As the global climate change problem becomes increasingly serious, countries have set goals to reduce greenhouse gas emissions in order to achieve the vision of carbon neutrality. Hydrogen energy, as a clean and efficient energy source, has become an important driving force for energy transformation. In this blog, gas analyzers play a vital role, providing precise monitoring and control for the production, storage, and utilization of hydrogen energy, and ensuring the safety and efficiency of the entire industry chain.

The Rise of Hydrogen Energy in the Global Industry

Hydrogen energy is a secondary energy source, and its main sources include fossil fuel reforming, water electrolysis, industrial by-product hydrogen, etc. Since it only produces water after combustion and no greenhouse gas emissions such as carbon dioxide, hydrogen energy is regarded as one of the important means to solve the problem of climate change. The main sources of hydrogen energy include the following:(Image source: cityandstate)

- Hydrogen production by water electrolysis: Hydrogen and oxygen are produced by electrolysis of water, which is one of the main methods for producing green hydrogen.

- Fossil fuel reforming: using fossil fuels such as natural gas and oil to generate hydrogen and by-products through chemical reactions.

- Industrial by-product hydrogen: Some industrial processes, such as the chlor-alkali industry, produce hydrogen as a by-product, which can be utilized.

- Biomass hydrogen production: Hydrogen is produced through the thermochemical conversion of biomass or biochemical processes.

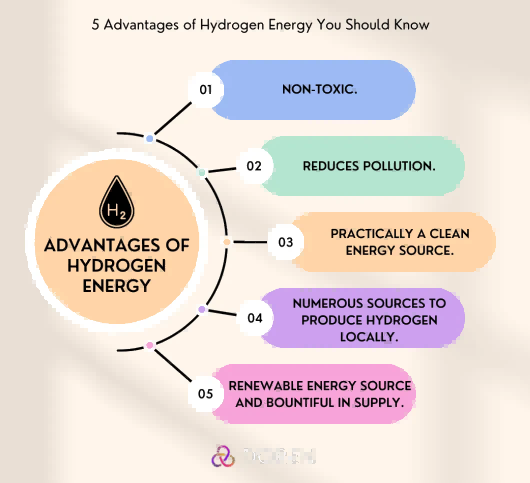

HydrogenmainAdvantagehave:(Image source: DoRen)

- Clean and environmentally friendly: Hydrogen only produces water after combustion, without any greenhouse gas emissions such as carbon dioxide, which helps reduce air pollution and address climate change.

- Efficient energy: Hydrogen energy has a high energy density, and the energy released per kilogram of hydrogen is much higher than traditional fossil fuels.

- Diversified applications: Hydrogen energy can be widely used in transportation, industry, power generation, energy storage, and other fields, and has broad application prospects.

- Renewable sources: Sustainable production of hydrogen can be achieved by electrolyzing water using renewable energy sources (such as wind and solar energy).

Hydrogen Energy Policies of Various Countries

In recent years, with the advancement of technology and policy support, the hydrogen energy industry has developed rapidly. Countries have introduced relevant policies to increase the research development and promotion of hydrogen energy technology.

European Union

The EU released its Hydrogen Strategy in 2020, planning to achieve 40GW of green hydrogen electrolyzer installed capacity by 2030 and establish a comprehensive hydrogen economy by 2050. The EU’s hydrogen policy emphasizes hydrogen production from renewable energy, namely “green hydrogen”, to reduce carbon emissions.

Japan

Japan released the Basic Strategy for Hydrogen Energy in 2017, planning to achieve widespread use of hydrogen energy in transportation, households and industry by 2030. The Japanese government also supports the construction of hydrogen energy infrastructure, such as hydrogen refueling stations and hydrogen pipelines, to promote the realization of a hydrogen energy society.

South Korea

South Korea released the Hydrogen Economy Development Roadmap in 2020, planning to achieve large-scale popularization of hydrogen fuel cell vehicles (FCEVs) and build 1,200 hydrogen refueling stations by 2040. The South Korean government also supports the research and development and commercial application of hydrogen energy technology to promote the development of the hydrogen economy.

China

China has clearly stated in its 14th Five-Year Plan that it will vigorously develop hydrogen energy and fuel cell technology. The Chinese government actively promotes the construction of hydrogen energy infrastructure and supports the application of hydrogen energy in transportation, industry and other fields. China has also increased investment in the research and development of hydrogen energy technology and encouraged enterprises to innovate and develop.

