Environmental protection and monitoring are crucial to maintaining the ecological balance of the earth. Continuous Emission Monitoring Systems (CEMS) play a key role in this area, monitoring pollutants in the atmosphere in real time to ensure that businesses and governments comply with emission standards. This article will compare several CEMS methods with different principles, explore their advantages and limitations, and potential applications in real-time environmental monitoring.

Comparison between the completely extractable cold-drying method and the completely extracted hot-wet method

In the CMES (Continuous Mercury Emission Monitoring System) gas analyzer, the fully extracted cold-dry method and the fully extracted hot-moisture method are two different gas sampling and processing methods. They have different characteristics when processing and analyzing gas samples. and applications.Here’s a comparison of the two methods:

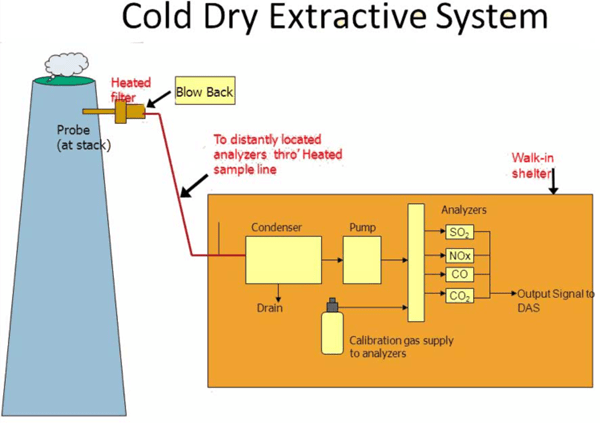

1、Complete extraction cold-drying method:

Principle: This method condenses and removes moisture in the sample gas through cooling. This prevents water vapor from interfering with gas analysis.

advantage:

- Reduce water vapor interference: Remove moisture by cooling the sample gas. This method effectively reduces the interference of water vapor on gas analysis results. This is an important advantage for analytical projects where moisture may cause chemical reactions or physical absorption.

- Enhance analytical accuracy: The removal of water vapor helps improve the detection accuracy of certain gas components, especially in applications that pursue high-precision analysis, such as trace gas analysis.

- Avoid equipment problems caused by water vapor: Water vapor may cause corrosion or other damage to components of some analytical instruments. This risk can be reduced by freeze-drying.

- Wide applicability: Suitable for various gas analyzes that require dry sample gas, such as VOCs (volatile organic compounds) analysis, trace gas analysis, etc.

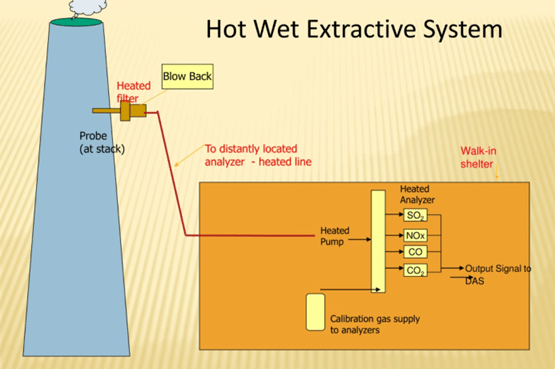

2、Completely extractable heat and moisture method:

Principle: This method keeps the sample gas at a high temperature, thereby avoiding the condensation of water vapor. This maintains the humidity of the original sample gas.

advantage:

- Keep the sample gas in its original state: By maintaining the high temperature state of the sample gas and avoiding condensation of water vapor, it can more accurately reflect the original composition and concentration of the sample gas, which is very important for certain analyses.

- Avoid condensable gas losses: In the freeze-drying method, in addition to moisture, other condensable gases may also be removed, which will affect the accuracy of the analysis. The thermo-moisture method avoids this problem because it does not involve a cooling process.

- Suitable for wet gas analysis: For those gases that inherently contain high moisture, such as exhaust gases, flue gases, etc., the thermal moisture method can provide more accurate analysis results.

- Avoid water vapor adsorption problems: Certain gas components may be adsorbed by water vapor during the cooling process, resulting in inaccurate analysis results. The thermo-moisture method reduces this risk because it does not involve cooling.

| Measurement methods | Completely extractable cold-drying method | Completely extractable heat and moisture method | |

| Preprocessing method | in situ | Post-processing method | Two-stage filtration + NO2 conversion |

| Features | 1、The sample transfer line does not require heating; 2、Integrated sampling probe and preprocessing 3、It has the functions of dust removal, water removal, ammonia removal, and organic matter removal. 4、Guaranteed response time and indication error 5、Reduce the loss of components to be measured during sample transportation. | 1、Simple structure and easy maintenance. 2、Condensation to remove water is simple and cheap. 3、When there is a heating blind spot at the joint, liquid water is easily formed, resulting in the loss of the component to be measured. 4、The adsorption of SO2 by water is easy to form in the condenser. In high-salt situations, the condenser is easy to be blocked by crystallization. | 1、The entire measurement process must be higher than the flue gas dew point. 2、Ensuring the normal functioning of the dust removal device can effectively prevent the occurrence of air chamber pollution. 3、Where there are many water-soluble salts in the flue gas, crystallization blockage is likely to form. 4、Improper installation position of the nitrogen oxide converter can easily cause equipment failure. |

When choosing between these two methods, the decision needs to be made based on the specific analysis needs and the characteristics of the sample gas. For example, for the analysis of gases that contain components that are prone to condensation or that are sensitive to water vapor, the freeze-dry method may be more appropriate; while for analyzes that require maintaining the original humidity state of the sample gas, the hot-wet method may be a better choice.

