Tighter air-quality standards are reshaping how power plants operate. Today, regulators expect precise tracking of every gas released into the atmosphere. That’s where a high-accuracy process gas analyzer becomes indispensable. It delivers real-time, trustworthy measurements of key pollutants, helping plants prove—without doubt—that they meet legal limits.

This isn’t just about ticking compliance boxes. Accurate gas measurement safeguards workers, protects equipment, and optimizes combustion efficiency. For power generation, where NOₓ, SO₂, CO₂, and other emissions are under constant scrutiny, such precision is the difference between running smoothly and facing costly penalties.

By continuously monitoring multiple gases at once, these analyzers keep plant managers “regulation-ready” at all times. In the sections ahead, we’ll look at how advanced sensing technology, fast response times, and intelligent features make these tools essential for today’s power sector.

Why Is a High-Accuracy Process Gas Analyzer Critical for Emissions Compliance in Power Generation?

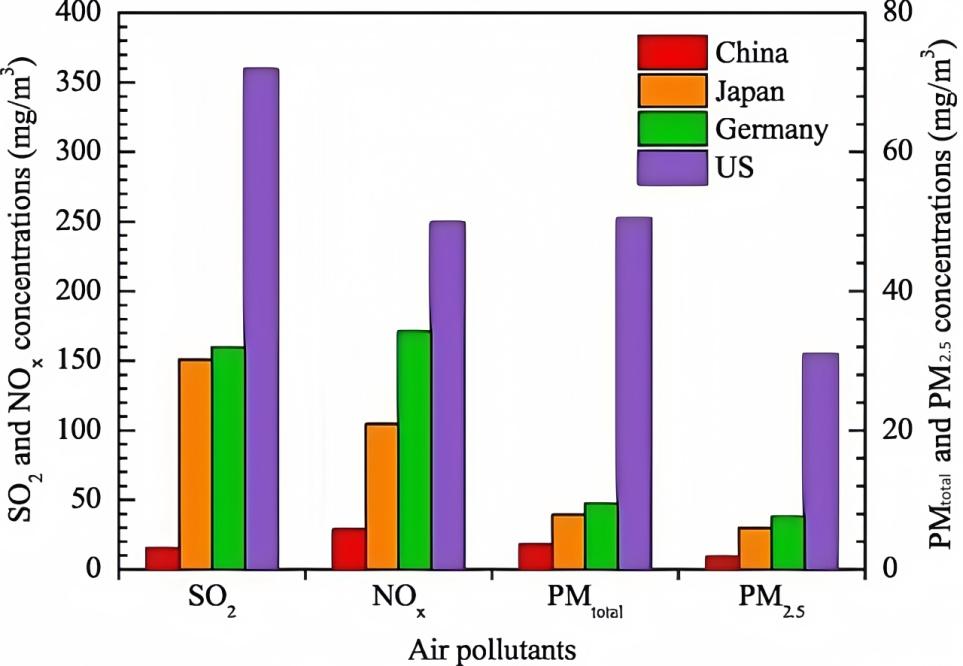

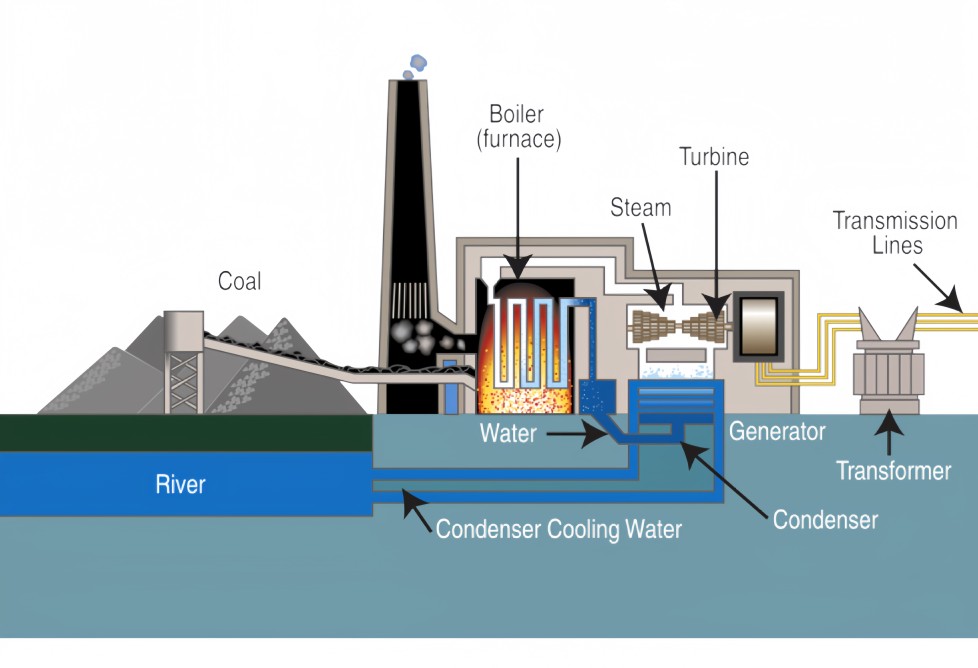

(Air pollutant emissions from coal fired power plants)

In power plants, every stack release is under the microscope. Combustion processes generate a mix of regulated gases—NOₓ, SO₂, CO₂, CO, particulate matter, and sometimes volatile organic compounds (VOCs). Each pollutant has a strict emission limit, and breaching those limits can trigger heavy fines or forced shutdowns.

