In chemical production, the use and storage of hazardous chemicals always involve certain risks. During the production process, the release of hazardous gases may have a serious impact on personnel safety and environmental protection. To detect and prevent these potential threats promptly, the industry has resorted to advanced technologies and equipment, such as industrial gas analyzers, to achieve rapid detection and early warning of harmful gases during the production of hazardous chemicals.

Potential Risks in the Production of Hazardous Chemicals

A variety of hazardous chemicals, including ammonia, hydrogen sulfide, and chlorine, are commonly used in chemical plants, refineries, power stations, and other industrial facilities. These chemicals may release toxic and hazardous gases during processing, transportation, storage and use. These hazardous gases may cause serious harm to workers, surrounding residents, and the environment, such as asphyxiation, poisoning, and even explosions. There are a variety of potential hazards and risks during the production of chemicals, including the following:

Toxic gas release: In chemical production, many chemicals are toxic, such as ammonia, chlorine and hydrogen sulfide. These chemicals may leak into the environment in case of improper operation or accidents, posing a poisoning or even fatal danger to human beings.

- Fires and explosions: Some chemicals are flammable or explosive, such as ethanol and formaldehyde. During the production process, if not properly controlled, they may cause fires or explosions due to sparks, static electricity or other ignition sources.

- Corrosive substances: Many chemicals are corrosive, such as acids and alkalis. When these substances are spilled or come into contact with the skin, eyes, etc., they may cause burns or corrosive damage.

- Asphyxiation and oxygen deficiency: Some gases are asphyxiating, such as nitrogen and carbon dioxide. Leakage of these gases above safe concentrations in a confined space may result in insufficient oxygen in the air, causing asphyxiation or even death.

- Environmental pollution: Leaks and emissions during the production of chemicals may contaminate soil, water and air, causing serious impacts on the surrounding environment and ecosystems, and even leading to ecological disasters.

These potential risks need to be fully emphasized and controlled in the chemical production process. Through the use of advanced equipment such as industrial gas analyzers, it is possible to monitor the concentration of harmful gases in a timely manner and warn of potentially dangerous situations, so that effective measures can be taken to safeguard the safety of the production process and the health of the environment.

The Role of Industrial Gas Analyzers

An industrial gas analyzer is a device used to detect and analyze the composition of gases. It quickly and accurately detects the concentration of harmful gases in the air and provides real-time data and alerts to help plant managers take quick action to protect workers and the environment. Industrial gas analyzers play a vital role in the chemical production process and their functions and roles include the following:

- Gas Composition Detection: Industrial gas analyzers are capable of accurately detecting various gas compositions in the air, including but not limited to hazardous gases, combustible gases, and inert gases. With different sensors and detectors, the concentration of multiple gases can be monitored simultaneously.

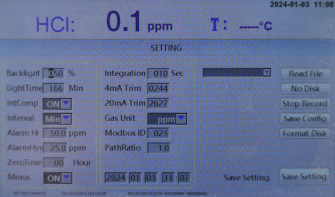

- Real-time monitoring: Industrial gas analyzers are capable of monitoring gas concentrations in real-time and reflecting them instantly on the monitoring interface. This real-time monitoring capability allows plant managers to keep abreast of the gas situation at the production site and detect abnormalities in a timely manner.

- Data logging and analysis: Industrial gas analyzers are capable of logging gas concentration data and storing it in the equipment or central control system. By analyzing this data, trends in harmful gas concentrations can be understood and potential safety risks can be predicted.

- Early Warning System: Industrial gas analyzers are equipped with an early warning system that sounds an alarm once the concentration of a hazardous gas is monitored above a set safety threshold. This timely warning enables plant managers to take prompt action to avoid accidents.

- Guidance on safety measures: Industrial gas analyzers not only provide data on the concentration of harmful gases, but also advise and guide plant managers on safety measures based on preset safety standards. This helps managers to respond quickly and accurately to different situations.

- Automation and Remote Monitoring: Some industrial gas analyzers have automation and remote monitoring capabilities that allow for the automatic operation of the equipment and remote data access. By connecting to the Internet, managers can monitor gas conditions in various areas of the plant from anywhere, anytime, and respond to potential safety threats promptly.

In summary, industrial gas analyzers play a vital role in the chemical production process. Through real-time monitoring, data analysis and early warning systems, they can help factory managers identify and respond to potential threats of harmful gases in a timely manner, safeguarding the safety of workers and the environment.

Real-time Monitoring and Data Analysis

Real-time monitoring and data analysis are one of the core functions of industrial gas analyzers. Through the industrial gas analyzer, factory managers can understand the concentration of various harmful gases in the air at the production site in real time, and analyze the data in depth, to find out the abnormal situation in time and take necessary measures to ensure production safety.

First of all, industrial gas analyzers are equipped with a variety of sensors and detectors that are capable of monitoring the concentration of multiple hazardous gases simultaneously. These sensors are able to continuously collect gas samples during real-time operation and transmit the data to a centralized control system. Through a connected monitoring interface, plant managers can access this data anytime, anywhere to understand the current air quality situation.

Secondly, industrial gas analyzers are able to analyze the collected data in depth. Managers can view historical data to understand trends in harmful gas concentrations and compare data from different time periods to detect anomalies. For example, if there is a sudden increase in the concentration of a certain hazardous gas, it may mean that there is a leak or other safety hazard present. By analyzing the data for trends, managers can detect these anomalies in time and take appropriate measures to deal with them.

