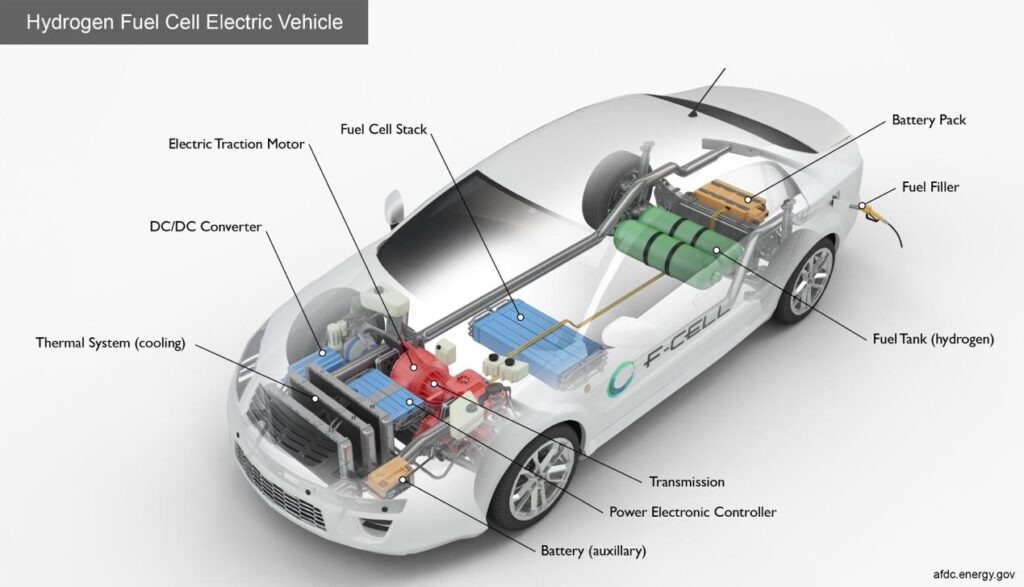

Hydrogen fuel cells promise clean energy—but impurities and imbalanced gas flows can silently degrade their performance. Ignoring gas composition means risking efficiency, lifespan, and safety. The solution? Precision gas analysis.

A hydrogen fuel cell gas analyzer is essential for monitoring real-time gas composition, ensuring optimal performance, maximizing efficiency, and preventing safety risks in fuel cell systems.

Despite understanding the answer, you might wonder how exactly a gas analyzer achieves these goals, and what technologies enable such accuracy. This is where the engineering of systems like those from ESEGASbecomes crucial.

What Key Gases Need Monitoring in a Hydrogen Fuel Cell?

The performance and safety of a hydrogen fuel cell depend heavily on the exact composition of its reactant and byproduct gases, yet many systems operate without real-time verification.

Even minimal contamination—such as a few parts per million of carbon monoxide—can irreversibly damage the platinum catalyst. Meanwhile, poor control of nitrogen dilution or water vapor accumulation can choke performance and create thermal imbalances.

A hydrogen fuel cell gas analyzer from ESEGAS provides continuous, high-precision measurement of all critical gases involved in the electrochemical process: hydrogen (H₂), oxygen (O₂), water vapor (H₂O), nitrogen (N₂), and carbon monoxide (CO). Monitoring these gases allows operators to protect sensitive components, maintain fuel efficiency, and avoid system failures.

