Since the industrial revolution, the content and types of pollutants emitted into the atmosphere by human beings have been increasing year by year, and the resulting atmospheric pollution problem has attracted the attention of many countries around the world, so it is necessary to accurately monitor the key components. The detection methods of atmospheric components are mainly divided into direct detection and remote sensing detection. Direct detection can obtain high-precision measurement data at the sampling point, but the representative range of the results is limited and cannot observe the vertical structure of the atmospheric composition; remote sensing technology is a comprehensive detection technology that has been rapidly developed in recent decades, and its application is a powerful complement to the traditional sampling methods, which can monitor the atmospheric composition in real-time at long distances, analyze the multi-component atmospheric mixture quickly, and obtain the ground or airborne data of the atmospheric composition without tedious sampling procedures. without the need for cumbersome sampling procedures that can be obtained on the ground or high altitude three-dimensional spatial data over a large area and a long period of time. In particular, it has unique advantages in the detection of the vertical structure of atmospheric composition. It has unique advantages in detecting the vertical structure of atmospheric components.

The monitoring and management of methane, a major greenhouse gas, is particularly important in the context of global climate change. Especially in the oil and gas industry, methane leakage not only brings environmental problems but also may lead to energy waste and safety risks. Therefore, efficient and accurate methane monitoring technology is an important tool to ensure safe and environmentally friendly operations in these industries. In this blog, we will introduce the working principle of methane remote sensing monitor and discuss its application in oil and gas pipeline monitoring.

Tunable Laser Spectral Absorption (TDLAS) Technology Principle

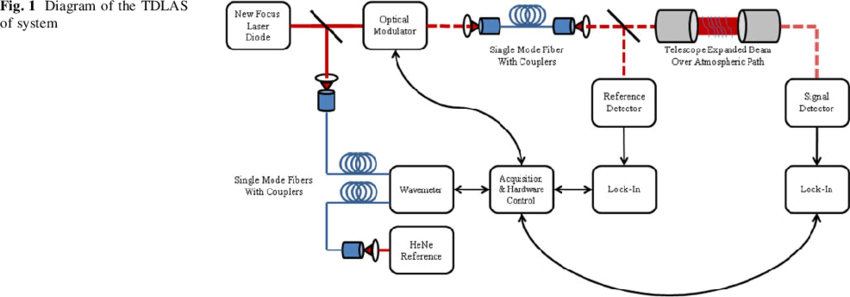

Tunable Diode Laser Absorption Spectroscopy (TDLAS, sometimes referred to as TDLS, TLS, or TLAS) is a technique for measuring the concentration of certain substances (e.g., methane, water vapor, etc.) in gas mixtures using a tunable diode laser and laser absorption spectroscopy. Compared to other concentration measurement techniques TDLAS has the advantage of being able to achieve very low detection limits (on the order of ppb) compared to other concentration measurement techniques. The advantage of TDLAS over other concentration measurement techniques is its ability to achieve very low detection limits (ppb order of magnitude). In addition to concentration, the temperature, pressure, velocity and mass flux of the observed gas can be determined. TDLAS is by far the most common laser-based absorption technique used for the quantitative assessment of gas-phase substances.

1. Principles

TDLAS utilizes the principle of spectral absorption of a laser beam with atmospheric methane molecules to measure methane concentration. The principle of operation can be briefly described as follows:

- The laser emits a laser beam with a specific wavelength.

- This laser beam travels through the atmosphere and passes through the absorption region of methane molecules.

- Part of the laser beam is absorbed by methane molecules and its intensity is proportional to the methane concentration.

- The detector measures the intensity of the beam after it has passed through the atmosphere and compares it to a reference intensity that has not passed through the atmosphere.

- By comparing the difference between these two intensity values, the methane concentration in the atmosphere can be calculated.

2. Technical characteristics

The application of Tunable Laser Spectral Absorption (TDLAS) technology to methane remote sensing monitors is an advanced method for detecting atmospheric methane concentrations.TDLAS utilizes the optical absorption spectrum generated by a laser beam as it passes over atmospheric methane molecules to measure methane concentrations. It has the advantages of high sensitivity, high resolution and high accuracy. The application of TDLAS to methane remote sensing monitors has the following technical characteristics:

- High sensitivity: TDLAS enables highly sensitive detection of atmospheric methane concentrations and accurate measurements even at low concentrations.

