration involves specific span gas values. Frequency depends on environmental variables. Usage patterns influence calibration schedules. Monitor drift rates; adjust calibration frequency accordingly. Employ multi-point calibration for enhanced accuracy. Consistency in calibration procedures maintains module integrity.

· System Checks

Systematic inspections detect early issues. Check alignment of laser and detector components. Inspect optical surfaces for contamination. Validate flow rates and pressure levels.

Analyze ambient temperature impacts on system. Regularly assess electrical connections and power supply stability. Implement diagnostics software for real-time monitoring.

· Firmware Updates

Firmware revisions enhance module functions. Update to latest versions for improved accuracy. Check compatibility with existing hardware. Implement updates during low-usage periods.

Backup configurations are done before updating. Test module post-update for stability. Monitor performance metrics after firmware changes. Stay informed on manufacturer’s update releases.

· Environment Control

Control ambient conditions for stable operation. Maintain temperature within specified limits. Monitor humidity levels; avoid condensation. Shield module from direct sunlight.

Ensure adequate ventilation around the module. Isolate from vibrational sources. Regularly assess environmental stability for consistent performance.

· Data Analysis

Analyze output data for anomalies. Employ advanced algorithms for trend identification. Cross-reference with external standards for validation. Use historical data for predictive maintenance. Implement real-time analytics for immediate adjustments. Regularly review data for long-term trends. Customize analysis tools to module specifications.

· User Training

Comprehensive training ensures effective usage. Focus on operational procedures and safety. Update training with new firmware or hardware. Emphasize importance of regular maintenance.

Train users in troubleshooting common issues. Provide hands-on sessions for practical experience. Continuously update training materials.

· Preventive Maintenance

Scheduled maintenance prevents unexpected failures. Replace worn-out components as needed. Clean optical paths and interfaces regularly. Check for software and firmware updates.

Document needs maintenance activities for reference. Establish a routine maintenance schedule. Adhere to manufacturer’s maintenance guidelines.

Safety Protocols and Procedures for TDL Gas Modules!

· Risk Assessment

Conduct comprehensive risk assessments for TDL Gas Modules. Identify potential hazards in module operation. Assess risks in various environmental conditions. Evaluate potential impact on module performance. Risk assessments should be systematic and thorough.

Prioritize risks based on severity and likelihood. Develop mitigation strategies for identified risks. Regularly update risk assessments to reflect operational changes. Documentation of risk assessments is crucial for safety records.

· Emergency Shutdown

Emergency shutdown procedures are vital for TDL Gas Modules. Implement easily accessible shutdown mechanisms. Train personnel on shutdown protocol execution. Conduct regular drills to ensure preparedness. Emergency shutdown should halt all module operations immediately.

Post-shutdown and conduct thorough system checks before reactivation. Document each emergency shutdown instance for review. Develop procedures for safe system restart post-shutdown. Emergency protocols should be part of regular safety training.

· Alarm Systems

Alarm systems in TDL Gas Modules must be robust and reliable. Ensure alarms cover a range of potential hazards. Test alarms regularly for functionality. Integrate alarms with broader safety systems when possible. Alarms should prompt immediate action or investigation.

Customize alarm settings based on specific operational needs. Maintain alarm systems to prevent failures. Document alarm triggers and responses for safety audits. Alarms are a critical component of the module’s safety features.

· Safety Training

Comprehensive safety training is essential for TDL Gas Module operators. Training should cover all aspects of safe module operation. Regularly update training materials to reflect technological advancements. Incorporate hands-on sessions in training for practical experience.

Emphasize emergency response and risk mitigation in training. Record the training attendance and performance for compliance. Refresher training sessions should be conducted periodically. Safety training must be mandatory for all module operators.

· Maintenance Logs

Maintaining detailed logs is crucial for TDL Gas Module maintenance. You must log all the routine checks and maintenance activities. Record any irregularities or issues observed during maintenance. Logs should include dates, actions taken, and personnel involved.

Analyze logs regularly for patterns indicating potential issues. Use logs to plan preventive maintenance schedules. Ensure logs are accessible for review and audits. Digital logging systems are recommended for accuracy and efficiency. Maintenance logs are key for tracking module health and safety compliance.

