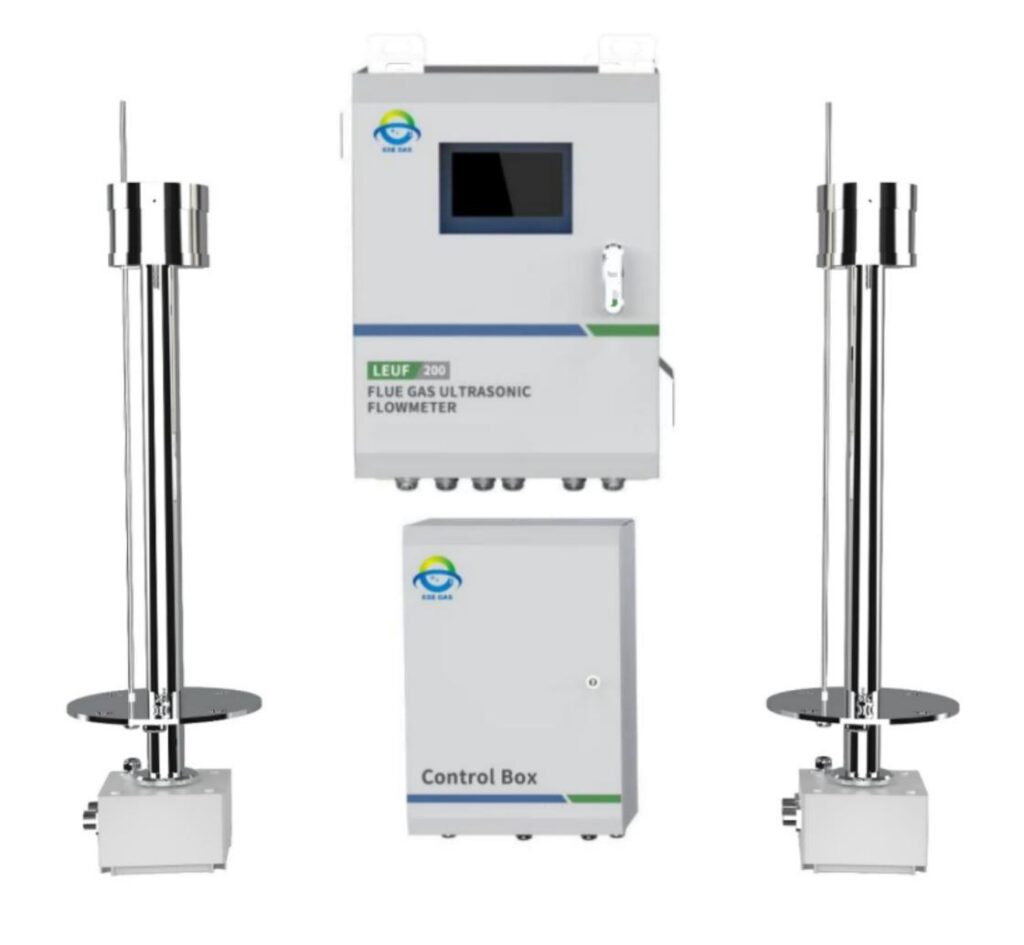

Welcome to the ESEGAS FAQ hub for Ultrasonic Flow Meters. Here you’ll find answers to the most common questions about our industry-leading LEUF‑200 Ultrasonic Flow Meter, designed for high-precision gas flow measurement in power plants, chemical processing, CEMS, and more.

What is an Ultrasonic Flow Meter?

An Ultrasonic Flow Meter is a non-intrusive flow measurement device that uses high-frequency sound waves to measure the velocity of gas in a pipeline or duct. It calculates flow by comparing the time it takes for ultrasonic signals to travel with and against the flow direction.

Key benefits:

- No pressure drop

- No moving parts

- High durability

- Ideal for industrial gas flow monitoring

How Does the ESEGAS LEUF‑200 Flow Meter Work?