In the hydrogen energy industry, the application of gas analyzers runs through all links such as production, storage, transportation, and application. Accurate gas monitoring and analysis can not only improve the efficiency of hydrogen energy production, but also ensure the safety and stability of the entire industry chain. The following is a detailed description of the specific application of gas analyzers in the hydrogen energy industry.

Gas Analysis in Hydrogen Production

1. Hydrogen production by water electrolysis

Hydrogen production by water electrolysis is one of the important ways to produce green hydrogen energy. In this process, the gas composition in the electrolyzer needs to be monitored in real-time to ensure the purity and production efficiency of hydrogen. Applications of gas analyzers include:

- Hydrogen and oxygen concentration monitoring: The electrolyzer produces hydrogen and oxygen by electrolyzing water. The gas analyzer can detect the concentration of hydrogen and oxygen in real-time to ensure the normal progress of the electrolysis process. By monitoring the gas composition, problems in the electrolyzer can be discovered and solved in time, and the electrolysis process can be optimized.

- Impurity detection: Impurities (such as nitrogen, carbon dioxide, etc.) may be generated during the electrolysis process. The gas analyzer can detect and quantify the content of these impurities to ensure that the purity of the produced hydrogen meets the requirements.

2. Hydrogen production from fossil fuel reforming

Fossil fuel reforming is one of the main ways to produce hydrogen. The process involves complex chemical reactions that require precise control of reaction conditions. Applications of gas analyzers include:

- Reaction gas monitoring: During the natural gas reforming process, the gas analyzer can monitor the concentration of carbon monoxide, carbon dioxide, hydrogen, and other components in the reactor to ensure the efficient progress of the reaction.

- By-product detection: By-products are produced during the reforming of fossil fuels. Gas analyzers can detect the content of these by-products, help optimize reaction conditions, reduce by-product generation, and increase hydrogen yield.

3. Hydrogen purity detection

The purity of hydrogen has an important impact on its application effect, especially in hydrogen fuel cells and industrial hydrogen. The application of gas analyzers in hydrogen purity detection includes:

- Detection of impurities in hydrogen: Hydrogen may contain a variety of impurities, such as nitrogen, oxygen, carbon monoxide, methane, etc. These impurities will affect the purity and use of hydrogen. The gas analyzer can accurately detect the impurity content in hydrogen to ensure that the purity of hydrogen meets the application requirements.

- Quality Control: During the hydrogen production process, gas analyzers can be used for quality control to ensure the purity and consistency of each batch of hydrogen. High-purity hydrogen helps improve the efficiency and life of fuel cells and reduce byproducts and pollution in industrial processes.

Gas Monitoring in Hydrogen Storage and Transportation

Hydrogen is highly flammable, and safety during its storage and transportation is of vital importance. Applications of gas analyzers in hydrogen storage and transportation include:

1. Hydrogen storage

- Storage tank gas monitoring: During high-pressure gaseous hydrogen storage and cryogenic liquid hydrogen storage, the gas analyzer can monitor the hydrogen concentration in the storage tank in real-time to ensure the safety of the storage tank. By monitoring the pressure and concentration of hydrogen, leaks, and other potential risks can be discovered promptly.

- Environmental monitoring: Monitoring the hydrogen concentration in the environment around the hydrogen storage facility is also an important safety measure. Gas analyzers can detect the hydrogen content in the ambient air, prevent potential leakage risks, and ensure the safety of storage facilities.

2. Hydrogen transportation

- Pipeline gas monitoring: When hydrogen is transported through a pipeline, the gas analyzer can monitor the pressure and concentration of the gas in the pipeline in real-time to ensure the safe operation of the pipeline. By monitoring the gas composition in the pipeline, leakage problems can be discovered and handled promptly to ensure transportation safety.

- Transport container monitoring: During hydrogen transportation, the gas analyzer can monitor the hydrogen concentration and impurity content in the transport container to ensure the purity and safety of hydrogen during transportation.

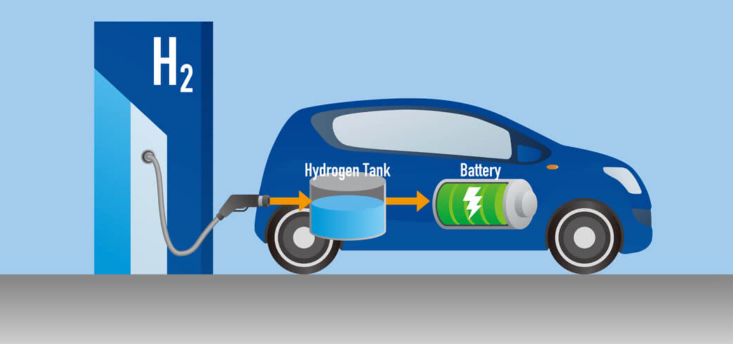

Application of Hydrogen in Transportation

Hydrogen fuel cell vehicles (FCEV) are an important application of hydrogen energy in the transportation field, especially in long-distance transportation and heavy-duty vehicles. FCEV has extremely high requirements for the purity of hydrogen and the safety of the gas supply system. Gas analyzers play a key role in the production, testing and application of hydrogen fuel cells.

