Guess what? The future of SO2 detection has landed, and it’s all thanks to the cool UV-DOAS SO2 Gas sensor. Talk about an upgrade in environmental monitoring tech! These little geniuses use some serious spectral analysis to spot SO2 levels with amazing precision.

This isn’t just a step forward; it’s a massive leap for gas detection. Whether it’s keeping industrial sites safe or safeguarding our environment, these UV-DOAS sensors are key players. They give us the lowdown on SO2 levels in real-time, so we can jump into action fast. We’re talking about a whole new chapter in gas detection here.

Understanding UV-DOAS Gas Sensors!

· Principles of UV-DOAS technology

Light Absorption

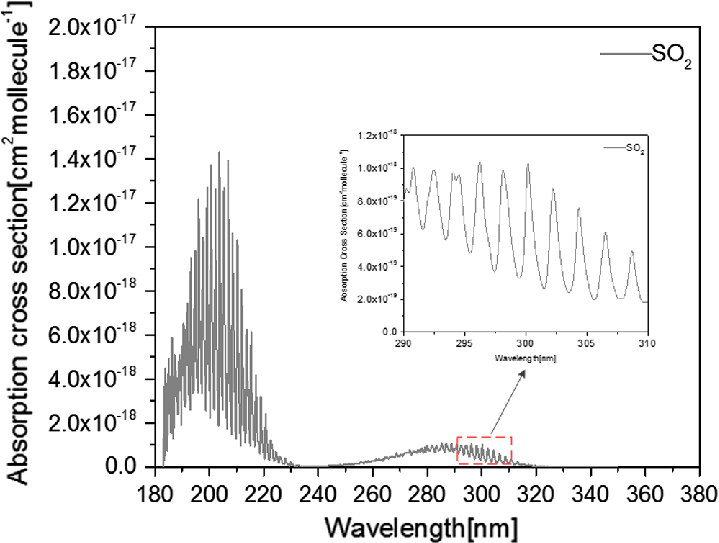

UV-DOAS gas sensors function by measuring how SO2 absorbs UV light. This absorption varies with SO2 concentration, aiding accurate detection. Each light wavelength corresponds to a specific gas absorption level. SO2 uniquely absorbs UV, making detection precise. Sensors identify gases by comparing light before and after passage.

Optical Depth

Optical depth relates to how far UV light penetrates the gas. Deeper penetration indicates lower gas concentrations. SO2’s presence alters the light’s path length. Sensor calibration is vital for interpreting optical depth accurately. A balance between depth and clarity ensures effective measurement.

Integration Time

Integration time is crucial for UV-DOAS sensors. It’s the duration for measuring light absorption. Shorter times yield rapid readings but may reduce accuracy. Longer times enhance detection sensitivity, important for low concentrations. Optimal integration time balances speed and precision.

Absorption Coefficient

The absorption coefficient quantifies how well SO2 absorbs UV. Higher coefficients indicate stronger absorption. It varies with gas composition and concentration. This coefficient is key to determining SO2 levels. Calibrating sensors for specific coefficients enhances accuracy.

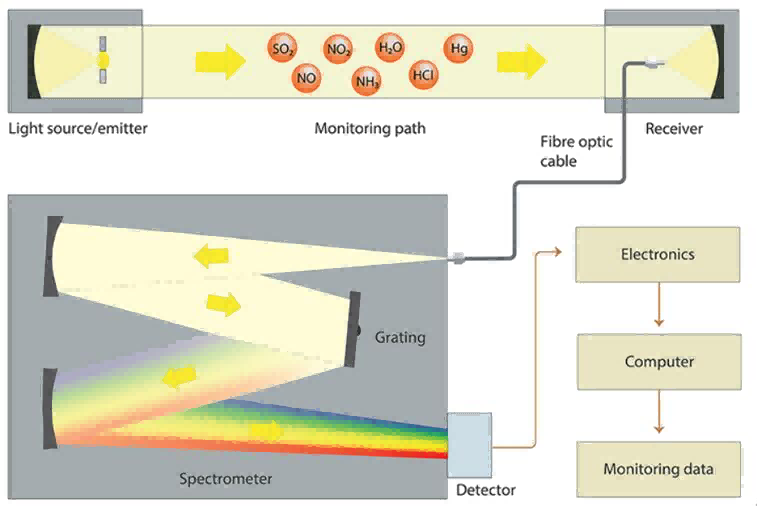

· Components and Functioning of UV-DOAS Gas Sensors

UV Source

Picture this: The UV source is like the opening act of our gas detection concert. It’s all about shining the right light to kickstart the process. Think of it as the unsung hero that needs to stay consistent, because, without it, our whole system could be off tune. And you know, its lifespan really matters for keeping our sensor show going strong.

