In today’s industrial environment, stricter emission limits demand faster, more reliable measurement of gases such as SO₂, NOₓ, CO, CO₂ and O₂. At the same time, operational inspections and audits require instruments that can move with your team, not stay locked to a single location. Fixed systems often struggle to keep up with varied measurement points across a plant. Moreover, the on-site realities—dusty ductwork, high temperatures, humid stack emissions and hard-to-reach sample lines—make traditional single-gas monitors or immobile installations less useful. You need a tool that adapts to field diagnostics, burner tuning and both start-up and shutdown checks.

In the following sections, we’ll dig deeper into the technical criteria that really matter, followed by practical deployment guidance and a checklist to help you choose the right solution for your plant. By tracking this path, you’ll gain clearer insight into how a Portable Multifunction Gas Analyzer can become a strategic tool for process safety, regulatory compliance and operational efficiency.

What Technical Criteria Should You Use to Choose a Portable Multifunction Gas Analyzer?

Gas components measured & cross-interference management

In many industrial stacks, accurate monitoring means capturing a full set of gases — SO₂, NO, NO₂, CO, CO₂ and O₂ (and sometimes CH₄). A truly multifunction portable analyzer must do more than detect one or two gases. Furthermore, you must consider cross-interference: dust, moisture, high CO₂ concentration, HCl and other contaminants can distort results. Advanced designs use technologies like UV-DOAS to measure SO₂/NO/NO₂ directly and avoid interference by dust or CO₂/HCl. For example, the ESEGAS UV-GAS-500 series supports SO₂/NO/NO₂ measurement with UV-DOAS, making it less sensitive to particulates and interfering compounds. Use this lens when evaluating an analyzer: how many components does it measure, and how well does it handle real-world interference?

Measurement technology and accuracy

Measurement method drives performance. For example:

- UV-DOAS excels at SO₂/NOx measurement because it can capture direct absorption of ultraviolet light by those species.

- ECD (electrochemical detection) is often used for O₂ due to its robust response.

- NDIR (non-dispersive infrared) and GFC (gas filter correlation) methods handle CO and CO₂ reliably. The UV-GAS-500 spec shows UV-DOAS for SO₂/NO/NO₂, NDIR/GFC for CO/CO₂.

Beyond technology: check range and resolution. For example, the standard UV-GAS-500P supports SO₂/NO/NO₂ ranges up to 3000 ppm, O₂ measuring 0-25 %. Therefore, method + range define how well the tool will perform under your operating conditions.

Durability and field-readiness

Field environments are harsh: hot stacks, high dust loads, humidity, variable access. A portable multifunction gas analyzer must be rugged and ready for those settings. Things to look for:

- Battery operation with sufficient continuous run time (for example 8h or more) so you don’t get cut off mid-inspection.

- Minimal sample conditioning required (less filters, fewer moving parts) so you reduce downtime.

- Design built for dust, vibration, temperature extremes. If the unit handles the industrial core stack environment, you’re safer.

Integrated diagnostics & data connectivity

Modern monitoring is about more than gas concentration: you need context. Instruments that integrate sensors for flue temperature, pressure, flow velocity, sampling velocity allow you to derive excess air, emission rates, and dig deeper into process performance. The UV-GAS-500 series supports multi-parameter diagnostics and offers interfaces like RS-485, USB or SD-card for data logging. Thus, you can move from simply reading “SO₂ = 400 ppm” to “Here’s the emission rate; here’s the excess air; here’s how your burner is performing.”

Ease of operation and maintenance

In practice, an analyzer that sits idly because it’s hard to operate is a liability. Choose one with:

- Touch-screen UI and intuitive workflow so field technicians (not just specialists) can run it.

- Minimal moving optical parts (e.g., UV-DOAS systems often eliminate rotating mirrors), which reduces wear and maintenance.

