Industrial gas measurement can be complex, expensive, and error-prone. Traditional flow meters often fall short in dynamic, high-temperature environments. Ultrasonic Flow Meter technology from ESEGAS provides an accurate, maintenance-free solution.

The ESEGAS Ultrasonic Flow Meter is a non-intrusive, high-precision instrument engineered for harsh industrial environments. It enables continuous, contact-free measurement of gas flow, making it a preferred solution in power plants, chemical facilities, and emission control systems.

Even if you’re familiar with standard flow measurement technologies, the innovation behind ESEGAS products—particularly the LEUF‑200 series—offers a next-level understanding of flow dynamics in industrial plants. Let’s examine why ESEGAS stands out.

How Does the ESEGAS Ultrasonic Flow Meter Work?

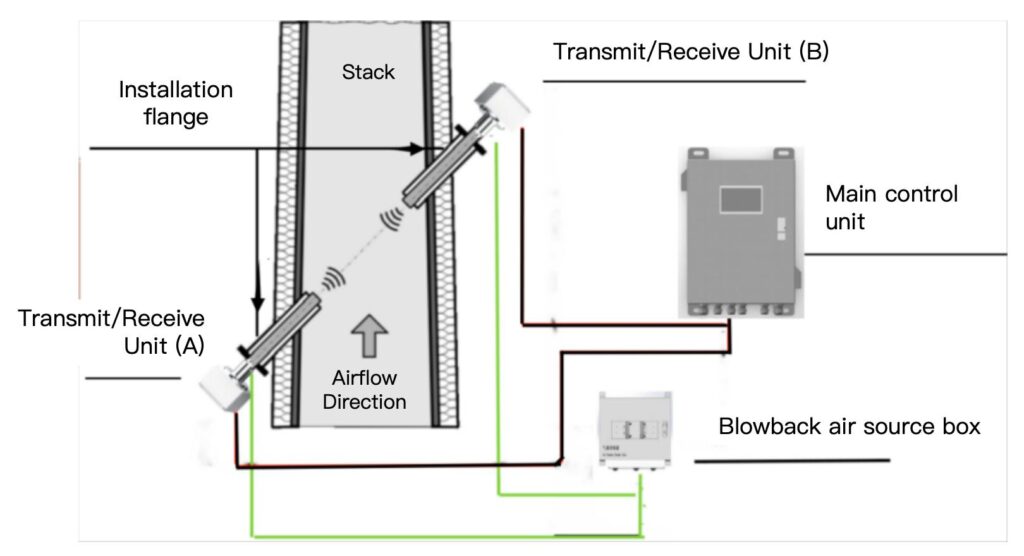

The ESEGAS Ultrasonic Flow Meter operates on the principle of the transit-time (or “time-of-flight”) method. In essence, it measures the difference in the travel time of ultrasonic pulses between two sensors—one transmitting upstream, the other downstream. When gas flows through the pipe, it accelerates the downstream signal and delays the upstream one. By comparing the time difference, the meter calculates the velocity of the gas and converts it to volumetric or mass flow.

Unlike intrusive flow meters that suffer from pressure drop, wear, or contamination, the ESEGAS system uses externally mounted transducers. This non-invasive configuration ensures no contact with the gas, preserving the integrity of both the measurement and the medium.

Advanced signal processing technologies in ESEGAS products allow for high repeatability and exceptional noise immunity, even in turbulent or particulate-laden flows such as flue gas or combustion exhaust.

In Which Industrial Applications Is ESEGAS Most Widely Used?

The ESEGAS Ultrasonic Flow Meter—especially the LEUF‑200 model—is purpose-built for the most demanding industrial gas measurement environments. Its rugged design, high-temperature resistance, and non-intrusive measurement capabilities make it highly versatile across several key sectors. Below are the main industrial applications where ESEGAS is not only widely used but also industry-preferred:

1. Continuous Emissions Monitoring Systems (CEMS)

In compliance-driven industries such as power generation and waste incineration, CEMS is a critical application. The ESEGAS LEUF‑200 is engineered to provide reliable and accurate gas flow measurements within flue gas ducts and chimneys, where gas composition, temperature, and velocity can vary significantly. With ATEX and IECEx certifications, it is ideal for hazardous areas.

