The risks of unmonitored emissions are growing—non-compliance means penalties, reputation loss, and environmental damage. Exhaust gas analyzer offers real-time, accurate solutions to track emissions from stationary sources.

Monitoring stationary pollution sources with an exhaust gas analyzer ensures precise emission tracking, regulatory compliance, and data-driven control for industrial operations.

For industries relying on combustion, merely knowing emissions exist isn’t enough. Understanding their composition, volume, and fluctuation is critical to avoid penalties and optimize processes. Keep reading to explore how monitoring technology bridges environmental responsibility with operational excellence.

What Are Stationary Pollution Sources, and Why Is Monitoring Them Crucial?

Unseen doesn’t mean safe—stationary sources continuously emit regulated pollutants.

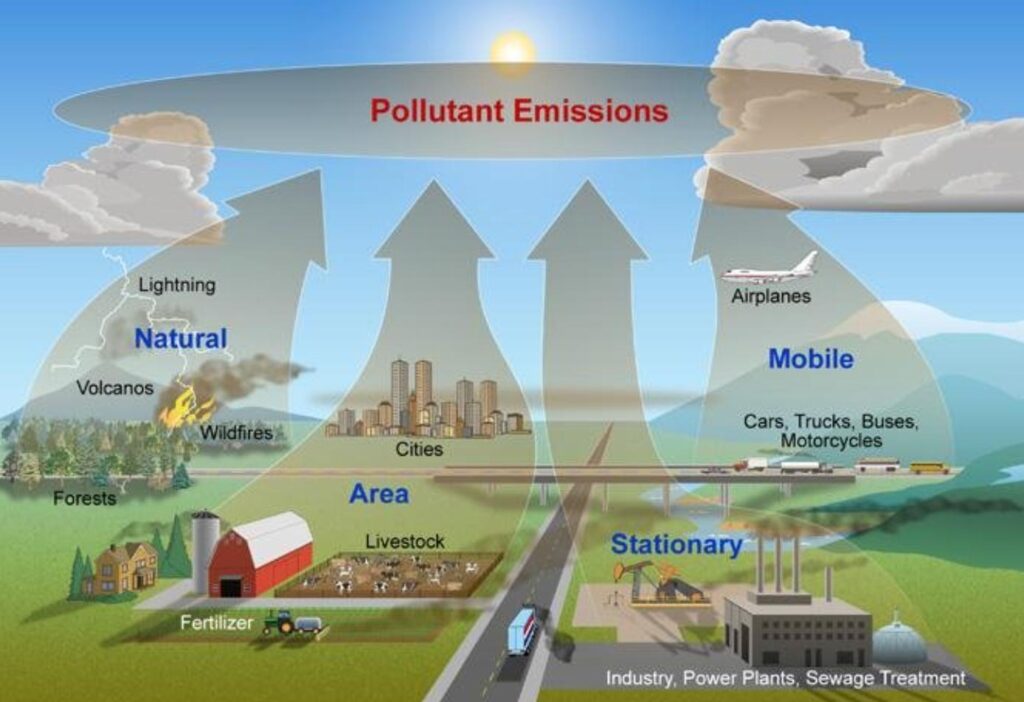

Stationary pollution sources refer to fixed sites that emit pollutants into the atmosphere as part of their operations. These include industrial facilities such as coal-fired power plants, cement manufacturing lines, waste incineration units, steel mills, and chemical refineries. Unlike mobile sources, these emitters release pollutants from specific, constant locations like stacks or flue outlets.

These emissions include nitrogen oxides (NOx), sulfur dioxide (SO₂), carbon monoxide (CO), volatile organic compounds (VOCs), particulate matter (PM), and other harmful gases. Without continuous monitoring, emissions can easily exceed legal thresholds, leading to environmental harm and regulatory violations. By tracking these sources consistently, operators can understand the performance of combustion processes and take timely action to minimize pollution and stay compliant.

What Role Does an Exhaust Gas Analyzer Play in Monitoring These Sources?

Real-time precision transforms monitoring into active control.

An exhaust gas analyzer plays a central role in any emission monitoring system by continuously measuring the concentration of key pollutants in exhaust gases. Installed directly within or downstream of the emission stack, it collects samples in real time and analyzes their chemical composition. This allows industrial facilities to detect and correct process deviations immediately.

