When a single gas leak can cost lives and millions in damage, instant detection isn’t a luxury—it’s a necessity. Portable gas analyzers offer real-time protection, right where it matters.

Portable gas analyzers play a crucial role in ensuring industrial safety by immediately detecting hazardous gases on-site. Their mobility and accuracy significantly reduce toxic or flammable gas exposure risks.

While fixed monitoring systems have their place, they can’t match the speed and flexibility of portable analyzers. In this article, we explore why portable solutions like those from ESEGAS are rapidly becoming the frontline defenders in industrial safety strategies.

How do Portable Gas Analyzers Improve On-Site Detection Efficiency?

Traditional gas monitoring systems—primarily fixed installations—are constrained by their static nature. They monitor only designated zones, often leaving critical blind spots in large-scale or dynamic environments such as refineries, chemical plants, or confined spaces like tanks and pipelines.

In high-risk environments, waiting for data from limited fixed sensors can delay crucial decisions. Gas leaks, oxygen depletion, or toxic build-ups often occur in areas not covered by stationary systems. Without immediate and mobile detection, teams risk exposure, operational delays, and even fatalities.

Most ESEGAS portable models come equipped with:

- Multi-gas sensors, detecting up to 5 gases simultaneously (e.g., CO, H₂S, CH₄, O₂, SO₂).

- Fast response times (T90 < 10s), crucial for early intervention.

- Data logging and wireless transmission, allowing integration with centralized safety systems.

- Intuitive interfaces and rugged casings, built for harsh industrial use.

The efficiency gain lies not only in detection speed but also in operational agility. Workers can carry out safety checks without shutting down production lines or setting up cumbersome equipment. This immediate feedback loop empowers personnel to act quickly—whether that means evacuating a zone, adjusting ventilation, or conducting targeted maintenance.

Additionally, portable analyzers facilitate predictive maintenance by identifying gas trends over time. When used routinely, they help create a gas exposure map of the facility, which improves long-term planning and reduces emergency incidents.

In summary, ESEGAS portable gas analyzers enhance detection efficiency by combining precision, mobility, and user-friendly technology, helping industries respond faster, safer, and smarter.

In Which Industrial Environments Are Portable Gas Analyzers Most Needed?

Industrial operations vary drastically in environment, scale, and gas exposure risks. Yet a common issue persists across many sectors: hazardous gases are often present in areas where permanent monitoring systems are unavailable or impractical. Fixed detectors can’t follow workers into every confined space, remote zone, or maintenance corridor.

In environments where gases like methane (CH₄), hydrogen sulfide (H₂S), carbon monoxide (CO), or oxygen deficiency pose serious threats, every unmonitored space is a potential danger zone. Many high-risk activities—such as plant turnarounds, emergency repairs, or field inspections—happen outside the reach of fixed systems.

ESEGAS portable gas analyzers provide a flexible and reliable alternative for ensuring worker safety in these challenging environments. Their compact, rugged, and intrinsically safe designs make them indispensable across several critical industries:

1. Oil & Gas (Upstream, Midstream, Downstream)

- Risk: Explosive gases (CH₄, VOCs), toxic leaks (H₂S), flammable atmospheres.

- Use Case: During pipeline inspections, wellhead maintenance, and tank cleaning, technicians rely on ESEGAS portable analyzers to verify atmospheric safety before entry and continuously monitor conditions in real time.

2. Chemical and Petrochemical Plants

- Risk: Release of volatile organic compounds (VOCs), corrosive gases (Cl₂, NH₃), or oxygen displacement.

- Use Case: When dealing with reactive processes or chemical storage, portable gas analyzers are used during troubleshooting, line purging, or emergency shutdowns to detect leaks instantly and prevent chain-reaction hazards.

3. Mining and Underground Operations

- Risk: Methane accumulation, oxygen deficiency, carbon monoxide from equipment.

- Use Case: Mines are dynamic and structurally evolving spaces. ESEGAS devices allow personnel to check tunnel air quality, monitor blasting zones, and ensure escape routes are safe.

4. Wastewater Treatment Facilities

- Risk: Anaerobic processes emit H₂S, CH₄, and NH₃ gases, especially in digesters or sludge handling areas.

- Use Case: Operators conducting pump maintenance or entering wet wells must first assess gas concentration using portable units to avoid asphyxiation or poisoning.

5. Confined Space Entry (All Industries)

- Risk: Poor ventilation leads to invisible gas buildup—often undetectable without active monitoring.

- Use Case: Whether in ship hulls, silos, or storage tanks, workers use ESEGAS analyzers before and during entry to meet regulatory requirements and ensure personal safety.

6. Power Generation (Thermal, Nuclear, Renewable)

- Risk: CO and NOx emissions, insulating gas leaks (like SF₆), combustible dust atmospheres.