- High resolution: TDLAS has a high spectral resolution and can distinguish different wavelengths of light in the atmosphere, thus realizing accurate measurements of methane.

- Rapid Response: TDLAS responds quickly and can monitor changes in methane concentration in real-time, helping to detect pipeline leaks and other anomalies promptly.

- Remote Monitoring: TDLAS is capable of monitoring methane concentrations over long distances, making it suitable for remote monitoring of large pipeline systems.

Application of Tunable Laser Spectral Absorption (TDLAS) Technology to Methane Remote Sensing Monitors

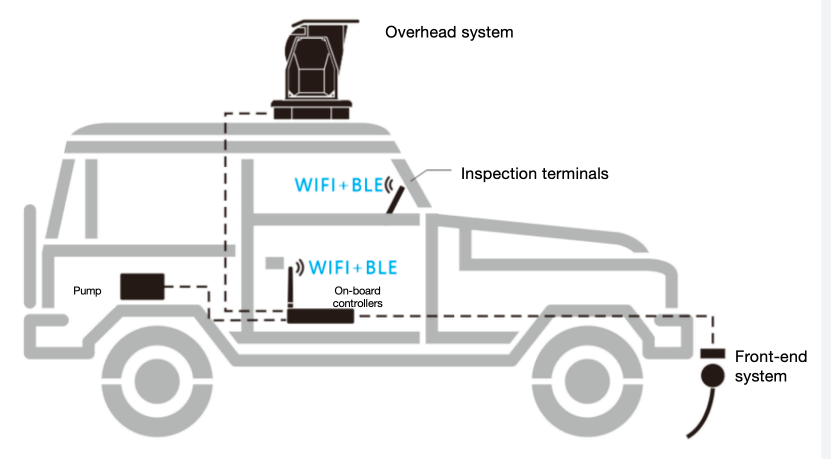

In the oil and gas industry, methane remote sensing monitors using TDLAS technology can be installed at fixed monitoring stations or mobile inspection vehicles, or carried by drones for aerial inspections. These monitors can continuously monitor methane concentrations along the route, and once an abnormally high methane concentration is detected, the system automatically alerts the operator, indicating possible leaks, and crews can then proceed to the site for detailed inspection and repair.

Application scenarios for TDLAS on methane remote sensing monitors include, but are not limited to, the following:

- Pipeline Leak Detection: TDLAS can monitor the methane concentration in the atmosphere around the pipeline in real-time so that pipeline leaks can be detected in time and emergency measures can be taken.

- Pipeline safety assessment: Through continuous monitoring of methane concentration, the safety of pipeline systems can be assessed and pipeline anomalies can be detected promptly.

- Environmental monitoring: TDLAS can be used to monitor methane concentrations in the environment around pipelines, assess the impact of pipelines on the surrounding ecosystem, and protect the health of the environment and ecosystems.

In addition, TDLAS technology makes it possible to conduct comprehensive environmental monitoring of pipelines, helping companies to identify potential risk points in advance and develop more effective maintenance and emergency response plans. With this advanced technology, safety standards and environmental performance in the oil and gas industry can be significantly improved.

Application of methane remote sensing monitors on oil and gas pipelines

The application of methane remote sensing monitor on oil and natural gas pipelines is a very important part of modern energy industry that concerns energy security, environmental protection and economic efficiency. In the following, we will discuss in detail the specific applications and benefits of this technology in oil and gas pipeline monitoring.

1. Leak detection and localization

Operational Processes:

- Inspection: Methane remote sensing monitors can be mounted on a variety of platforms such as drones, helicopters or ground vehicles. These devices fly or travel along pipelines and utilize laser technology for real-time monitoring of methane concentrations. Especially in remote or inaccessible areas, the convenience and safety afforded by drones greatly improves monitoring efficiency.

- Data Acquisition and Analysis: The monitor scans the atmosphere for methane concentrations through laser absorption spectroscopy. When an abnormally high methane concentration is detected, the system immediately alerts the operations center and records the exact location and concentration data for further analysis.