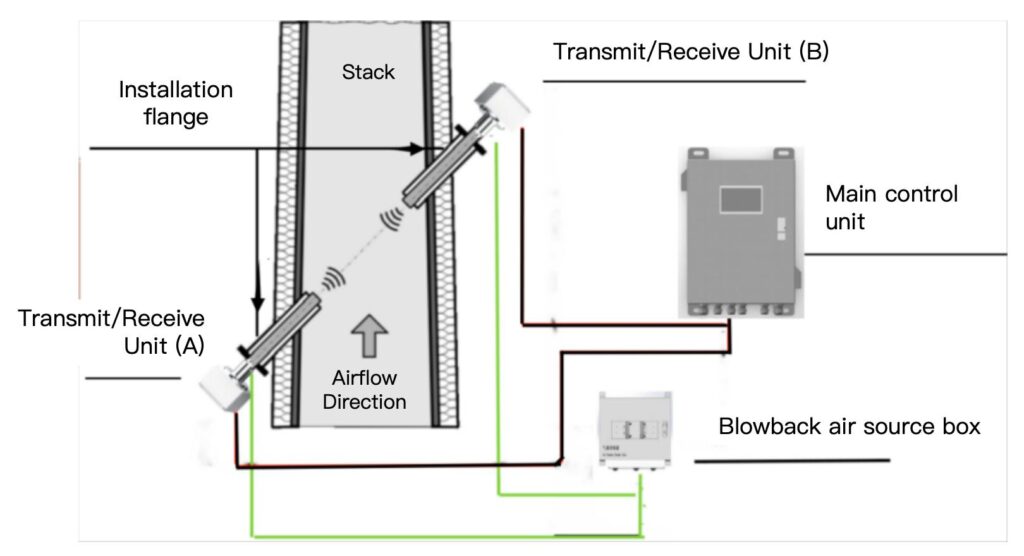

The LEUF‑200 Ultrasonic Flow Meter operates using the time-of-flight principle. It transmits and receives ultrasonic pulses across the full diameter of the duct and calculates flow based on the time difference between upstream and downstream signals.

This method ensures accurate measurement regardless of gas temperature, pressure, or composition—making it reliable even in complex environments like flue gas ducts or combustion exhaust systems.

What Gases Can Be Measured with ESEGAS Ultrasonic Flow Meter?

ESEGAS Ultrasonic Flow Meters can measure a wide range of industrial gases, including:

- Flue gas and stack emissions

- Combustion air and exhaust gas

- Process gases (e.g. ammonia, hydrogen, nitrogen)

- Ventilation and HVAC gases

They are compatible with both clean and dust-laden gases, upstream or downstream of filters.

Is the LEUF‑200 Ultrasonic Flow Meter Suitable for CEMS Applications?

Yes. The LEUF‑200 Ultrasonic Flow Meter is optimized for use in Continuous Emission Monitoring Systems (CEMS). It complies with major environmental standards such as:

- HJ 75-2017 / HJ 76-2017

- HJ 212-2017 (Data communication)

- GB/T 16157

Its non-contact design ensures long-term reliability with minimal maintenance—ideal for stack emission reporting.

What Is the Accuracy of the LEUF‑200 Flow Meter?

The LEUF‑200 provides highly accurate measurements, even under harsh industrial conditions:

- Velocity accuracy: ±0.1 m/s

- Reproducibility: ±1% (above 2 m/s)

- Temperature accuracy: ±1°C

It also includes temperature and pressure compensation, essential for calculating standard volumetric flow.

Does Ultrasonic Flow Meter Installation Require Process Downtime?

No. Thanks to its non-intrusive design, the LEUF‑200 can be installed on existing ducts or chimneys without cutting into the process line. Installation typically involves:

- Mounting angled flanges (30°–60°)

- Placing probes and signal cables

- Connecting the main control unit

- Running a brief configuration process via touchscreen or Modbus

ESEGAS also provides on-site support for optimal installation.

Why Is a Blowback or Purge System in Ultrasonic Flow Meter Needed?

In dusty environments, such as flue gas or combustion applications, soot and moisture can accumulate on sensor heads. The LEUF‑200 Ultrasonic Flow Meter includes an automated purge system that:

- Keeps the sensor face clean

- Prevents measurement drift

- Ensures long-term stability

The purge air system uses 0.1–0.6 MPa clean instrument air at 3–6 L/min.

How Often Does the Flow Meter Require Maintenance?

The LEUF‑200 is designed for low-maintenance operation. Typical maintenance includes:

- Cleaning the probe face (1–6 months interval depending on site conditions)

- Checking purge system and air filters

- Occasional calibration if required

Built-in self-diagnostics help identify signal or sensor anomalies in real time.

Can the ESEGAS Flow Meter Integrate with SCADA or PLC?

Yes. The LEUF‑200 supports multiple output formats:

- 3-channel 4–20 mA analog output

- RS485 Modbus RTU for digital communication

- USB for local data storage and firmware updates

It can be seamlessly integrated into DCS, SCADA, and energy management platforms.

What Industries Commonly Use ESEGAS Flow Meters?

The ESEGAS LEUF‑200 Ultrasonic Flow Meter is trusted across multiple sectors:

- Power Generation: Coal, biomass, waste-to-energy

- Chemical & Petrochemical: Process control and gas recycling

- Cement & Steel: Emission control and combustion monitoring

- Environmental Monitoring: Government-regulated CEMS sites

- HVAC & Ventilation: Industrial and agricultural gas systems

How Do I Troubleshoot Signal or Measurement Issues?

Common causes of abnormal flow readings of Ultrasonic Flow Meter include:

- Incorrect installation angle or sensor distance

- Sensor contamination (dust, condensation)

- Signal cable or grounding faults

- Parameter misconfiguration

Still Have Questions?

Need help selecting the right Ultrasonic Flow Meter for your industrial application?