Inaccurate oxygen control can damage metal quality—especially in high-temperature metallurgy. Processes fluctuate fast, but a reliable oxygen analyzer offers real-time precision and process stability.

In the metallurgical industry, an oxygen analyzer plays a vital role in controlling oxygen concentration during smelting, refining, and combustion. Its accuracy directly impacts steel quality, energy efficiency, and plant safety.

Understanding why oxygen monitoring matters is just the beginning—mastering how it works and where it fits ensures smarter decisions, optimized performance, and cost savings.

Why Must Oxygen Concentration Be Precisely Monitored in Metallurgy?

Poor oxygen control isn’t just inefficient—it compromises metal quality and plant safety.

In metallurgical processes such as steelmaking, even minor fluctuations in oxygen concentration can dramatically impact material composition, thermal efficiency, and equipment life. Too much oxygen promotes excessive oxidation, which leads to slag formation, loss of valuable alloying elements (like chromium or manganese), and embrittled steel. Conversely, insufficient oxygen results in incomplete combustion of fuels, increased CO emissions, and energy waste.

An oxygen analyzer enables real-time tracking of oxygen levels in furnaces, converters, and gas treatment systems. This precise monitoring allows operators to adjust air/fuel ratios, regulate reducing or oxidizing atmospheres, and maintain consistent temperature profiles. It also ensures safe operating conditions by avoiding explosive oxygen-rich environments. In essence, precise oxygen control is foundational to producing high-quality steel, improving yield, minimizing rework, and protecting both personnel and assets.

How Does an Oxygen Analyzer Measure Oxygen Concentration?

In metallurgical processes, precise oxygen control is fundamental to ensure efficient combustion, product quality, and operational safety. ESEGAS provides a variety of oxygen analyzer technologies to accommodate different process conditions. Each type employs a specific sensing principle and is suited to particular stages of the metallurgical workflow. Below are the main types offered by ESEGAS:

1. Zirconia Oxygen Analyzer

- Measurement Principle: Uses zirconium dioxide sensors to detect oxygen partial pressure via an electrochemical reaction.

- Features: High-temperature tolerance, fast response, corrosion resistance.

- Typical Applications: Flue gas measurement, combustion control in furnaces and kilns.

- Advantages: Direct high-temperature measurement; long service life in harsh conditions.

- Limitations: Single-gas focus; requires thermal stabilization.

2. Electrochemical Oxygen Analyzer

- Measurement Principle: Measures oxygen via a redox reaction that generates an electric current proportional to O₂ concentration.

- Features: Compact design, simple installation, fast start-up.

- Typical Applications: Heat treatment furnaces, inert gas monitoring.

- Advantages: Cost-effective; good for moderate temperatures.

- Limitations: Sensitive to humidity and contaminants; sensor life is limited.

3. Paramagnetic Oxygen Analyzer

- Measurement Principle: Relies on the paramagnetic properties of oxygen, which is attracted to a magnetic field.

- Features: High precision, fast dynamic response.

- Typical Applications: Critical refining steps, atmosphere control.

- Advantages: High accuracy; suitable for continuous monitoring.

- Limitations: Requires clean sample gas; sensitive to vibration and dust.

4. TDLAS (Tunable Diode Laser) Oxygen Analyzer

- Measurement Principle: Uses laser absorption at specific wavelengths to detect oxygen concentration in a non-contact manner.

- Features: High selectivity, non-invasive design, minimal drift.

- Typical Applications: Automated plants, advanced metallurgical processes.

- Advantages: Low maintenance; fast and accurate; unaffected by dust or corrosives.

- Limitations: Higher cost; requires proper optical alignment.

Comparison Table of ESEGAS Oxygen Analyzers

| Type | Measurement Principle | Best For | Temperature Range | Maintenance | Key Advantages |

| Zirconia | Electrochemical (zirconia sensor) | High-temp flue gas, combustion | High | Low | Durable, fast response |

| Electrochemical | Redox reaction | Medium-temp heat treatment | Medium | Medium | Compact, cost-effective |

| Paramagnetic | Magnetic susceptibility of O₂ | Precise refining control | Medium | Medium | High accuracy, fast response |

| TDLAS | Laser absorption spectroscopy | Automated, dusty or corrosive areas | Wide | Very Low | Non-contact, high selectivity, low drift |