1. Fuel cell production

Stack gas analysis: During the production of fuel cell stacks, gas analyzers can detect the gas composition in the stack to ensure the optimization of reaction conditions. By monitoring the concentration of hydrogen and oxygen, the efficiency and stability of the stack can be improved.

Impurity detection: Impurities (such as carbon monoxide, methane, etc.) that may be introduced during the production process will affect the performance of the fuel cell. Gas analyzers can detect and quantify these impurities to ensure a pure environment during the production process.

2. Fuel cell vehicle operation

Fuel quality monitoring: During the operation of a fuel cell vehicle, a gas analyzer can monitor the purity and pressure of hydrogen in real time to ensure efficient operation of the fuel cell. By monitoring the quality of hydrogen, the performance and range of the vehicle can be improved.

Emission monitoring: Although the main emission of fuel cell vehicles is water, there may be trace amounts of other gases emitted during actual operation. Gas analyzers can detect the composition of emissions to ensure the environmental performance of the vehicle.

Gas Analysis in Hydrogen Energy Infrastructure Construction

1. Hydrogen refueling station

Hydrogen refueling stations are an important part of hydrogen energy infrastructure, and their safe operation depends on accurate gas monitoring. The applications of gas analyzers in hydrogen refueling stations include:

Hydrogen concentration monitoring: Hydrogen concentration monitoring in hydrogen refueling stations is the key to ensuring safe operation. Gas analyzers can detect the hydrogen concentration in hydrogen refueling stations in real time to prevent leakage and explosion risks.

Hydrogen purity detection: The purity of hydrogen supplied by the hydrogen refueling station has an important impact on the performance of hydrogen fuel cell vehicles. The gas analyzer can detect the purity of hydrogen to ensure the quality of gas supply.

2. Hydrogen pipeline

Hydrogen pipelines are the main mode of large-scale hydrogen transportation. The safe operation of the pipeline requires real-time monitoring of the pressure and concentration of the gas in the pipeline. The applications of gas analyzers in hydrogen pipelines include:

Gas composition monitoring in pipelines: Gas analyzers can detect the hydrogen and impurity content in hydrogen pipelines to ensure pipeline integrity and transmission efficiency. By monitoring the gas composition in pipelines, leakage problems can be discovered and handled in a timely manner.

Leak detection and early warning: Leak detection of hydrogen pipelines is an important measure to ensure safety. Gas analyzers can provide highly sensitive and fast-response leak detection, timely early warning and processing, and ensure the safe operation of hydrogen pipelines.

The application of gas analyzers in the hydrogen energy industry is a key technical means to ensure the safety and efficiency of hydrogen production, storage, transportation and application. From gas composition monitoring and hydrogen purity testing in the hydrogen production process to safety monitoring in hydrogen storage and transportation, as well as the application of hydrogen in transportation, gas analyzers provide accurate and real-time gas analysis and control, ensuring every link in the hydrogen energy industry chain. With the continuous development of hydrogen energy technology and the expansion of its application, gas analyzers will continue to play an important role and provide solid technical support for the safe and efficient use of hydrogen energy.

Challenges of Hydrogen Energy Development

- Cost of production

Despite the continuous progress of hydrogen energy technology, the production cost of green hydrogen is still high. Reducing the energy consumption of water electrolysis and increasing hydrogen production are the current research focuses. Gas analyzers can help reduce the cost of hydrogen production by optimizing the production process and providing accurate gas monitoring data.

- infrastructure

The widespread application of hydrogen energy requires perfect infrastructure support. At present, the number of hydrogen refueling stations and hydrogen pipelines in the world is still limited, which restricts the market development of hydrogen energy. Gas analyzers play an important role in infrastructure construction, ensuring the safety and efficiency of each link and providing guarantee for the expansion of the hydrogen energy industry.

- Technical Standardization

The hydrogen energy industry involves multiple links and requires unified technical standards and safety specifications. While promoting the development of hydrogen energy, countries are also actively formulating relevant standards. The standardization of gas analysis technology helps to improve the accuracy and comparability of monitoring data and promote international cooperation and technical exchanges.