Dilution extraction analysis method

In the CMES (Continuous Mercury Emission Monitoring System) gas analyzer, the dilution extraction analysis method can be realized by dilution in the flue and dilution outside the flue. These two dilution methods have their own characteristics and are suitable for different monitoring needs and conditions. Here’s a comparison of the two methods:

Principle: Inside the flue, close to the gas emission source, the sample gas is mixed with the diluent gas (usually dry, clean air), and then the diluted gas is sent to the analytical instrument for detection.

advantage:

- Reduce the impact of high temperature and high humidity conditions: Diluting the sample gas inside the flue can reduce the impact of high temperature and high humidity on the analytical instrument and sample gas components.

- Reduce corrosion and clogging of sample gas pipelines: The diluted gas has lower temperature and humidity, reducing pipeline corrosion and clogging problems.

- Improve component stability: For some volatile components, such as mercury, in-flue dilution helps maintain their stability.

Principle: Outside the flue, that is, after the sample gas has been extracted from the flue, it is mixed with the diluent gas and then sent to the analytical instrument.

advantage:

- Operational Flexibility: Out-of-flue dilution provides greater operational flexibility for easy adjustment and maintenance.

- Easier to control the dilution ratio: Dilution occurs outside the flue, and it is relatively easy to control and monitor the dilution ratio.

- Strong adaptability: For changing working conditions and different types of gas components, dilution outside the flue provides better adaptability.

| Measurement methods | dilution extraction type | |

| Dilution method | Dilution in the flue | Dilution outside the flue |

| Features | 1. Simplify the system structure. Compared with complete extraction, CEMS pretreatment is simple, only the front-end particulate matter is filtered, and there is no need for heating pipelines and water removal devices. 2. Maintenance work is reduced. The sample gas flow rate of dilution sampling is low, and only a small amount of water, particles and pollutants are required to enter the system. The filter use time is extended and the system maintenance workload is reduced. 3. Wet basis measurement. Dilution sampling does not remove water. The measured pollutant concentration is the wet basis concentration. It is necessary to convert the dry and wet basis into the dry basis concentration. Humidity measurement is particularly important. 4. Less impact from leakage. After dilution, the sampling pipeline has positive pressure transmission, and leakage will not cause changes in the composition. 5. Suitable for situations where the flue gas temperature is high, the concentration of particulate matter is low, and the flow field is uniform. | 1. Simplify the system structure. Compared with complete extraction, CEMS pretreatment is simple, only the front-end particulate matter is filtered, and there is no need for heating pipelines and water removal devices. 2. Maintenance work is reduced. The sample gas flow rate of dilute sampling is low and only a small amount of water, particles and contaminants are required to enter the system. The service life of the filter is extended, and the system maintenance workload is reduced. 3. Wet basis measurement. Dilution sampling does not remove water. The measured pollutant concentration is the wet basis concentration. It is necessary to convert the dry and wet basis into the dry basis concentration. Humidity measurement is particularly important. 4. The impact of leakage cannot be monitored. The particulate matter is filtered outside the flue and then diluted. Small leaks occurring at the front end of the dilution are difficult to detect and monitor. 5. Suitable for situations where the concentration of particulate matter is relatively high, the flue gas temperature is low, the humidity is high, and the flow field is evenly distributed. |

When selecting an appropriate dilution method, comprehensive considerations need to be made based on factors such as monitoring objectives, sample gas characteristics, equipment installation environment, and maintenance costs. For example, for applications that require a high degree of control over sample gas conditions (such as gas analysis in high-temperature, high-humidity environments), in-flue dilution may be more appropriate, whereas for situations requiring greater operational flexibility and ease of maintenance, out-of-flue dilution may be is a better choice.

Conclusion

CEMS methods with different principles have their own advantages and limitations and are suitable for different monitoring applications. Selecting an appropriate CEMS method requires consideration of monitoring objectives, cost, and operational complexity. Overall, the continuous development and improvement of CEMS methods provides more options for real-time environmental monitoring, which is expected to better protect our environment and human health. In the future, as technology further develops, we can expect more innovations and breakthroughs to improve the performance and availability of CEMS to more effectively monitor and reduce pollutant emissions.

If you have any question, welcome to contact us!