Sample Cell

Now, the sample cell is where the magic happens. It’s like a tiny stage where SO2 and UV light have their meet-cute. The design of this little chamber is a big deal – it’s what makes our measurements sharp and on point. And just like any star performer, it needs regular TLC to keep shining.

Detector

Here’s where the detector steps in. It’s kind of like a talent scout, picking up what happens after the gas and light have their moment. It’s all about turning those light vibes into numbers we can use. Calibration is key here – it’s like fine-tuning a guitar, making sure we’re always hitting the right notes.

Spectrometer

The spectrometer is it’s our gas analyzer. It breaks down the light into a rainbow of data, picking out each color’s story. This part is super important for spotting the unique signatures of different gases. Think of it as our gas detective, always on the case, and it needs to stay sharp – regular check-ups are a must.

Optical Components

Optical components are the backstage crew. They’re the mirrors and lenses that make sure the light hits its mark. Just like any good tech team, their work is all about precision. If they’re not lined up just right, the whole show can be thrown off.

Data System

Now, our data system is the brain of the operation. It takes all those light signals and turns them into something we can actually understand. The smarter is the software the more clearly our picture of the gas scene. It’s like having a top-notch translator on hand. And yeah, keeping it up to date is super important.

Fiber Optics

Last but not least, fiber optics. These guys are the roadies, carrying the light from point A to B. They give us the flexibility to design our sensor just right. High-quality fibers mean less light gets lost along the way. Keeping them in check is like making sure our cables aren’t frayed – it keeps the music playing without a hitch.

Advantages of UV-DOAS Gas Sensors Over Traditional Methods!

· Enhanced Sensitivity for Precise Monitoring

UV-DOAS sensors, they’re a game-changer. Unlike old-school methods, they catch even the tiniest SO2 levels. This is super crucial for nailing accurate environmental checks.

Think about it – in areas where gas is barely there, these sensors are like detectives finding clues. They’re also about keeping things safe in industrial zones, spotting risks before they blow up into real problems.

· Top-notch Selectivity for Accurate Detection

The selectivity? It’s a big win for UV-DOAS sensors. They’re like experts, telling SO2 apart from other gases without breaking a sweat. This means way fewer false alarms, a headache with older sensors.

More reliable readings, that’s what you get. Super important in places juggling different gas types. These sensors cut through the chaos, pinpointing SO2 when it matters most. They rock in both industrial settings and in keeping an eye on the environment.

· Built to Last

Now, let’s talk lifespan. UV-DOAS sensors are tough cookies. Fewer moving parts mean they wear out less. That equals staying in the game longer. Less replacing parts saves cash over time.

They’re built sturdy, perfect for rough spots. These sensors keep doing their thing, rain or shine, for ages. And less downtime for fixing stuff? That’s always good news.

· Speedy Response for Quick Action

Response time is Lightning-fast. UV-DOAS sensors give you the lowdown in real-time. When things go south, that quick info can be a lifesaver. In industries where gas levels can flip in a heartbeat, this speed is key. It means being able to jump on problems fast. For keeping things safe and smooth, these sensors are clutch.

· Low Maintenance, High Performance

Talk about low maintenance. UV-DOAS sensors are pretty much set-and-forget. Their straightforward design means less fussing over them. This is a big plus, especially in spots that are tough to get to. Fewer check-ups save time and effort. They just keep rolling, reliable and steady, no matter where they are.

· Cost-Effective for the Long Haul

And the cost need think big picture. Sure, there’s an upfront spend, but these sensors save you money down the road. Their tough-as-nails build and chill maintenance needs mean fewer expenses over time. For keeping an eye on gases non-stop, they’re a smart wallet-friendly pick. They’re not just about saving bucks at the start, but also about cutting costs as you go.