Regulations such as the U.S. EPA’s 40 CFR Part 75 and the EU’s Large Combustion Plant Directive demand accurate reporting of NOₓ, SO₂, and CO₂ at very low concentrations. Only a high-accuracy process gas analyzer can measure these levels with the precision needed to satisfy both the letter and the spirit of the law. This precision not only ensures compliance but also provides legally defensible data for environmental audits.

Beyond meeting thresholds, accurate and continuous readings foster transparency—both with regulators and the surrounding community. For official reporting, plants often choose analyzers tested and certified by recognized bodies such as TÜV.

To understand why these instruments are so effective, consider their core strengths:

- Stringent Standards Compliance – Designed to meet or exceed legal limits for NOₓ, SO₂, CO₂, and other gases.

- Multi-Gas Capability – Simultaneous monitoring of O₂, NOₓ, SO₂, CO₂, VOCs, and more from a single system.

- Unbroken Data Record – 24/7 logging creates an auditable, tamper-proof record of plant emissions.

By capturing every pollutant with uncompromising accuracy, a high-quality analyzer gives operators the confidence to stay within environmental limits—day in, day out—while avoiding the costly consequences of non-compliance.

How Do Advanced Sensor Technologies Enhance the Performance of a High-Accuracy Process Gas Analyzer?

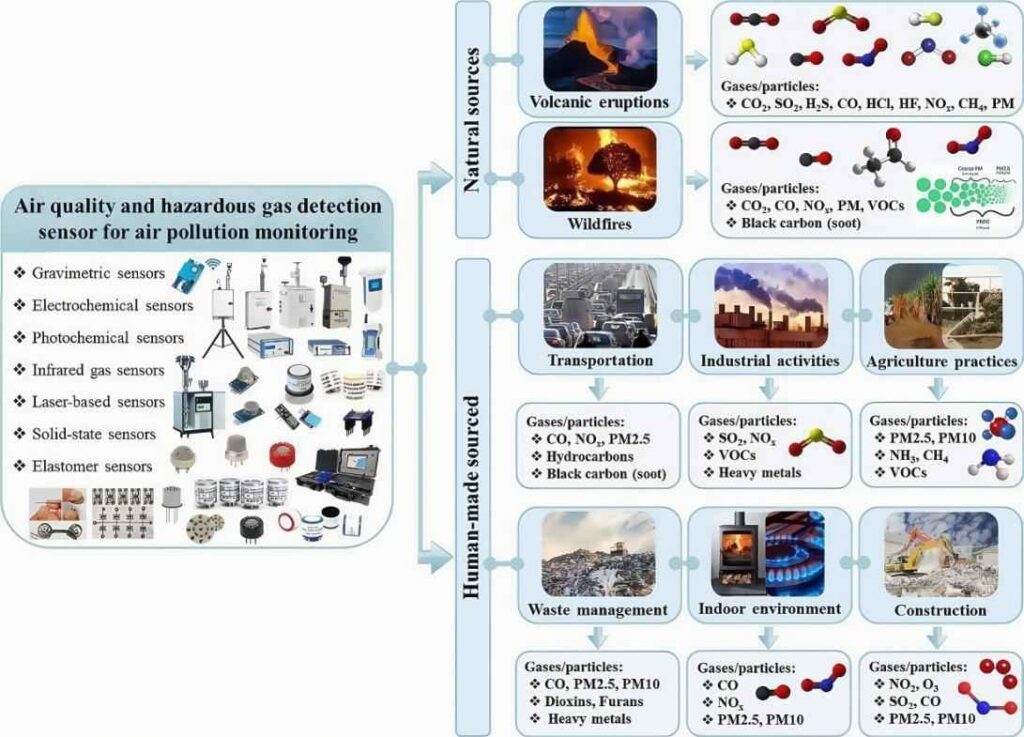

A high-accuracy process gas analyzer isn’t built around a single detection principle—it’s a fusion of specialized sensor technologies, each chosen for its strengths. This multi-technology design ensures every gas is measured using the most suitable method, resulting in data that plant operators can trust.

