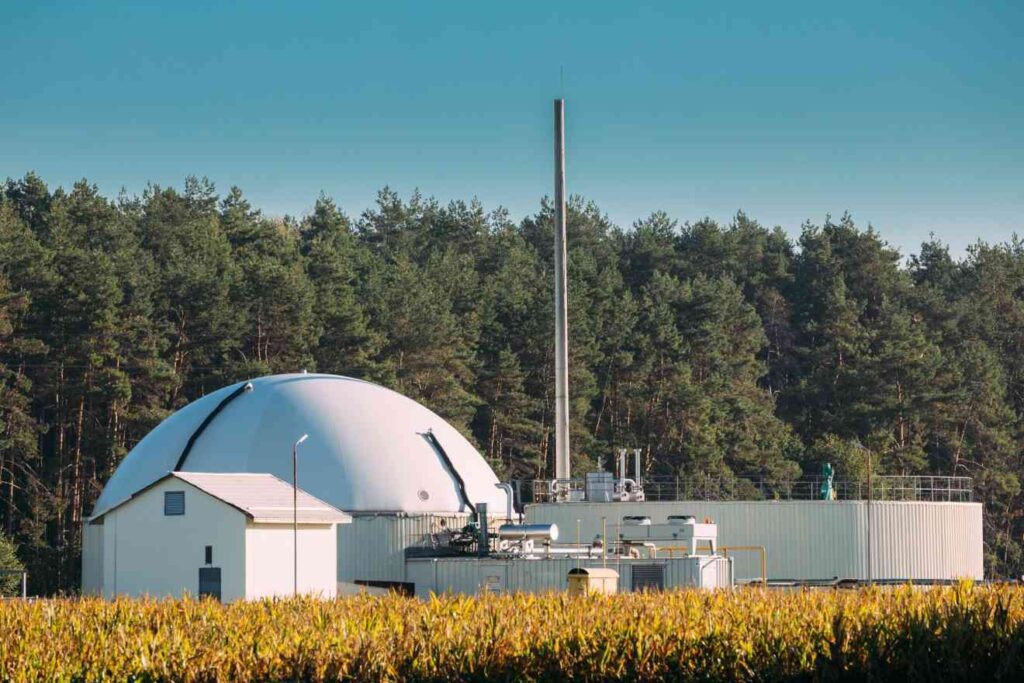

Septic tanks trap combustible and toxic gases. Without precise monitoring, leaks, explosions, or poisonings can happen—and compliance falters. A fit-for-purpose biogas analyzer closes the gap, turning invisible risks into actionable data and automated safety.

A biogas analyzer safeguards septic tank operations by continuously measuring CH₄, CO₂, O₂, and H₂S with NDIR and electrochemical sensors, using sample conditioning (heated lines, drying, filtration) to prevent condensation and corrosion. Certified hardware (e.g., ATEX/IECEx), routine calibration, and SCADA integration enable alarms, ventilation, or flaring for safety and compliance.

Knowing you must “monitor” is only step one. The real win comes from choosing the right sensing stack, installing it correctly, conditioning the sample, and binding data to automatic responses that reduce risk and cost.

Why do septic tanks require continuous Biogas Analyzers monitoring?

Incidents escalate in seconds: methane ignites, H₂S incapacitates, oxygen disappears. Communities complain, regulators investigate, and operations halt. Continuous biogas monitoring turns these hidden hazards into trends, alarms, and interlocks you can act on.

Septic tanks generate combustible CH₄ and toxic H₂S in humid, corrosive headspaces. Continuous monitoring maintains safety margins (e.g., ≤20–50% LEL for CH₄, low-ppm H₂S alerts, O₂ <19.5% deficiency), protects assets from sulfuric corrosion, stabilizes digestion performance, documents compliance, and triggers automated ventilation/flaring and access controls.

1) Life-safety and explosion prevention

Septic headspace commonly swings through methane concentrations that can enter flammable ranges. Continuous analyzers track CH₄ relative to its Lower Explosive Limit (~5% v/v) and Upper Explosive Limit (~15% v/v). Configuring graded setpoints—e.g., pre-alarm at ~1% CH₄ (≈20% LEL), high at ~2.5% (≈50% LEL)—enables timely responses: start fans, lock access, and, if necessary, divert or flare. Real-time O₂ measurement confirms that confined spaces remain below enrichment levels and keeps personnel out when O₂ drops below safe limits (commonly <19.5% v/v).

2) Toxic exposure control (H₂S and co-contaminants)

Hydrogen sulfide incapacitates rapidly; even short spikes are dangerous. Continuous H₂S monitoring detects both baseline elevation and fast transients caused by load shocks, temperature shifts, or scum disturbance. Typical alarm tiers (e.g., 5–10–20 ppm) support escalating responses—PPE upgrades, evacuation, and process adjustments. Where ammonia or VOCs are present, auxiliary channels add context and reduce false security.

