Introduction

In the current climate change environment, finding clean energy alternatives to traditional fossil fuels has become crucial. Biomass gasification technology has become a high-profile energy production method, which converts biomass waste into syngas that can be used for power generation, heating and fuel production. However, to use this technology effectively we need to accurately measure and analyze the gases produced by biomass gasification. This article will explore the biomass gasification process and which gas analyzers to use for effective monitoring and control.

Part 1: Basic Principles of Biomass Gasification

- What is biomass gasification?

Biomass resources usually refer to terrestrial plants (wood, fuelwood, straw, etc.), aquatic plants, human and animal excrement, etc., which are mainly composed of lignin or cellulose and other organic matter. There are many varieties and large quantities. China’s annual output reaches more than 5 billion tons, among which the harvestable crop straw reaches more than 800 million tons. Biomass resources generally have three uses: energy, feed and fertilizer. Biomass energy is the earliest, most abundant, and most direct energy source used by humans. Up to now, more than 1.5 billion people in the world still use biomass as their living energy source.

Biomass energy is most likely to become one of the main energy sources in the 21st century. It is estimated that the energy stored by plants every year is approximately 10 times the world’s main fuel consumption, but its use as energy is less than 1% of the total. Experts believe that biomass energy will become an important part of sustainable energy in the future. By 2015, 40% of total global energy consumption will come from biomass resources.

The traditional utilization method of directly burning biomass not only has low thermal efficiency, but is also labor-intensive and polluting. Due to the improvement of living standards and changes in lifestyle, more and more farmers have switched to clean and efficient energy such as liquefied gas. A large amount of crop straw is discarded as waste or burned in the fields, which is a waste of resources and pollutes Environment, severe cases may also cause the closure of airports and highways. Therefore, it is necessary to develop, promote and apply new technologies to convert biomass energy into efficient and high-grade clean energy to replace fuels such as coal, oil and natural gas.

Biomass gasification is one of the most effective measures to convert biomass energy into efficient, high-grade clean energy. This technology uses a set of mechanical devices to burn biomass anoxically and convert most of the organic matter in the biomass into combustible gases (H, CO, CH, etc.) through reduction and cracking processes. After dust removal, cooling and After purification and other processes, it is sent to the gas storage cabinet, and then sent to each household through gas pipelines for cooking and heating. This technology is one of the important means to utilize biomass energy with high efficiency and high grade. It was identified as one of the priority technologies for development as early as 1990 at the Fourth World Energy Conference.

- Advantages of biomass gasification

Biomass gasification has many advantages over other biomass energy conversion technologies, including:

- Clean energy: The gases produced during biomass gasification are relatively clean and emit lower greenhouse gas emissions than burning biomass.

- Waste utilization: It can effectively process and utilize agricultural and forest wastes and reduce environmental problems.

- Renewability: Biomass is a renewable resource, so biomass gasification is expected to be a sustainable source of energy.

- Fuel Diversity: Synthetic gas can be used as a variety of fuels, including liquefied natural gas (LNG) and hydrogen.

Part 2: The Importance of Biomass Gasification Gas Analysis

Biomass gasification is a complex chemical process by which biomass waste is converted into syngas, which plays an important role in different applications. In order to achieve efficient production and ensure safe and environmentally friendly performance, the gases produced must be monitored and analyzed. The following is the analysis of biomass gasification gas Detailed description of importance:

- Monitoring and controlling gas composition

During the biomass gasification process, carbon, hydrogen, oxygen and other elements in the raw materials react with atmospheric gases to produce synthetic gas. The composition of this synthesis gas depends largely on the reaction temperature, pressure, oxygen supply and the type of biomass. Different applications require different gas compositions, so the gas composition needs to be accurately controlled and adjusted. For example, when synthesis gas is used to manufacture hydrogen fuel cells, high-purity hydrogen is required, while when used to fuel power generation, a certain proportion of carbon monoxide and hydrogen is required.

Gas analyzers provide real-time gas composition data to ensure that the composition of the synthesis gas is within the required range. This helps improve production efficiency and reduces problems that changes in gas composition can cause, such as equipment clogging, unstable reactions or the generation of contaminants.

The quality of synthesis gas is closely related to its gas composition. High-quality synthesis gas can be used for efficient energy production, while low-quality gas can degrade equipment performance or cause erratic operation. For example, synthesis gas used in gas turbines or fuel cells to generate electricity needs to meet strict quality standards to ensure efficient operation of the equipment.

Gas analyzers can monitor the concentration of key gas components such as carbon monoxide, hydrogen and methane to ensure their quality. Through real-time monitoring, reaction conditions can be adjusted in time to maintain the required synthesis gas quality.

- Safety and environmental protection

The biomass gasification process involves high temperatures, high pressures and the generation of toxic gases, so strict safety needs to be maintained. Gas analyzers play a key role in safety. They can be used to monitor the concentration of harmful gases, such as carbon monoxide and hydrogen sulfide, and identify potential hazards in a timely manner. If the concentration of harmful gases exceeds safety standards, the instrument can trigger an alarm or automatically shut down the reactor to prevent accidents.

