Process Gas Analyzer (Oil refinery)

Even slight emission deviations in a refinery can lead to major safety issues or regulatory penalties. Thus, downstream process gas analyzers are critical. They continuously monitor NOₓ, CO, H₂S, and CH₄, helping refinery plants stay within evolving global standards. These analyzers deliver accurate, second-by-second data—unlike traditional grab samples that are too slow.

Beyond checking regulations, the data helps engineers optimize performance. This includes fine-tuning combustion to reduce fuel loss, catching leaks early, and improving overall process efficiency. In high-pressure refining environments, real-time insight becomes both a control tool and a safety system.

Moreover, these analyzers support proactive decision-making. Engineers gain clarity into process dynamics and prevent small issues from becoming costly upsets. In this way, analyzers serve not just technical compliance, but also strategic optimization, empowering both program engineers and general technical audiences.

How Do Downstream Process Gas Analyzers Improve Emission Accuracy with TDLAS and NDIR?

Tunable Diode Laser Absorption Spectroscopy (TDLAS) and Non-Dispersive Infrared (NDIR) form the backbone of today’s downstream process gas analyzers. Each technology addresses distinct industrial needs.

TDLAS: Precision for Trace Gases

TDLAS leverages a tunable diode laser to scan specific absorption lines for gases like H₂S and CH₄. This laser-based method provides exceptional sensitivity—down to parts-per-billion levels—and rejects interference from other compounds. Measurements arrive in under a second, ideal for safety-critical zones such as flare stacks and sulfur recovery units where fast, accurate detection is non-negotiable. The ESE–LASER series, for example, delivers stable, high-resolution trace gas readings by combining long-path cells with lock-in amplification.

NDIR: Rugged and Cost-Effective

In contrast, NDIR technology measures gases such as CO and CH₄ through infrared absorption at fixed wavelengths. Though less sensitive than TDLAS, NDIR provides broad-range, robust measurements—often at lower cost and with minimal maintenance. It suits applications like fired heaters and flue gas monitoring, offering reliable gas concentration control over time.

Strategic Deployment in ESEGAS Instruments

ESEGAS combines both technologies to match specific applications:

- Use ESE-LASER series (TDLAS) for detecting ppb-level H₂S or CH₄ in sensitive zones.

- Use NDIR-based units in the ESEGAS for continuous monitoring of CO and hydrocarbon levels in combustion streams.

By integrating both technologies, operators benefit from both high precision and operational versatility. This ensures accurate, real-time emission monitoring—even across complex refinery zones.

What Are the Key Emission Hotspots in Downstream Refineries?

Pinpointing emission hotspots matters in refinery. It lets operators deploy the right downstream process gas analyzers in the right zones. Here are the four critical areas:

- Fired Heaters and Boilers

These high-temperature units generate NOₓ and CO during combustion. Monitoring here ensures complete burning and minimizes excess O₂ usage. This helps boost fuel efficiency and reduces pollutant formation such as prevents CO spikes and cuts fuel waste.

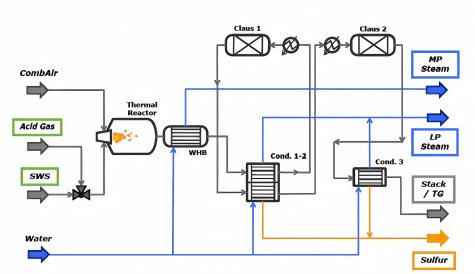

(Sulfur recovery units)

SRUs must remove H₂S efficiently. Incomplete removal can lead to toxic leaks or SO₂ emissions. TDLAS analyzers are ideal for this zone due to their trace-level detection and quick response.

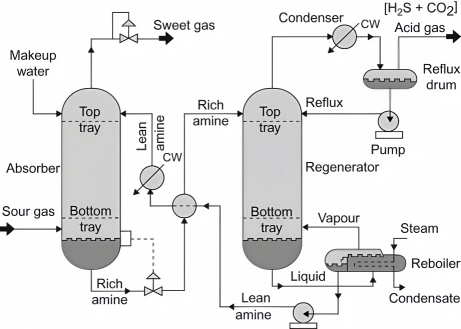

- Amine Treatment & Tail Gas Treatment Units (TGTUs)

(Amine system)

These units process acidic gases. They often emit residual CH₄ and H₂S. Real-time gas monitoring ensures process stability, supports environmental-health-safety compliance, and allows early detection of upset conditions.

(Flare stacks)

Flares handle variable gas compositions and high flows. Issues like incomplete combustion or poor mixing can lead to CH₄ slip and elevated CO or NOₓ emissions. Continuous monitoring supports combustion tuning and emission reduction strategies.

By matching analyzer type to hotspot zone—and combining that with robust sampling systems—refinery teams gain operational clarity, ensure environmental compliance, and optimize performance under tight controls.

How Can Downstream Process Gas Analyzers Improve Compliance and Safety?

(Safety)

Refineries now operate under tight global emission standards—from U.S. EPA rules to EU directives and China’s GB norms. Non-compliance can bring heavy fines, plant shutdowns, or even endanger lives. In this high-stakes setting, reliable instrumentation becomes more than support—it becomes essential.