- Use Case: During boiler inspections, turbine maintenance, or battery room checks, portable analyzers support both preventive and emergency diagnostics.

| Industry | Common Gas Hazards | Typical Use Cases | Why Use ESEGAS Portable Analyzers |

| Oil & Gas(Upstream–Downstream) | CH₄, H₂S, VOCs, CO | Pipeline inspection, tank cleaning, leak detection, confined space entry | Explosion-proof design, real-time multi-gas detection in hazardous zones |

| Chemical & Petrochemical | VOCs, NH₃, Cl₂, CO, O₂ deficiency | Process maintenance, emergency shutdowns, valve inspections | Detects corrosive and toxic gases with high accuracy, supports complex gas matrices |

| Mining & Tunneling | CH₄, CO, O₂ deficiency | Pre-entry checks, blasting zone analysis, escape route monitoring | Rugged design, fast response time, reliable in low-ventilation underground settings |

| Wastewater Treatment | H₂S, CH₄, NH₃, O₂ deficiency | Digester checks, pump station access, sludge handling | Prevents exposure to toxic gases in anaerobic environments; supports confined space protocols |

| Confined Spaces (All Industries) | O₂ deficiency, CO, CH₄, H₂S | Tank entry, silo inspections, ship hull access | Ensures regulatory compliance (OSHA/ISO), compact and wearable for constant safety monitoring |

| Power Generation | CO, NOx, SF₆, CH₄ | Boiler room entry, turbine maintenance, battery storage checks | Detects insulating gas leaks, supports environmental compliance, ideal for both fossil and renewables |

In each of these environments, the ability to move with the worker and offer real-time, high-precision readings makes portable gas analyzers not just helpful—but essential. ESEGAS devices are purpose-built to meet the demands of such sectors, with certifications like ATEX and IECEx ensuring compliance even in explosive atmospheres.

What Are The Key Differences Between Portable And Fixed Gas Analyzers?

Portable and fixed gas analyzers serve the same fundamental purpose—detecting hazardous gases to ensure workplace safety—but their design, functionality, and application scenarios differ significantly. Understanding these differences is essential for selecting the right monitoring strategy for a given industrial environment.

1. Deployment and Flexibility

Fixed gas analyzers are permanently installed at designated locations within industrial facilities. They are optimized for continuous monitoring of specific areas, such as production lines, control rooms, or storage tanks. These systems are ideal for environments where gas presence is expected and consistent, providing constant data with minimal user intervention.

In contrast, portable gas analyzers, like those designed by ESEGAS, are mobile and operator-driven. They can be carried to any location within or outside the plant, enabling real-time, on-demand measurements. This flexibility is crucial during equipment maintenance, area inspections, confined space entries, or emergency response operations where fixed detectors are unavailable or insufficient.

2. Installation and Infrastructure Requirements

Fixed systems require significant installation planning, including wiring, sensor mounting, calibration infrastructure, and integration with centralized SCADA or DCS systems. This setup can be expensive and time-consuming, especially in complex facilities.

Portable analyzers eliminate the need for infrastructure. They are plug-and-play devices, often battery-powered, with built-in data storage or wireless communication. ESEGAS models are known for their fast deployment and user-friendly interfaces, allowing safety teams to perform diagnostics without halting operations or modifying the site.

3. Monitoring Scope and Coverage

While fixed analyzers provide long-term data trends and automated alerts, they monitor only the specific locations where they’re installed. This leaves blind spots in mobile work zones or evolving operational layouts.

Portable units, on the other hand, offer dynamic coverage. A single device can move with the worker, enabling checks at multiple points—especially valuable in large facilities, outdoor pipelines, or areas under construction. With ESEGAS portable analyzers, multi-point inspections can be done quickly and precisely, thanks to advanced sensors that detect up to five gases simultaneously.

4. Response Time and Use Case Suitability

Both types of analyzers are capable of fast response, but use-case dictates optimal application. Fixed units excel in process environments where automatic shutoff or ventilation control is required. They’re typically networked for system-wide safety management.

Portable analyzers are essential for task-specific, temporary, or mobile applications. For instance, during plant turnarounds, shutdowns, or leak investigations, ESEGAS portable models allow teams to verify gas concentrations before restarting systems—something fixed detectors can’t dynamically adapt to.

5. Maintenance and Calibration

Fixed analyzers require routine service, often managed by maintenance teams or third-party vendors. These systems usually include self-diagnostics but may involve downtime for sensor replacement or recalibration.

Portable analyzers, though requiring regular calibration as well, are designed for field-friendly maintenance. ESEGAS provides docking stations and calibration kits that simplify upkeep, even in remote locations. Some models also include auto-calibration reminders and smart diagnostics to reduce user error.

What Role Do Portable Gas Analyzers Play In Emergency Response?

