In the context of global environmental protection and sustainable development, monitoring of biogas and landfill gas has become increasingly important. These gases have complex compositions and potential risks, and traditional monitoring methods often fail to provide accurate and real-time data. In this case, infrared gas analyzers, with their efficient and precise features, have gradually become the preferred tool for monitoring biogas and landfill gas.

Infrared gas analyzers are widely used for the monitoring of biogas and landfill gas, providing real-time, accurate measurements of gas concentrations to ensure compliance with environmental and safety requirements.

The advantages of infrared gas analyzers are not only reflected in their precise detection capabilities but also their adaptability to various environmental conditions. Using advanced infrared spectroscopy technology, they can precisely differentiate gas components and enable efficient real-time monitoring. Let’s explore their specific applications in biogas and landfill gas monitoring.

Why Choose Infrared Gas Analyzers for Monitoring Biogas and Landfill Gas?

Biogas and landfill gas typically consist of a mixture of gases, including methane (CH₄), carbon dioxide (CO₂), hydrogen sulfide (H₂S), and others. Traditional gas detection technologies often only detect individual gases, with poor sensitivity and selectivity, making them susceptible to interference from other gases, resulting in inaccurate measurements.

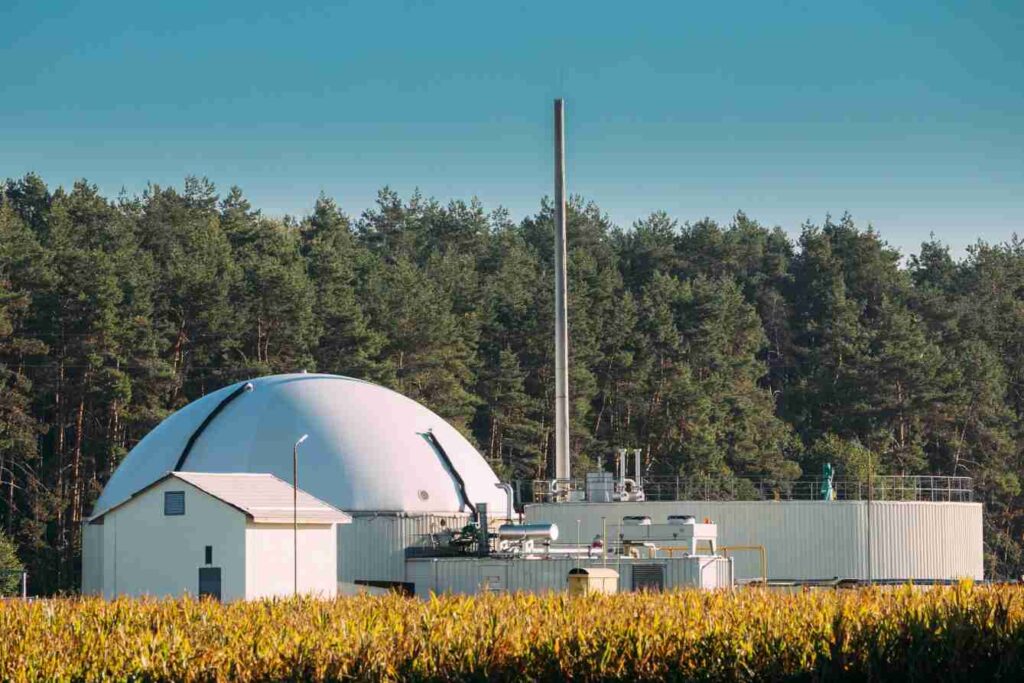

Pic Source:UNIVERSITY OF NOTRE DAME

Infrared gas analyzers, with their high selectivity and sensitivity, can effectively differentiate between the various components of gas mixtures, ensuring precise monitoring.

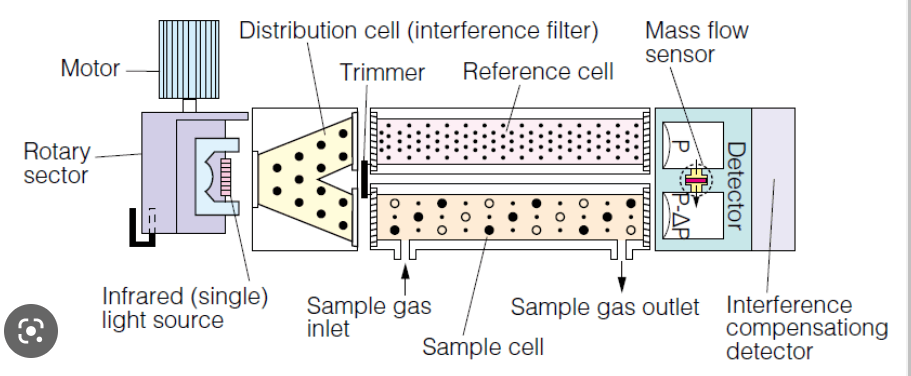

Infrared gas analyzers utilize infrared spectroscopy to detect the absorption of specific wavelengths of light by gas molecules. Different gas molecules absorb infrared light at specific wavelengths, and by measuring the absorption intensity at these wavelengths, the gas type and concentration can be accurately determined. In biogas and landfill gas monitoring, infrared gas analyzers can effectively differentiate and quantify methane, carbon dioxide, and other key components. This high selectivity and sensitivity make infrared gas analyzers an ideal choice for monitoring biogas and landfill gas.

Advantages of Infrared Gas Analyzers

In biogas and landfill gas monitoring, precise measurements are essential, but reliability in harsh environments is also key. Traditional instruments can be affected by temperature, humidity, and gas interferences, which may reduce measurement accuracy.

