In modern industry, environmental monitoring, and scientific research, accurate measurement of gas flow rate is crucial. As an advanced gas flow measurement device, an ultrasonic flowmeter has gradually become the preferred tool for gas flow rate detection due to its non-contact, high-precision, and low-pressure loss characteristics. This BLOG will discuss in detail the working principle, application field, technical advantages, challenges, and future development trends of ultrasonic flowmeters in gas detection.

Working Principle of Ultrasonic Flow Meter

Ultrasonic flow meters measure the flow rate of gas through the propagation characteristics of ultrasonic waves in gas. There are two common measurement methods: the time difference method and the Doppler effect method.

1. Time difference method

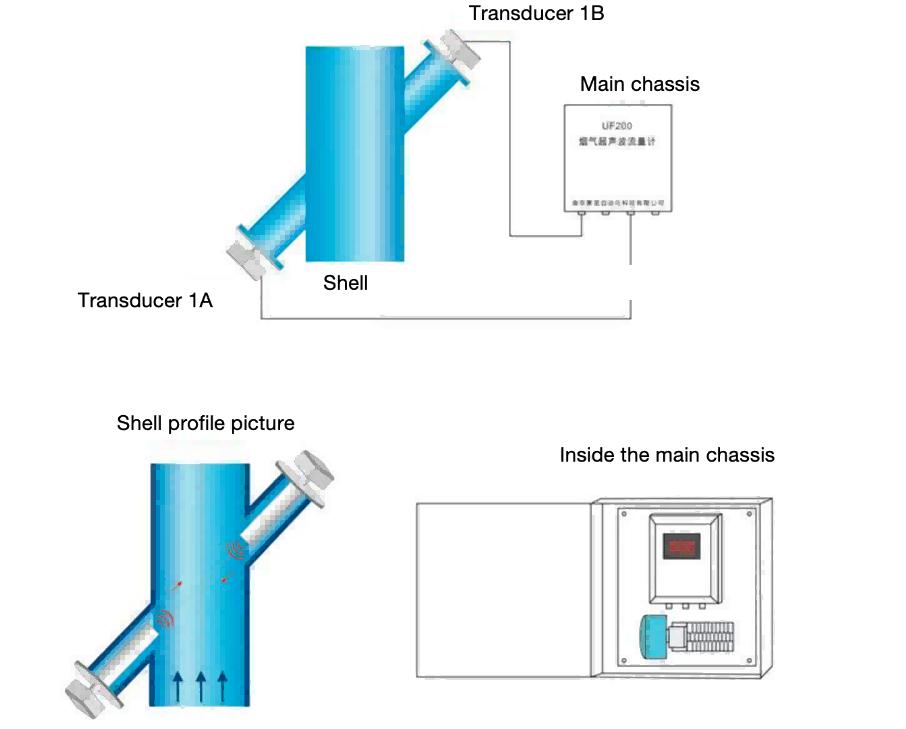

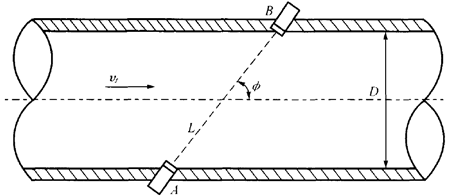

The time difference method is one of the most commonly used measurement methods in ultrasonic flow meters. This method calculates the flow rate based on the difference in the time it takes for ultrasonic waves to propagate downstream and upstream in the gas. Ultrasonic flow meters usually install two ultrasonic probes on both sides of the pipe, one upstream and the other downstream. When the gas flows, the ultrasonic wave in the downstream direction will propagate faster than in the upstream direction. By measuring the difference in these two propagation times, the flow meter can accurately calculate the flow rate of the gas. This is also the working principle of the ESE-LEUF-200 ultrasonic flow meter.

The transmit/receive probe consists of a piezoelectric ultrasonic generator and a receiver. The acoustic pulse and the direction of gas flow from the angle α, and the ultrasonic and gas flow direction countercurrent and downstream transmission time is determined by the angle α and the gas flow velocity v, the larger the difference between the ultrasonic transmission time, the faster the gas flow rate, temperature, and pressure fluctuations can cause the ultrasonic propagation speed changes, but in this measurement method, does not affect the calculation of the gas flow rate.

The Ultrasonic Flow Meter for Flue Gas Application measures the flow rate of gases discharged from ducts, flues, exhaust gases, and flues; it can be used in both pure and raw gases; i.e. in closed circuits as well as in open gas circuits.

2. Doppler effect method

The Doppler effect method measures flow velocity based on the change in the reflected frequency of ultrasound in flowing gas. When ultrasound encounters tiny particles or bubbles in the gas, a frequency shift occurs, and this frequency change is proportional to the gas flow rate. By detecting the change in frequency, the ultrasonic flow meter can accurately measure the flow rate of the gas. The Doppler effect method is particularly suitable for measuring gas fluids containing suspended particles or bubbles.