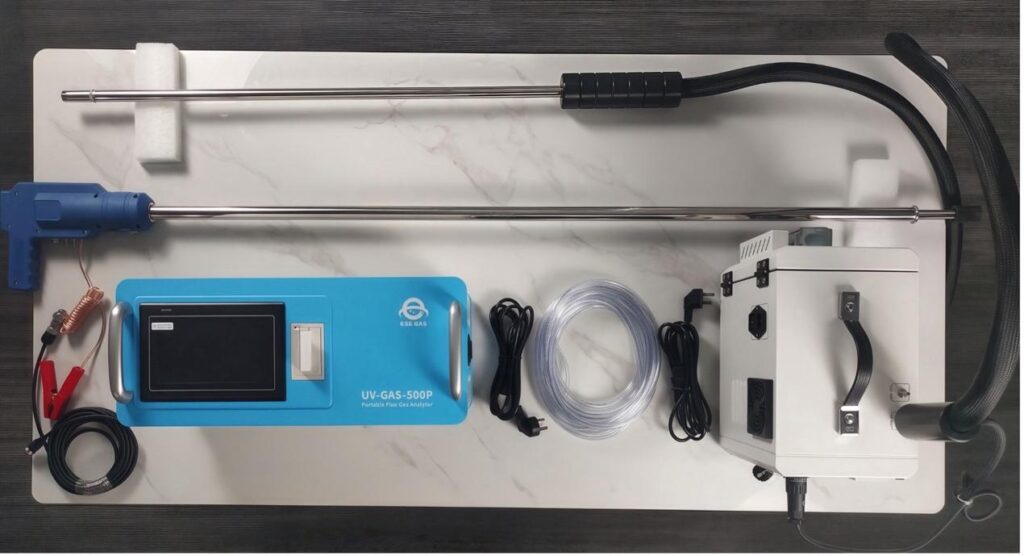

- Clear sample system architecture (analyzer + sampling probe + heated sample line) so set-up is quick and less error-prone.

In short: it should be portable not only in weight, but in ease of use. That means less training and lower long-term maintenance cost.

How Does a Portable Multifunction Gas Analyzer Truly Transform On-Site Monitoring?

When you bring a portable multifunction gas analyzer into the field, the way you conduct inspections changes fundamentally. Imagine a technician walking between several boiler stacks: instead of using different single-gas devices for SO₂, NOₓ, CO, etc., they plug in one analyzer and read all critical gases in real time. This dramatically speeds up diagnostics — and allows for immediate action. For instance, if the CO level suddenly spikes, you can immediately adjust the burner air-to-fuel ratio instead of waiting for lab results.

Beyond speed, having real-time, multi-gas data greatly enhances process safety and emissions compliance. Instant detection of harmful gases (like CO, SO₂ or NO₂) helps flag abnormal combustion or potential leaks early. Moreover, because the analyzer also captures flue diagnostics — such as flow velocity, pressure and temperature — you can calculate excess air and derive pollutant emission rates. That means emission data comes with context: you see not only “what” is out there, but also “why” it’s happening.

Data quality and traceability also improve when you use a high-spec analyzer. Advanced technologies like UV-DOAS, combined with NDIR and electrochemical sensors, minimize interference and deliver reliable readings — even in dusty, humid or challenging flue environments. Because the device supports USB or SD card interfaces, you can export logs, generate reports and store measurements systematically, making them audit-ready and defensible.

Last but not least, the operational costs and flexibility benefits are significant. You no longer need to invest in multiple fixed analyzers or juggle separate units for different gases. One portable device does it all — and you can move it across plants, stacks, or even lend or rent it to neighboring sites. Plus, since modern units (for example, the ESEGAS UV-GAS-500P) use no moving optical parts, maintenance is simpler, downtime is reduced, and long-term service costs go down.

How Should You Deploy a Portable Multifunction Gas Analyzer on Site?

Before you begin field measurements, following a solid deployment checklist and best practices ensures accuracy, safety, and long-term value. Below is a structured guide for on-site use of a portable multifunction gas analyzer like the ESEGAS UV-GAS-500P.

Pre-Deployment Planning

- Define clear measurement objectives: Decide which gases you need to measure (e.g., SO₂, NO, NO₂, CO, CO₂, O₂), the expected concentration ranges, and what regulatory standard or compliance requirement you are targeting.

- Assess sampling point access: Make sure your sample probe can reach the stack, duct, or boiler safely. Plan for safe working conditions, particularly at height or in confined spaces.

- Prepare the proper sample line: Determine whether you need a heated probe or heated/insulated sample line to prevent condensation in humid or high-temperature flue gas. For example, ESEGAS’s kit includes a heated probe and gas cooler.

- Check instrument readiness: Confirm the analyzer is properly calibrated, and verify its battery is fully charged — the UV-GAS-500P supports around 8 h of continuous use.

On-Site Setup

Once on location, your setup matters:

- Connect the heated sampling line and gas cooler to handle moisture and avoid condensation. This is particularly critical in wet, high-humidity flue environments.

- Turn on the instrument and ensure a stable sampling flow — for the UV-GAS-500P, the intake flow should be about 1.5–2 L/min.

- Record flue diagnostics such as temperature, pressure and flow velocity. These measurements, together with sampling velocity, help you calculate key parameters like excess air coefficient and pollutant emission rate.

Measurement & Data Management

- Allow the analyzer to stabilize and then acquire steady readings for each gas. Cross-check the values against your expected process conditions for plausibility.

- Export logged data via USB or SD card (supported by the UV-GAS-500P) so you can archive and analyze later.

- For traceability, document details such as location, date & time, operating conditions (stack temperature, pressure), and any anomalies you observed.

Post-Analysis Actions

- Interpret results: For instance, elevated CO or NOₓ may signal poor burner tuning or excess air; high SO₂ could reflect high sulfur content in fuel.

- Use the excess air coefficient and emission rate (derived from diagnostics) to drive corrective actions: adjust air/fuel ratio, retrofit burner, or revise maintenance plans.