3) Structural and asset integrity

H₂S oxidizes to H₂SO₄, attacking concrete, coatings, and metallics. Corrosion isn’t linear; it accelerates when humidity and H₂S peak together. Continuous trending of H₂S, temperature, and dew point allows targeted dosing of nitrate/iron salts, ventilation scheduling, and prioritization of high-risk structures, extending the life of covers, ducts, and instrumentation.

4) Process stability and digester health

The CH₄/CO₂ ratio and O₂ ingress tell you if anaerobic biology is on track. Continuous profiles reveal diurnal swings, infiltration after rainfall, or shock loads from high-fat inflows. Early detection prevents foam events, scum disturbances, or acidification. Operators can tune recirculation, dilution, or feed equalization before gas quality collapses.

5) Odor management and community relations

H₂S and reduced sulfur compounds drive complaints. Continuous headspace monitoring, tied to weather data and site operations, helps correlate events, automatically start scrubbers or fans, and document response times—turning community interactions from reactive to preventative.

6) Why “continuous” beats “periodic”

Periodic handheld measurements miss transients caused by pump cycling, truck offloads, or temperature inversions. Headspace gases stratify and change minute-to-minute with mixing and barometric shifts. Fixed analyzers with conditioned sampling capture these dynamics, enabling interlocks (ventilation, flare, access lockouts) that periodic checks can’t provide.

Which Biogas Analyzers gas species and parameters matter most?

Focus on four core gases: CH₄, H₂S, O₂, CO₂. CH₄ defines explosion risk and energy content; H₂S drives acute toxicity and corrosion; O₂ confirms confined-space safety and detects air ingress; CO₂, with CH₄, fingerprints digestion health. Where feed varies, add NH₃ (odor/toxicity from nitrogen-rich loads) and H₂ (early upset marker). Choose fit-for-purpose sensing—NDIR for CH₄/CO₂; electrochemical for H₂S/O₂/NH₃—so alarms and interlocks are based on stable, selective measurements.

Pair gas readings with dew point/humidity, temperature, static and barometric pressure, and (when quantifying emissions/energy) flow. These matrix parameters prevent condensation bias, enable dry-gas/STP normalization, and explain weather-driven swings. Together, the core gases plus supporting conditions turn raw numbers into actions: calibrating ventilation and access controls, prioritizing anti-corrosion work, optimizing scrubbers, and producing defensible environmental and safety records.

What analyzer technologies should I select?

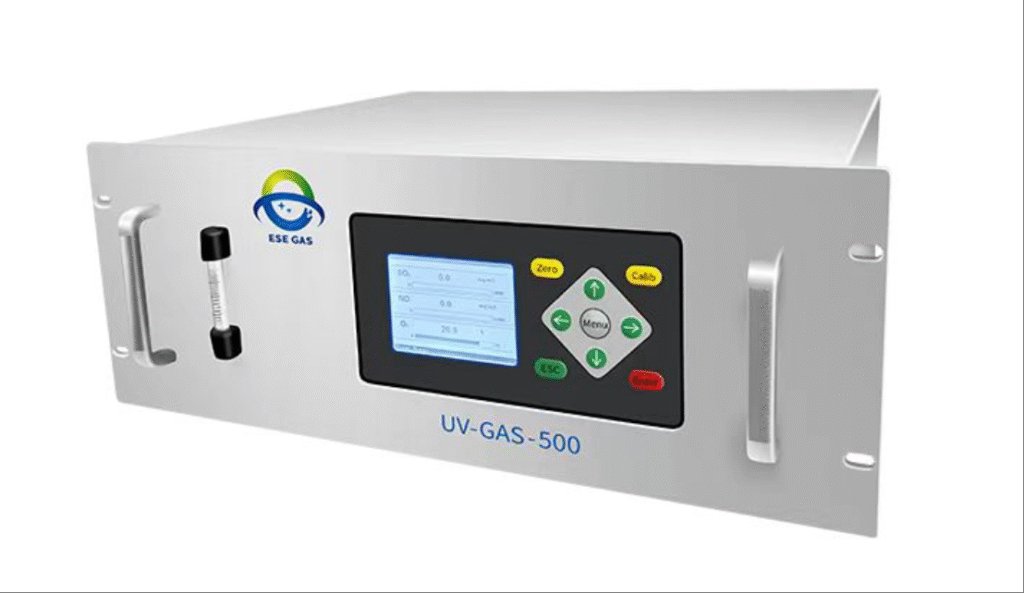

Our model UV-GAS-500 model can measure SO2 based on DOAS and PLS,able to measure the concentration of gases including SO2, NO2, NO, NH3, Cl2, O3, H2S, etc,It has features of high measurement accuracy,outstanding,reliablility ,fast response time and wide applicable scope.