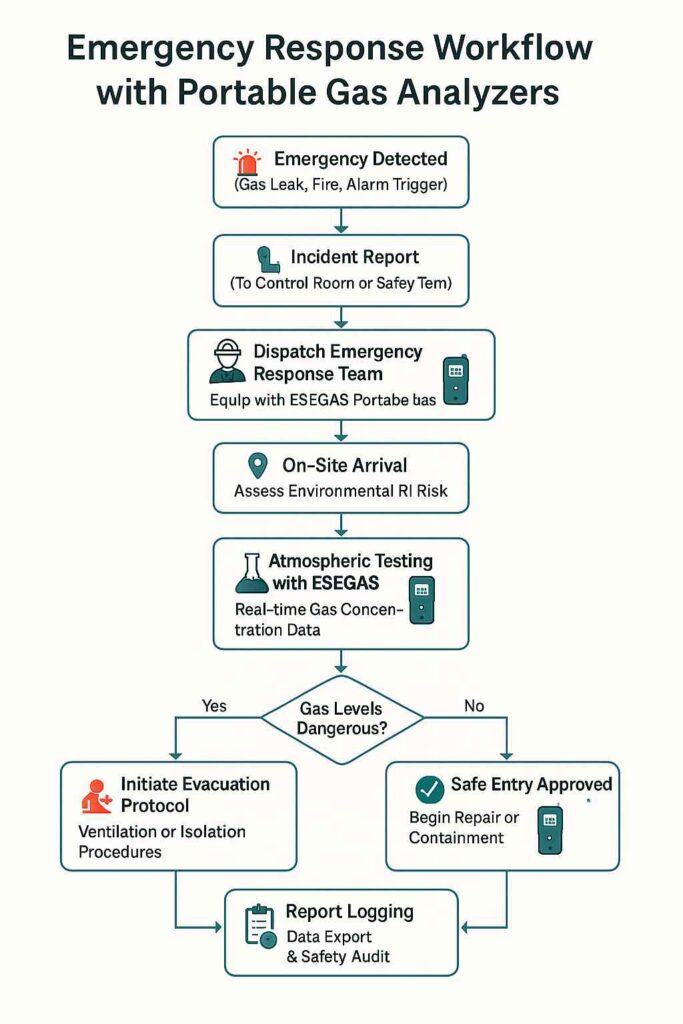

In emergency situations, every second counts. Whether it’s a gas leak, chemical spill, equipment malfunction, or confined space rescue, the ability to quickly assess atmospheric conditions can be the difference between a contained incident and a catastrophic event. This is where portable gas analyzers become indispensable—functioning as frontline diagnostic tools that guide first responders, engineers, and safety personnel through rapidly changing and often hazardous environments.

Unlike fixed gas detection systems, which are designed for continuous monitoring of known locations, portable gas analyzers are built for immediate deployment in unpredictable scenarios. During an emergency, responders cannot afford to rely solely on pre-installed infrastructure, which may not cover the affected zone or could itself be compromised. Portable analyzers from ESEGAS provide the agility and precision required to assess the situation directly at the source—on the ground, inside a tunnel, or within a compromised processing unit.

Time is a critical factor during any gas-related emergency. Portable devices from ESEGAS feature ultra-fast sensor response times, often under 10 seconds (T90), allowing responders to determine the presence and concentration of dangerous gases such as hydrogen sulfide (H₂S), methane (CH₄), carbon monoxide (CO), or oxygen-deficient atmospheres in real time. With this data, incident commanders can make informed decisions: whether to evacuate personnel, ventilate a structure, isolate a leak, or safely enter a hazardous area for repairs.

Moreover, many emergencies occur in low-visibility or high-noise environments, where rapid situational awareness is compromised. ESEGAS analyzers are engineered for such conditions—with audible alarms, vibration alerts, and visual indicators that immediately notify the user of dangerous gas levels. Their rugged, intrinsically safe design ensures reliability even in the most extreme environments, including zones classified as ATEX/IECEx hazardous.

Another key function of portable gas analyzers during emergencies is their role in post-incident investigation and verification. After containment efforts, responders use these devices to confirm that the air is safe for re-entry or that gas concentrations have returned to acceptable thresholds. This verification step is crucial to avoid secondary incidents and to meet legal and procedural safety requirements.

In summary, portable gas analyzers are not just helpful tools in emergency response—they are critical instruments that enable fast, informed, and life-saving decisions. The ability to deploy, detect, and act within moments is what defines effective response, and ESEGAS portable analyzers are purpose-built to deliver exactly that level of confidence when it matters most.

Conclusion

Portable gas analyzers are indispensable in modern industrial safety systems. Their mobility, versatility, and speed—especially those engineered by ESEGAS—ensure that no hazardous zone is left unmonitored. When lives and assets are on the line, portable detection isn’t optional—it’s essential.

If you want to know more details, contact with us please!