For example:

- NDIR (Non-Dispersive Infrared) – Ideal for CO and CO₂, it detects gases by their unique infrared absorption patterns. NDIR sensors maintain stability over years of operation, even in dusty flue gas conditions.

- TDLAS (Tunable Diode Laser Absorption Spectroscopy) – Delivers ultra-fast, pinpoint readings for NH₃, HCl, or H₂O, with minimal cross-interference. This makes it invaluable for mixed or variable flue gas streams.

- Paramagnetic O₂ Sensors – Use a non-depleting magnetic cell for long-term, drift-free oxygen monitoring—critical for combustion control.

- Electrochemical Cells – Accurately detect trace oxygen or toxic gases in low-concentration ranges, often where other methods fall short.

By combining these methods in one system, a high-accuracy analyzer can track the complete emissions profile of a power plant—from major greenhouse gases to trace contaminants. This integration not only improves accuracy but also enhances selectivity, helping plants meet compliance targets without overestimating or underreporting emissions.

What Features Make a High-Accuracy Process Gas Analyzer Ideal for Continuous Monitoring?

In continuous emissions monitoring, downtime is the enemy. A high-accuracy process gas analyzer must run reliably, maintain precision, and require minimal manual intervention. Modern designs achieve this through a combination of smart automation, robust engineering, and proactive fault detection.

First, scheduled calibration and validation routines keep the analyzer on-spec around the clock. Many systems can inject zero or span gases at set intervals or use internal standards for self-checks—reducing the need for constant technician attention.

Second, integrated self-diagnostics monitor sensor performance, flow rates, and sample integrity in real time. If drift, leaks, or failures occur, the system triggers instant alarms. This early warning prevents inaccurate reporting and unscheduled shutdowns.

Third, rugged sensor and optical components resist wear. Non-depleting paramagnetic O₂ cells, for example, deliver stable readings for years with minimal recalibration. Heated sample lines, particulate filters, and gas coolers prepare even hot, wet, and dusty flue gas for precise measurement, protecting sensitive detectors from damage.

Together, these features ensure a high-accuracy process gas analyzer stays online and accurate 24/7, giving plant managers confidence in every data point they report.

How Does Real-Time Data From a High-Accuracy Process Gas Analyzer Improve Power Plant Performance and Compliance?

(Coal-fired power plant operation)

In modern power plants, emissions monitoring is no longer a passive compliance task—it’s an active control tool. A high-accuracy process gas analyzer streams live gas concentration data directly into the plant’s control system, linking environmental compliance with operational efficiency.

For example, real-time oxygen readings allow operators to fine-tune the fuel-to-air ratio in boilers. Maintaining optimal flue O₂ levels ensures complete combustion, reducing excess oxygen that cools the flame and wastes fuel. At the same time, continuous CO tracking helps minimize unburned fuel losses. Together, these adjustments cut emissions while lowering operating costs—a clear win for both budgets and the environment.

Real-time data also acts as an early warning system. If a pollutant level rises toward its regulatory threshold, the analyzer triggers instant alerts, giving operators time to correct the process before a violation occurs. All measurements are fed into the plant’s DCS or SCADA platform, enabling automated logging, trend analysis, and predictive maintenance planning.

By turning gas measurement into a real-time, actionable tool, a high-accuracy process gas analyzer helps plant teams stay in control—maximizing efficiency while keeping emissions within safe and legal limits.

Conclusion

Power plants face tough emissions rules, and a high-accuracy process gas analyzer is an ideal solution. Its precision sensors and robust design ensure pollutant levels are measured correctly even in hard conditions. Automated calibration and diagnostics make it reliable 24/7. Meanwhile, live data flows help optimize the boiler and avoid violations. The end result is a win for everyone: plants keep clean-air permits, avoid fines, and often save fuel.

In today’s regulatory environment, investing in a top-tier process gas analyzer is not just smart – it’s essential for any power generation facility that wants to run efficiently and stay compliant.

If you want to know more, contact with us please!