Infrared Gas Analyzers

Infrared gas analyzers, due to their non-contact operation and rapid response features, can effectively reduce interference and improve measurement accuracy.

One significant advantage of it is their non-contact working principle. Traditional gas sensors typically rely on direct contact with the gas sample, making them more susceptible to environmental influences and requiring frequent calibration and maintenance. In contrast, infrared gas analyzers measure the absorption characteristics of infrared light by gas molecules without direct contact with the sample, avoiding many of the interference issues seen in traditional methods.

Moreover, infrared gas analyzers offer rapid response times, allowing real-time feedback on gas concentration changes. This ensures that biogas and landfill gas monitoring remains accurate, even in environments where temperature and humidity fluctuate or gas composition changes frequently.

How to Choose the Right Infrared Gas Analyzer?

With so many brands and models of infrared gas analyzers on the market, choosing the right one can be challenging. Beyond price, how can you ensure the analyzer meets the specific requirements for monitoring biogas and landfill gas?

When selecting, it is important to consider the analyzer’s detection range, response time, stability, and whether it features automatic calibration.

- First, the detection range is a crucial factor when selecting an infrared gas analyzer suitable for biogas and landfill gas monitoring. The concentration of methane in biogas and landfill gas can vary significantly, so the analyzer’s detection range should cover these fluctuations.

- Second, response time is another key consideration. A rapid response capability allows the analyzer to provide real-time updates on concentration changes, helping to detect potential safety hazards promptly.

- Stability is another critical factor. The stability of the infrared gas analyzer directly affects the reliability of monitoring data in harsh environments. Therefore, selecting an analyzer with high stability and low maintenance requirements is important.

- Finally, some advanced infrared gas analyzers come with automatic calibration features, which help reduce human error and ensure data accuracy over extended periods of use.

If you want to know more about purchase tips, please read this article:

IR-GAS-600 Series Gas Analyzer

The IR-GAS-600 series is an infrared gas analyzer developed by our company for environmental monitoring and industrial emission analysis. It measures CO, CO2, CH4, N2O, and O2 concentrations with high accuracy, stability, reliability, and fast response time.

IR-GAS-600 model high-stability infrared detectors for simultaneously measuring CO, CO2, and CH4. H2 always reads correctly, independent of the background gas composition. An optional non-depleting paramagnetic sensor can be used to conduct O2 analysis. All sensors/detectors are temperature-controlled or temperature-compensated for maximum analytical stability.

Both types of analyzers are available with analysis of:

- Carbon Monoxide (CO) via infrared detector

- Carbon Dioxide (CO2) via infrared detector

- Oxygen (O2) via electrochemical sensor or optional paramagnetic

- Methane (CH4) via infrared detector

CO, CO2, CH4, C3H8, and other molecules absorb infrared light at specific wavelengths. Their absorption intensity follows Lambert-Beer’s Law. When light passes through a gas at its characteristic absorption wavelength, the intensity weakens. The degree of attenuation is directly related to the gas concentration, in line with Lambert-Beer’s Law. The basic principle of NDIR sensor structure, is shown below

Specific Applications of Infrared Gas Analyzers in Biogas and Landfill Gas Monitoring

As environmental regulations become stricter, monitoring the emissions of biogas and landfill gas has become increasingly important. How can we ensure that gas emissions do not exceed the regulatory limits and take timely corrective actions?

Infrared gas analyzers monitor gas concentrations in real-time, helping businesses and authorities detect abnormalities and ensure compliance.

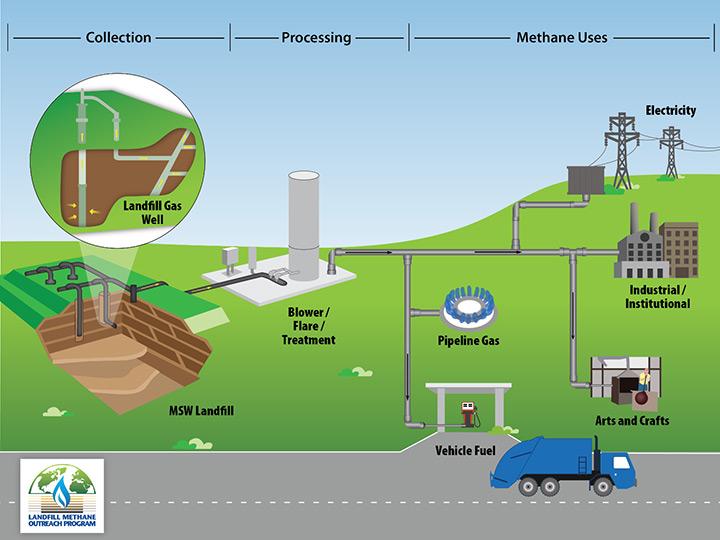

In biogas and landfill sites, controlling gas emissions is a critical component of environmental protection. Infrared gas analyzers monitor methane, carbon dioxide, and other key components in real-time. They ensure gas concentrations stay within compliance standards. When linked to control systems, they trigger alarms or activate emission controls. This helps businesses prevent exceeding emission limits and reduce pollution.

In addition, during methane recovery at landfill sites, infrared gas analyzers monitor concentration fluctuations, ensuring both the efficiency and safety of the recovery system.

Conclusion

Infrared gas analyzers offer precision, sensitivity, and stability for monitoring biogas and landfill gas. With ongoing technological improvements, they help regulatory authorities and businesses ensure emission compliance. They also support environmental protection and safety management.

If you want to know more information, please contact us!