As global warming and climate change become increasingly serious problems, reducing carbon dioxide emissions has become a global concern. Carbon Capture and Storage (CCS) technology is considered an effective means to solve this problem. In this process, gas analyzers play a crucial role in accurately monitoring and analyzing the composition of gases in the CCS process to ensure the safety and efficiency of the whole process.

Carbon Capture and Storage (CCS) Technology Profile

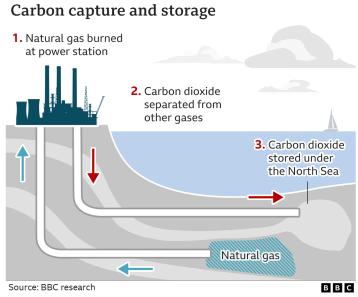

Carbon Capture and Storage (CCS) technology is an important means of combating climate change by capturing carbon dioxide (CO2) from industrial emissions or power generation and storing it safely underground to reduce greenhouse gas (GHG) emissions in the atmosphere.CCS technology consists of three key steps: carbon capture, transportation, and storage.

1. Carbon Capture

Carbon capture is separating carbon dioxide from the flue gases of power plants, factories, or other emission sources. Commonly used carbon capture technologies include:

- Chemical absorption: Separation of carbon dioxide is achieved by using an absorbent (e.g., an amine solution) that reacts with the carbon dioxide in the flue gas to form a renewable compound.

- Physical adsorption: Capture of carbon dioxide by surface adsorption using porous materials such as activated carbon or zeolites.

- Membrane Separation: Gas separation technology that separates carbon dioxide from other gases by selective transmission of specific membrane materials.

- Cryogenic separation: Separation is achieved by utilizing low temperatures to condense carbon dioxide into a liquid or solid.

2. Carbon Transport

Carbon transportation is the process of transporting captured CO2 from the source to the storage site. The main modes of transportation are:

- Pipeline transportation: Carbon dioxide is transported to the storage site in a supercritical fluid state through specialized high-pressure pipelines.

- Ship transport: Carbon dioxide is compressed or liquefied and transported by dedicated ships to a storage site away from the source of emissions.

- Transportation by rail or truck: In some cases, compressed or liquefied carbon dioxide may also be transported by rail or truck.

3. Carbon Storage

Carbon storage is the process of injecting carbon dioxide into deep underground rock formations for long-term sequestration, and the main storage sites include:

- Oil and gas fields: Injecting CO2 into depleted oil and gas fields can both increase oil and gas recovery and enable CO2 storage.

- Deep saline aquifers: Carbon dioxide is injected into deep underground saline aquifers to ensure long-term safe storage of carbon dioxide through the confinement of the geological structure.

- Coal seams: Injecting carbon dioxide into unmined coal seams can increase the recovery rate of coalbed methane while realizing carbon dioxide storage.

Gas Analyzers in CCS Technology

Gas analyzers play an important role in every aspect of CCS technology:

Gas analyzers play a vital role in all aspects of Carbon Capture and Storage (CCS) technology, from gas monitoring during the capture phase to environmental assessment during the storage phase, the use of gas analyzers ensures that the entire process is efficient and safe.

1. Carbon capture phase

During the carbon capture phase, gas analyzers are primarily used to monitor the concentration of carbon dioxide in the flue gas, as well as the purity and composition of the gas during the capture process. This information is critical for optimizing the capture process, improving capture efficiency, and reducing operating costs.

- Monitoring of carbon dioxide concentration in flue gas: The gas analyzer can measure the concentration of carbon dioxide in the flue gas in real-time, providing a basis for the adjustment of the capture process.

- Evaluating Capture Efficiency: By analyzing the gas composition before and after capture, a gas analyzer can evaluate the efficiency of a carbon capture system.

- Monitoring of gas purity: In some capture technologies, such as chemical absorption, the concentration of carbon dioxide in the absorbent needs to be monitored to ensure the regeneration and recycling of the absorbent.

2. Carbon transportation phase

During the carbon transportation phase, gas analyzers are used to monitor the pressure, temperature, and concentration of carbon dioxide in the transportation pipeline or vessel to ensure the safety of the transportation process.

- Monitoring CO2 leaks: By continuously monitoring the concentration of CO2 in a pipeline or vessel, gas analyzers can detect leaks in time to prevent the release of CO2 into the atmosphere.