Application Fields of Ultrasonic Flowmeter in Gas Detection

Ultrasonic flowmeters are widely used in a variety of gas detection scenarios due to their excellent performance. The following are several major application areas:

Oil and Gas Industry

In the oil and gas industry, accurate measurement of gas flow rate is essential to ensure production efficiency and safety. Ultrasonic flowmeters can be used to measure natural gas, refinery gas, gas fuel, etc. Its non-contact measurement feature ensures that the gas is not disturbed during the measurement process. At the same time, ultrasonic flowmeters can work stably in harsh environments such as high pressure, high temperature, and corrosive gas, so they are widely used in the oil and gas field.

Environmental monitoring and emission control

As global environmental regulations become increasingly stringent, the monitoring of industrial exhaust gases has become particularly important. Ultrasonic flow meters play a key role in detecting the exhaust gas flow rate in chimneys and exhaust ducts, helping companies to effectively control emissions to meet environmental protection requirements. In addition, ultrasonic flow meters can also be used to measure wind speed and airflow changes in the atmosphere, providing accurate data for meteorological research and environmental monitoring.

Aerodynamics and wind tunnel testing

In aerodynamic research and wind tunnel testing, the measurement of air velocity is an important part of evaluating the aerodynamic characteristics of aircraft, cars, and buildings. Ultrasonic flow meters can accurately measure the air velocity and distribution at different locations in the wind tunnel without disturbing the airflow, providing reliable data for design and optimization. In addition, the high precision and high resolution of ultrasonic flow meters make them more and more widely used in wind tunnel experiments.

Medical equipment and respiratory monitoring

Ultrasonic flowmeters are increasingly used in the medical field, especially in respiratory monitoring and anesthesia equipment, where they are used to measure the flow rate and volume of a patient’s respiratory gas. Their non-invasive measurement features enable real-time monitoring and provide accurate respiratory parameters, providing an important reference for doctors’ diagnosis and treatment. In addition, the portability and ease of operation of ultrasonic flowmeters make them widely used in various medical environments.

Industrial process control

In many industrial process controls, accurate measurement of gas flow rate is crucial. For example, in chemical production, the gas flow rate directly affects the reaction process’s efficiency and the product’s quality. Ultrasonic flow meters can provide real-time and accurate gas flow rate data to help engineers optimize process parameters and ensure the stability and efficiency of the production process. In addition, ultrasonic flow meters can also be used in processes such as combustion control, gas mixing, and gas separation to improve the accuracy and response speed of process control.

Technical Advantages of ESE-LEUF-200 Ultrasonic Flow Meter

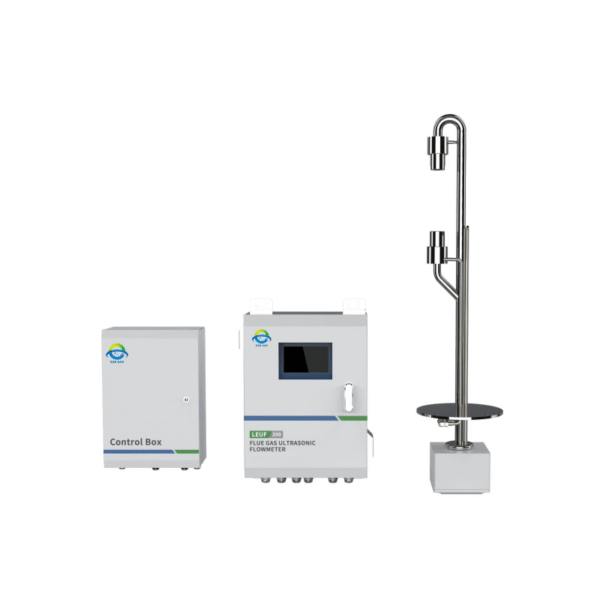

Ultrasonic Flow Meter LEUF-200

Introduction ESEGAS Ultrasonic Flow Meter LEUF-200 for Flue Gas Application is to measure the flow rate of the gas; it can also calculate and output the volumeflow rate according to the flow rate and the flue size; if you input the temperature and pressure of the flue gas, you can calculate the flow rate under…

1. Non-contact measurement

Ultrasonic flowmeters use a non-contact measurement method, and the probe does not need to directly contact the gas, which avoids the risk of contamination and corrosion. This feature makes ultrasonic flowmeters particularly suitable for measuring gases that are highly corrosive, flammable, explosive, or contain particulate matter.

2. High precision and low-pressure loss

Ultrasonic flowmeters can provide high-precision gas flow measurement, especially in low flow rates and large-diameter pipes, and can still maintain excellent measurement accuracy. In addition, since the measurement process of ultrasonic flowmeters does not cause airflow disturbances or pressure loss, the stability of gas flow is ensured.