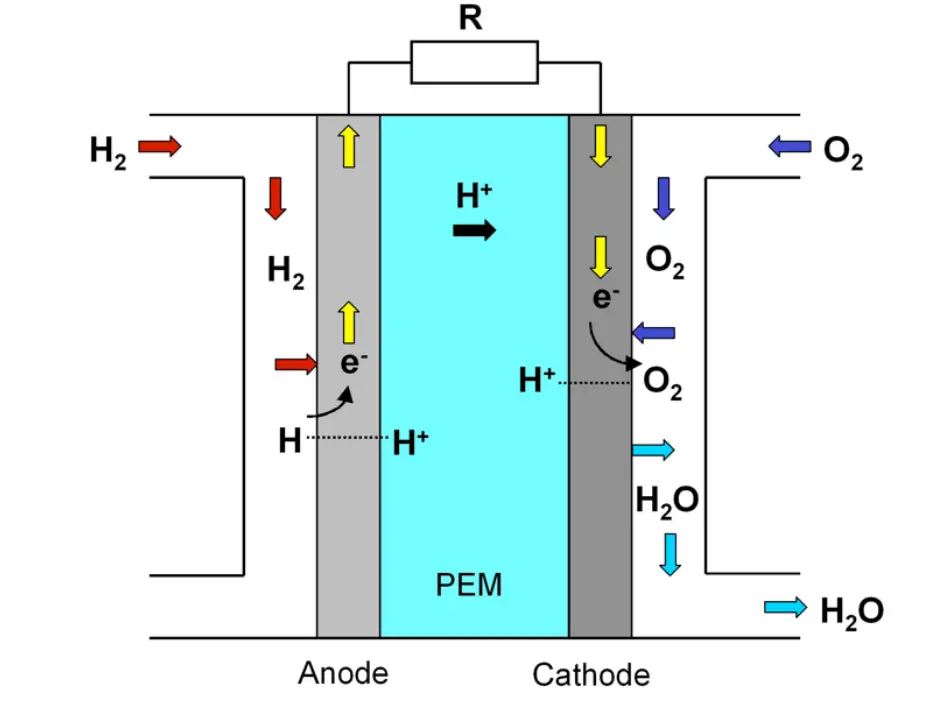

- Hydrogen (H₂) is the primary fuel, and its purity directly affects the electrochemical reaction. Any reduction in hydrogen quality leads to poor electron production and increased resistance. ESEGASanalyzers detect trace-level impurities to ensure consistent hydrogen integrity.

- Oxygen (O₂), typically supplied from air, must be monitored to ensure correct stoichiometric ratios. Insufficient oxygen reduces power output, while excess oxygen can cause drying of the membrane electrode assembly (MEA).

- Water vapor (H₂O) plays a dual role: it is a byproduct of the fuel cell reaction and also crucial for humidifying the proton exchange membrane. If not balanced correctly, dehydration or flooding may occur—both of which reduce efficiency and damage components. ESEGAS analyzers track water vapor levels in both anode and cathode exhaust streams.

- Nitrogen (N₂) enters the system with ambient air and serves no direct electrochemical purpose. However, excessive nitrogen can dilute oxygen concentration and lower cell efficiency. Real-time analysis ensures nitrogen presence remains within acceptable limits.

- Carbon monoxide (CO), even in trace amounts, can poison the catalyst layer of the fuel cell. This is especially critical for reformate-based hydrogen sources. ESEGAS analyzers are capable of detecting CO in sub-ppm levels, offering essential protection for the catalyst and overall system longevity.

Pic resource: grz-technologies

By constantly analyzing these gases, operators can optimize feed gas mixtures, preempt component degradation, and maintain safe, efficient fuel cell operation under all load conditions.

How Does a Hydrogen Fuel Cell Gas Analyzer Work?

A hydrogen fuel cell system operates in a delicate balance. Small shifts in gas composition—whether due to leaks, feedstock changes, or environmental conditions—can lead to major performance losses or even system failure.

Without precise, real-time gas monitoring, engineers rely on estimates, increasing risks of inefficiency, catalyst damage, and unsafe operation.

A hydrogen fuel cell gas analyzer from ESEGAS continuously monitors gas streams using advanced sensing technologies. These instruments deliver immediate insight into chemical composition, enabling intelligent system control, fault detection, and efficiency optimization.

A hydrogen fuel cell gas analyzer typically operates in four stages:

1. Sampling

Gas is extracted from the anode or cathode exhaust using heated sample lines to prevent condensation and preserve gas integrity. The sample is directed into the analyzer, often through a conditioning system that filters particulates and controls pressure and temperature.

2. Detection & Measurement

Various sensor technologies are used depending on the gases being measured:

- TCD (Thermal Conductivity Detector): Measures changes in thermal conductivity between hydrogen and carrier gases—ideal for high H₂ concentrations.

- NDIR (Non-Dispersive Infrared): Detects gases like CO and CO₂ based on their infrared absorption characteristics.

- FTIR (Fourier Transform Infrared Spectroscopy): Offers multi-gas analysis with high specificity—useful for complex reformate streams.

- Electrochemical sensors: Used for trace gas detection, such as ppm-level CO or O₂.

3. Signal Processing & Calibration

Sensor signals are converted into digital data, corrected for temperature, pressure, and humidity. Built-in microcontrollers apply calibration curves to ensure accuracy across different operating conditions.

4. Data Output & Integration

Processed data is transmitted to the fuel cell control unit (FCU) or SCADA systems using analog or digital protocols (e.g., 4–20 mA, Modbus, Profibus). This enables real-time response to deviations, such as adjusting inlet flow rates or initiating shutdown protocols.

How Can Gas Analysis Optimize Fuel Cell Performance?