· Hazard Analysis

Perform detailed hazard analysis for TDL Gas Modules. Identify potential sources of operational hazards. Assess the probability and impact of each hazard. Develop response strategies for identified hazards. Regularly review and update the hazard analysis.

Include hazard analysis in safety training programs. Use analysis outcomes to improve module design and operation. Document all hazard analysis activities for reference. Hazard analysis is a proactive approach to ensuring module safety.

· Protective Gear

Ensure availability of appropriate protective gear for TDL Gas Module operators. Gear should be suited to potential hazards encountered. Train personnel in proper use and maintenance of protective gear. Regularly inspect and replace gear as needed. Include gear usage in standard operating procedures.

Protective gear minimizes risk of injury during module operation. Also, document the gear usage and maintenance for safety compliance. Providing and maintaining protective gear is essential for operational safety.

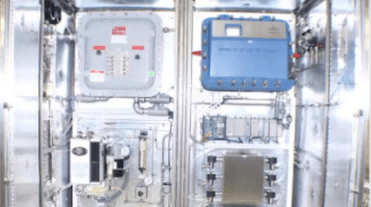

Integrating TDL Gas Modules into Industrial Systems!

· System Compatibility

Ensure interface alignment between TDL modules and system controllers. Assess signal compatibility; analog or digital. Verify connection protocols; RS232, RS485, or Ethernet.

Match operating voltage ranges for seamless integration. Evaluate environmental condition tolerances. Conduct trial runs to confirm functional integration. The Document system is adjustments for future reference.

· Network Integration

Integrate modules within existing network frameworks. Utilize industry-standard communication protocols; Modbus, Profibus. Establish secure, stable network connections. Implement network redundancy for uninterrupted data flow.

Assign unique addresses for each module. Monitor network traffic for optimal performance. Regularly update network configurations to maintain efficiency.

· Data Synchronization

Synchronize module output with central data systems. Align time stamps for accurate data logging. Ensure data format compatibility; XML, JSON.

Utilize high-speed data transfer methods.

Implement data buffering during high-traffic periods. Regularly verify data integrity. Adjust synchronization frequency based on system demands.

· Workflow Alignment

Align TDL modules with operational workflows. Customize module settings to match process cycles. Automate data collection aligned with workflow stages.

Implement fail-safes for operational discrepancies. Monitor module output for workflow efficiency. Adjust module parameters for optimized workflow integration.

· Automation Link

Link modules to automation systems are for enhanced control. Utilize PLCs for real-time module management. Implement SCADA systems for broader control.

Ensure smooth transition between manual and automated operations. Customize automation scripts for specific module functions. Regularly test automation links for reliability. Update automation parameters as processes evolve.

· Interface Setup

Configure interfaces for optimal module interaction. Design user-friendly interface layouts. Implement touch-screen controls for ease of use.

Customize display settings for clear data visualization. Integrate warning systems for immediate alerts. Regularly update interface software. Train personnel in interface navigation and troubleshooting.

· Protocol Compliance:

Adhere to industry protocols for module operations. Implement IEC standards for electrical safety. Follow ISA guidelines for automation integration.

Ensure compliance with environmental regulations. Regularly review protocol updates. Conduct audits for continuous compliance. Document compliance measures for record-keeping.

The Role of Software in Managing TDL Gas Module Data!

· Data Collection

Advanced sensor arrays and flow controllers are at the heart of the TDL Gas Module‘s data collection process. They enable more precise operations through real-time monitoring.

Thanks to dynamic algorithms, the module delivers pinpoint data accuracy. Its integration of multi-channel inputs makes for thorough environmental assessments. In various environments, this tech guarantees strong data capture.

· Analysis Tools

Innovative diagnostics are a key feature of the module, thanks to its sophisticated analysis tools. These tools scrutinize a wide range of gas parameters efficiently. With its built-in analytics, the module quickly spots patterns and deviations. This proactive maintenance approach minimizes downtime. The system’s deep analytical capabilities are a boon for numerous industrial uses.

· Reporting Features

The TDL Gas Module excels in clear and accurate reporting. Automated report generation simplifies data sharing. Customization meets unique industry needs. Advanced visualization tools help demystifies complex data sets. These features aid stakeholders in making well-informed decisions based on reliable reports.