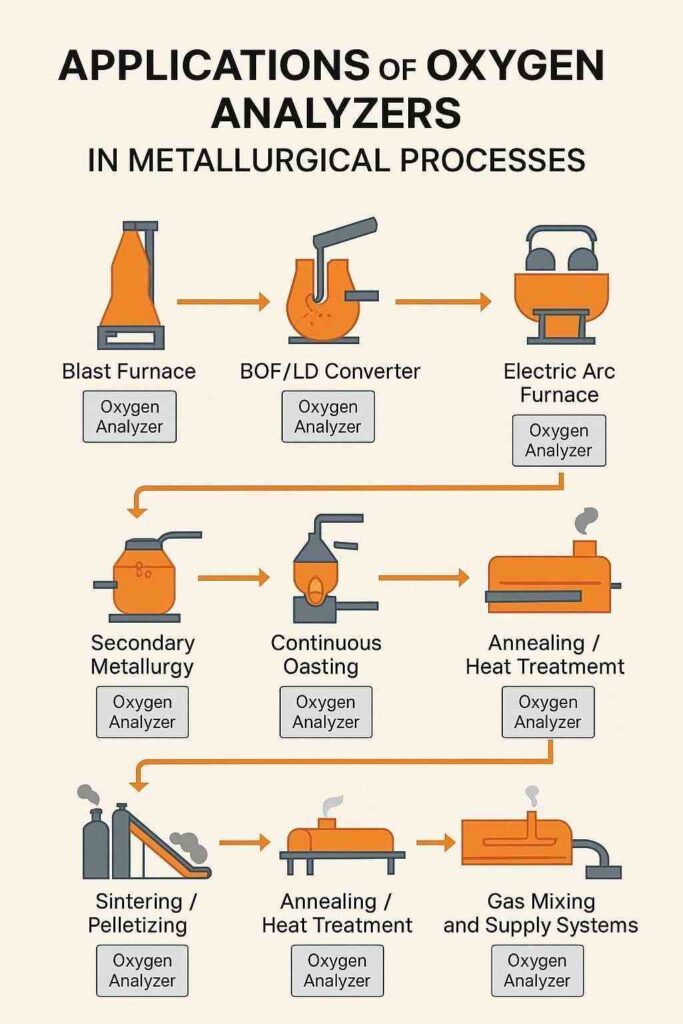

Where Is an Oxygen Analyzer Used in Metallurgical Processes?

The oxygen analyzer is a critical instrument throughout various stages of metallurgical operations, where oxygen concentration directly affects combustion efficiency, chemical reactions, metal quality, and process safety. From raw material processing to final product heat treatment, accurate oxygen monitoring enables operators to optimize process control, reduce energy consumption, and meet stringent environmental and quality standards. Below are the key application areas where oxygen analyzers play an essential role in modern metallurgy:

1. Blast Furnaces (BF)

In blast furnace ironmaking, oxygen plays a dual role: supporting combustion and influencing the reduction of iron oxides. Monitoring oxygen concentration in the off-gas allows operators to fine-tune fuel injection rates (coke, pulverized coal, or natural gas) and ensure optimal carbon usage.

- Application: Off-gas analysis to control combustion balance and monitor process efficiency.

- Benefit: Improves fuel efficiency, reduces CO₂ emissions, and ensures stable furnace operation.

- Analyzer Types Used: Zirconia oxygen analyzer for high-temperature flue gas monitoring.

2. Basic Oxygen Furnaces (BOF) / Linz-Donawitz (LD) Converters

In BOF steelmaking, oxygen is blown at high velocity into the molten pig iron to oxidize impurities such as carbon, silicon, and phosphorus. The oxygen flow and reaction rate must be tightly controlled to avoid over-oxidation and slag foaming.

- Application: Oxygen measurement in converter exhaust or during oxygen injection.

- Benefit: Ensures efficient impurity removal, improves steel purity, reduces slag losses.

- Analyzer Types Used: Paramagnetic oxygen analyzer for precise control, and TDLAS oxygen analyzer where non-contact measurement is preferred.

3. Electric Arc Furnaces (EAF)

EAFs rely on electric energy and often oxygen lances to assist in the melting process. Controlling the oxygen content in the furnace atmosphere is vital to avoid excessive oxidation of alloying elements and refractories.

- Application: Atmosphere monitoring and post-combustion control of CO and O₂.

