(Chemicals from Coal gasification)

For decades, the coal gasifier was a bit of a mystery. It was a massive steel vessel, a “black box” where complex chemistry happened at extreme temperatures and pressures. Engineers could monitor inputs and outputs. They could track temperature and pressure. But they couldn’t truly see what was going on inside. This lack of visibility meant control was reactive. Operators would see a problem after it happened, not as it started. This changed everything. Today, the syngas analyzer acts as our window into the gasifier. It gives us a real-time, high-definition view of the process.

This article will show you why a syngas analyzer is more than a monitoring tool. It is the core of a data-driven strategy. This tool helps transform coal gasification. It takes it from an educated guess to an optimized science. We’ll explore how this single piece of equipment improves efficiency, safety, and profitability. It’s the key to smarter, more effective operations.

Why Is a Syngas Analyzer the Most Critical Tool for Process Visibility?

Let’s be honest. A gasifier’s true output is its syngas. The quality of this gas is the ultimate report card. It tells us everything about the process. Other measurements, like temperature and pressure, are only indirect indicators. They tell you if something is wrong. They don’t tell you what is wrong. A syngas analyzer provides a direct readout of the chemistry. It delivers a perfect snapshot of the reaction. This makes it an essential diagnostic tool.

A syngas analyzer measures specific gas components. Each reading reveals something vital. It’s like a doctor checking a patient’s vitals. Here’s what you need to know about each key component:

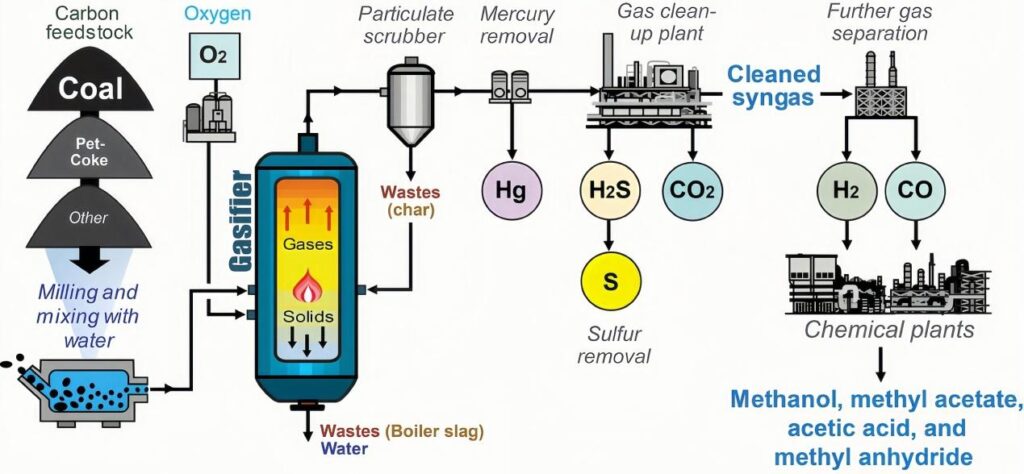

- Carbon Monoxide (CO) & Hydrogen (H2): These are the two primary products. They are the goal of the entire process. The ratio between them (H2/CO) is a critical KPI. It determines if the syngas is suitable for downstream use. For example, for methanol synthesis, a specific H2/CO ratio is necessary.

- Methane (CH4): This gas is a sign of inefficiency. High methane levels mean the coal feedstock isn’t being converted properly. This represents wasted energy. You’re not getting full value from your fuel.

- Carbon Dioxide (CO2): A higher-than-expected CO2 level suggests issues. It may mean the temperature is too low. It could also mean the residence time is too short. It’s a direct measure of an inefficient process.

- Hydrogen Sulfide (H2S): This is a critical safety and environmental parameter. H2S must be monitored constantly. It’s a hazardous gas. It can also poison valuable downstream catalysts.

How Does a Syngas Analyzer Enable a Coal Gasification to Move Beyond Simple Monitoring?

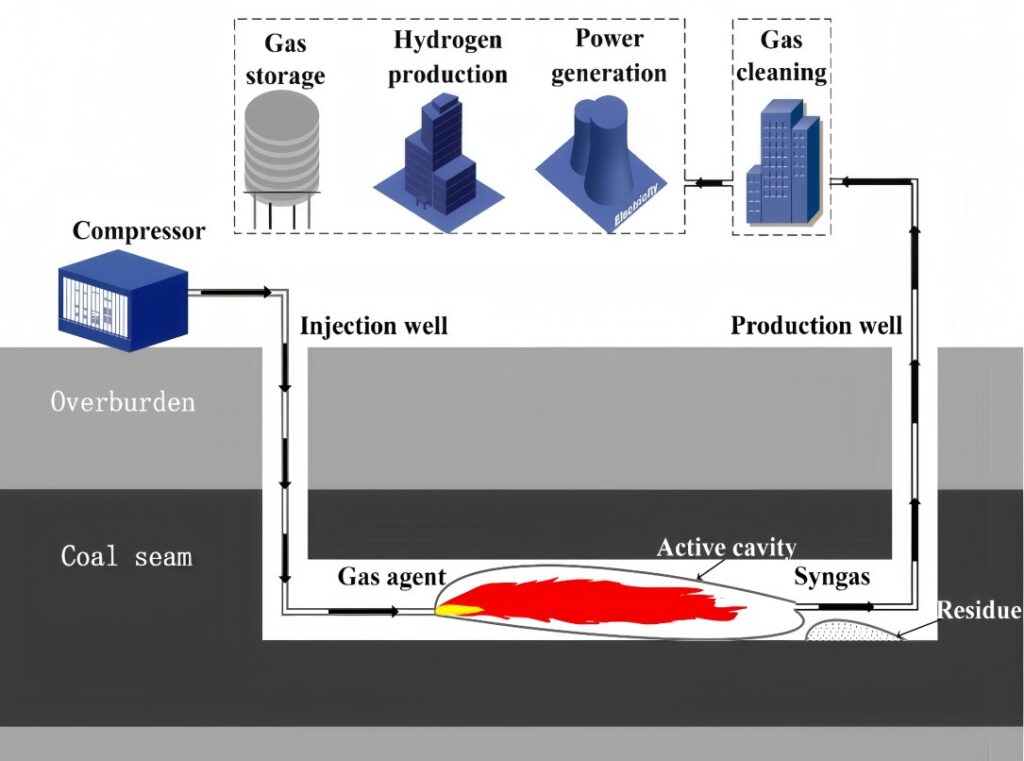

(UCG)

