Precise gas measurement is crucial for safety, efficiency, and compliance in industrial processes. Without accurate monitoring, industries face risks like process inefficiencies, safety hazards, and regulatory fines.

A Tunable Diode Laser Absorption Spectroscopy (TDLAS) gas analyzer uses laser technology to detect specific gases in various industrial environments, enhancing process control, safety, and environmental compliance. TDLAS gas analyzers provide rapid, precise, and non-intrusive gas measurements, revolutionizing gas detection across sectors.

Unlike conventional gas analyzers, TDLAS analyzers offer unmatched precision, speed, and selectivity. Read on to learn about TDLAS technology, its applications, and its unique advantages over traditional methods.

How Does a TDLAS Gas Analyzer Work?

Problem: Traditional gas analyzers often lack the specificity or speed required in critical applications, leading to suboptimal monitoring.

Solution: TDLAS analyzers target specific gas absorption lines with tunable diode lasers, ensuring rapid, selective detection.

A TDLAS gas analyzer operates by emitting a laser beam tuned to the exact wavelength that the target gas absorbs. When the laser passes through the gas sample, the target gas absorbs some of the laser light. By measuring the light intensity before and after passing through the gas, the analyzer determines the gas concentration. This method’s precision comes from the fact that each gas has unique absorption wavelengths, allowing the TDLAS analyzer to target specific gases accurately and quickly.

Taking diode laser as the light source, by adjusting the current of laser current controller, the laser emitted by diode can be swept through a narrow wavelength range, and by selecting the suitable laser modulation current, the output wavelength range of the laser can completely cover the absorption spectrum of the gas to be measured, and then the detector can be used to receive the intensity of laser light propagated in the gas to be measured, and the basic theory of Beer-Lambert’s law is fulfilled by the absorption of the gas.

Lambert’s law, the absorbed light intensity with gas concentration is e exponential decay relationship, by analyzing the change of light intensity can be deduced from the concentration of the gas to be measured. TDLAS on the diode laser mode has certain requirements, which require that the diode laser must be a single-mode laser, and the measurement process needs to be strictly controlled by the working temperature of the laser, the change of the temperature will lead to the drift of the spectral range of the light source when the spectral range exceeds the absorption range of the gas, it is necessary to control the laser working temperature strictly.

When the spectral range exceeds the gas absorption range, the gas absorption will not be detected. In summary, TDLAS has high requirements for the working environment.

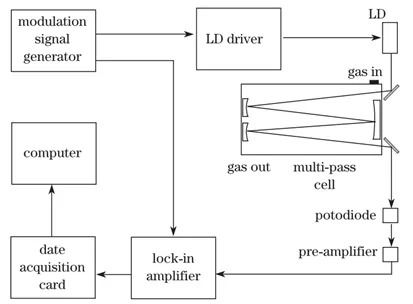

Diagram of a typical TDLAS test system

What Are the Main Applications of TDLAS Gas Analyzers?

Many industrial processes require continuous, reliable gas monitoring to maintain safety and efficiency, but traditional methods may fall short in harsh or dynamic conditions. TDLAS gas analyzers excel in diverse industrial environments, from power plants to petrochemical refineries.

- Power Generation: TDLAS analyzers monitor combustion processes, measuring gases like O2, CO, and CO2 to optimize efficiency and reduce emissions.

- Petrochemical Industry: Detecting hydrocarbons or hydrogen sulfide (H2S) with TDLAS ensures safety and regulatory compliance in potentially hazardous environments.

- Environmental Monitoring: By continuously measuring greenhouse gases, such as methane (CH4) or ammonia (NH3), TDLAS analyzers help industries comply with environmental regulations.

- Chemical Manufacturing: TDLAS gas analyzers ensure that specific gas concentrations are tightly controlled to maintain product quality and safety in chemical reactions.

- Healthcare and Pharmaceutical: The medical and pharmaceutical sectors use TDLAS to monitor gases like oxygen or nitrogen, especially in controlled environments where precision is essential.

Why is TDLAS Technology More Accurate Than Other Gas Analysis Methods?

Traditional gas analyzers may suffer from cross-sensitivity and delayed responses, affecting accuracy and reliability.TDLAS technology minimizes interference and provides real-time results, leading to highly accurate and responsive measurements.

The precision of TDLAS analyzers is due to their ability to focus on specific absorption lines unique to each gas. Unlike infrared or electrochemical sensors, TDLAS technology experiences little interference from other gases, making it ideal for selective gas monitoring. Moreover, TDLAS analyzers provide real-time measurements, essential for applications where quick detection is critical, such as detecting hazardous leaks.

What Advantages Do TDLAS Gas Analyzers Offer?

