Industrial regulators around the world push for ultra-low emissions, often below 100 mg/m³ or low ppm levels for key pollutants like SO₂ and NO. Facilities must prove compliance 24/7 with data that meets tight accuracy requirements. When emissions fall into these low ranges, many traditional analyzers start to lose signal clarity and struggle to provide consistent data.

At these low concentrations, operators need instruments that deliver reliable, continuous, and high-accuracy monitoring. That means stable baselines, minimal drift over time, and strong resistance to interference from moisture, dust, and other flue gas constituents. Many legacy technologies—including basic NDIR analyzers—are optimized for higher pollutant levels and often require frequent calibration or complex interference corrections to keep readings within compliance.

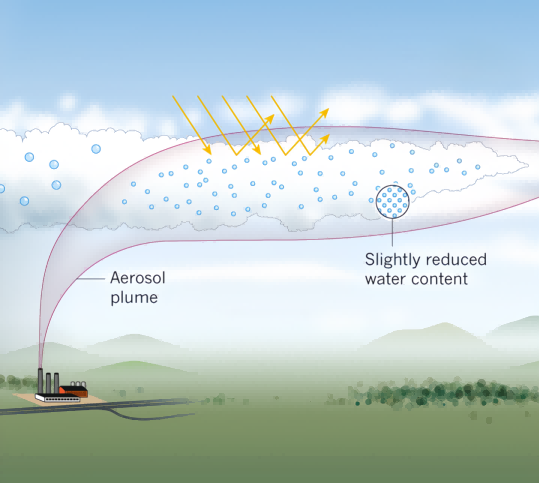

UV-DOAS gas analyzers answer this challenge head-on. Using ultraviolet differential optical absorption spectroscopy, they detect unique absorption features of target gases with high sensitivity and selectivity even at low plume concentrations. This makes them better suited to meet strict environmental requirements while delivering trustworthy data around the clock without frequent manual adjustments.

In short, when your goal is accurate, stable, and regulator-ready monitoring of low-level plumes, UV-DOAS gas analyzers outperform traditional options in real-world industrial applications—and that’s why many engineers choose them for critical emission compliance work.

What Makes UV-DOAS Gas Analyzer Unique in Low-Level Plume Monitoring?

At its core, a UV-DOAS gas analyzer measures gas concentrations by tracking how ultraviolet (UV) light is absorbed by molecules in a gas stream. When UV light passes through a plume, specific gases absorb unique wavelengths of that light. By analyzing how much light is absorbed at each wavelength, the system calculates real-time concentrations using principles like the Beer-Lambert Law, which links light absorption to molecular concentration. This method gives fast, accurate results for gases such as SO₂, NOx, and ozone even at low levels.

What really sets UV-DOAS apart is its differential spectral fitting. Instead of looking at absorption at a single wavelength, it measures absorption patterns across many wavelengths. The analyzer then matches these patterns to known spectral fingerprints of target gases. This approach boosts selectivity and cuts down signals from interfering components in the gas.

In contrast, many traditional gas analyzers like NDIR (Non-Dispersive Infrared) focus on broad infrared absorption bands. While effective for certain gases, NDIR can struggle to distinguish overlapping signals when multiple species are present or when concentrations drop into the low ppm range. UV-DOAS’s multi-wavelength fitting gives clearer separation of gas signatures and more reliable results in complex industrial stacks.

Because of these differences, a UV-DOAS gas analyzer excels in situations where precise, interference-resistant detection matters most. Its spectral fitting and wide detection range make it ideal for continuous, low-level plume monitoring under strict regulatory limits.

What Core Advantages Does a UV-DOAS Gas Analyzer Offer for Low-Level Plume Monitoring?

When emissions fall into the ultra-low range, such as below 50–100 mg/m³, conventional analyzers often struggle to separate real signal from background noise. A UV-DOAS gas analyzer, by contrast, delivers measurement performance built for this challenge. Its strengths span from fundamental detection mechanics to real-world field resilience, making it ideal for strict plume compliance monitoring.

High Sensitivity at Low Concentrations

UV-DOAS technology delivers strong signals even at ultra-low concentrations of gases like SO₂ and NO. With advanced designs, it can measure ranges down to tens of milligrams per cubic meter accurately, which is essential for regulatory compliance and plume trend analysis. This high sensitivity comes from deep UV absorption cross-sections that produce clear, measurable signals at low ppms. In plume monitoring, where small concentration shifts matter, this sensitivity lets you detect real changes instead of noise.

Superior Selectivity & Reduced Cross-Interference

Unlike some traditional analyzers, UV-DOAS separates overlapping gas signatures by fitting the full UV spectrum. This spectral fitting process ensures that similar-absorbing gases do not confuse the measurement. In real flue gas, components like water vapor, dust, and other constituents often distort readings from simpler IR methods. UV-DOAS’s spectral approach reduces these effects, enabling multi-gas detection (e.g., SO₂, NO, NO₂) without extra converters or complex hardware.

Enhanced Stability & Low Drift in Field Conditions

Drift—where readings shift over time without real gas changes—is a core challenge in low-level monitoring. UV-DOAS naturally mitigates many baseline shifts because it measures differential absorption rather than absolute intensity, so background effects cancel out. Moreover, many UV-DOAS systems include automatic baseline correction and compensation features. This means longer calibration intervals and fewer false readings in real industrial environments, improving day-to-day data reliability.

Real-Time, Continuous Monitoring Capability

A top requirement for plume monitoring is near real-time data. UV-DOAS analyzers operate continuously, with automated measurements and fast response times. This helps operators detect transient emission events and maintain up-to-date compliance records without periodic manual checks. In addition, these systems support remote diagnostics and seamless integration into environmental monitoring networks, making them practical for modern plant operations.