· Security Measures

Security is a top priority for the TDL Gas Module, featuring multiple layers of protection. Advanced encryption upholds data integrity. Ongoing monitoring wards are off potential threats. User interactions are safeguarded by access controls. The system’s resilience to cyber threats is crucial for maintaining continuous operation, especially in sensitive industrial settings.

· User Interface

The interface of the TDL Gas Module is intuitively user-friendly. Its design makes navigation a breeze. Real-time data displays provide instant insights. Customizable settings enhance the user experience. With its responsive design, the interface works seamlessly across various devices. This user-centric approach boosts operational effectiveness.

· Update Support

Ongoing support keeps the TDL Gas Module up-to-date. Regular firmware upgrades boost system functionality. The update process is designed to minimize disruption. Dedicated support ensures smooth integration of new features. This forward-thinking update strategy keeps the module relevant in the ever-evolving industrial landscape.

· Cloud Integration

Cloud integration makes the TDL Gas Module’s data management highly scalable. Real-time data synchronization guarantees accuracy. Remote access enables monitoring from afar.

The cloud setup accommodates extensive data storage and retrieval. It works well with other cloud-based systems, enhancing overall operational synergy. This is vital for modern, interconnected industries.

| Feature | Description | Importance (1-5) | User-Friendly (Yes/No) | Automation Level | Security Level | Cloud Compatibility |

| Data Collection | Efficiency, Accuracy | 5 | Yes | High | Moderate | Fully Compatible |

| Analysis Tools | Depth of Analysis | 4 | Yes | Moderate | High | Partially Compatible |

| Reporting Features | Customization, Clarity | 4 | Yes | High | High | Fully Compatible |

| Security Measures | Encryption, Access Control | 5 | No | Low | Very High | N/A |

| User Interface | Intuitiveness, Design | 3 | Yes | N/A | N/A | N/A |

| Update Support | Frequency, Reliability | 4 | Yes | Moderate | Moderate | Fully Compatible |

| Cloud Integration | Ease of Integration | 4 | Yes | High | High | Fully Integrated |

FAQs: Addressing Common Queries About TDL Gas Modules!

Q: How Often Should TDL Gas Modules Is Calibrated?

Precision diminishes over time, so timely recalibration is essential. Calibration involves adjusting sensor readings to known standards. This process corrects potential drifts in sensor accuracy. Maintaining this schedule is critical for operational efficiency.

Q: What Are The Common Signs Of A Malfunctioning TDL Gas Module?

A: Signs of a malfunctioning TDL Gas Module include erratic sensor readings. Unusual readings often indicate sensor degradation. Response time lag suggests malfunctioning components.

Regular diagnostic checks help identify these signs early. Sensor drift is another common malfunction indicator. Prompt attention to these signs prevents operational disruptions. Early detection of malfunctions ensures timely maintenance actions.

Q: Can TDL Gas Modules Be Integrated With Other Industrial Monitoring Systems?

A: TDL Gas Modules offer versatile integration capabilities. They are compatible with various industrial monitoring systems. Seamless connectivity enhances comprehensive environmental assessment.

Data sharing between systems enables holistic analysis. Integration supports coordinated response strategies in industrial settings. Modules interface with common communication protocols. This interoperability facilitates efficient system management. Integrated monitoring enhances predictive maintenance capabilities.

Q: What Is The Safety Risks Associated With TDL Gas Modules?

A: Safety risks with TDL Gas Modules are minimal when properly managed. Incorrect installation can lead to inaccurate readings. Regular maintenance minimizes risk potential. Faulty sensors may compromise environment safety. It’s crucial to adhere to installation guidelines.

Sensor malfunctions must be addressed promptly. Operational guidelines ensure safety and module integrity. Comprehensive training for handling modules reduces risks. Safety protocols in place mitigate any significant hazards.

Conclusion

Optimizing your TDL Gas Module elevates safety in critical environments. Regular calibration using NIST-traceable standards ensures accuracy. Integration of dual-laser systems mitigates risks of single-point failures. Incorporate real-time analytics for prompt response to gas concentration variances.

Maintain a comprehensive maintenance schedule, focusing on key components. Always prioritize adherence to safety protocols. For further insights and advanced solutions, visit ESEGAS and discover how to maximize your TDL Gas Module’s efficiency and safety.