Industrial Applications of UV-DOAS Gas Sensors!

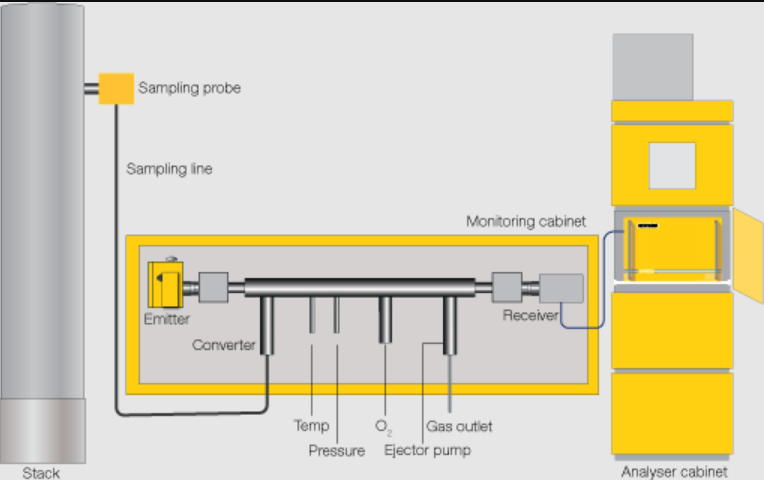

· Emission Monitoring

In emission monitoring, UV-DOAS sensors are indispensable. Factories use them to track SO2 emissions gas analyzer. Compliance with environmental regulations is ensured. They monitor exhaust gases continuously.

Accurate SO2 measurement helps in reducing pollution. Industries rely on these sensors for environmental stewardship. Effective monitoring leads to cleaner production methods. They play a key role in sustainable industrial practices.

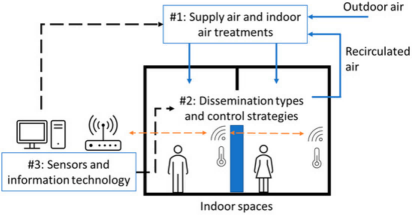

· Air Quality

Air quality control assessment heavily relies on UV-DOAS technology. Urban areas benefit from its precise SO2 detection. It helps in assessing pollution levels accurately. Public health initiatives use these readings.

Air quality management becomes more effective. Cities use these sensors for environmental health monitoring. They provide data for creating cleaner urban environments. Their role is crucial in managing urban air quality.

· Process Control

Process control in industries uses UV-DOAS sensors. They ensure safe levels of SO2 in production. Operational efficiency is improved with accurate gas monitoring.

These sensors are vital in chemical processes. They prevent hazardous concentrations from forming. Safety in manufacturing environments is enhanced. Operational continuity is maintained through constant monitoring. They are essential in maintaining industrial safety standards.

· Environmental Safety

Environmental safety is bolstered by UV-DOAS sensors. They detect harmful SO2 levels in natural habitats. Wildlife protection efforts benefit from this monitoring.

Pollution impact on ecosystems is assessed. Conservation strategies are informed by accurate data. These sensors aid in protecting biodiversity. Environmentalists rely on them for ecological research. They play a pivotal role in environmental conservation efforts.

· Industrial Compliance

UV-DOAS sensors are key in ensuring industrial compliance. Regulations regarding SO2 emissions are strictly monitored. Industries use these sensors to adhere to legal standards.

Compliance with environmental laws is simplified. They provide documentation needed for regulatory reporting. Industries avoid penalties by using these sensors. They ensure responsible industrial practices. Their usage is fundamental in maintaining legal compliance.

· Gas Analysis

Gas analysis in laboratories utilizes UV-DOAS sensors. They provide precise measurements of SO2 in samples. Research and development benefit from this accuracy.

Chemical analysis becomes more reliable. These sensors are used in scientific studies. They contribute to advancements in environmental science. Their precision aids in developing new technologies. They are indispensable tools in analytical chemistry.

Implementation of UV-DOAS in Air Quality Management!

· Smog Monitoring

UV-DOAS sensors are vital in smog monitoring. Cities use them to track SO2 levels during smog events. Reliable detection helps in issuing health advisories. Accurate data guides public safety measures. Smog reduction strategies rely on these sensors.