- Maintain your analyzer: clean filters, check and replace sample line segments if needed, and adhere to a calibration schedule. Follow ESEGAS’s maintenance guide to preserve measurement accuracy.

By following this checklist and these best practices, you maximize the value of your portable multifunction gas analyzer, ensuring it delivers reliable, regulatory-grade monitoring — not just once, but consistently, over time.

Conclusion

In conclusion, a well-chosen portable multifunction gas analyzer can completely transform your on-site gas monitoring. By delivering multi-gas, real-time, accurate, and portable measurements, it directly supports process safety, emissions compliance, and operational efficiency. Instead of juggling single-gas devices or relying solely on fixed systems, you get a flexible, all-in-one solution.

However, not all analyzers are created equal. The value you gain depends heavily on whether the instrument meets the technical criteria we’ve discussed — from measurement technology and cross-interference robustness to data connectivity and field durability. If you are interested our portable flue gas analyzer UV-GAS-500P, visit our YouTube channel to have a full view!Or contact with us!

Looking ahead, gas regulation is only going to tighten, and plants will increasingly chase decarbonization and efficiency goals. In that evolving landscape, flexible, high-precision on-site monitoring tools won’t just be a nice-to-have — they’ll be strategic assets. Investing now can give you not just compliance, but operational insight and agility for the long run.

FAQ: What Makes a Portable Multifunction Gas Analyzer a Game-Changer for On-Site Monitoring?

Q1: What gases can a portable multifunction gas analyzer measure simultaneously?

A: A high-end portable multifunction gas analyzer (e.g., the ESEGAS UV-GAS-500P) can measure multiple key flue gas components at once — such as SO₂, NO, NO₂, CO, CO₂, and O₂.

This multi-gas capability reduces the need for separate analyzers and speeds up on-site inspections.

Q2: How does the UV-DOAS technology in a portable analyzer work, and why is it beneficial?

A: UV-DOAS (Ultraviolet Differential Optical Absorption Spectroscopy) works by shining UV light through the gas sample and detecting how much is absorbed by target gases.

It is particularly useful for measuring SO₂, NO, and NO₂ with high accuracy and minimal cross-interference from dust, moisture, CO₂ or HCl — improving reliability in harsh industrial conditions.

Q3: Is the measurement accuracy and stability good enough for regulatory compliance?

A: Yes. For example, in the ESEGAS UV-GAS-500P, the measurement ranges are: SO₂/NO/NO₂ = 0–1000 ppm, O₂ = 0–25%, CO = 0–2000 ppm, CO₂ = 0–25%, with an accuracy of about ±2% FS.

These specifications make it suitable for on-site compliance checks, audits, and emission reporting.

Q4: How field-ready is a portable multifunction gas analyzer?

A: Very field-ready. The ESEGAS UV-GAS-500P, for instance, is rugged and battery-powered (up to 8 hours of continuous use), enabling inspections across multiple sites.

Because its optical system has no moving parts, it tolerates dust, vibration and temperature changes, making it well-suited for industrial environments.

Q5: Can a portable analyzer provide more than just gas concentration data?

A: Absolutely. Portable multifunction analyzers often include integrated diagnostics — such as on-board sensors for flue temperature, pressure, flow velocity, and sampling velocity.

These data let you calculate excess air coefficient and pollutant emission rates, giving important context to gas measurements.

Q6: How do I get and store the measurement data from a portable gas analyzer?

A: Most portable units (like the UV-GAS-500P) support data export via USB or SD card, allowing you to log readings, download reports, and integrate them into your emission compliance system.

This ensures traceability and makes the data audit-ready.

Q7: What are the operational and cost benefits of using a portable multifunction analyzer?

A: Since one device handles many gases, you reduce the number of dedicated analyzers required.

It’s mobile — you can move it across different stacks, boilers or sites.

Maintenance is also simpler, because the design (e.g., UV-DOAS) often uses no moving optical parts, reducing wear and service cost.

Q8: How do I ensure reliable results when using a portable analyzer on-site?

A: To maximize reliability:

- Define your measurement goals: which gases, what ranges, regulatory standard.

- Use proper sampling hardware (heated probe or line if needed).

- Confirm your analyzer’s calibration and battery status before field use.

- During measurement, let readings stabilize before logging data; record operational parameters like temperature and pressure.

- Regularly maintain the system: clean filters, check sample lines, and follow the calibration schedule.

Q9: Is a portable analyzer just for spot checks, or can it complement a fixed CEMS system?

A: A portable multifunction gas analyzer is ideal for spot checks, audits, burner tuning, and diagnostic inspections.

But it can also complement fixed Continuous Emission Monitoring Systems (CEMS) by providing flexible, real-time spot data, helping you validate or cross-check long-term emissions trends.

Q10: Which industries benefit most from using a portable multifunction gas analyzer?

A: Industries with combustion processes or strict emission requirements — such as power plants, steel mills, waste incinerators, petrochemical facilities — benefit heavily.

Engineers and EHS professionals use these analyzers for on-site inspections, compliance audits, and process optimization.