Seamless Integration and Intelligent Design

Downstream process gas analyzers integrate smoothly with Distributed Control Systems (DCS), and they support industrial protocols like Modbus and Profibus. They also include scheduled calibration for long-term stability. As a result, your team spends less time on manual checks and enjoys higher uptime and fewer surprises.

Real-Time H₂S Detection with TDLAS

For example, installing the ESE-LASER-600 TDLAS analyzer on a Sulfur Recovery Unit (SRU) outlet delivers instant H₂S alerts. Operators can catch excursions in seconds rather than minutes, significantly reducing risk to personnel and community. This rapid trace-level detection is critical in safety-sensitive zones.

CO Control with NDIR in Heaters

Meanwhile, the ESEGAS NDIR analyzer delivers continuous CO readings from fired heaters. Early detection of CO spikes supports tighter combustion control, reduces fuel waste, and protects equipment from heat stress or soot damage. This proactive monitoring extends both compliance integrity and system life.

Building a Safety-First Culture

By embedding these analyzers into control logic and setting smart alert thresholds, your safety systems act before metrics become critical. This real-time monitoring serves as an early warning tool—improving risk management and operational confidence. Over time, it fosters a proactive culture focused on prevention, not reaction.

In short, ESEGAS downstream process gas analyzers deliver both compliance assurance and operational safety. They turn precise, automated monitoring into a strategic asset.

How Downstream Process Gas Analyzers Solve Sampling Challenges?

Accurate emissions control starts with preserving sample integrity. However, gas samples from refineries often degrade before reaching the downstream process gas analyzer. Moisture, particulates, temperature shifts, and liquid carryover can all distort readings. Without addressing these issues, measurement precision and system reliability suffer.

Common Sampling Risks

- Moisture condensation: When gas cools, water can condense and trap soluble gases like H₂S or CH₄.

- Particulate interference: Dust or mist fouls sensors, impairs flow, and triggers drifts or errors.

- Liquid carryover: Sour gas streams often contain amines, glycol, or oil droplets. These damage optics and skew readings.

How ESEGAS Designs Reliable Sampling

ESEGAS systems integrate smart conditioning features that preserve gas integrity throughout:

| Feature | Purposes |

| Heated sample lines | Keep gas above dew point to prevent condensation |

| Anti-condensation probes | Prevent droplets from forming near the inlet |

| PTFE moisture traps & filters | Remove liquid carryover before analyzers or optics get affected |

| Automatic blowback | Flush particulates and debris without interrupting sampling |

These measures ensure representative, clean gas reaches analyzers and avoid misreads linked to sampling faults.

The Value of Integrity

Maintaining clean, stable samples does more than protect analyzers—it ensures that emission readings reflect actual process conditions. With reliable sample delivery, engineers gain trusted data that supports control actions, assures compliance, and extends analyzer life.

In essence, mastering the sampling system is vital to leveraging downstream process gas analyzers effectively. It turns emission monitoring from guesswork into a dependable tool for optimization and safety.

How Do Downstream Process Gas Analyzers Enable Better Operational Decisions?

Emission data from downstream process gas analyzers isn’t just about compliance—it powers operational excellence. Engineers can turn raw gas measurements into strategic advantages across refinery operations.

Practical Ways Emission Data Drives Decisions

- Automatically trim NOₓ and O₂ levels in real-time through closed-loop feedback. This improves combustion efficiency and cuts pollutant formation while saving fuel.

- Prevent catalyst poisoning by flagging early H₂S or ammonia slip. This preserves catalyst life and avoids costly downtime.

- Detect flare inefficiencies by monitoring CH₄ spikes. Operators can then fine-tune flare combustion to reduce methane slip.

- Optimize energy use by identifying CO-rich zones in fired heaters. With this insight, you adjust burner settings for better heat transfer and fewer emissions.

Why Real-Time Analytics Matter

Many plants still depend on lab testing or grab-sample methods. These approaches lag actual events and restrict timely response. By contrast, online process gas analyzers deliver second-by-second visibility. With real-time dashboards and live feedback, operators respond swiftly to process changes.

From Data to Operational Intelligence

Integrating emission data with operational intelligence systems empowers higher-level decision-making. Platforms offer real-time dashboards, trend analysis, root-cause detection, and actionable alerts—all to preempt issues. For example, digital twins or advanced real-time optimizers can simulate scenarios and optimize operations before changes are applied.

What It Means for Engineers and Operators

- Labs measure historic data; process gas analyzers track live conditions.

- Control rooms gain clarity on combustion, flaring, and process stability.

- Every sensor point becomes a decision point—driving safer, cleaner, cost-effective refinery operations.

Ultimately, downstream process gas analyzers transform emission tracking into real-time situational awareness. They give program engineers and refinery leaders data they can act on—today, not later.

Conclusion

Regulations are tightening worldwide. Carbon accountability is growing. Refineries must deliver more—using less energy, emitting fewer pollutants, and minimizing risk. In this context, investing in robust downstream process gas analyzer is not optional; it’s strategic.

ESEGAS downstream process gas analyzers do more than report numbers—they offer visibility, safety, and control. They integrate with control systems, support scheduled calibration, and deliver fast, accurate data across NOₓ, CO, H₂S, and CH₄. That ensures compliance with global standards—from the U.S. EPA to EU and China GB regulations.

If you want to know more, contact with us please!