They provide insights into pollution sources. Continuous monitoring helps in understanding smog patterns. These sensors are essential for urban environmental health.

· Emission Tracking

UV-DOAS sensors excel in emission tracking. Industries use them to monitor SO2 discharge. It helps in adhering to environmental standards. Accurate emission data supports sustainability efforts. Factories depend on these sensors for environmental responsibility.

They ensure emissions stay within safe limits. Continuous tracking aids in minimizing ecological impact. These sensors are key in responsible industrial operations.

· Health Safety

Public health safety benefits from UV-DOAS sensors. They monitor air quality to protect community health. Precise SO2 detection informs health risk assessments.

Communities rely on this data for safety planning. These sensors support initiatives to reduce respiratory risks. They are crucial in managing public health crises. Accurate SO2 monitoring helps in safeguarding public well-being.

· Regulatory Compliance

Regulatory compliance is ensured by UV-DOAS sensors. They provide accurate SO2 measurements for legal adherence. Industries use them to meet environmental regulations.

Compliance with air quality standards is simplified. Authorities use this data for enforcement. These sensors aid in upholding environmental laws. Their role in regulatory adherence is indispensable.

· Pollution Prevention

Pollution prevention strategies incorporate UV-DOAS sensors. They detect rising SO2 levels early. Preventive actions are based on accurate data. Environmental agencies rely on these sensors. They inform policies to reduce pollution. Continuous SO2 monitoring supports proactive measures. These sensors play a critical role in environmental protection.

· Data Accuracy

Data accuracy is a hallmark of UV-DOAS sensors. They provide precise SO2 measurements. Reliable data is essential for informed decisions. Accurate readings support various air quality initiatives. Researchers depend on this data for studies. Accurate SO2 monitoring underpins effective environmental policies. These sensors are fundamental in air quality management.

Technical Aspects of UV-DOAS Gas Sensors!

· Measurement Accuracy

UV-DOAS sensors excel in measurement accuracy. SO2 levels are detected with high precision. Calibration ensures consistent performance. Accurate readings are crucial for reliable data.

These sensors minimize errors in gas measurement. Industries and researchers depend on their precision. Accurate detection is vital in air quality management. They provide trustworthy data for environmental analysis.

· Linearity Error

Linearity error in UV-DOAS sensors is minimal. This ensures accurate readings across different concentrations. Consistent performance is maintained over various ranges.

Calibration minimizes any potential linearity deviations. They deliver reliable data even at varying gas levels. Accuracy is not compromised over diverse measurement ranges. These sensors are trusted for their consistent linearity.

· Response Time

The response time of UV-DOAS sensors is remarkably swift. They detect changes in SO2 levels quickly. Timely data is essential for prompt action. Rapid response aids in emergency situations.

These sensors adapt quickly to environmental changes. Fast detection is key in dynamic scenarios. They are crucial for real-time monitoring.

· Stability

Stability is a key feature of UV-DOAS sensors. They maintain consistent performance over time. Long-term reliability is assured through robust design. Stable readings are essential for continuous monitoring. These sensors resist environmental fluctuations. Consistent performance underpins their reliability. They are valued for their enduring accuracy.

· Zero Drift

Zero drift in UV-DOAS sensors is remarkably low. This ensures long-term accuracy without recalibration. Consistent readings are maintained over time. They provide reliable data without frequent adjustments. Low zero drift is crucial for dependable measurements. These sensors are trusted for their sustained precision.

· Span Drift

Span drift in UV-DOAS sensors is effectively managed. This maintains accuracy over different measurement ranges. Regular calibration counters any potential drift.

They ensure consistent accuracy across all ranges. Reliable performance is sustained over various concentrations. These sensors are renowned for their dependable span stability.

| Technical Aspect | Measurement Accuracy | Linearity Error | Response Time | Stability | Zero Drift | Span Drift |

| Gas Concentration | High Accuracy | ≤ ±2%FS | < 25s | High | ≤ ±2%FS | ≤ ±2%FS |

| Optical Depth | Accurate Detection | Low Error | Fast | Consistent Performance | Minimal | Minimal |

| Integration Time | Optimal Accuracy | N/A | Varies (Longer for Better Accuracy) | Stable Over Time | N/A | N/A |

| Absorption Coefficient | Precise Measurement | N/A | N/A | Reliable | N/A | N/A |

| Optical Density | High Measurement Accuracy | N/A | N/A | Stable | N/A | N/A |

| Light Intensity | Accurately Measured | N/A | Quick Response | High Reliability | Low | Low |

| Gas Path Length | N/A | N/A | N/A | N/A | N/A | N/A |

Spectrum Analysis Process in UV-DOAS Gas Sensors!

