Process gas analyzers enable safe entry into tanks and pipelines by continuously monitoring ambient gases for hazards. These advanced monitors measure oxygen, flammables, and toxic gases in real time, verifying that conditions meet safety criteria before and during entry. By delivering rapid, accurate readings, the analyzers allow instant action—triggering ventilation or aborting entry if dangerous levels appear. The result is a proactive safety system that warns of danger before workers are exposed.

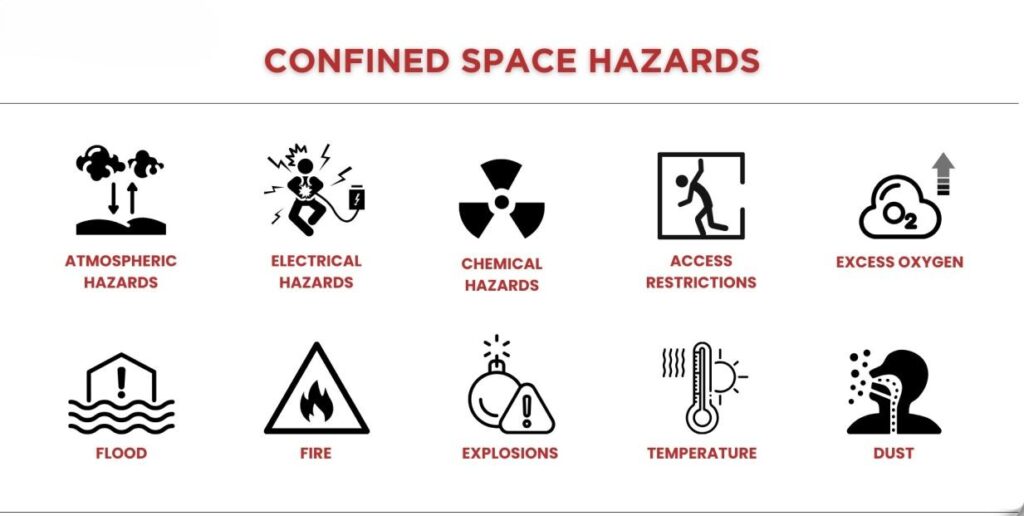

What Are the Common Hazards in Confined Spaces?

According to the Occupational Safety and Health Administration (OSHA), atmospheric testing is mandatory before entering permit-required confined spaces. This testing must assess:

1. Oxygen (O2) Deficiency

Oxygen levels can drop below safe thresholds in confined spaces, leading to asphyxiation risks. OSHA mandates that oxygen concentrations remain between 19.5% and 23.5% to ensure safety. Factors (such as chemical reactions, rusting, or displacement by other gases) can reduce oxygen levels.

2. Toxic Gas Accumulation

Hazardous gases like hydrogen sulfide (H₂S) and carbon monoxide (CO) can accumulate in confined spaces. H₂S, heavier than air, tends to settle at lower levels, posing inhalation risks. CO, a colorless and odorless gas, can result from incomplete combustion processes and is highly toxic.

3. Flammable Atmospheres

The presence of flammable gases such as methane (CH4) or solvent vapors can create explosive environments. Methane, being lighter than air, can rise and accumulate near ceilings, while solvent vapors may linger at various levels.

4. Gas Stratification

Gas stratification means heavy gases (e.g. hydrogen sulfide) settle near the floor while lighter gases (like methane) rise to the ceiling. Without testing at multiple levels, workers could enter pockets of dangerous gas unknowingly. Due to differences in gas densities, stratification can occur, where heavier gases settle at the bottom and lighter ones rise. This layering necessitates atmospheric testing at multiple levels to detect all potential hazards.

5. Regulatory Compliance

OSHA requires that confined spaces be evaluated for atmospheric hazards before entry. Employers must implement a permit-required confined space program, including proper testing and monitoring protocols. Because gas layering can hide threats, best practices call for sampling at various heights (often following the “four-foot rule”) and using filters on sample lines to protect equipment.

Confined spaces present various hazards, including oxygen deficiency, toxic and flammable gases, and gas stratification. Adhering to regulatory standards and conducting comprehensive atmospheric testing are essential steps in mitigating these risks and ensuring worker safety.

How Do Process Gas Analyzers Protect Workers in Confined Spaces?

(Protection for workers in confined spaces)

Confined spaces—such as tanks, silos, and underground pipelines—pose significant risks due to potential atmospheric hazards. Process gas analyzers serve as critical tools in identifying and mitigating these dangers, ensuring worker safety through real-time monitoring and alerts.