- Benefit: Enhances energy efficiency and reduces electrode consumption.

- Analyzer Types Used: Zirconia oxygen analyzer or electrochemical analyzers depending on gas extraction design.

4. Secondary Metallurgy (Ladle Furnace, Vacuum Degassing)

After primary steelmaking, oxygen levels must be carefully managed during alloying, desulfurization, and degassing stages to meet strict compositional requirements.

- Application: Monitoring residual oxygen in inert or reducing atmospheres during refining.

- Benefit: Prevents reoxidation, ensures final chemistry accuracy, and improves steel cleanliness.

- Analyzer Types Used: Electrochemical oxygen analyzers are common in ladle refining and vacuum oxygen monitoring.

5. Continuous Casting and Tundish Operations

Although not a high oxygen-consuming step, continuous casting requires inert or low-oxygen atmospheres in some operations (especially for high-grade alloys or stainless steel).

- Application: Inert gas monitoring to ensure low O₂ atmosphere above molten steel.

- Benefit: Reduces surface oxidation and inclusion formation.

- Analyzer Types Used: Paramagnetic or electrochemical oxygen analyzers, depending on accuracy requirements.

6. Annealing and Heat Treatment Furnaces

Heat treatment processes such as annealing, normalizing, and carburizing demand precise control of the furnace atmosphere. Excess oxygen can cause decarburization, scaling, or undesired oxidation.

- Application: Monitoring oxygen concentration in protective or reducing gas atmospheres (e.g., N₂ + H₂ or N₂ + CO).

- Benefit: Ensures surface integrity, improves mechanical properties, and maintains material specifications.

- Analyzer Types Used: TDLAS oxygen analyzers for non-invasive control; electrochemical sensors for compact setups.

7. Sintering and Pelletizing Plants

In iron ore sintering or pellet production, oxygen monitoring in the combustion zone and exhaust gas is vital for maximizing yield and minimizing emissions.

- Application: Flue gas analysis for combustion control and emission monitoring.

- Benefit: Optimizes burner operation and ensures environmental compliance.

- Analyzer Types Used: Zirconia oxygen analyzers for high-temperature gas measurement.

8. Gas Mixing and Supply Systems

Many modern steel plants use mixed gases (O₂, N₂, Ar, CO) for different furnace or process applications. Real-time oxygen measurement ensures correct gas composition and prevents safety incidents.

- Application: Inline monitoring of industrial gas mixtures.

- Benefit: Improves atmosphere precision and operational safety.

- Analyzer Types Used: TDLAS or paramagnetic analyzers with fast, precise response.

Summary Table: Applications of Oxygen Analyzer in Metallurgy

| Process Stage | Application Point | Purpose | Recommended Analyzer Type |

| Blast Furnace | Off-gas analysis | Combustion control, CO₂ reduction | Zirconia |

| BOF / LD Converter | Exhaust gas, oxygen lance | Impurity oxidation, slag control | Paramagnetic, TDLAS |

| Electric Arc Furnace | Furnace atmosphere | Post-combustion control, energy efficiency | Zirconia, Electrochemical |

| Ladle Refining / VD | Argon bubbling, vacuum chamber | Deoxidation, alloy control | Electrochemical |

| Continuous Casting / Tundish | Tundish cover gas | Surface protection, oxidation prevention | Paramagnetic |

| Annealing / Heat Treatment | Furnace atmosphere | Decarburization control, scale prevention | TDLAS, Electrochemical |

| Sintering / Pelletizing | Flue gas, combustion zone | Burner efficiency, emission monitoring | Zirconia |

| Gas Supply & Mixing | Gas pipelines, mixers | Process gas purity, explosion prevention | TDLAS, Paramagnetic |

What Are the Economic Benefits of Using an Oxygen Analyzer?

Better control equals better profits.

A well-implemented oxygen analyzer reduces fuel costs by optimizing combustion efficiency. It minimizes rework by maintaining tight process control, enhances safety by detecting dangerous oxygen levels early, and cuts emissions to meet environmental standards. Over time, these benefits contribute to a more sustainable and profitable metallurgical operation.

Conclusion

In today’s competitive and automated metallurgical environment, an oxygen analyzer is more than a sensor—it’s a strategic tool for quality, efficiency, and sustainability.

if you want learn more about oxygen analyzer, please contact us directly!