The primary value lies in its ability to provide actionable data. For example, elevated CO levels may indicate incomplete combustion, while excessive NOx levels can point to high-temperature spikes. With reliable, continuous data, operators can fine-tune combustion parameters, reduce excess emissions, and optimize fuel usage—all while ensuring that emissions stay within legal limits.

Which Technologies Enhance Monitoring Efficiency in Exhaust Gas Analyzers?

Not all analyzers are equal—technology defines performance.

Modern exhaust gas analyzers are equipped with a variety of analytical techniques, each tailored to specific monitoring needs and gas types. The most common technologies include:

- Non-Dispersive Infrared (NDIR): Ideal for detecting CO, CO₂, and hydrocarbons. It operates by measuring the absorption of infrared light by gas molecules, providing high accuracy and stability.

- Chemiluminescence Detection (CLD): Specially used for NO and NO₂ measurements. It relies on the light emitted during the reaction between NO and ozone, making it highly sensitive to low concentrations.

- Ultraviolet Fluorescence (UVF): Used for SO₂ detection by analyzing the fluorescent light emitted by SO₂ molecules under UV excitation.

- Paramagnetic/Oxygen Sensors: These measure oxygen content based on the magnetic properties of oxygen molecules, crucial for combustion control.

- Fourier Transform Infrared (FTIR): A versatile method capable of analyzing multiple gas species simultaneously.

These technologies ensure that monitoring remains accurate even in high-dust, high-moisture, or high-temperature environments. Some analyzers are even equipped with automatic calibration systems and self-diagnostics to minimize maintenance and ensure long-term performance.

How Do Exhaust Gas Analyzers Support Regulatory Compliance?

Non-compliance costs—monitoring protects reputation and bottom line.

Government regulations around the world have made continuous emissions monitoring a legal requirement for many industries. For example, China’s “Pollutant Discharge Permit” system and national CEMS (Continuous Emission Monitoring Systems) guidelines require real-time data reporting. Similarly, the US EPA mandates 40 CFR Part 60/75 compliance for air emissions, and the EU’s IED (Industrial Emissions Directive) sets strict monitoring standards.

An exhaust gas analyzer forms the heart of any compliant CEMS installation. It delivers validated and traceable emissions data that is essential for official reporting and auditing. Many analyzers also support automatic data logging, encrypted transmission, and integration with environmental databases, which streamlines compliance documentation.

More importantly, these analyzers help companies take a proactive approach—identifying potential non-compliance risks before they escalate. This not only avoids fines and production halts but also enhances corporate social responsibility and brand reputation in environmentally conscious markets.

How to Choose the Right Exhaust Gas Analyzer for Different Stationary Sources?

One size doesn’t fit all—customization ensures effectiveness.

Different industries and emission processes require specific analyzer configurations. For instance, power generation plants typically require analyzers that can withstand high flue gas temperatures and handle high dust loads. Cement kilns often need equipment resistant to corrosive gases and particulate buildup. Chemical and pharmaceutical plants may prioritize precision in low-concentration VOC measurement.

When selecting an exhaust gas analyzer, factors to consider include:

- Target gas types and concentration ranges

- Operating temperature and humidity conditions

- Sampling method (in-situ vs extractive)

- Calibration requirements and frequency

- Maintenance accessibility and cost of ownership

In some applications, portable analyzers may also be used for spot-checks or validation, but for regulatory monitoring, a fixed, integrated solution is recommended. Ultimately, aligning analyzer capabilities with process requirements ensures longevity, accuracy, and efficiency.

How Does Remote Monitoring Enhance Emission Management?

Connected systems mean smarter decisions.

The industrial Internet of Things (IIoT) has transformed how emissions are managed. Today’s exhaust gas analyzersoften come with built-in data connectivity features, allowing real-time transmission of emissions data to centralized control rooms or cloud platforms.

This enables plant managers and environmental officers to monitor emissions trends, identify anomalies, and implement corrective actions instantly—even from offsite locations. In addition to real-time alerts, advanced systems support predictive analytics, helping detect sensor drift, calibration needs, or mechanical issues before they cause data gaps.

Remote monitoring also simplifies regulatory reporting by automating data formatting and submission to environmental authorities. This reduces the administrative burden while increasing transparency and accountability across multi-site operations.

Conclusion

Exhaust gas analyzers are indispensable tools for modern emission control. They provide accurate, real-time data that ensures regulatory compliance, protects the environment, and improves process efficiency across all types of stationary pollution sources. Their integration with advanced technologies and remote systems marks a new era in intelligent environmental management.