Pre-Entry Atmospheric Testing

Before any entry into a confined space, it’s essential to assess the atmosphere for potential hazards. Process gas analyzers equipped with remote sampling pumps allow technicians to draw air samples from the space without direct exposure. These devices measure:

- Oxygen Levels: Ensuring concentrations are within the safe range of 19.5% to 23.5%.

- Flammable Gases: Detecting combustible gases to prevent fire or explosion risks.

- Toxic Gases: Identifying harmful substances like hydrogen sulfide (H₂S) and carbon monoxide (CO).

Continuous Monitoring During Occupancy

Atmospheric conditions within confined spaces can change rapidly. Continuous monitoring ensures that any fluctuations are detected in real-time. Process gas analyzers worn by workers or placed within the space provide ongoing data, alerting personnel to emerging hazards and enabling swift responses.

Real-Time Data and Situational Awareness

Advanced process gas analyzers offer real-time data transmission to monitoring stations outside the confined space. This feature enhances situational awareness for safety personnel, allowing for informed decision-making and rapid intervention when necessary.

Compliance with Safety Regulations

Utilizing process gas analyzers aligns with Occupational Safety and Health Administration (OSHA) standards, which mandate atmospheric testing before and during entry into confined spaces. These devices help employers meet regulatory requirements and demonstrate a commitment to worker safety.

Process gas analyzers are indispensable in safeguarding workers operating in confined spaces. Through pre-entry testing, continuous monitoring, real-time data provision, and regulatory compliance, these instruments play a vital role in preventing accidents and ensuring a safe working environment.

What Should You Consider When Selecting the Process Gas Analyzers for Confined Space Applications?

Choosing the right process gas analyzer for confined space environments is critical for ensuring worker safety and operational efficiency. Confined spaces are prone to rapid changes in atmospheric conditions due to factors like gas stratification and limited ventilation. Continuous monitoring ensures that any hazardous developments are detected in real-time, allowing for swift corrective actions. Here are key factors to consider:

1. Gas Detection Capabilities

Ensure the process gas analyzers can detect a range of gases commonly found in confined spaces:

- Oxygen (O₂): Monitoring for both deficiency and enrichment.

- Carbon Monoxide (CO): A toxic gas resulting from incomplete combustion.

- Hydrogen Sulfide (H₂S): A toxic gas with a characteristic rotten egg smell.

- Methane (CH₄): A flammable gas that can displace oxygen.

Advanced analyzers, like those from ESEGAS, utilize high-stability infrared detectors and Tunable Diode Laser (TDL) technology for accurate measurements of CO, CO₂, and CH₄.

2. Sensor Technology

Different sensors offer varying advantages:

- Infrared (NDIR) Sensors: Ideal for detecting CO₂ and CH₄ with high accuracy.

- Electrochemical Sensors: Suitable for measuring toxic gases like CO and H₂S.

- Optional Thermal Conductivity Detectors (TCD): Effective for detecting hydrogen concentrations.

- Optional Electron Capture Detector (ECD): Effective for detecting Oxygen (O2)

ESEGAS process gas analyzers combine these technologies to provide comprehensive gas detection solutions.

3. Portability and Ease of Use

In confined spaces, portability is essential. Select process gas analyzers that are compact, lightweight, and easy to operate. Features like intuitive interfaces and quick calibration procedures enhance usability.

4. Response Time and Accuracy

Rapid detection of hazardous gases is vital. Choose process gas analyzers with fast response times and high accuracy to ensure timely alerts and interventions.

5. Durability and Maintenance

Confined spaces can be harsh environments. Opt for process gas analyzers built with robust materials that can withstand challenging conditions. Additionally, consider devices that require minimal maintenance and offer long sensor life.

6. Data Logging and Connectivity

Modern analyzers often come with data logging capabilities and connectivity options. These features allow for real-time monitoring and data analysis, facilitating compliance with safety regulations and improving incident response.

7. Compliance with Safety Standards

Ensure the analyzer meets relevant safety standards and certifications, such as those set by OSHA. Compliance indicates that the device has been tested and approved for use in hazardous environments.

By carefully evaluating these factors, you can select the process gas analyzers that effectively safeguard workers in confined spaces and align with your operational requirements.

What Advanced Technologies Enhance the Performance of Modern Process Gas Analyzers?