In addition, gas analyzers also help monitor and reduce the emission of harmful gases to ensure environmental protection. Carbon dioxide emissions from synthesis gases need to be monitored and controlled to reduce adverse effects on the atmosphere.

In short, gas analysis plays a vital role in biomass gasification. It not only ensures reasonable control of the composition and quality of synthetic gas, but also helps improve production efficiency, ensure safety and reduce environmental impact. Choosing a gas analyzer suitable for specific application needs is critical to achieving sustainable biomass gasification.

Part 3: Commonly Used Gas Analyzers

In order to effectively monitor and analyze the gas produced during the biomass gasification process, appropriate gas analyzer Crucial. The following are commonly used Detailed description of gas analyzer:

- working principle: Gas chromatography mass spectrometer (GC-MS) is an advanced gas analysis instrument that combines gas chromatography and mass spectrometry technology. It first uses gas chromatography to separate the gases in a mixture into its individual components, and then feeds those components into a mass spectrometer for mass spectrometry analysis. This process allows users to analyze multiple gas components simultaneously, providing high-resolution and high-sensitivity data.

- application: GC-MS is often used in the research and development stages to gain insight into the composition of synthesis gases. It is suitable for applications requiring detailed compositional analysis, such as fuel cell research, new materials development and gas pollution monitoring.

- working principle: Gas chromatograph (GC) is a common gas analysis instrument used to separate and quantitatively analyze components in gas mixtures. It uses a gas chromatography column to separate the components in a gas sample and then uses a detector to quantitatively analyze each component.

- application: GC is often used in actual production environments to ensure the quality and consistency of synthesis gas. It is suitable for a variety of applications, including gas-to-power generation, liquefied natural gas (LNG) production, fuel processing and more.

- working principle: A mass spectrometer (MS) is an advanced gas analysis instrument that determines the compounds in a gas sample by separating it and measuring its mass spectrum. Mass spectrometers typically have high resolution and accuracy and can be used to analyze various components in synthesis gases.

- application: Mass spectrometers are commonly used in applications that require high-precision analysis, such as fuel cell research, specialty gas production, and synthesis gas analysis in the petrochemical industry.

- working principle: Infrared spectrometers use the infrared spectral characteristics of absorption and emission from a sample to determine gas composition. It determines the presence of different molecules by measuring the absorption of infrared light at different wavelengths in a sample.

- application: Infrared spectrometer is a fast and accurate gas analysis instrument that is widely used in practical applications, especially for monitoring and controlling gas quality. It is suitable for applications such as fuel processing, gas supply and environmental monitoring.

- working principle: The gas sensor is a portable gas analysis instrument that can monitor the concentration of specific gases in synthetic gas in real time. They are usually based on different sensing principles such as electrochemistry, infrared spectroscopy or optics.

- application: Gas sensors are suitable for applications that require real-time monitoring of gas concentrations, such as industrial gas monitoring, indoor air quality detection, and fire detection.

Choosing the right gas analyzer depends on application needs, budget, and environmental conditions. Different instruments have their own advantages and limitations, so these factors need to be considered comprehensively when selecting an instrument to ensure that it can meet the monitoring and analysis needs of the biomass gasification process.

Part 4: Choosing the Right Gas Analyzer

Choosing the right gas analyzer depends on a variety of factors, including application needs, budget, and environmental conditions. Below is a detailed explanation of some of the key factors in selecting a gas analyzer:

- Application requirements

Application requirements are one of the decisive factors in selecting a gas analyzer. Different applications require different gas analyzers, as they may require different performance and functionality.

- Component analysis: If the application requires detailed compositional analysis, such as the need to accurately measure multiple gas components, then a gas chromatography mass spectrometer (GC-MS) may be an ideal choice. This instrument provides high resolution and sensitivity, enabling accurate identification and quantification of various gas components.

- QC: If the main concern of the application is quality control of the gas, such as ensuring that the synthesis gas meets specific quality standards, then a gas chromatograph (GC) may be a more practical choice. It provides fast, reliable component analysis to ensure consistent quality.

- real-time monitoring: For applications that require real-time monitoring of gas concentrations, such as fire detection or indoor air quality monitoring, gas sensors may be a suitable choice. These portable sensors can provide real-time data for timely action.

- Budget

Budget is one of the key considerations when choosing a gas analyzer. Different types of gas analyzers have different costs, so a balance needs to be struck between performance and cost.

- High performance instrument: High-performance instruments, such as gas chromatography-mass spectrometers (GC-MS) and mass spectrometers (MS), are generally more expensive but provide high-resolution and high-precision data. These instruments are typically used in research and development, or applications that require extremely high precision.

- mid-range instrument: Gas chromatographs (GC) and infrared spectrometers (IR) are generally located in the mid-range price range, offering good performance and cost-effectiveness. They are suitable for a wide range of applications and meet many monitoring needs.