In addition, industrial gas analyzers allow for real-time evaluation of data through preset safety criteria. Once the monitoring of harmful gas concentration exceeds the safety threshold, the analyzer will issue an alarm to remind the management to take action. This early warning feature helps managers respond to emergencies in a timely manner and avoid accidents.

In summary, real-time monitoring and data analysis is an important function of industrial gas analyzers. By monitoring the concentration of harmful gases in the air and analyzing the data in-depth, it can help factory managers find abnormalities in time and warn of potential safety risks, so as to guarantee the safety and stability of the production process.

Early Warning Systems and Security Measures

Early warning systems and safety measures are one of the key features of industrial gas analyzers that help plant managers respond to potential safety risks in a timely manner, keeping workers and the environment safe. The following is a detailed description of the Early Warning System and Safety Measures:

Early warning systems:

Industrial gas analyzers are equipped with an early warning system that sounds an alarm once the concentration of a hazardous gas is monitored above a set safety threshold. This warning is usually given by sound, light or vibration to ensure that the warning signal is received and noticed by management.

The early warning system has a high degree of sensitivity and accuracy, and is able to issue an immediate alarm when the concentration of harmful gases exceeds the safety threshold, enabling managers to take timely measures to avoid accidents.

The early warning system can also issue different alarms according to different levels of danger to help managers judge the seriousness of the situation and take appropriate emergency measures.

Guidance on safety measures:

As soon as an industrial gas analyzer sounds an alarm, plant managers need to take immediate safety measures. Depending on the alarm signal and the specific situation, managers can take different measures to respond to the hazardous situation according to predefined safety procedures and contingency plans.

Industrial gas analyzers are often equipped with a safety measures guidance function that can provide appropriate safety recommendations and guidance to managers based on real-time monitored hazardous gas concentration data. For example, if harmful gas concentrations are detected above safety thresholds, the analyzer may recommend evacuating workers, shutting down relevant equipment, initiating emergency procedures, etc.

The Safety Measures Guidance function helps managers respond quickly and accurately to different situations, effectively reducing the risk of accidents and maximizing the safety of workers and the environment.

Through the early warning system and safety measures guidance function, the industrial gas analyzer can help factory managers to detect and respond to potential safety risks in a timely manner, to ensure the safety and stability of the production process. Managers only need to follow the alarm signals and safety recommendations provided by the analyzer, and quickly take measures to effectively respond to emergencies, avoid accidents, and safeguard the safety of workers and the environment.

Automation and Remote Monitoring

Automation and remote monitoring is one of the advanced features of industrial gas analyzers that allows plant managers to automate and remotely monitor production sites. The following is a detailed description of the automation and remote monitoring features:

Automated functions:

Some advanced industrial gas analyzers have automation features that enable automatic operation and control of the equipment. With preset parameters and programs, the analyzer can automatically perform gas sample collection, analysis and data logging without human intervention.

Automation features allow industrial gas analyzers to continuously monitor airborne concentrations of hazardous gases and transmit data in real time to a central control system in 24/7 operation.

Remote monitoring function:

Industrial gas analyzers have a remote monitoring function that enables remote monitoring of the production site through a network connection. Managers can access the monitoring data and operator interface of the industrial gas analyzers from anywhere, anytime by connecting to the plant’s central control system via the Internet.

The remote monitoring function allows managers to realize real-time monitoring and management of the production site without having to be on duty. No matter where they are, as long as there is a network connection, managers can always understand the gas situation in each area of the plant, and take timely action to detect abnormalities.

Remote operation and control:

In addition to monitoring capabilities, industrial gas analyzers have the ability to be operated and controlled remotely. Through a remote connection, managers can remotely adjust the analyzer’s operating mode, set parameters, start or stop the analysis process, and more.

Remote operation and control functions enable managers to respond quickly to changing production needs and emergencies, and realize remote control and management of the production process.

Through automation and remote monitoring functions, the industrial gas analyzer realizes intelligent management and remote control of the production process. Management personnel do not need to stay at the production site for a long time, but can monitor the gas situation anytime and anywhere, detect abnormalities and take measures in a timely manner, which improves production safety and efficiency and reduces labor costs.

Case Study: Application of Industrial Gas Analyzers

As an example, a chemical plant uses a large amount of ammonia as a raw material in its production process. In order to ensure the safety of the production process, they have installed several industrial gas analyzers, which are located at key locations in the production plant. One day, due to a pipeline leak, the ammonia concentration began to rise above the safety threshold. The industrial gas analyzers immediately raised an alarm, and the plant management quickly took emergency measures to evacuate the workers and shut down the relevant equipment, preventing a more serious accident from occurring.

Conclusion

As an advanced safety monitoring equipment, industrial gas analyzer plays an important role in chemical production process. Through real-time monitoring, data analysis and early warning systems, it can help plant managers identify and respond to potential threats of harmful gases in a timely manner, safeguarding the safety of workers and the environment. With the continuous development of technology, industrial gas analyzers will continue to play an even more important role in providing a more reliable guarantee for industrial safety and environmental protection.more information pls visit :Shop – Gas Analyzer Manufacturers (esegas.com)