(ESEGAS Explosion-proof Zirconia Oxygen Analyzer ESE-Z-100)

Understanding explosion-proof standards for industrial gas analyzers is not optional. It is essential for safety, operational compliance, and risk control in hazardous environments. In facilities where flammable gases or vapors may be present, even a tiny spark can trigger a disaster. Explosion-proof standards ensure that gas analyzers are engineered and tested to avoid ignition sources in these dangerous areas. This protects personnel, equipment, and plant infrastructure from fires and explosions.

This guide answers key questions about explosion-proof standards for industrial gas analyzers. You will learn what explosion-proof standards are and why they matter. You will also find out which global standards apply to gas analyzers, how to read certification markings, and how to pick the right analyzer based on hazardous area classification.

In doing so, you will gain practical insight into hazardous area certification and gas analyzer safety. These insights help you manage compliance more effectively and choose equipment that fits both your technical needs and safety requirements.

What Is Hazardous Area Classification?

Global Classification Systems

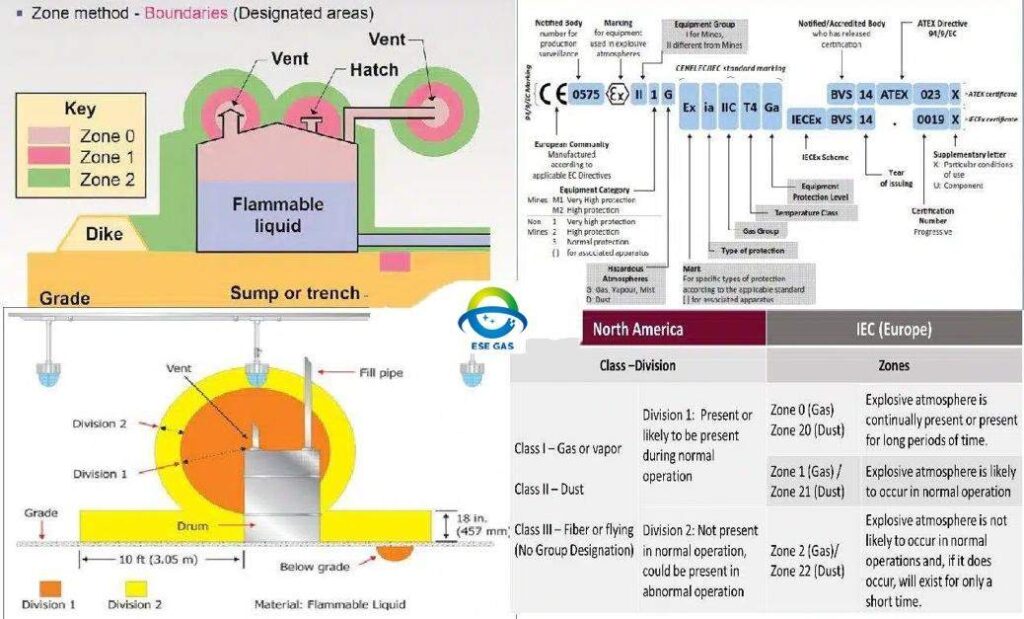

Hazardous area classification tells engineers and safety teams where explosive atmospheres may exist. In the IEC/ATEX zone system, areas with flammable gases or vapors are labeled Zone 0, Zone 1, or Zone 2. Zones 20, 21, and 22 apply to areas with combustible dust. These labels reflect how often an explosive atmosphere is likely to occur and how long it persists. Zone 0 means a continuous hazard; Zones 1 and 2 indicate decreasing likelihood and duration of explosive conditions.

In contrast, North America uses the Class/Division system defined by the NEC (National Electrical Code). Here, Class I, Division 1 means flammable gas or vapor is present in normal operation. Division 2 means hazardous substances are unlikely during typical operation. Both systems serve the same purpose: to guide safe equipment selection.

Transitioning between systems is common. For example, Zone 0 generally correlates with Class I, Division 1 for gas environments. This alignment helps multinational teams plan compliance and equipment requirements across regions.

How Classification Dictates Certification Requirements

Once you know the classification, you know the minimum explosion-proof standards your industrial gas analyzers must meet. Higher-risk zones require stricter protection. For Zone 0, where explosive atmospheres exist continuously or for long periods, equipment must have the highest protection level (e.g., intrinsically safe or flameproof designs). This ensures that the analyzer won’t create an ignition source in the most dangerous environments.

In less severe areas like Zone 2, explosive atmospheres are unlikely under normal conditions. In these areas, analyzers can use protection methods suitable for rare hazards while still meeting safety standards.