Applications:

☑ Flue gas continuous emission monitoring (CEMS) for the power plants

☑ DeSOx process monitoring (analyze SO2 and O2)

☑ Waste incineration flue gas continuous emission monitoring (analyze SO2, NO, NO2 and O2)

☑ Sulfur recovery process gas analysis (analyze SO2 and H2S)

☑ On-line air monitoring (analyze SO2,NO2 and O3)

Sampling & conditioning (where accuracy is won or lost)

- Extractive, heated sampling: Use a corrosion-resistant probe with sintered filter and auto-drain, then heated lines kept ≥5–10 °C above measured dew point.

- Drying & filtration: Peltier cooler or membrane dryer + staged PTFE/SS filters. Keep lines short and constant-flow to reduce adsorption and lag.

- Materials: 316L wetted parts, acid-gas-resistant elastomers, and sulfur-tolerant pumps; avoid brass/copper.

- Dual-path strategy: For high H₂S sites, run separate sample paths—one protected for CH₄/CO₂ and one ruggedized for H₂S—to extend sensor life and reduce cross-effects.

Ranges, response, and integration (specs that matter)

- Ranges: CH₄ 0–100% v/v (NDIR/TDLAS); CO₂ 0–50% v/v (NDIR); H₂S 0–200/1,000/5,000 ppm (EC or tape for low-level); O₂ 0–25% v/v (EC/paramagnetic); NH₃ 0–100/500 ppm (EC).

- Dynamics: Demand published T90, drift/month, and temperature coefficients. Transient capture matters during pump cycling or truck offloads.

- I/O: 4–20 mA for alarms/interlocks; Modbus RTU/TCP (or RS-485) for diagnostics and trending; relay contacts for graded alarms.

- Self-diagnostics: Flow/pressure sensors, condensate alarms, and sensor health flags (bias current, zero stability) reduce nuisance trips.

Q&A about biogas analyzers in biogas monitoring

How should a septic tank sampling system be installed?

A perfect sensor can’t fix a poor sample. Placement and extraction determine data quality.

For headspace gas, use an extractive probe on the tank cover, equipped with a sintered filter and condensate barrier. Route the sample via heated sample lines to a conditioning cabinet, then to the analyzer. Multi-point rotary valves can sweep several tanks. Combine fixed online systems (alarms/trending) with a portable analyzer for audits and spot checks.

How does sample conditioning prevent condensation and corrosion?

Water and sulfur compounds wreck sensors and bias data. Condition first, measure second.

Deploy a heated probe and lines to stay above dew point, then a chiller or membrane dryer to stabilize humidity. Add PTFE/SS filtration stages (coarse→fine), auto-draining knock-out pots, and acid-gas-resistant seals. Keep line lengths short, avoid dead legs, and maintain constant flow to minimize adsorption and lag.

What calibration and maintenance practices keep accuracy high?

Drift turns alarms into noise; unplanned downtime costs more than scheduled care.

Implement zero/span routines with certified gases (e.g., CH₄/CO₂ in N₂; H₂S in balance N₂) and establish automatic reminders based on hours or exposure. Track T90 response, baseline noise, and cross-interference checks (e.g., H₂S on SO₂). Replace pump heads, filters, and H₂S cells proactively; document everything for audits.

How should monitoring data drive safety and compliance actions?

Data silos don’t save lives—automatic interlocks do.

Export via 4–20 mA, Modbus RTU/TCP, or RS-485 to SCADA. Configure graded setpoints: pre-alarm (ventilation), high alarm (access lockout), and high-high (flare/torch or process shutdown). Time-stamp and retain records for environmental and occupational audits; share dashboards with operations, EHS, and maintenance.

Which performance metrics matter—and how do we quantify ROI?

PAS lead: “Accurate enough” is not a spec. Tie performance to outcomes.

Specify range (e.g., CH₄ 0–100% v/v; H₂S 0–5,000 ppm), accuracy (±% of reading), LoD, T90, drift/month, and availability. ROI comes from avoided incidents, fewer manual entries, reduced complaints, and validated carbon/energy reporting. Build a model: (incident probability × consequence) + labor saved − consumables & calibration gas.

What are common faults and how do we troubleshoot them?

Most failures start in the sample path, not the sensor board.

Low readings often trace to condensation dilution—check dew point control and drains. Slow response? Inspect for clogged filters or pump wear. Unstable H₂S? Look for cell saturation or sulfuric acid formation; replace consumables and verify scrubbers. Negative pressure leaks show as O₂ excursions—pressure test and reseal fittings.

Which deployment patterns fit rural, municipal, and co-digestion sites?

Different feedstocks mean different moisture and sulfur loads—design accordingly.

Rural septic clusters benefit from portable analyzers plus a shared online station. Municipal tanks use fixed, multi-point extractive systems with robust drying and redundancy. Food-waste/co-digestion sites typically require higher H₂S ranges, more aggressive conditioning, and anti-fouling measures due to fats and surfactants.

Conclusion

Choose the right gases, install the right sampling and conditioning, and run disciplined calibration/automation. That’s how septic-tank biogas monitoring evolves from a compliance checkbox into a reliable safety, uptime, and sustainability engine.