In high stakes industrial settings, a malfunction of the ESEGAS gas analyzer demands immediate attention. When the analyzer goes offline or gives unreliable data, you must act decisively to prevent extended downtime, compromise of safety systems, and regulatory non compliance. You must act with ESEGAS’s team!

Why Does a Gas Analyzer Failure Demand Immediate Action?

When your gas analyzer goes offline, you cannot afford to wait. A malfunction in a critical instrument like the gas analyzer puts your system and your team at real risk. First and foremost, safety and regulatory compliance are on the line. A failed analyzer cannot reliably measure key gases—such as O₂, CO, H₂S or NOₓ—in your process stream. Without valid readings, you lose visibility into combustion efficiency, emissions output and hazardous‐gas build‐up. This vulnerability raises the odds of unsafe conditions and non‐compliance with environmental permits.

Second, the operational cost and downtime mount quickly. When an analyzer fails:

- Control loops that depend on its output may drift or shut down.

- Production monitoring becomes suspect, forcing manual checks or stoppages.

- Emissions reporting will lag or become inaccurate, possibly triggering regulatory alarms.

Because of these ripple effects, early intervention saves the plant from extended shutdowns and high reactive maintenance costs.

Third, this is about trust and asset management. Responding promptly to a fault in your analyzer strengthens your instrumentation strategy. You show your operators, management and suppliers that you treat measurement systems as core assets. In doing so, you align with best practices in reliability engineering and asset management. Over time, that builds confidence in the supplier‐relationship and in your measurement infrastructure.

In short: a failed gas analyzer is not just a thing to log and forget—it demands swift diagnostics, decisive action and a structured follow-up. That approach protects safety, keeps costs down, and preserves trust in your instrumentation portfolio.

What Pre-Support Checks Can You Perform on Your ESEGAS Gas Analyzer?

When your gas analyzer from ESEGAS struggles, you don’t have to wait blindly for service. By performing a set of systematic checks yourself, you can often resolve the issue faster — or at least gather the right data for effective remote support.

1. Verify Basic Hardware Integrity

Start with power and connectivity. Make sure the unit receives correct voltage, the power-on self-test (POST) completes successfully, and all cables and fuses appear intact. A failed POST or loose cable often signals a hardware fault rather than a complex system error.

2. Confirm Sample System Integrity

Next, inspect the sampling train: the sample line, filters, pump and fittings. Check for blockages, leaks or kinks in the tubing. In industrial environments, contamination or flow interruptions are a common cause of reading instability. As the manufacturer notes, maintaining clean tubing and proper filters helps ensure reliable performance.

3. Check the Installation Environment

Don’t overlook the surroundings. Ensure ambient conditions (temperature, humidity, vibration) remain within the analyzer’s specifications. Verify whether the unit is in a hazardous-area zone and whether its explosion-proof rating is matched correctly. Environmental stress can degrade sensor behavior and lead to unusual faults.

4. Review Calibration Status and Sensor Lifetime

Sensors age, and drift can set in without warning. Review the calibration log: when was the last calibration? Are there any indications of sensor end-of-life? For example, ESEGAS notes that uncalibrated or overdue devices risk inaccurate data. If you spot a zero error or wide span deviation, schedule calibration immediately.