· Spectrum Acquisition

In UV-DOAS SO2 gas sensors, light absorption is key. Specific wavelengths are critical for accurate detection. Ultraviolet light interacts with sulfur dioxide uniquely.

Capturing this interaction is essential for precise readings. The sensor’s optical components play a crucial role. Each component must function optimally for reliable data. Calibration ensures the sensor’s accuracy over time. Regular maintenance is vital for consistent performance.

· Baseline Correction

Baseline correction is a pivotal step. It removes background noise from the signal. Ensuring clarity in the data is crucial. Even minor impurities can affect readings. The goal is to isolate the SO2 signal.

Advanced algorithms refine the data further. Precision in this process is paramount. Consistency in baseline correction ensures reliable results. It’s a delicate balance of technology and expertise.

· Spectral Decomposition

Spectral decomposition separates the different components. It’s like untangling a complex web. Each element of the spectrum is analyzed. The focus is on identifying sulfur dioxide peaks.

Accuracy in decomposition defines the sensor’s effectiveness. Advanced software aids in this intricate process. It’s a blend of science and technological artistry. Mastery of spectral decomposition is essential for accuracy.

· Reference Selection

Choosing the right reference is critical. It sets the standard for comparison. Precision in reference selection is non-negotiable. It ensures that the readings are grounded in reality.

The reference must represent typical SO2 characteristics. It’s a guidepost for the entire analysis. Accuracy in reference selection directly impacts the results. It’s the foundation upon which reliability is built.

· Least Squares Fit

Least squares fit are a mathematical approach. It fine-tunes the data analysis. The goal is to minimize errors in the readings. It’s a balance of precision and practicality.

This technique sharpens the final output. Ensuring that the data aligns is closely with real values. It’s a critical step in data verification. The integrity of the sensor’s output hinges on this process.

· Peak Identification

Identifying peaks is the final challenge. It’s where the data speaks. Distinct peaks indicate sulfur dioxide presence. Clarity in peak identification is crucial.

It’s the culmination of all previous steps. The sensor’s effectiveness is judged here. Accurate peak identification confirms the sensor’s reliability. It’s where science meets the real world in a tangible way.

Our model ESE-UV-500 model can measure SO2 based on DOAS and PLS, can measure the concentration of gases including SO2,NO2, NO,NH3,CL2,O3,H2S etc,It has features of high measurement accuracy, outstanding,reliability, fast response time and wide applicable scope

Applications :

☑ Flue gas continuous emission monitoring ( CEMS ) for the power plants

☑ DeSOx process monitoring (analyze SO2 and O2)

☑ Waste incineration flue gas continuous emission monitoring (analyze SO2, NO, NO2 and O2)

☑ Sulfur recovery process gas analysis (analyze SO2 and H2S)

☑ On-line air monitoring (analyze SO2,NO2 and O3)

SO2 gas analyzer is essential tools for environmental monitoring, emissions control, and occupational safety. They are used in various industries, including power plants, refineries, chemical manufacturing, and air quality monitoring stations. By providing accurate and real-time measurements of SO2 concentrations, these analyzers help ensure regulatory compliance, assess pollution levels, and enable the implementation of effective control measures to reduce sulfur dioxide emissions.

Want to know more about the parameters? Click here

Conclusion

So, UV-DOAS SO2 Gas sensors they’re leading the charge in the detection revolution. Their knack for pinpointing sulfur dioxide levels is top-notch. These sensors are big deals in industrial safety and protecting our environment. They dish out spot-on, real-time data, letting us tackle SO2 issues head-on.

This tech isn’t just cool; it’s a total game-changer. Looking for the best in SO2 detection? Swing by ESEGAS Dive into this tech wonder and join the gas detection revolution.