An important rule in hazardous area certification is this: equipment certified for a higher-risk zone can safely be used in a lower-risk zone, but not vice versa. That means a Zone 0-rated gas analyzer can operate in a Zone 1 or Zone 2 area. This flexibility streamlines procurement and ensures compliance across multiple facility zones.

Understanding these classifications helps you match the right explosion-proof standards with your facility’s risk profile, ensuring reliable gas analyzer safety and compliance.

What Are the Key International Explosion-Proof Standards for Industrial Gas Analyzers?

When you specify, design, or procure industrial gas analyzers for hazardous areas, you must understand the major global explosion-proof standards. These standards define how devices like analyzers are tested, certified, and marked to operate safely without causing ignition in explosive atmospheres. This section explains the most important certification systems used around the world.

1. IECEx — The Global Certification Scheme

The IECEx System is an international certification scheme that provides a unified approach to testing and approving electrical equipment for explosive atmospheres. It is based on the IEC 60079 series, which sets technical rules for explosion protection methods such as flameproof enclosures and intrinsic safety. This system supports mutual recognition of certificates across many countries, helping equipment move freely in the global market. IECEx certification gives confidence that devices meet consistent safety criteria and have undergone rigorous testing and quality audits by accredited labs.

Key parts of the IEC 60079 standards include:

- 60079-0: General requirements for Ex equipment.

- 60079-1: Flameproof enclosure (‘d’ protection).

- 60079-11: Intrinsic safety (‘i’ protection).

- 60079-7: Increased safety (‘e’ protection).

These parts cover the design, construction, and testing procedures that ensure gas analyzers won’t ignite surrounding hazardous atmospheres.

2. ATEX — European Union Directive for Hazardous Atmospheres

The ATEX Directive (2014/34/EU) is the mandatory EU regulation for equipment intended for use in explosive atmospheres such as chemical plants and refineries. ATEX ensures that explosion-proof devices meet strict requirements for design, testing, and marking under European law. Devices compliant with ATEX carry both the CE mark and the “Ex” symbol, indicating conformity with health and safety requirements.

Under ATEX, equipment is categorized and matched to hazard zones. Higher category ratings require greater protection measures. Gas analyzers installed in EU plants must meet the appropriate category for their location, ensuring both safety and legal compliance within the European market.

3. Chinese GB/T Explosive Atmospheres Standards

China has its own set of national standards for explosive atmospheres, mainly the GB/T 3836 series, which are aligned with IEC technical requirements but include localized specifications and test methods.

Under this system, explosion-proof gas analyzers must hold a valid explosion-proof certificate and meet the requirements for the specific hazardous area where they will be used. Chinese regulations prohibit using uncertified equipment in explosive environments, making compliance essential for both safety and legal operation.

In addition to GB/T standards, China now also requires CCC-Ex certification for explosion-proof products placed on the market. This new requirement ensures devices meet both national and international safety benchmarks before they are sold or installed.

4. Other Regional Standards & Certification Bodies

Beyond IECEx, ATEX, and China’s standards, many regions have their own hazardous area certification systems. These systems often reference IEC technical criteria but include local compliance steps:

- North America (USA/Canada): UL, FM, and CSA provide hazardous locations certification tied to the NEC/CEC (Class/Division and Zone systems). Equipment must meet standards such as UL 1203 for explosion-proof enclosures to operate legally in classified areas.

- Brazil: INMETRO certification is mandatory for Ex equipment in Brazilian markets.

- South Korea: KCs/KOSHA standards cover electrical equipment for hazardous locations, often harmonized with IEC criteria.

- Japan: TIIS certification aligns with IEC standards but adapts to local regulatory requirements.

- Australia/New Zealand: Recognize IECEx through ANZEx certification with national conformity checks.

- Eurasian Customs Union: EAC certification ensures hazardous area equipment meets regional safety regulations.

Each regional system supports safety and compliance within its jurisdiction while often leveraging core IEC technical standards, helping manufacturers and end users navigate global requirements.

How Do You Read Explosion-Proof Markings and Code Systems for Industrial Gas Analyzers?

When you work with explosion-proof standards for industrial gas analyzers, correctly reading the nameplate codes is vital. These markings tell you where and how the analyzer can safely operate in hazardous atmospheres. Understanding this helps engineers, safety teams, and procurement specialists avoid errors that can lead to unsafe installations or non-compliance.