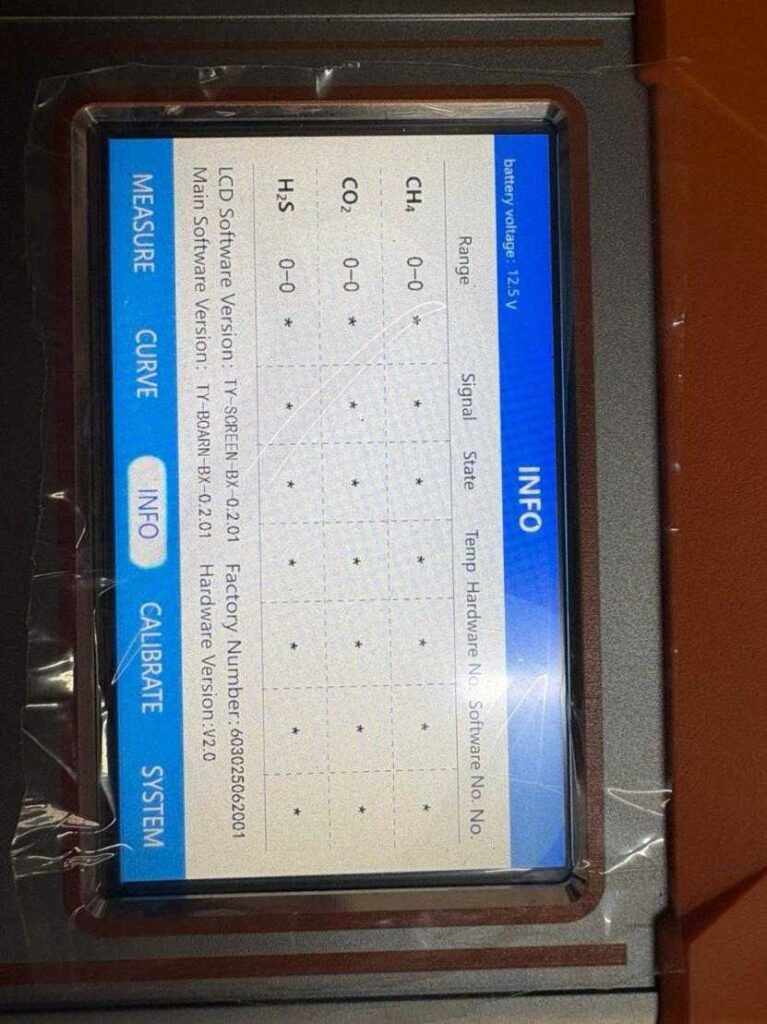

5. Record Error Codes and Capture Logs

Finally, capture every clue. If the unit displays error codes, log them. If it supports screenshots or system logs, save those. These data serve as your “case file” for remote support and expedite the manufacturer’s troubleshooting. By arming yourself with error history and the checks you’ve already conducted, you reduce back-and-forth and cut down resolution time.

With these five first-line diagnostics, you shift from reactive waiting to proactive troubleshooting. This approach supports not only faster recovery but also helps your team build stronger instrumentation governance — aligning hardware integrity, sample system health and environmental conditions all at once.

How Do You Engage ESEGAS Remote Support & Escalation for a Gas Analyzer?

Once your ESEGAS gas analyzer fails to respond to your initial checks, it’s time to escalate with confidence and clarity. First, contact the ESEGAS support team promptly. Be prepared with key details: the unit’s serial number, installation date, a clear description of the fault, pictures and videos, and the results of your own diagnostic checks. That sets the stage for faster, more effective support.

During remote assistance, ESEGAS technicians will guide you through systematic troubleshooting. They’ll help isolate whether the issue originates in the sensor module, electronics, sample train or software. This structured approach ensures you’ve covered all bases before considering a return.

If remote diagnostics conclude that onsite repair won’t suffice, prepare for a factory-inspection return. At this stage, document all steps: obtain shipping authorization, follow packing instructions, and review the warranty or service agreement to understand who covers cost, responsibility, and turnaround expectations.

By following this escalation path—structured communication, logical remote troubleshooting, clear trigger for return—you not only resolve the immediate issue but also demonstrate good instrumentation governance. That builds confidence in your measurement infrastructure, strengthens your supplier relationship, and supports long-term reliability.

What Service Terms Should You Know for ESEGAS Gas Analyzer?

Understanding the service terms for a gas analyzer—especially one from ESEGAS—is not just useful; it’s essential. These terms guide your expectations, protect your budget and reinforce operational stability.

Warranty Period

ESEGAS provides a standard warranty of one year after the customer receives the equipment. Within this period, you are generally eligible for repair or replacement under specified conditions. Knowing the start date and coverage scope ensures you don’t miss the window for cost-free support.

Repair Lead-Time

Service speed becomes crucial when uptime matters. ESEGAS commits to addressing simple faults—often via remote support—within 24 hours. If onsite repair is insufficient and a factory inspection is required, the process typically wraps up within 15 days. Fast turnaround helps reduce production risk.

Manuals & Documentation

The instrument comes with operating manuals, calibration guides and maintenance documentation upon request. Retain these documents for your engineering and EHS teams. They provide the know-how your staff needs and help you hold suppliers accountable.

Payment and Terms

Standard payment terms might be framed as 30 % advance and balance on delivery or start-up. Importantly, you should clarify what service or warranty covers and what falls under “wear & tear” or misuse. For instance: Are consumables included? Does damage from improper sample systems count? These distinctions affect cost allocations.