Industries face ongoing demands for accurate, efficient, and robust gas monitoring solutions.TDLAS gas analyzers meet these needs with fast response times, durability, and low maintenance.

- High Speed and Sensitivity: TDLAS gas analyzers can deliver measurements in seconds, ensuring rapid detection of any changes in gas composition.

- Non-Intrusive Measurement: The laser-based method does not require direct contact with the gas, reducing contamination risks and maintenance costs.

- Low Cross-Sensitivity: TDLAS is highly selective, focusing on specific gas absorption lines, which minimizes interference from other gases.

- Durability in Harsh Environments: TDLAS gas analyzers are built for challenging conditions, offering consistent performance in high temperatures, pressures, and corrosive environments.

- Cost-Effective Operation: With fewer moving parts and minimal need for recalibration, TDLAS analyzers have low operational costs over their lifespan.

How Does TDLAS Compare to Other Gas Analysis Technologies?

Each gas analysis method has limitations, and industries need the best fit for their specific applications.TDLAS technology outperforms traditional methods in specificity, speed, and adaptability to challenging environments.

- Electrochemical Sensors: Common in portable devices, electrochemical sensors are economical but often lack the specificity and durability needed for continuous monitoring.

- Non-Dispersive Infrared (NDIR) Sensors: While useful for many applications, NDIR sensors can be slower and susceptible to interference from other gases, which reduces accuracy.

- Mass Spectrometry: Though highly accurate, mass spectrometers are often bulky and expensive, making them less practical for real-time or field-based applications.

- TDLAS: With fast response times, high sensitivity, and robust performance under harsh conditions, TDLAS gas analyzers offer a superior choice for real-time and precise gas monitoring.

ESE-LASER-100

TDL laser gas analysis system ESE-LASER-100 uses the whole process of high-temperature combined heat extraction to monitor HCL/HF/NH3 gas in the sample gas. The system consists of a sampling unit, a transmission unit, a preprocessing unit, a control unit, and an analysis unit. The analysis unit uses TDLAS technology.

Based on the principle of tunable laser absorption spectroscopy (TDLAS), a laser gas analyzer scans and analyzes the gas absorption spectrum lines of a specific wavelength and realizes the gas concentration measurement by combining the digital lock-in amplifier and advanced technology such as the long path gas chamber. ESE-LASER series can realize high resolution, high precision, stable, and reliable measurement of trace gases, and meet the requirements of process analysis and environmental detection.

Technical Parameter

| Measured gas | HCL/HF/NH3 |

| Method | Tunable Diode Laser Spectrometry (TDLAS) |

| Range | HCL/HF: 0-50ppm,0-100ppm,0-500ppm( Customized)NH3:Above 20ppm |

| Accuracy | Less than 15S (at a gas flow rate of 3 L/min) |

| Precision | 1ppm |

| Displayed resolution | 0.1ppm |

| Response time | Warm-up time |

| Sampling Gas Temperature | ≥180℃ |

| Analog Output | 4`20mA DC, Insulating output, maximum load is 900 ohm, |

| Digital Output | RS232/485 |

| Power Supply | 90-240VAC / 50/60Hz 120W |

| Warm up time | 30 minutes |

| Interface | RS232 |

| Ambient Temperature | Temp:-10-50℃ Humidity:0-90%RH |

| Dimension | 760(H)×500(L)×255(W)mm(analysis cabinet)700(H)×450(L)×210(W)mm(control cabinet) |

What Are the Future Trends in TDLAS Technology?

As industrial processes and environmental regulations evolve, the demand for precise, adaptable gas monitoring continues to grow.TDLAS technology is advancing to meet new challenges in accuracy, miniaturization, and integration with smart systems.

Emerging trends in TDLAS gas analyzers include:

- Increased Sensitivity: New advancements allow TDLAS to detect even lower gas concentrations, making it suitable for applications requiring ultra-trace level detection.

- Miniaturization: Compact TDLAS devices are becoming available for portable and remote applications, widening their scope across industries.

- Integration with IoT: Modern TDLAS analyzers increasingly integrate with IoT systems, enabling real-time data analysis and remote monitoring.

- Environmental Applications: As environmental regulations tighten, TDLAS analyzers are essential for tracking pollutants and greenhouse gases, supporting global emissions reduction goals.

Conclusion

In summary, TDLAS gas analyzers represent a breakthrough in gas detection technology. With speed, accuracy, and adaptability advantages, TDLAS has become the preferred choice across industries requiring precise and reliable gas monitoring. As technology advances, TDLAS analyzers are poised to meet the evolving demands of industrial, environmental, and safety applications, ensuring a safer and more sustainable future.If you have any questions, please get in touch with us!