Reliable gas sensing sits at the heart of every safe and efficient industrial operation. Plants today face tighter emission limits, more complex process conditions, and rising expectations for environmental compliance. A single faulty reading can disrupt fuel-air control, trigger false alarms, or mask a real safety risk. Because of this, industries—from power generation to cement and steel—depend on instruments that deliver stable, traceable, and fast gas-concentration data. Reliable sensing is no longer “nice to have.” It is a core part of process integrity, worker safety, and regulatory confidence.

In this context, non-dispersive infrared sensors have become one of the most trusted tools for gas detection. They offer high selectivity, strong signal stability, and long service life, which engineers and EHS teams value. Operators rely on these sensors to monitor CO, CO₂, CH₄, and other infrared-active gases in real time, even in harsh or fast-changing environments. Their design avoids moving optical parts, which improves durability and keeps maintenance predictable. Because they integrate easily into control systems, they support both frontline operations and long-term reliability planning.

How Does a Non-Dispersive Infrared Sensor Detect Gas with Such High Accuracy?

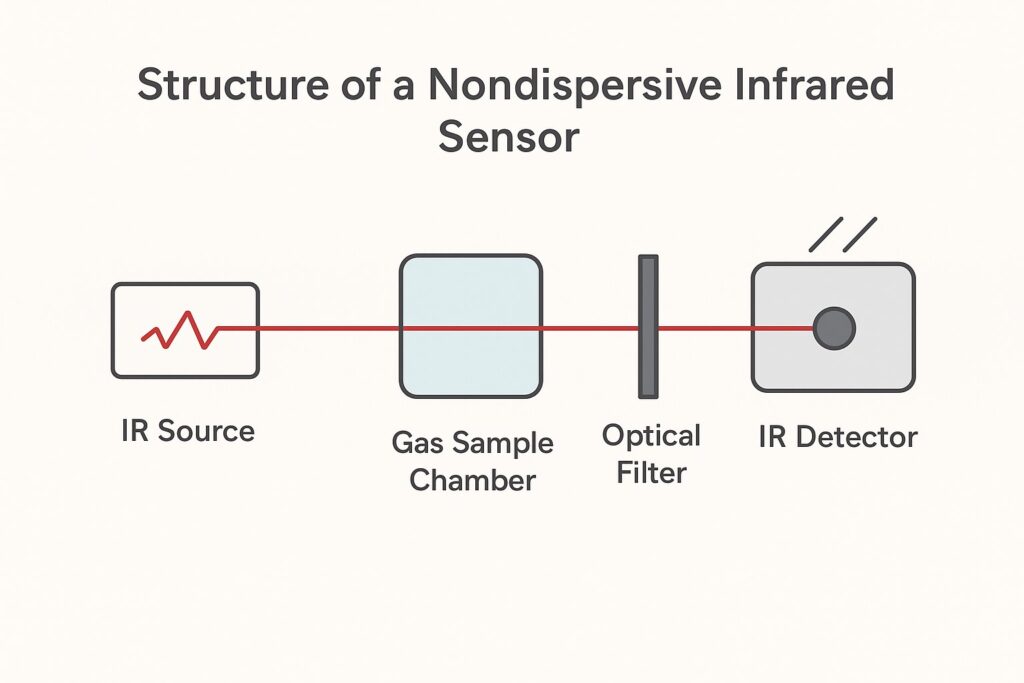

A non-dispersive infrared sensor works on a simple idea: gases absorb infrared light at specific wavelengths. Unlike dispersive spectroscopy, it does not split light with a prism or grating. Instead, it uses a broad infrared source and a narrow optical filter to isolate the exact wavelength a target gas absorbs. This stripped-down design gives the sensor a clean, direct signal path that avoids many alignment issues found in more complex optical systems. As a result, the sensor stays stable even when conditions around it shift, which is a big advantage in busy plant environments.

The sensing principle comes from the Beer–Lambert law, which links light absorption to gas concentration and optical path length. When infrared light passes through the gas cell, part of the light is absorbed by the target molecules. The sensor measures this drop in intensity and converts it into an accurate gas reading. The idea sounds straightforward, but it reflects a powerful piece of physics that allows engineers to measure trace gas levels with confidence. Because the law is predictable and linear in controlled conditions, it forms a solid foundation for reliable industrial measurement.