Hydrogen(H2) Gas Analyzer

Our ESE-IR-600 model H2 gas analyzer can be used to accurately measure hydrogen in five-gas mixtures .In most of industry, the gas mixture inlcuding oxygen, carbon monoxide, carbon dioxide, methane, and hydrogen (O2 / CO / CO2 / CH4 / H2). Our measurement/correction methodology is designed to ensure that gas analyzers are equipped with the correct settings to accurately calculate hydrogen concentrations within the gas mixture.

Applications for Hydrogen(H2) Gas Analyzer

- Hydrogen production and purity

- Syngas & gasification

- Pyrolysis

- Steel-making

- Power generation

- Metal heat-treating

TCD (Thermal Conductivity Detector) technology is another commonly used sensing technology in hydrogen gas analyzers, including those designed for hydrogen gas analysis. In a TCD-based hydrogen gas analyzer, the principle of operation is based on the thermal conductivity difference between hydrogen and other gases present in the sample. The TCD consists of two temperature-sensitive elements, typically made of platinum or tungsten wire, which are heated to a constant temperature. One element is exposed to the reference gas (usually air or an inert gas), while the other is exposed to the sample gas containing hydrogen. When the sample gas flows through the TCD, the thermal conductivity of the reference gas remains constant, while the thermal conductivity of the sample gas changes due to the presence of hydrogen. The difference in thermal conductivity between the reference and sample gases causes a temperature imbalance between the two elements of the TCD. This temperature difference is measured and converted into an electrical signal, which is then correlated with the hydrogen concentration in the sample gas. TCD-based hydrogen gas analyzers offer several advantages:

- High Sensitivity: TCD technology provides high sensitivity to hydrogen gas, allowing for accurate and precise measurements even at low concentrations.

- Wide Measurement Range: TCD-based analyzers can measure a wide range of hydrogen concentrations, from trace levels to high percentages.

- Fast Response Time: TCD sensors offer fast response times, enabling real-time monitoring and detection of changes in hydrogen concentration.

- Selectivity: TCD technology is relatively selective to hydrogen and can distinguish it from other gases present in the sample.

- Robust and Reliable: TCD sensors have a simple design with no moving parts, making them robust and reliable. They can withstand harsh operating conditions and require minimal maintenance.

TCD technology is widely used in various applications where accurate and reliable measurement of hydrogen gas concentrations is required, including hydrogen production, storage, and distribution, fuel cell systems, industrial processes, and hydrogen safety monitoring.

| Specifications | |||||

| GAS | Lowest Range | Highest Range | LR resolution | HR resolution | Accuracy FS |

| CO | 0-5% | 0-100% | 0,001 % | 0,01 % | ≤ ±2% |

| CO2 | 0-5% | 0-100% | 0,001 % | 0,01 % | ≤ ±2% |

| CH4 | 0-5% | 0-100% | 0,001 % | 0,01 % | ≤ ±2% |

| CnHm | 0-10% | 0,001 % | 0,01 % | ≤ ±2% | |

| THERMAL CONDUCTIVITY DETECTOR (TCD) | |||||

| H2 | 0-20% | 0-100% | 0,01% | 0,01% | ≤ ±3% |

| ELECTROCHEMICAL DETECTOR (ECD) | |||||

| O2 | 0-25% | 0,01 % | 0,01 % | ≤ ±3% | |

Future Outlook

As an important part of future energy transformation, hydrogen energy has broad development prospects. With the increasing global demand for clean energy, the hydrogen energy industry is expected to achieve rapid growth in the next few decades. Continuous investment from governments and enterprises and continuous technological progress will promote the important position of hydrogen energy in the global energy system. Gas analysis technology will play a vital role in this process to ensure the safety and efficiency of hydrogen energy production and application.

As a key tool in the hydrogen energy industry chain, the application scope of gas analyzers is constantly expanding. From hydrogen production, purity testing to storage, transportation and terminal applications, gas analyzers provide accurate monitoring and control for every link. In the future, with the continuous innovation of hydrogen energy technology, the performance and functions of gas analyzers will be further improved, contributing to the realization of global energy transformation and sustainable development.

The combination of hydrogen energy and gas analysis will promote the advancement of clean energy technology and build a greener and safer energy future. Through continuous research and innovation, we can look forward to the arrival of a clean energy era with hydrogen energy as the core and gas analysis as the guarantee.

if you have questions, please contact us directly!