- Why it’s ideal: High-temperature tolerance, non-intrusive installation, no moving parts, and stable performance in dusty, acidic, or moist gas flows.

2. Combustion Air and Exhaust Gas Monitoring

In boilers, furnaces, and incinerators, managing the air-to-fuel ratio is essential for both efficiency and emissions control. The ESEGAS Ultrasonic Flow Meter ensures precise measurement of combustion air and flue gas, enabling real-time optimization of combustion efficiency and reduced pollutant output.

- Why it’s ideal: Bidirectional flow measurement enables simultaneous tracking of incoming and outgoing gas, with fast response times for control systems.

3. Power Generation (Thermal, Biomass, Waste-to-Energy)

Power plants require continuous monitoring of gas flow in large ducts to ensure efficient combustion and exhaust gas treatment. The LEUF‑200 is extensively used in coal-fired, biomass, and waste-to-energy plants for monitoring stack gas flow and controlling flue gas desulfurization (FGD) systems.

- Why it’s ideal: The meter handles large pipe diameters (up to several meters), extreme temperatures, and aggressive flue gas environments with no signal loss.

4. Chemical and Petrochemical Industries

In chemical processing, gas flow must be monitored under potentially corrosive, high-pressure, or explosive conditions. ESEGAS meters offer excellent chemical resistance and explosion-proof options, making them suitable for hydrogen, ammonia, nitrogen, or hydrocarbon monitoring in production lines.

- Why it’s ideal: Non-intrusive sensors eliminate risk of contamination or sensor degradation from aggressive media. The system is fully compliant with hazardous zone certifications.

5. Steel, Cement, and Metallurgy

These industries generate dust-heavy, high-temperature gases during production. Whether it’s in sintering plants, kilns, or blast furnaces, accurate flue gas flow data is essential for emissions control, energy recovery, and system balancing.

- Why it’s ideal: The LEUF‑200’s robust ultrasonic transducers operate reliably even in ducts with high particulate load, extreme temperatures (>300°C), and strong vibration.

6. Environmental Compliance and Air Quality Management

Environmental authorities require real-time, validated emission data. ESEGAS meters support automated environmental monitoring, particularly when integrated into emission control platforms and air quality databases.

- Why it’s ideal: High accuracy at low and high flow velocities, real-time data output, and compatibility with EPA and EU standards for emission reporting.

7. Gas Distribution and Process Optimization

For gas recovery systems or internal gas routing (e.g., process gas reuse in refineries or heat recovery systems), precise volumetric and mass flow measurement is essential. ESEGAS meters ensure reliable data across variable flow profiles.

- Why it’s ideal: Automatic temperature and pressure correction, optional multi-path configurations, and customizable outputs for SCADA integration.

Summary of Key Application Environments:

| Sector | Typical Application | Why ESEGAS Excels |

| Power Plants | Stack gas, flue gas, combustion air | High-temp, large ducts, dynamic gas flows |

| Chemical & Petrochemical | Process gas monitoring | Explosion-proof, non-intrusive, precise |

| Steel & Cement | Kiln exhaust, dust-laden flows | Resistant to particulates and vibration |

| Environmental Monitoring | CEMS, emission reporting | Certified accuracy, regulatory compliance |

| Waste-to-Energy | Flue gas treatment, combustion optimization | Multi-path stability, fast response |

| Industrial Boilers | Air/fuel ratio control | Bidirectional flow, real-time data output |

This comprehensive versatility explains why the ESEGAS Ultrasonic Flow Meter is becoming a standard choice for flow measurement in modern, performance-oriented industrial plants. Its application footprint continues to grow as industries seek to digitize operations, improve environmental performance, and reduce lifecycle costs.