Different gases absorb infrared energy at different “signature” wavelengths, and NDIR technology takes full advantage of this behavior. CO, CO₂, and CH₄ show strong absorption bands in the mid-infrared region, making them ideal candidates. Some systems also track gases like SO₂, NO, and NO₂ when optical paths and filters are optimized. This ability to tune the sensor toward specific bands helps engineers reduce cross-interference and maintain high selectivity. It also lets plants match each sensor channel to the gas that matters most for their process or emissions profile.

The “non-dispersive” design also gives the sensor several practical benefits. It removes moving optical parts, which reduces drift and mechanical failure. It keeps the optical path short and clean, which improves stability in dusty or high-vibration areas. And it simplifies the electronics so that calibration stays manageable over long service cycles. These strengths make NDIR a natural fit for real-world industrial work, where robustness, repeatability, and low maintenance often matter as much as raw precision.

What Makes the Component Architecture of a Non-Dispersive Infrared Sensor So Effective in Industrial Use?

A non-dispersive infrared sensor relies on a clear and efficient optical layout that turns a simple idea into a stable measurement system. It starts with an infrared light source that sends energy through a defined gas cell. The optical path holds the sample, while a set of narrowband filters isolates the wavelengths linked to the target gas. A sensitive detector then measures how much light passes through, and the electronics convert that signal into a gas concentration. This structure may look straightforward, but each part plays a precise role in maintaining accuracy and reducing noise in harsh operating conditions.

The ESEGAS ESE-IR-100M builds on this architecture with several advanced features. It uses a gas filter correlation setup with a long-path absorption cell to push detection limits lower while keeping cross-interference under control. The low-temperature IR detector helps reduce drift, cut noise, and improve long-term stability, which matters when plants need continuous monitoring. The system separates the light source, detector, and control electronics into modular blocks, which makes maintenance easier and speeds up troubleshooting. This layout also improves reliability because each part operates within a controlled environment.

The sensor also integrates smoothly with modern control systems. It offers RS-232, RS-485, and 4–20 mA outputs, which fit directly into PLCs, DCS platforms, and standalone monitoring units. These interface options help engineers route data into existing plant networks without redesigning their infrastructure. They also support real-time alarms, trend tracking, and automatic control actions. As a result, the sensor becomes more than a measurement device; it acts as part of a larger operational strategy.

Taken together, these elements show why this architecture works so well in industrial settings. The optical design provides stable measurement, the modular structure enhances durability, and the flexible outputs allow easy integration. Plants can select the configuration that fits their process, from low-level detection to continuous emission checks. This combination of robustness and adaptability is what keeps NDIR technology relevant across so many sectors.

Why Do Plant Engineers Rely on Non-Dispersive Infrared Sensors in Real Industrial Applications?

Non-dispersive infrared sensors support a wide range of industrial tasks because they handle real-world gas conditions with steady performance. Plants use them to track CO and CO₂ in stacks, control combustion in furnaces, and monitor biogas or syngas streams with shifting compositions. They also appear in indoor air systems, leak-detection setups, and ambient air stations. These applications share one need: stable gas data that responds quickly to changing process loads. When readings drift, operators lose confidence, so a sensor that holds its baseline becomes a core part of plant reliability.

These sensors stand out because they offer strong selectivity, long-term stability, and low maintenance—traits that engineers value under tight schedules. The ESEGAS module reinforces these strengths with fast response, low drift, and high precision. This combination makes the technology a natural fit for systems that run around the clock. It also helps operators avoid disruptions caused by false alarms or slow measurements. When the module stays stable, the entire control loop runs more smoothly.

Heavy industries depend heavily on these advantages. Power plants rely on accurate CO readings to balance combustion; cement plants track CO₂ and kiln off gas; steel mills monitor furnace atmospheres; and petrochemical sites check critical lines for leaks. In these environments, NDIR sensors help teams meet emission limits, improve process efficiency, and maintain safe working conditions. ESEGAS highlights similar deployments in power, steel, and bio-energy sectors, where the technology supports consistent, real-time insight.