3. Wide range of applications

Ultrasonic flowmeters are suitable for various gas media, including air, natural gas, hydrogen, oxygen, nitrogen, etc. Whether in high-temperature and high-pressure industrial environments or low-temperature and low-pressure laboratory conditions, ultrasonic flowmeters can provide stable and reliable measurement results.

4. Easy to install and maintain

The installation process of the ultrasonic flow meter is very simple, especially the external clamp probe, which can be directly installed on the outer wall of the pipe without cutting the pipe or interrupting the gas flow. In addition, the ultrasonic flow meter has no mechanical moving parts, a low failure rate, and a low daily maintenance cost.

5. Real-time monitoring and data analysis

Modern ultrasonic flow meters usually have digital signal processors that can analyze measurement data in real time and transmit it to the control system wirelessly or wired. This real-time monitoring capability makes ultrasonic flow meters widely used in industrial automation and process control.

6.Temperature can be measured at the same time as the flow rate

Our technology enables the simultaneous measurement of gas flow rate and temperature.

| Technical advantages | illustrate |

| Non-contact measurement | The probe does not come into direct contact with the gas, thus avoiding contamination and corrosion, and is suitable for highly corrosive or flammable and explosive gases. |

| High precision and low-pressure loss | Provides high-precision gas flow rate measurement without causing gas flow disturbances or pressure loss. |

| Wide range of applications | Applicable to various gas media, such as air, natural gas, hydrogen, oxygen, etc. |

| Easy installation and maintenance | The clamp-on probe is easy to install without cutting the pipe and has low daily maintenance costs. |

| Real-time monitoring and data analysis | Equipped with a digital signal processor, it analyzes and transmits measurement data in real-time and is widely used in industrial automation and process control. |

| Temperature can be measured at the same time as the flow rate | Our technology enables the simultaneous measurement of gas flow rate and temperature. |

Product site installation pictures

Challenges and Solutions of Ultrasonic Flowmeter in Gas Detection

Although ultrasonic flowmeters have many advantages, they still face some challenges in gas flow detection. For example, in the measurement of low-pressure or rarefied gas, due to the low gas density, the attenuation of ultrasonic signals is large, which may affect the measurement accuracy. In addition, for gas flows containing a large number of suspended particles or bubbles, the propagation path and reflection characteristics of ultrasonic signals become complicated, thereby increasing the uncertainty of measurement.

To meet these challenges, researchers and engineers are constantly improving the design and algorithms of ultrasonic flowmeters. For example, by using higher frequency ultrasonic signals, the measurement accuracy in low-density gases can be improved; by optimizing the signal processing algorithm in the Doppler effect method, noise can be filtered more effectively and the signal stability can be enhanced. In addition, ultrasonic flowmeters with integrated temperature and pressure sensors can also compensate for changes in gas parameters and improve measurement accuracy.

Future Development Trends of Ultrasonic Flow Meter in Gas Detection

With the advancement of science and technology and the increase in industrial demand, the application of ultrasonic flowmeters in gas detection will continue to expand and show the following development trends:

1. Intelligence and Automation

In the future, ultrasonic flowmeters will be more intelligent, automatically adapt to different gas media and working conditions, and realize self-calibration, self-diagnosis, and other functions. In addition, ultrasonic flowmeters will be combined with the Industrial Internet and the Internet of Things to become part of smart factories and smart cities, providing comprehensive gas flow monitoring and management solutions.

2. Multifunctional integration

With the development of sensor technology, ultrasonic flowmeters will gradually develop towards multifunctional integration. In the future, ultrasonic flowmeters can not only measure the flow rate of gas but also monitor gas temperature, pressure, humidity, and other parameters at the same time, providing users with more comprehensive gas monitoring data.

3. Miniaturization and portability

With the advancement of microelectronics technology, ultrasonic flow meters will become more miniaturized and portable. This will enable ultrasonic flow meters to be used in more scenarios, such as mobile monitoring, on-site detection, etc. In addition, miniaturized ultrasonic flow meters will also be more suitable for measurement needs in small spaces or special environments.

4. Environmental protection and sustainable development

In the future, ultrasonic flowmeters will make more contributions to environmental protection and sustainable development. The production and use process will be more energy-saving and environmentally friendly, and the selection of materials will pay more attention to recyclability and low carbon emissions. This will help users achieve accurate measurements while reducing negative impacts on the environment.

Conclusion

Ultrasonic flowmeters have become an important tool in the field of gas flow rate detection due to their unique technical advantages. In the future, with the development of trends such as intelligence, multi-functional integration, miniaturization and environmental protection, ultrasonic flowmeters will continue to play an irreplaceable role and provide more accurate, efficient and environmentally friendly gas flow rate measurement solutions for various industries. In this process, the technological innovation of ultrasonic flowmeters will further promote the development of gas detection technology, help realize Industry 4.0 and intelligent manufacturing, and contribute to environmental protection and sustainable development.