What Are the Advantages Over Traditional Flow Meters?

Compared to vortex, thermal, or differential pressure-based devices, the ESEGAS Ultrasonic Flow Meter offers several unique benefits:

- No moving parts: Ensures long service life with virtually zero mechanical wear.

- Zero pressure drop: Because it’s non-intrusive, there’s no flow obstruction or energy loss.

- Low maintenance: The absence of in-line sensors means no clogging, corrosion, or cleaning required.

- High-temperature and high-dust resistance: Capable of operating in flue gas ducts at temperatures exceeding 300°C.

- Flexible installation: Can be mounted on existing pipes without shutdown or process interruption.

- Bidirectional flow measurement: Detects both forward and reverse flow with equal precision.

These attributes translate into significant operational savings and increased measurement reliability across complex industrial operations.

How Does ESEGAS Ensure Measurement Accuracy?

Accuracy is critical in regulatory compliance, cost allocation, and process efficiency. ESEGAS applies several advanced engineering principles to maximize precision:

- Multipath configuration: LEUF‑200 can employ multiple signal paths across the duct to average out flow profile distortions and ensure more representative readings.

- Digital Signal Processing (DSP): Enhances time resolution and reduces background noise interference, especially in turbulent flows.

- Temperature and pressure compensation: With integrated input ports for sensors, the system calculates flow under standard conditions, improving reliability for billing or reporting purposes.

- Self-diagnostic features: Built-in monitoring of signal quality and sensor status helps detect and prevent measurement drift or failure.

- Custom calibration support: Field calibration can be tailored based on pipe geometry, media characteristics, and installation location.

These features guarantee that your flow data is not only accurate but also stable over long periods with minimal manual intervention.

Is the ESEGAS Flow Meter Compatible With Modern Industrial Systems?

Absolutely. In today’s automated industrial environment, interoperability is crucial. The Ultrasonic Flow Meter from ESEGAS offers excellent integration capabilities, including:

- Communication protocols: MODBUS RTU, MODBUS TCP/IP, and 4–20mA output enable seamless integration with PLCs, DCS, or SCADA systems.

- Data logging and remote access: Advanced models offer on-device storage of flow data and remote monitoring through Ethernet or wireless gateways.

- Modular design: Enables customization of output modules, sensor configurations, and power options.

- Compact footprint: Especially the LEUF‑200 is designed to be lightweight and easy to mount, even in constrained installation zones like vertical stacks or rooftop ducts.

These features make ESEGAS meters ideal for both new projects and retrofit installations, ensuring that plants can modernize without overhauling existing infrastructure.

How Does ESEGAS Support Energy and Environmental Management?

With increasing pressure to reduce emissions and optimize energy usage, industrial operators are turning to precision instrumentation for actionable insights. The Ultrasonic Flow Meter from ESEGAS supports these efforts by:

- Monitoring exhaust gas volumes: Ensures that emission reports are accurate and legally compliant.

- Detecting process inefficiencies: Identifies leaks, underperforming burners, or poor draft conditions that may waste energy.

- Supporting ESG goals: Accurate gas flow data can feed into environmental KPIs and corporate sustainability reporting.

- Reducing downtime: Non-intrusive diagnostics help prevent unplanned shutdowns due to sensor failure or drift.

- Enabling real-time control: Live flow data allows for dynamic optimization of combustion and filtration systems.

With its application in environmental monitoring and fuel consumption tracking, the ESEGAS meter becomes a strategic asset, not just a measurement tool.

Conclusion

ESEGAS has redefined what industrial flow measurement can achieve with its advanced Ultrasonic Flow Metertechnology. From exceptional accuracy and zero-maintenance design to seamless integration and environmental compliance, the LEUF‑200 series offers a smart, scalable solution for modern industrial needs. If your plant demands reliable gas flow monitoring in harsh conditions, ESEGAS stands out as the clear choice.