Tackling the Challenges of Syngas Analyzer Monitoring in Complex Industrial Environments

Syngas (synthetic gas) production is fundamental in industries like steel manufacturing, waste gasification, and fuel cell development. However, accurately analyzing its fluctuating composition—rich in CO, CO₂, CH₄, H₂, and O₂—remains a persistent challenge. When these components aren’t measured with precision, the result is decreased operational efficiency, higher emissions, and elevated safety risks.

ESEGAS’s Syngas Analyzer is a high-performance solution for simultaneous, real-time monitoring of CO, CO₂, CH₄, H₂, and O₂ in syngas streams. It supports process optimization, energy efficiency, and emission control with unmatched precision.

From Problem to Precision: Why Keep Syngas Analyzer Heading?

If you’re already convinced ESEGAS delivers precision, you’ll want to know how it achieves this, what industries benefit most, and the specific technical specifications that set this analyzer apart. The following sections break down the exact advantages and real-world value.

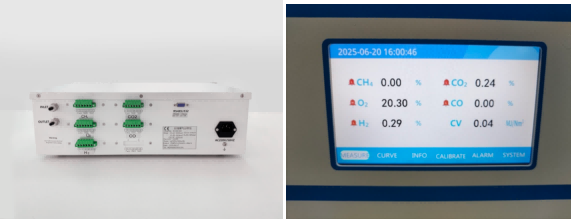

What Are the Key Technical Specifications of ESEGAS’s Syngas Analyzer?

Accurate gas analysis isn’t optional—it’s essential. ESEGAS ensures you never have to compromise.

- CO, CO₂, CH₄ Measurement:

- Range: 0–100% (customizable)

- Resolution: 0.001% (LR)

- Accuracy: ±2% of full scale

- Method: Non-dispersive infrared (NDIR)

- H₂ Measurement:

- Method: Thermal Conductivity Detector (TCD)

- Range: 0–100%

- Accuracy: ±2%

- O₂ Measurement:

- Method: Electrochemical or Paramagnetic

- Range: 0–25%

- Accuracy: ±2%

- Additional Features:

- Real-time output via Modbus, 4–20 mA, RS485

- Integrated temperature and pressure compensation

- Durable, corrosion-resistant housing

These analyzers are designed for multi-gas analysis in challenging syngas environments, delivering reliable performance across wide temperature and humidity ranges.

Which Industries and Applications Benefit from Syngas Analyzer?

Every industry using syngas faces unique challenges—ESEGAS’s analyzer is engineered to adapt.

From high-temperature blast furnaces to complex gasification reactors, syngas composition must be continuously monitored and controlled. ESEGAS’s Syngas Analyzer offers real-time multi-gas analysis that enhances precision, improves safety, and ensures regulatory compliance across a wide array of industrial applications.

1. Steel Manufacturing and Metallurgy

In blast furnaces, syngas—rich in CO and H₂—is a crucial energy source. Monitoring this gas in real time ensures consistent fuel quality and efficient combustion.

- Use Case: Continuous CO/CO₂/H₂ analysis for hot blast stoves and reheating furnaces

- Benefits:

- Improved fuel-to-air ratio control

- Reduced energy consumption

- Enhanced safety by detecting oxygen ingress or gas imbalances

2. Coal and Biomass Gasification

Gasification converts carbonaceous materials into syngas through partial oxidation. Gas composition directly affects downstream processes like power generation and syngas-to-liquid conversion.

- Use Case: Tracking CO, CH₄, H₂ levels during synthesis gas production

- Benefits:

- Enables process optimization by fine-tuning gasifier parameters

- Maximizes thermal efficiency and syngas yield

- Real-time alerts for operational anomalies

3. Waste-to-Energy and Incineration Plants

These facilities depend on stable combustion of complex waste streams. Variations in gas composition can pose risks or reduce energy recovery efficiency.

- Use Case: Monitoring CH₄, CO₂, and O₂ during waste combustion

- Benefits:

- Ensures real-time monitoring of critical safety parameters

- Supports emission reduction and regulatory compliance

- Helps maintain optimal burner performance

4. Fuel Cell Manufacturing

For solid oxide or proton exchange membrane fuel cells, precise syngas control—particularly the H₂ content—is essential for performance and longevity.

- Use Case: Measuring H₂ purity and CO contamination in reformate gas

- Benefits:

- Maintains optimal H₂/CO ratios

- Protects fuel cell membranes from degradation

- Supports high-efficiency energy conversion

5. Biogas and Anaerobic Digestion Plants

In biogas upgrading systems, monitoring CH₄, CO₂, and trace H₂ improves process control and output gas quality.

- Use Case: Supervising gas output from digesters and scrubbers

- Benefits:

- Enhances methane yield

- Enables selective removal of CO₂ and other impurities

- Integrates with automation systems for smart control

6. Petrochemical and Refining Operations

Steam reforming, catalytic cracking, and other refining processes produce and use syngas streams. Reliable analyzers help maintain product consistency.

- Use Case: Inline CO/H₂/CH₄/O₂ tracking in reforming units

- Benefits:

- Facilitates multi-gas analysis with high accuracy

- Improves catalyst performance and process efficiency

- Enables predictive maintenance based on gas trends

Whether you’re optimizing a coal gasifier or recovering energy from wastewater, ESEGAS’s analyzer supports precise, real-time monitoring that improves decision-making. Application areas include:

| Industry | Application Example | Benefit |

| Steel Production | Blast furnace gas monitoring | Improved fuel control & safety |

| Coal Gasification | Syngas composition optimization | Enhanced thermal efficiency |

| Fuel Cell Manufacturing | Hydrogen content monitoring | Maximized H₂/CO ratio |

| Waste-to-Energy Plants | Combustion gas analysis | Emission compliance & process safety |

| Biogas Plants | CH₄/CO₂/H₂ balancing | Efficient gas upgrading |

How Does ESEGAS Syngas Analyzer Add Value in Efficiency, Safety, and Compliance?

In modern industries, it’s not just about data—it’s about what that data enables.

By leveraging multi-gas real-time monitoring, ESEGAS allows operators to:

- Optimize combustion and gasification by fine-tuning fuel-to-air ratios.

- Ensure regulatory compliance with emissions standards.

- Protect catalysts and sensitive equipment from composition imbalances.

- Increase energy recovery from waste streams.

- Enable process automation with real-time outputs.

Ultimately, this supports process optimization, lowers operational costs, and strengthens environmental compliance.

Conclusion: Choose Precision, Choose ESEGAS

ESEGAS’s Syngas Analyzer isn’t just a measurement tool—it’s a strategic asset. With advanced technologies like NDIR, TCD, and paramagnetic sensors, plus integrated digital communications and robust build quality, it addresses today’s industrial syngas challenges head-on.