- Assessing transportation safety: Monitoring the pressure and temperature of CO2 is critical to assessing safety risks during transportation.

3. Carbon storage phase

During the carbon storage phase, gas analyzers are used to monitor carbon dioxide concentrations around the storage site and groundwater quality to ensure that carbon dioxide is being stored safely and efficiently.

- Monitoring of carbon dioxide concentrations at storage sites: periodic testing of carbon dioxide concentrations around storage sites to assess storage effectiveness and to monitor potential leakage.

- Assessment of environmental impacts: Monitoring of carbon dioxide levels and other chemical constituents in groundwater to assess the impacts of carbon storage on the groundwater environment.

Technical characteristics of gas analyzers

The use of gas analyzers in CCS technology relies on their high accuracy, sensitivity, and fast response:

- High accuracy: Gas analyzers can accurately measure the concentration of each component of a gas, usually with an error of a few parts per million.

- High sensitivity: Gas analyzers can detect very low concentrations of gases, which is critical for monitoring trace leaks.

- Fast response: The gas analyzer can monitor changes in gas composition in real-time, providing data support for the timely adjustment of process parameters.

Our CO2 Gas Analyzer

Measuring CO2 gas involves the use of two main technologies: Tunable Diode Laser Absorption Spectroscopy (TDLAS) and Non-Dispersive Infrared (NDIR).

TDLAS is a relatively new technology that relies on the absorption of light to measure the concentration of CO2 in a gas. It uses a laser to detect the molecules in a sample and then calculates the concentration based on their optical absorption. This technique is advantageous in that it has a high degree of accuracy, can measure small concentrations, and does not require calibration with reference gases.

Non-dispersive infrared (NDIR) is a more traditional method of measuring CO2 gas. This technique relies on the infrared absorption of CO2 molecules and the detection of infrared radiation by an optical detector. NDIR is typically used to measure larger concentrations of gases, but it is not as accurate or sensitive as TDLAS. Additionally, NDIR requires calibration with reference gases to properly measure the concentrations of CO2 in a sample.

What is the application of CO2 measurement?

CO2 monitoring is important in order to accurately assess the amount of CO2 emissions produced during different industrial activities.

- Landing fills and agricultural

- Metallurgical industry

- Combustion engineers, furnaces, and boilers

- Vehicles are the three main sources of CO2 emissions.

- Gasification

In the metallurgical industry, monitoring of CO2 emissions can be used to evaluate the efficiency of the smelting process. This can be done by measuring the amount of CO2 generated during the process. In landfills, CO2 is a by-product of landfill gas and the monitoring of this gas can be used to measure the efficiency of the landfill operations. The gas mainly contains CO2 and CH4, and if it is used for combustion or power generation, CO2 can also be used to evaluate its efficiency. In vehicle carbon emissions, CO2 is a major greenhouse gas and monitoring of this emission can effectively measure which types of vehicles produce a large amount of CO2. This can help in developing strategies to reduce the emission of this greenhouse gas and help fight climate change. Overall, CO2 monitoring is an important tool for assessing the amount of CO2 emissions produced during different industrial activities. By measuring and monitoring these emissions, it can help in reducing greenhouse gas emissions and the effects of climate change. By doing this, it can also have a positive effect on the environment.

Challenges and perspectives of gas analyzers in CCS technology

Although gas analyzers play an important role in CCS technology, they still face several challenges:

- Environmental adaptability: The environmental conditions in CCS technology are complex and variable, and gas analyzers need to adapt to harsh environments such as high temperatures, high pressures, and corrosive gases.

- Long-term stability: Carbon storage is a long-term process that requires a gas analyzer with good long-term stability and reliability.

- Cost-effectiveness: Improving the performance of gas analyzers often comes with increased costs, and balancing performance and cost can be a challenge.

Looking to the future, as technology continues to advance, gas analyzers will become more accurate, stable, and economical, providing stronger support for the development of carbon capture and storage technologies.

Conclusion

Gas analyzers play a crucial role in carbon capture and storage (CCS) technology by monitoring and analyzing the gas composition in real-time to ensure the safety and efficiency of the entire process. Facing the challenges of environmental adaptability, long-term stability, and cost-effectiveness, future gas analyzers need to be more advanced and economical to better serve the development of CCS technology. With the growing global demand to reduce CO2 emissions, the application of gas analyzers in the field of carbon capture and storage (CCS) will be even more promising.more information pls visit www.esegas.com