Are you still relying on outdated gas analysis techniques? Conventional methods can be time-consuming, prone to inaccuracies, and require frequent maintenance. In contrast, laser gas analysis technology is revolutionizing the way industries measure and monitor gases by providing accurate, reliable, and real-time solutions.

Laser gas analysis technology employs laser-based spectroscopy to measure gas concentrations with unmatched precision and minimal interference. This cutting-edge approach is widely utilized in sectors such as petrochemicals, energy production, and environmental monitoring, making it an indispensable tool for modern industries.

To fully understand why laser gas analysis technology is reshaping industrial practices, let’s explore how it works, its advantages over traditional methods, and the various applications that benefit from this breakthrough technology.

How Does Laser Gas Analysis Technology Work?

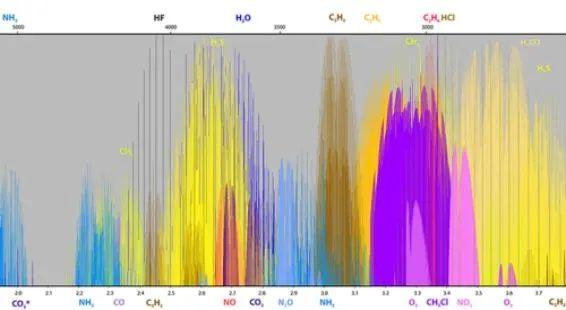

Ever wondered how laser technology can measure gases with such precision? The core of laser gas analysis lies in Tunable Diode Laser Absorption Spectroscopy (TDLAS), a technique that identifies gases based on their unique optical absorption properties.

Here’s how it works:

- A laser beam, tuned to specific wavelengths, is emitted through a gas sample.

- Certain gas molecules absorb light at characteristic wavelengths as the laser passes through.

- The system measures the intensity of the absorbed light and calculates the gas concentration based on this absorption.

This method offers unparalleled sensitivity and specificity, even in environments with high levels of background noise or cross-contamination. Unlike conventional techniques, TDLAS can detect trace amounts of gases in real time without physical contact, ensuring fast and reliable results.

For example, in industries where safety is critical, such as oil and gas, the ability to instantly measure flammable or toxic gases can prevent accidents and reduce downtime.

What Are the Advantages of Laser Gas Analysis Over Traditional Methods?

Are you struggling with inefficiencies and inaccuracies in your gas monitoring systems? Laser gas analysis technology addresses these pain points with its superior performance in several key areas:

1. High Accuracy and Sensitivity

Traditional methods often face challenges in distinguishing target gases from other components in the sample. Laser gas analysis, however, uses precise laser wavelengths to isolate specific gases, even at very low concentrations. This level of accuracy is critical for applications such as emissions monitoring and process optimization.

2. Fast Response Time

Unlike older technologies, which may require minutes or even hours to deliver results, laser gas analysis provides instantaneous measurements. This rapid response is invaluable in dynamic processes where conditions can change rapidly, such as combustion monitoring in power plants.

3. Low Maintenance and Cost Efficiency

Conventional gas analyzers often involve moving parts, chemical reagents, and frequent calibration, all contributing to higher maintenance costs. In contrast, laser gas analyzers have fewer mechanical components and do not require consumables, making them more cost-effective in the long run.

4. Non-intrusive and Safe Operation

Traditional sampling methods require physical contact with the gas, which can be risky in hazardous environments. Laser-based systems operate remotely, ensuring safety and reducing the risk of contamination or equipment damage.

By addressing these challenges, laser gas analysis technology enables industries to achieve greater efficiency, safety, and compliance with regulatory standards.

TDL Laser Gas Analysis System

TDL laser gas analysis system ESE-LASER-100 uses the whole process of high-temperature combined heat extraction to monitor HCL/HF/NH3 gas in the sample gas. The system consists of a sampling unit, a transmission unit, a preprocessing unit, a control unit, and an analysis unit. The analysis unit uses TDLAS technology.

Based on the principle of tunable laser absorption spectroscopy (TDLAS), a laser gas analyzer scans and analyzes the gas absorption spectrum lines of specific wavelength, and realizes the gas concentration measurement by combining the digital lock-in amplifier and advanced technology such as a long path gas chamber. ESE-LASER series can realize high resolution, high precision, stable, and reliable measurement of trace gases, and meet the requirements of process analysis and environmental detection.

Applications

- SCR, incineration & combustion processes

- Emission monitoring: Power generation, engine development, waste incineration furnaces

- Environmental monitoring: Landfill & green-house gases, livestock, …

- Chemical engineering: Production control & monitoring …

- Safety: Leak detection, refrigeration, toxic gases.

- Climate control & monitoring: Livestock, climate chambers & rooms

A TDL (Tunable Diode Laser) laser gas analysis system is a gas monitoring and analysis solution that utilizes the TDLAS (Tunable Diode Laser Absorption Spectroscopy) technique. It is designed to measure and analyze the concentration of specific gases in various applications, including industrial processes, environmental monitoring, and research. solution that utilizes the TDLAS (Tunable Diode Laser Absorption Spectroscopy) technique. It is designed to measure and analyze the concentration of specific gases in various solution that utilizes the TDLAS (Tunable Diode Laser Absorption Spectroscopy) technique. It is a solution that utilizes the TDLAS (Tunable Key components and features of a TDL laser gas analysis system typically include:

Laser Source: The system incorporates a tunable diode laser as the light source. The laser emits light at specific wavelengths that correspond to the absorption lines of the target gas to be analyzed.