Key Elements in Explosion-Proof Markings

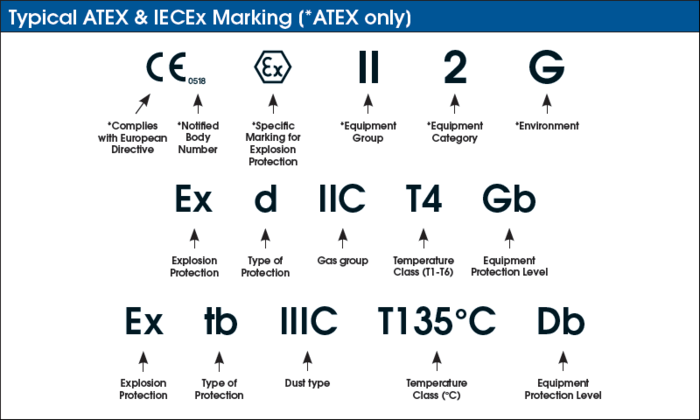

Most hazardous-area nameplates follow a structured format like “Ex d IIC T4 Gb”. Each part conveys specific safety information:

- “Ex” shows the device is certified for explosive environments.

- “Ex d” means the analyzer has a flameproof enclosure, designed to prevent internal sparks from igniting gases outside the device.

- “IIC” identifies the gas group associated with the highest ignition risk, such as hydrogen or acetylene. This tells you the analyzer meets stringent clearance and energy-limit requirements.

- “T4” is the temperature class and limits the device’s maximum surface temperature (≤ 135 °C) so it won’t ignite surrounding gas.

- “Gb” is the Equipment Protection Level (EPL) indicating a high level of protection, suitable for Zone 1 gas atmospheres.

By combining these elements, the marking explains both the type of explosion protection and the risk environment where the analyzer can be installed.

Breaking Down a Typical Nameplate Example

Let’s simplify a common marking like:

“II 2G Ex d IIC T4 Gb”

Here’s what it means in practice:

- “II” signals equipment for surface industrial use, not mining.

- “2G” shows this device is certified for Zone 1 explosive gas areas, where explosive atmospheres are likely during normal operation.

- “Ex d” means the housing is flameproof, containing any internal ignition safely.

- “IIC” indicates it’s suitable for the most demanding gas group (highest risk).

- “T4” limits surface temperature to prevent ignition below 135 °C.

- “Gb” tells you this unit has a high protection level for gas atmospheres — ideal for many industrial gas analyzer applications.

Because each segment carries clear meaning, decoding these markings ensures you select analyzers that match your site’s hazardous area classification and safety plan.

Why Markings Matter in the Field

Correct interpretation prevents mistakes like installing equipment with too low a protection level in a high-risk zone. For example, choosing a device rated for Zone 2 instead of Zone 1 can expose your facility to unplanned fires or explosions. Reading nameplates accurately ensures the gas analyzer aligns with your hazardous area certification requirements, protecting personnel and assets while meeting regulatory expectations.

Understanding these marking codes is a small step that leads to safer decision-making when buying, installing, and maintaining explosion-proof industrial gas analyzers.

How Do You Choose the Right Explosion-Proof Gas Analyzer Under Explosion-Proof Standards for Industrial Gas Analyzers?

Selecting the correct explosion-proof gas analyzer requires a clear understanding of protection techniques, hazardous area requirements, and how the analyzer fits into your safety systems. This section walks you through the decision-making process in simple, practical terms.

Protection Techniques and Technologies

First, you need to know the main explosion protection methods used in hazardous-area equipment:

- Flameproof Enclosure (Ex d): A rugged metal enclosure stops any internal ignition from spreading to the outside atmosphere. It works well for analyzers with higher power electronics or infrared (IR) sensors.

- Intrinsic Safety (Ex i): This method limits voltage and current so low that even a fault cannot ignite explosive gas. It suits low-power circuits and sensors.

- Increased Safety (Ex e): Ex e prevents arcs and hot spots through design improvements like enhanced insulation. It often complements other methods, especially for connection hardware.

- Encapsulation (Ex m): Essential components are molded in resin to block explosive atmosphere contact, ideal for small modules.

- Positive Pressure (Ex p): The analyzer enclosure is kept at a higher clean-air pressure to stop explosive gas from entering. This can protect sensitive electronics when other methods are impractical.

When choosing, think about the sensor type and power needs. For example, IR gas analyzers with complex optics and heaters often need robust flameproof housings, while low-power loop-powered analyzers can use intrinsic safety circuitry to reduce wiring and installation costs.

Selecting Based on Hazardous Area

Next, match the analyzer’s certification with your plant’s hazardous area classification (Zones or Classes). The principle is simple: the higher the zone risk, the stricter the protection requirement.

- In Zone 0 (continuous explosive atmosphere), only analyzers with intrinsic safety (Ex i) or equivalent protection can be used.

- In Zone 1, you can choose analyzers with flameproof (Ex d), intrinsic safety, or even pressurization (Ex p) depending on the instrument’s power and function.