All service content is based on the customer’s specific requirements and response from the ESEGAS team. By mastering these service terms, you shift from reactive to proactive: you know when you’re covered, how quickly you’ll get support, what documentation you should keep and where your financial responsibilities lie. This clarity strengthens your role as an instrumentation-asset owner, not just a user.

Conclusion

In closing, let’s tie together the path you should follow when an ESEGAS gas analyzer stops working. First, act swiftly with those first-line checks we covered: inspect power supply and cabling, assess the sampling train, verify installation environment and review sensor status. Next, if the issue persists, engage remote support from ESEGAS; follow their guidance and escalate to a return if onsite repair fails. Then move into root-cause and preventive actions: analyze why the failure occurred and embed improvements to avoid a repeat.

If you prefer a direct route, feel free to contact our team at any time. Visit our website or email us at [email protected]. We will guide you step-by-step and ensure minimal disruption to your operations.

FAQ – Service Terms for ESEGAS Gas Analyzer

Q1: What is the standard warranty period for an ESEGAS gas analyzer?

A1: ESEGAS typically offers a 1-year warranty from the date the customer receives the equipment. This means within that period, defects in workmanship or manufacturing may be addressed under warranty. (For example, the model IR-GAS-600 lists a one-year warranty.) It’s important to note: the warranty coverage may exclude consumables, damage from misuse, or installation outside specified conditions.

Q2: What is the expected repair lead-time under service terms?

A2: Under normal service terms:

- Simple issues can be addressed within 24 hours via remote support.

- If a unit needs to be returned to the factory for inspection, the typical turnaround is around 15 days from receipt.

This quick lead-time helps reduce production downtime and supports reliability.

Q3: What manuals and documentation do ESEGAS provide?

A3: ESEGAS provides the following products’ documentation upon request:

- Operating manual (including installation, sample system, calibration instructions), test report, product certification, shipment list

- Service/documentation manual for maintenance and repair

- Calibration and QA procedure guidelines

Having these documents helps your team handle routine tasks, understand service conditions, and communicate effectively with ESEGAS support.

Q4: What are the standard payment and delivery terms for ESEGAS gas analyzers?

A4: Typical terms are:

- 30% advance payment when placing the order

- Balance (70%) due before shipment or at start-up

It’s critical to link these payment milestones with delivery, commissioning and warranty eligibility. Additionally, you should clarify what is covered under warranty and what isn’t — for example: wear & tear items, damage due to misuse, or travel costs for on-site engineers may fall outside warranty coverage.

Q5: If I need engineer training or on-site support, what training and travel cost terms apply?

A5: While standard warranty may cover the gas analyzers, training of your personnel or on-site engineer visits often involve additional costs:

- If you require ESEGAS engineers or service staff to travel to your site for training or commissioning, you will typically cover the travel, accommodation and daily allowance costs of the engineers.

- It’s wise to ask also about the training scope (operator training, maintenance staff, calibration staff), the number of personnel, the duration, and whether there are packaged service contracts or extra fees.

By clarifying these terms upfront, you avoid surprises and integrate training into your total cost of ownership (TCO) for the analyzer.

Q6: What should I watch out for in the warranty service terms?

A6: Key items to check include:

- Start-date of the warranty (upon receipt of goods or commissioning)

- Conditions that void warranty (e.g., incorrect installation, use outside specifications, unauthorized service)

- Whether shipping costs are covered when returning a unit under warranty

- Definition of “wear & tear” or consumables that are excluded

- Whether calibration exclusions apply (e.g., if sensors degrade due to harsh environment)

- Whether the warranty covers software, firmware upgrades, or only hardware

Being aware of these helps you manage risk, support planning for maintenance, and negotiate service contracts.

Q7: Can training plus support be bundled or is it charged separately?

A7: While some sellers might bundle basic training with purchase, in many cases additional or bespoke training sessions are treated as separate service items. If you expect:

- Training for multiple shifts or sites

- On-site commissioning over several days

- Custom calibration or workflow training

You should clarify whether these are included in the base purchase price or will invoke extra service charges (travel, accommodation, daily‐rate for engineer). Documenting these details ensures transparency and aligns with your EHS and instrumentation strategy.