Environmental Resilience & Low Maintenance

Finally, UV-DOAS analyzers are built for tough field conditions. They lack moving optical parts, which reduces failure risk and maintenance needs. Their UV spectrum design also inherently limits interference from moisture and dust, common in industrial stacks. The long-life pulse UV light sources (e.g., xenon lamps with service life up to ~10 years) further cut operating costs and downtime.

In summary, the combination of ultra-low detection sensitivity, spectral selectivity, stability under real conditions, continuous operation, and rugged design makes the UV-DOAS gas analyzer an exceptional choice for low-level plume monitoring. These advantages help facilities meet the toughest standards while simplifying long-term operation and reducing risk.

How Is a UV-DOAS Gas Analyzer Used in Real-World Plume Monitoring?

In practice, the UV-DOAS gas analyzer isn’t just a lab tool—it’s a workhorse in demanding industrial settings where accurate plume readings matter. Its strengths in sensitivity, selectivity, and stability make it ideal for real-time emissions oversight, control optimization, and environmental reporting. Here, we explore the main ways facilities use this technology to turn raw data into better decisions and compliance outcomes.

First, industrial operators deploy UV-DOAS analyzers to meet strict emissions compliance requirements. In boilers, power plants, and waste incinerators, regulators often require continuous monitoring of trace pollutants like SO₂ and NOx. By delivering accurate measurements of these low-level gases in flue streams, UV-DOAS systems support compliance reporting with confidence. Real-time data helps avoid fines, prevent shutdowns, and document environmental stewardship.

Beyond compliance, facilities use UV-DOAS analyzers to optimize pollution control systems. For example, tracking emissions before and after scrubbers or selective catalytic reduction (SCR) units shows how well these devices perform under varying loads. UV-DOAS’s ability to measure NO and NO₂ directly, without converters, speeds up adjustments in reagent dosing and improves control loop responsiveness. This can reduce reagent costs and tighten emissions control.

Finally, many plants integrate UV-DOAS analyzers into continuous environmental reporting frameworks. By streaming 24/7 data to environmental management systems, analysts can generate historical trends, set automated alerts, and support audit-ready records. This continuous logging promotes greater transparency with regulators and stakeholders while enabling faster response to plume events or control system upsets.

Together, these use cases show how UV-DOAS gas analyzers go beyond measurement to become essential tools for compliance, process insight, and environmental accountability in modern emissions management.

Conclusion

In today’s emission-constrained world, operators need monitoring tools that perform reliably at trace levels. A UV-DOAS gas analyzer stands out because it brings together several core strengths in one package. First, it delivers high sensitivity, detecting gases like SO₂ and NOx even at ultra-low concentrations. It also offers excellent selectivity, separating overlapping gas signals by using multiple UV absorption bands rather than broad single-wavelength methods. On top of that, the technology offers stability and resilience in real industrial environments, with design features that reduce drift and support long calibration lifetimes, which matters when facilities must produce continuous, trustworthy data for regulators and stakeholders.

Equally important, UV-DOAS analyzers operate around the clock, providing real-time measurements with minimal maintenance. This continuous data flow supports timely decision-making, helps detect emission events early, and integrates smoothly into environmental management systems. When you combine these strengths—sensitivity, selectivity, stability, resilience, and continuous monitoring—you get a tool well-suited for the toughest plume monitoring challenges.

Therefore, for industrial sites that must maintain robust, accurate, and regulation-ready monitoring of low-level emissions, a UV-DOAS gas analyzer represents a technically sound and practical solution. If you want to know more, contact with us please!

FAQs

1. What is a UV-DOAS Gas Analyzer and how does it work?

A UV-DOAS gas analyzer measures gas concentration by shining ultraviolet light through a sample and detecting how much light different gases absorb. The analyzer uses the unique UV absorption patterns of target gases and applies differential spectral fitting to calculate real-time concentrations. This method supports high-accuracy detection even at ultra-low levels, making it suitable for plume monitoring.

2. Why choose a UV-DOAS Gas Analyzer for low-level plume monitoring?

UV-DOAS excels at detecting very low concentrations of pollutants such as SO₂, NO, and NO₂ with strong signal sensitivity and low interference. Its spectral fitting technique reduces cross-sensitivity from moisture or dust, enabling reliable multi-gas analysis without converters or complex hardware.

3. How low can a UV-DOAS Gas Analyzer measure pollutant concentrations?

Many UV DOAS analyzers achieve detection limits in the ultra-low range (e.g., tens of mg/m³ or better), which helps facilities reliably monitor emissions below strict regulatory thresholds. This capability is critical for compliance tracking and early detection of emission spikes.

4. Can a UV DOAS Gas Analyzer measure multiple gases at once?

Yes. UV DOAS analyzers can simultaneously measure several gases such as SO₂, NO, and NO₂ in one optical path without separate converters. This multi-component capability simplifies installation and reduces ongoing maintenance compared with single-gas analyzers.

5. Is UV-DOAS suitable for continuous, real-time monitoring?

Absolutely. UV-DOAS gas analyzer in CEMS systems operate 24/7 with automated measurements, fast response times, and remote diagnostics. This continuous monitoring supports regulatory compliance reporting and rapid detection of emission events.

6. How does UV-DOAS handle field-level environmental challenges like moisture and dust?

Because UV DOAS analyzes absorption patterns rather than absolute intensities, it inherently reduces the impact of moisture and dust on readings. The spectral approach also mitigates baseline drift, enhancing long term stability in complex industrial environments.