A syngas analyzer is an active participant in your control strategy. It’s not just a passive sensor. Think of it as the brain of your gasifier’s control system. The analyzer helps you make instant, informed decisions. This moves you from reactive fixes to proactive control. It’s a fundamental shift in how you operate. The benefits can be seen across a performance pyramid.

At the base of the pyramid is real-time operational control. An operator gets a live stream of data. If the H2/CO ratio starts to drop, the operator knows exactly what to do. They can adjust the steam-to-carbon ratio or the oxidant flow. These are precise, immediate changes. This prevents a major deviation. Without this data, an operator would be flying blind. They would have to wait for a temperature drop or a pressure change. By then, the problem has already grown.

Next, a syngas analyzer improves safety management. You can turn gas composition into a predictive safety tool. For example, a sudden jump in hydrogen or carbon monoxide levels could signal an issue. This could be a dangerous pressure build-up. It could be an early sign of a leak. When the analyzer is integrated with the plant’s Distributed Control System (DCS), it can trigger alarms. It can even initiate an automatic shutdown. This prevents dangerous situations. You are no longer just reacting to alarms. You are actively preventing a potential disaster.

Finally, we get to the top of the pyramid: unlocking economic and environmental gains. The syngas analyzer helps you hit your sweet spot. When you maintain the ideal H2/CO ratio, you maximize your final product yield. This could be hydrogen or methanol. You also reduce the amount of wasted gas like methane and carbon dioxide. This means you use less feedstock. Less feedstock means lower costs. It’s a clear return on investment. Furthermore, constant monitoring of H2S ensures environmental compliance. You avoid costly fines. You also prevent unscheduled shutdowns.

Can a Syngas Analyzer Be the Key to a Smarter, More Autonomous Plant?

The real power of a syngas analyzer lies in its data. When you collect this data over time, you can spot trends. This moves you from real-time response to predictive maintenance. Imagine a slow, consistent increase in carbon dioxide over several weeks. A simple monitoring system might not flag this. But an analyzer’s trend data would highlight it immediately. This trend could signal a subtle refractory degradation. Or it could show a sensor drift. It allows you to plan for a repair during a scheduled downtime. This prevents an unexpected, costly emergency shutdown.

The ultimate goal for many plants is full automation. The syngas analyzer makes this a reality. The analyzer can feed its data into a closed-loop control system. This system uses advanced algorithms. It can then automatically adjust process parameters. It creates a self-optimizing gasifier. It minimizes the need for human intervention. This pushes efficiency to its maximum theoretical limits. This is the future of coal gasification. It is a future built on precision and data.

Conclusion: From Guesswork to Operational Intelligence

A syngas analyzer is no longer an optional add-on. It’s a core component of any modern gasification plant. It pulls back the curtain on a complex process. It turns a “black box” into a transparent system. By providing continuous, high-fidelity data, it empowers you to make smarter decisions. It’s an investment in operational transparency. It maximizes asset performance. It ensures the long-term viability of your plant.

Are you ready to move from guessing to knowing? Let’s discuss how real-time analysis can transform your coal gasifier operations.

FAQs: Syngas Analyzers for Coal Gasifiers

1.What does a syngas analyzer measure in coal gasification?

A syngas analyzer measures the concentrations of key gases produced during coal gasification. The primary components it tracks are Carbon Monoxide (CO) and Hydrogen (H2), which are the main products. It also monitors inefficiencies and pollutants like Methane (CH4), Carbon Dioxide (CO2), and Hydrogen Sulfide (H2S).

2.Why is the H2/CO ratio so important for a coal gasifier?

The H2/CO ratio is a critical performance indicator. It tells you the exact composition of the product gas. Downstream processes, such as the production of methanol or ammonia, require a specific H2/CO ratio to operate efficiently. An analyzer helps operators maintain this ratio in real-time, which maximizes product yield and profitability.

3.How does a syngas analyzer improve safety in a gasification plant?

A syngas analyzer enhances safety by providing real-time data on gas composition. Sudden spikes in flammable or toxic gases like CO or H2S can signal a leak or process instability. By integrating the analyzer with the plant’s control system, you can trigger automatic alarms or shutdowns, preventing potential accidents before they become major events.

4.Can a syngas analyzer help a plant save money?

Yes, absolutely. A syngas analyzer helps save money in several ways. By minimizing wasted feedstock (indicated by high CH4 levels), you reduce operational costs. By optimizing the H2/CO ratio, you maximize the yield of your final product. Continuous monitoring also helps you avoid costly environmental fines and reduce unplanned downtime for maintenance, directly impacting your plant’s bottom line.

5.What is the difference between monitoring temperature and analyzing syngas?

Monitoring temperature is important, but it’s an indirect indicator of the process. It tells you if a problem is occurring (e.g., if the temperature drops). In contrast, a syngas analyzer provides a direct readout of the chemical reactions. It tells you what the problem is (e.g., incomplete carbon conversion or an incorrect steam-to-carbon ratio), allowing for more precise and effective corrective actions.