Gas Measurement Cell: A gas measurement cell or sample chamber is used to contain the gas sample being analyzed. The laser beam passes through this cell, and the gas molecules absorb specific wavelengths of light based on their concentration. 、

Detector: A photodetector or photodiode detects the intensity of the laser light after it has passed through the gas sample. The detector measures the amount of light absorbed by the gas, which is used to determine the gas concentration.

Optical Path and Beam Alignment: The system includes an optical path that ensures the laser beam passes through the gas sample cell accurately. Beam alignment is crucial to optimize measurement accuracy and stability.

Signal Processing and Analysis: The detected signal is processed and analyzed to calculate the concentration of the target gas. This involves comparing the absorbed light intensity to a reference measurement and applying calibration algorithms to obtain accurate results.

Data Display and Communication: TDL laser gas analysis systems often include displays to show real-time gas concentrations and system status. They may also have communication interfaces for data logging, remote monitoring, and integration with control systems. Advantages of TDL laser gas analysis systems include high precision, fast response time, wide dynamic range, and high selectivity for specific gases. They are particularly well-suited for trace gas analysis and applications where real-time measurements and robust performance are essential. The specific configuration and capabilities of a TDL laser gas analysis system may vary depending on the manufacturer and the intended application. It is important to consider factors such as the target gas, measurement range, accuracy requirements, environmental conditions, and any industry-specific compliance standards when selecting a TDL laser gas analysis system. manufacturer and the intended application. It is important to consider factors such as the target gas, measurement range, accuracy requirements, environmental conditions, and any industry-specific compliance standards when selecting a TDL laser gas analysis system manufacturer and the intended application. It is important to consider factors such as the target gas, measurement

Where Is Laser Gas Analysis Technology Used?

The versatility of laser gas analysis may surprise you. Its applications extend across various industries, benefiting from the technology’s precision and reliability.

1. Petrochemical Industry

In petrochemical plants, monitoring gases like methane, hydrogen sulfide, and carbon dioxide is critical for safety and efficiency. Laser gas analyzers provide real-time data, helping operators detect leaks and optimize processes.

For instance, a refinery can use TDLAS to measure the concentration of hazardous gases in flares or pipelines, reducing the risk of explosions and ensuring regulatory compliance.

2. Power Generation

Power plants, particularly those using fossil fuels, must monitor combustion processes to optimize energy output and minimize emissions. Laser gas analysis technology enables precise control of oxygen, carbon monoxide, and other gases in flue gas, ensuring maximum efficiency and compliance with environmental standards.

3. Environmental Monitoring

Governments and organizations worldwide rely on laser gas analysis to monitor air quality and greenhouse gas emissions. The ability to detect trace amounts of pollutants, such as sulfur dioxide or nitrous oxide, makes this technology essential for combating climate change and protecting public health.

4. Food and Beverage Industry

Even industries not traditionally associated with gas monitoring benefit from this technology. For example, in the food and beverage sector, laser gas analyzers are used to ensure proper packaging conditions by measuring oxygen or carbon dioxide levels.

5. Chemical Manufacturing

In chemical plants, controlling gas concentrations during production is critical to ensure product quality and safety. Laser gas analysis provides the real-time data needed to maintain these standards.

The adaptability of laser gas analysis ensures its relevance across diverse sectors, making it a cornerstone of modern industrial practices.

How Does Laser Gas Analysis Improve Environmental Sustainability?

Can advanced technology make a difference in the fight against climate change? The answer is a resounding yes. Laser gas analysis is crucial in monitoring and reducing greenhouse gas emissions, a key driver of global warming.

1. Real-Time Emissions Monitoring

Industries can use laser gas analyzers to track emissions of harmful gases like carbon dioxide, methane, and nitrous oxide. These systems provide real-time data, allowing companies to take immediate corrective actions, reducing their environmental impact.

2. Enhanced Leak Detection

Leaks in pipelines or storage facilities can release significant amounts of greenhouse gases. Laser-based technology enables precise detection of even small leaks, preventing unnecessary emissions and conserving resources.

3. Regulatory Compliance

Stricter environmental regulations demand accurate and reliable emissions data. Laser gas analysis helps industries meet these requirements, avoiding penalties and demonstrating their commitment to sustainability.

By integrating this technology into their operations, companies can contribute to global efforts to mitigate climate change while improving their efficiency and profitability.

What Are the Future Trends in Laser Gas Analysis Technology?

Curious about the next big advancements in gas monitoring? As industries continue to demand more efficient and precise measurement tools, laser gas analysis technology is evolving rapidly.

1. Integration with IoT and AI

The combination of laser gas analyzers with IoT (Internet of Things) devices and AI algorithms is opening new possibilities for predictive maintenance and process optimization. Smart sensors can now monitor gas concentrations in real time, sending data to cloud platforms for advanced analysis and decision-making.

2. Miniaturization and Portability

Ongoing research aims to make laser gas analyzers smaller and more portable, allowing their use in remote or hard-to-access locations. This development is particularly valuable for environmental monitoring in isolated areas.

3. Improved Sensitivity

Advances in laser technology are enhancing the sensitivity of gas analyzers, enabling the detection of even lower concentrations of gases. This is critical for applications in medical diagnostics and high-precision manufacturing.

These trends highlight the potential of laser gas analysis to transform even more industries in the years to come.

Conclusion

Laser gas analysis technology is revolutionizing the way industries monitor and measure gases, offering unparalleled precision, reliability, and efficiency. Its innovative principles, numerous advantages, and wide-ranging applications make it an essential tool for addressing the challenges of modern industrial and environmental requirements.

As advancements continue, this technology promises to play an even greater role in enhancing safety, sustainability, and operational excellence across the globe. If you have any questions, please get in touch directly with us and we will get back to you as soon as possible.