- low-cost instrument: Gas sensors are typically relatively inexpensive and suitable for budget-constrained applications. They provide real-time monitoring but are generally less accurate and resolution-resistant than advanced instruments.

- Environmental conditions

Biomass gasification is usually carried out under harsh environmental conditions, such as high temperature, high pressure and high humidity. Therefore, when choosing a gas analyzer, you need to consider the adaptability and durability of the instrument.

- Resistant to high temperatures and pressures: If the biomass gasification process takes place in a high-temperature and high-pressure environment, it is necessary to select an instrument that can operate reliably under these conditions. Some gas chromatography and mass spectrometry instruments may require special sample preparation or protection to accommodate these conditions.

- Waterproof: If the work environment may involve moisture or liquid splashing, consider choosing an instrument with good waterproof performance to prevent damage.

- Adaptability: Some gas analysis instruments may need to adapt to different types of gas samples, so the appropriate instrument needs to be selected according to specific application requirements.

In summary, choosing the right gas analyzer depends on application needs, budget, and environmental conditions. Different types of instruments offer different performance and functionality, so these factors need to be considered on a case-by-case basis to ensure that the most appropriate instrument is selected to meet the monitoring and analysis needs of the biomass gasification process.

Part 5: Our biomass gasification gas analyzer

Our Syngas Analyzers IR-GAS-600/600P is high-stability infrared detector for the simultaneous measurement of CO, H2,CO2, and CH4. These gases are suitable for challenging applications such as syngas and gasification atmospheres. In addition, analyzers may use a compensated thermal conductivity cell for H2. Electrochemical O2 sensors may also measure percent levels of oxygen in the sample gas stream.

IR-GAS-600 Continuous Industrial Syngas Analyzers and Gasification Analyzers

This model high-stability infrared detectors for simultaneously measuring CO, CO2, and CH4. H2 always reads correctly, independent of the background gas composition. An optional non-depleting paramagnetic sensor can be used to conduct O2 analysis. All sensors/detectors are temperature-controlled or temperature-compensated for maximum analytical stability. Both types of analyzers are available with analysis of:

- Carbon Monoxide (CO) via infrared detector

- Carbon Dioxide (CO2) via infrared detector

- Oxygen (O2) via electrochemical sensor or optional paramagnetic

- Methane (CH4) via infrared detector

- Hydrogen (H2) via thermal-conductivity detector

- the hydrogen reading is actively compensated for analytical interferences from CO / CO2 / CH4. This enables us to combine the durability of a thermal-conductivity detector while retaining the functional accuracy of a multi-gas instrument.

Applications:

- coal chemical process

- steel making process as blast furnace

- converter, coking, direct iron ,ore smelting reduction

- syngas production from Biomass and coal gas gasification processes

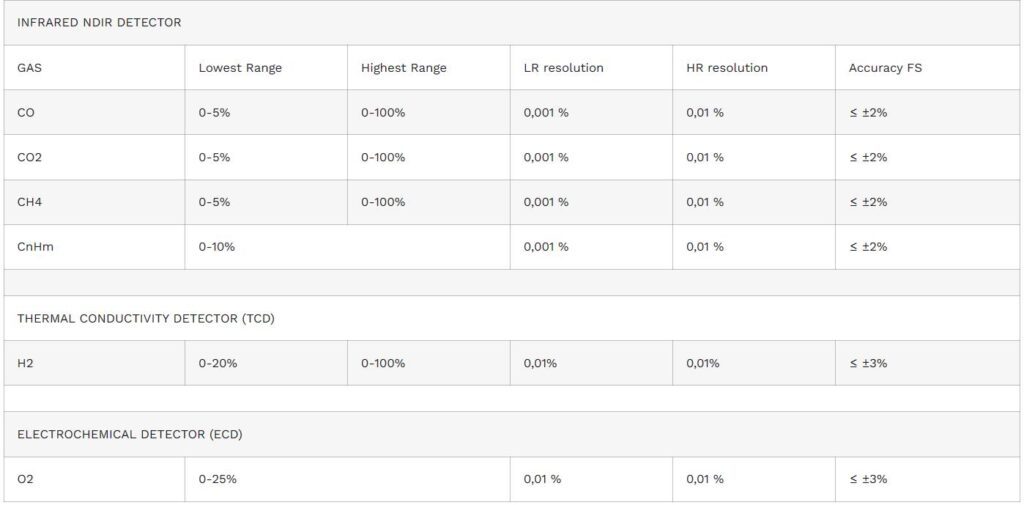

Specifications:

Conclusion

Biomass gasification technology offers huge potential for clean energy, but to realize its full utilization, the gases generated during the production process must be accurately analyzed and controlled. Selecting a gas analyzer that suits the application needs is a critical step in achieving this goal. Different types of gas analyzers have their own advantages and limitations, so application needs, budget, and environmental conditions need to be carefully considered when selecting an instrument. With the proper selection and use of gas analyzers, biomass gasification can become a strong supporter of sustainable clean energy and make a positive contribution to our environment and future. Feel free to ask us questions about gas analyzers and we will provide professional answers!