- In Zone 2, analyzers with increased safety (Ex e) or lower-risk protection may be acceptable.

For example, a refinery CEMS (Continuous Emissions Monitoring System) often sits in Zone 1 or Zone 2 environments. You would pick analyzers with certifications that match those zones to ensure compliance and minimize risk. In contrast, petrochemical process monitoring might see more frequent gas exposure, so stronger protection types like Ex d or Ex p are often needed.

Integration with Safety Systems

Finally, you must ensure the certified gas analyzer works seamlessly with your plant safety infrastructure:

- Connect certified analyzers to the Distributed Control System (DCS) so you can monitor gas levels in real time.

- Tie analyzer outputs into Safety Shutdown Systems to trigger automated shutoffs if hazardous gas levels rise.

- Integrate with Fire & Gas (F&G) detection systems to provide layered protection.

Proper integration not only ensures compliance with explosion-proof standards but also enhances operational safety, helping engineers and operators respond faster to abnormal conditions.

Choosing the right explosion-proof gas analyzer means balancing protection technology, hazardous area rating, and system integration. By following these steps, you ensure safety and compliance while optimizing performance and lifecycle cost.

Conclusion

In hazardous industrial settings, explosion-proof standards for industrial gas analyzers are more than regulatory checkboxes—they are fundamental to protecting life, property, and plant operations. These standards ensure that gas analyzers operate safely in environments where flammable gases, vapors, or dust might ignite. Without proper certification, even a momentary spark from an analyzer could trigger a catastrophic explosion. Safety and regulatory frameworks demand explosion-proof design to minimize these risks.

If you want to explore explosion-proof industrial gas analyzers that ESEGAS can offer, contact us today! Our solutions deliver world-class performance, safety, and compliance for demanding industrial applications.

FAQs:

1. What does “explosion-proof” mean for industrial gas analyzers?

“Explosion-proof” means the gas analyzer is designed and certified to operate safely in environments where flammable gases or vapors may be present. It prevents internal sparks or heat from igniting explosive atmospheres, protecting personnel and equipment. This protection is achieved through specific engineering methods and certifications that meet recognized standards such as ATEX and IECEx.

2. What are the main explosion-proof certification systems used globally?

The main international explosion-proof standards for industrial gas analyzers include IECEx (global certification based on IEC standards) and ATEX (mandatory in the European Union under Directive 2014/34/EU). Other regional standards also exist, such as UL/FM/CSA in North America and GB/T standards in China, all aligned around ensuring safe operation in explosive environments.

3. How are hazardous areas classified for explosion-proof equipment?

Hazardous areas are classified based on how often explosive atmospheres may occur. Under IEC/ATEX: Zone 0 has continuous explosive gas presence, Zone 1 is likely during normal operations, and Zone 2 is unlikely but possible. These zones guide what protection level is required for gas analyzers installed in those areas.

4. What do explosion-proof markings like “Ex d IIC T4 Gb” mean?

These markings tell you how the analyzer is certified:

- Ex – certified for hazardous atmospheres.

- d – flameproof enclosure prevents internal sparks from igniting outside gas.

- IIC – gas group for high-risk gases like hydrogen.

- T4 – maximum surface temperature rated to prevent ignition.

- Gb – Equipment Protection Level indicating suitability for Zone 1 environments. This coding helps you match the analyzer to site risk conditions.

5. What protection techniques are used in explosion-proof gas analyzers?

Common protection methods include:

- Flameproof enclosure (Ex d): rugged housings contain ignitions.

- Intrinsic safety (Ex i): limits energy so sparks can’t occur.

- Increased safety (Ex e): design improvements prevent arcs.

- Encapsulation (Ex m): sensitive parts are sealed in resin.

- Positive pressure (Ex p): clean air prevents explosive gas entry.

Choosing the right method depends on the analyzer technology and hazardous area rating.

6. How do I choose the right explosion-proof gas analyzer for my plant?

First, identify your hazardous area classification (e.g., Zone 0, Zone 1). Then select a gas analyzer with the appropriate certification (ATEX, IECEx, UL/CSA) and protection concept suited to that zone and your gas type. For example, analyzers with Ex d housings are common in Zone 1, while Ex i systems fit low-power signal circuits in Zone 0. Always confirm both the analyzer’s certification and your site’s zoning before purchase.

7. Can a gas analyzer be certified for a higher zone be used in a lower zone?

Yes. Equipment with certification for a higher-risk zone (e.g., Zone 0) can typically be used safely in lower-risk zones (e.g., Zone 1 or Zone 2). This flexibility can simplify procurement and installation, as long as the analyzer’s protective features exceed the minimum required level for the site.