Still, industrial environments bring their own challenges. Dust, humidity, and ambient temperature shifts can distort signals, while calibration drift and optical contamination can introduce errors. A well-designed NDIR system manages these issues with long optical paths, correlation filters, and dual-detector configurations that reduce noise. These features help keep the measurement stable even when the process environment is far from ideal. They also extend calibration intervals and reduce the need for constant manual checks.

Conclusion — Why Choose a Non-Dispersive Sensor for Industrial Gas Monitoring?

NDIR technology remains one of the most reliable tools for tracking key gases across industrial sites. It works by sending infrared light through a sample and measuring how target gases absorb specific wavelengths. This simple but robust principle gives stable readings even in harsh conditions.

ESEGAS’s non-dispersive sensor module shows how smart design strengthens this core idea. Its sealed optical bench, optimized path length, and stable IR source help reduce drift and noise. Its compact structure also supports fast response and long service life. When paired with proper sampling and conditioning, it delivers precise data for CO, CO₂, CH₄, and other critical gases.

These advantages explain why NDIR sensors remain essential for process control, leak detection, and safety compliance. They bring dependable accuracy, low maintenance, and long-term operational value—qualities every plant engineer depends on.

If you want a gas monitoring solution that is accurate, durable, and easy to integrate, we are here to help. Our team can walk you through sensor selection, system design, and application details so you get the best fit for your plant. Feel free to reach out to us for technical support, product demos, or tailored project advice. Let’s build a safer and more efficient gas monitoring system together.

FAQs:

Q1: What is a non-dispersive infrared (NDIR) sensor and how does it differ from other gas sensing technologies?

A1: A non-dispersive infrared sensor uses a broad IR light source, a gas cell, and a filter to isolate the absorption wavelength of a target gas — without using a prism or diffraction grating to split the light. In contrast, dispersive spectroscopy separates light across many wavelengths, making it more complex and less suited for rugged industrial monitoring. The simplified optical path of NDIR makes it especially suited for heavy-duty environments.

Q2: Which gases can an NDIR sensor detect and why is this important for industrial applications?

A2: NDIR sensors detect gases that absorb IR light at specific wavelengths. Common targets include Carbon Dioxide (CO₂) at about 4.26 µm, Carbon Monoxide (CO) at about 4.67 µm, and Methane (CH₄) at about 3.31 µm. This is important in industry because those gases are key for emissions monitoring, combustion control, process safety and regulatory compliance in power, steel, cement and chemical plants.

Q4: What environmental or operational challenges can affect NDIR sensor performance, and how are they mitigated?

A4: NDIR sensors may face interference from factors like humidity, particles, dust, temperature changes, or optical path contamination. To mitigate these issues, modern sensors include design features such as long optical paths, correlation filters, dual detector systems, and sample-conditioning (filtering/drying) upstream of the sensor. These improvements help maintain accuracy and reliability in real industrial plants.

Q5: How does the architecture of an NDIR sensor support its suitability for industrial integration?

A5: The architecture of an NDIR sensor typically includes five core parts: IR light source, gas sample optical path/cell, wavelength filter(s), detector, and signal-processing electronics. When designed for industry, this architecture provides:

- Clear signal flow (source → sample gas → filter → detector)

- Robust components (e.g., sealed optical cell)

- Flexible interface outputs (e.g., 4-20 mA, RS-485) for control-system integration

These attributes make it easier for plant engineers to integrate the sensor into control and safety systems.

Q6: What should procurement or EHS professionals consider when specifying an NDIR sensor for a plant application?

A6: When specifying an NDIR sensor, professionals should examine:

- Target gas and concentration range required for the process or emission point

- Sensor accuracy, drift and response time

- Environmental conditions (e.g., temperature, humidity, presence of particulates)

- Integration interface (analog/digital outputs)

- Maintenance demands and lifetime costs

Choosing a sensor that matches process risk and control system requirements helps avoid over- or under-specifying the instrumentation.