State-of-the-art process gas analyzers, such as those from ESEGAS, bring specialized features:

- Multi-Gas Support: ESEGAS analyzers can measure multiple gases simultaneously. NDIR and TDLAS detect CO, CO₂, and CH₄ together, while a thermal-conductivity sensor monitors H₂ and an electron capture detector (ECD) measures O₂. This covers all major confined-space hazards in one instrument.

- Modular Design: The system uses modular sensor cartridges and flow modules. Users can add or swap sensor types to match different gases or ranges. Swapping a single module for repair is faster and cheaper than replacing the entire system. ESEGAS also offers portable process gas analyzers, such as IR-GAS-600P, for ease-of-use.

- Advanced Sampling System: A high-flow pump draws air from the confined space into the process gas analyzers. Protective filters in the pump and sampling line trap dust and moisture. (Replaceable filters mean only the filter element needs changing, protecting the pump from contamination.) Heated sample lines (optional) prevent condensation in cold conditions. These measures keep the sensor chamber clean for reliable readings.

- Sensor Self-Test & Smart Diagnostics: ESEGAS process gas analyzers perform automatic sensor checks and self-calibrations. The device continually tests its sensors and reports baselines. If a sensor drifts or a filter clogs, the system flags it immediately. Such smart diagnostics enter a fail-safe alarm state before faulty data can be reported.

- Remote Control & Automation: Modern units support network connectivity and remote calibration. Safety teams can view live gas readings and device status through a web interface. ESEGAS notes that their automated process gas analyzers can even perform scheduled self-calibration and diagnostics, greatly reducing manual maintenance.

- Predictive Maintenance: Analyzer data can feed predictive algorithms. For example, ESEGAS highlights that AI/ML tools analyze trends and predict when a sensor or component needs service. This foresight helps plan maintenance proactively, reducing unexpected downtime.

These capabilities give operators and managers constant visibility into gas levels and system health. The modular, self-checking design keeps systems reliable longer, avoiding blind spots in safety coverage.

A robust monitoring strategy goes beyond simply meeting regulations. Continuous data collection builds a historical record of gas levels. Over time, teams can spot trends and anticipate issues. For example, a slowly rising flammable-gas concentration might signal a developing leak. Catching that trend early lets crews schedule repairs or ventilation long before an alarm is triggered.

What Are the Best Practices for Safety Teams Using Process Gas Analyzers in Confined Spaces?

In practical installations, process gas analyzers often reside in control rooms or trailers where technicians calibrate and monitor them. Sample lines feed air from the tank or pipeline to the analyzer’s multi-sensor module. From there, engineers adjust alarm set points, review trend charts, and coordinate ventilation in real time.

- Integrate Analyzers into Entry Protocols: Make analyzer readings the first step in any confined-space permit. Sample from the top, middle, and bottom of the space (using extension probes) to account for stratification. Maintain continuous monitoring once entry begins.

- Select Multi-Gas, Fast-Responding Units: Choose process gas analyzers that cover oxygen, combustible gases, and key toxics simultaneously. Verify that sensors settle quickly (ideally >95% reading within ~15 seconds). Rapid response minimizes worker exposure.

- Maintain Rigorously: Follow manufacturer calibration intervals and bump-test schedules. Use process gas analyzers’ self-test features to confirm functionality before each use. Replace filters and sensors as recommended. A well-maintained analyzer ensures valid data.

- Leverage Data Connectivity: Send process gas analyzers readings to your control system or cloud logging service. Review post-entry data reports for any anomalies. Use trend analysis to refine ventilation and maintenance strategies.

- Train Personnel: Ensure field crews and responders know how to operate the process gas analyzers and interpret alarms. Include analyzers use in safety drills. Establish clear response actions for each alarm condition so teams respond immediately and correctly.

- Invest in Smart Features: Favor process gas analyzers with modular designs and built-in diagnostics. Smart systems reduce manual workload: off-site managers can monitor devices remotely, and on-site staff benefits from guided calibration routines.

- Prepare Backup Plans: Even with process gas analyzers, never enter an unventilated space without precautions. Keep emergency breathing apparatus, portable gas detectors, and two-entry teams ready. Use live analyzer data to inform emergency response (e.g. responders should know current gas levels before entering).

By combining advanced process gas analyzers with rigorous procedures and training, organizations can shift from reactive compliance to proactive safety. This integrated approach safeguards personnel, optimizes operations, and fosters a culture of risk mitigation.