Technical Details:

- Spectral selection: Selecting spectral wavelengths that are sensitive to methane ensures that interference from other gases in the environment is minimized.

- Laser transmission distance: The design of the remote sensing monitor ensures that the laser can cover a sufficient distance to accommodate monitoring needs in different environmental and weather conditions.

2. Preventive maintenance

Operational Processes:

- Regular monitoring: Through regular remote sensing monitoring, a long-term data record of pipeline operations can be established. This data helps technicians analyze the health of the pipeline and identify possible leaks or potential risk areas.

- Data-driven maintenance decisions: Based on the data collected, operations teams can prioritize pipeline segments that show potential problems for targeted overhaul and maintenance to prevent possible large-scale spills.

Technical Details:

- Data Analytics Tool: Advanced data analytics and machine learning algorithms are used to analyze large amounts of data collected to identify leakage patterns and risk trends.

- Integrated systems: The monitoring system is integrated with other O&M systems in the enterprise, such as GIS (Geographic Information System), which allows for a more intuitive display of monitoring data and leak locations, and facilitates analysis of geographic and environmental factors.

3. Environmental protection and compliance

Operational Processes:

- Real-time monitoring: Real-time monitoring of methane leaks is critical for compliance with environmental regulations. The system instantly detects and records leaks, ensuring that companies can respond quickly and take action to minimize environmental impact.

- Reporting and Compliance: Automated data logging and reporting capabilities make it easy for organizations to prepare environmental compliance documents that show their efforts to monitor and respond to spills.

Technical Details:

- Threshold Setting: The system can set a safety threshold for methane concentration, and once data exceeding this threshold is monitored, the system will automatically alarm.

- Accuracy of remotely sensed data: Ensuring a high level of accuracy and repeatability of data is critical for environmental reporting and auditing.

Through these meticulous operational processes and technical details, the Methane Remote Sensing Monitor becomes an integral part of oil and gas pipeline safety management. It not only raises safety standards, but also reduces long-term operating costs through preventive maintenance and helps companies comply with increasingly stringent environmental regulations.

Telemetry Type Gas Sensing Module——50M/100M/200M

This product(Type 50M) belongs to the telemetry gas sensing products, referred to as “short telemetry module”, it is used to integrate into the handheld telemetry, Gimbal Scan Detector, airborne or vehicle gas detector, etc., it is telemetry (contactless measurement) to detect whether there is a danger in the target area, timely warning, to avoid the loss of life and property.

Product Characteristics

● High reliability, long service life;

● High precision, fast response;

● Uniqueness of gas detection;

● Small size / lightweight / easy to integrate

● Flexible usage / portable / cradle/vehicle / onboard

● True non-contact measurement

Technical Specifications

| Project | Description |

| Target Gas | Methane (CH4) |

| Detection Principle | Tunable laser spectrum absorbance technology (TDLAS) |

| Detect The Range | 0~100000 ppm.m |

| Detection Distance | Greater than 50 m |

| Response Time | ≤50ms |

| Sensitivity | 10(@1~30m)ppm.m. 50(@ 30~100m ) ppm.m |

| Signal Output | TTL(3.3V) Serial port communication (see the attachment for the protocol) |

| Working Voltage | 3.3-5.5VDC |

| Power Dissipation | <3W @ room temperature |

| Working Temperature | -20~60℃ |

| Working Humidity | 5% ~ 98% RH, with no condensation |

| Material / Weight | Aluminum alloy (surface sandblasting, black oxidation) / about 120g |

| Size | 48.5×37×66mm (length, width, and height) |

Application

◆ Natural gas terminal and station

◆ Natural gas long-distance transmission pipeline

◆LNG gas holder station

◆ Commercial gas pipeline

◆ Household gas pipeline

Conclusion

With the increasing global emphasis on environmental protection and energy security, the application of methane remote sensing monitoring technology in the oil and gas industry has become particularly important. This technology not only effectively improves the accuracy and efficiency of leak detection, but also helps companies realize more environmentally friendly and safer production operations. Looking ahead, with the further development of the technology, the application scope and effectiveness of methane remote sensing monitors are expected to be further enhanced.With this high-tech monitoring, we can better protect our environment and leave a cleaner, safer planet for future generations.

If you have any ideas or questions, please contact us by clicking the button below!