Hydrogen fuel cells rely on ideal operating conditions—perfect gas ratios, stable temperatures, and balanced humidity—to function efficiently. Yet, these conditions can shift rapidly under variable loads or environmental influences.

Without real-time gas analysis, these shifts go undetected. As a result, you may face power output loss, membrane dehydration or flooding, increased hydrogen consumption, or even accelerated degradation of the cell stack.

Continuous gas analysis, enabled by advanced systems like those from ESEGAS, gives operators the insights needed to fine-tune performance-critical parameters, resulting in optimized energy output, higher efficiency, and longer system lifespan.

Here’s how real-time gas analysis directly enhances fuel cell performance:

1. Precision Stoichiometry Control

- The ratio of hydrogen to oxygen must be balanced for optimal electrochemical reactions. A deficiency reduces power; an excess wastes fuel.

2. Membrane Humidity Management

- Proton Exchange Membrane Fuel Cells (PEMFCs) require a hydrated membrane for ionic conduction.

- Too little water dries out the membrane; too much leads to flooding and blockage of reactant pathways.

3. Thermal Balance Optimization

- Uneven gas flow can create localized heating, leading to material fatigue and uneven catalyst utilization.

- With real-time gas concentration data, fuel cell controllers can adjust flow rates and cooling strategies dynamically, ensuring even heat distribution and stable output.

4. Fuel Utilization Efficiency

- Efficient hydrogen usage directly reduces operational cost and improves energy conversion rate.

5. Real-Time Load Matching

- Load conditions change rapidly, especially in mobile or backup power systems.

- Real-time gas data enables predictive control logic that adjusts fuel cell behavior in anticipation of load variations, preventing efficiency drops or overshooting.

6. Catalyst Life Extension

- Detecting and controlling CO contamination or overfueling prevents catalyst poisoning and hot spots, which significantly extends system life.

In short, fuel cell performance is no longer a fixed characteristic—it becomes a dynamic variable that can be actively optimized. With intelligent gas analytics from ESEGAS, engineers gain the ability to maximize output per gram of hydrogen, per hour of operation, and per cycle of the cell stack. This transforms the fuel cell from a passive energy source into a precision-controlled energy engine.

What Safety Role Does a Gas Analyzer Play in Hydrogen Fuel Cell Systems?

Hydrogen, while a clean energy source, is also one of the most volatile gases in industrial use. It’s colorless, odorless, and highly flammable, with a low ignition energy and wide explosive range in air. On top of that, reformate hydrogen often carries trace carbon monoxide—a silent threat to the fuel cell catalyst.

In the absence of real-time gas monitoring, small leaks can go unnoticed, and contaminants like CO can silently degrade system integrity. A single undetected fault can lead to fire, explosion, or total system failure. These are not theoretical risks—they are documented causes of shutdowns in transport, stationary power, and industrial systems alike.

A hydrogen fuel cell gas analyzer from ESEGAS acts as the system’s safety guardian, providing early detection of dangerous conditions before they escalate. Through precise measurement of hydrogen, carbon monoxide, oxygen, and other relevant gases, the analyzer continuously evaluates both the integrity and the chemical stability of the fuel cell environment.

Gas analyzers detect hydrogen leaks at parts-per-million levels, giving operators time to trigger ventilation, shutoffs, or alarms well before flammability limits are reached. Similarly, ESEGAS analyzers monitor for carbon monoxide, a potent catalyst poison that can destroy the cell’s electrochemical activity if left unchecked. In reformate-based systems, where CO is a common byproduct, this early warning function is essential. The analyzer also ensures that air starvation or flooding does not occur, both of which can lead to localized overheating or pressure buildup—two precursors to catastrophic failure.

In integrated fuel cell systems—such as those found in vehicles or aerospace—ESEGAS analyzers provide real-time data directly to the safety control unit. This allows for instant shutdowns, controlled venting, or system isolation based on dynamic conditions, not delayed sensor triggers. The result is a tightly controlled safety loop that minimizes risk while maximizing uptime.

Ultimately, a hydrogen fuel cell without a gas analyzer is flying blind in a volatile environment. With a precision analyzer from ESEGAS, operators gain not just visibility—but command over safety-critical parameters. It’s not just about performance anymore—it’s about protecting the technology, the operators, and the environment around it.

Conclusion

Hydrogen fuel cell gas analyzers are vital for unlocking the full potential of clean energy systems. By enabling precise performance monitoring, enhancing safety, and reducing maintenance costs, ESEGASanalyzers ensure that hydrogen fuel technology delivers on its promise—efficiently and safely.

If you want to know more, contact with us please!