In industrial and urban infrastructure, gas pipeline systems are important for energy transportation and storage. However, these pipelines will inevitably experience aging, corrosion, mechanical damage, and other problems during long-term use, leading to gas leakage. Gas leakage will not only cause waste of resources and economic losses but may also cause serious accidents such as fires and explosions, posing a major threat to human safety and environmental protection. Traditional gas leak detection methods often have problems such as slow response, low accuracy, and difficulty in covering a large area. Therefore, a more efficient and sensitive detection technology is particularly necessary. In this context, the vehicle-mounted laser gas detection system has become an innovative solution for pipeline gas leak monitoring.

This article will deeply explore the basic principles, technical advantages, application scenarios, actual cases, and future development trends of the vehicle-mounted laser gas detection system to help readers better understand how this technology plays a key role in monitoring pipeline gas leaks.

Basic Principles of Vehicle-mounted Laser Gas Detection System

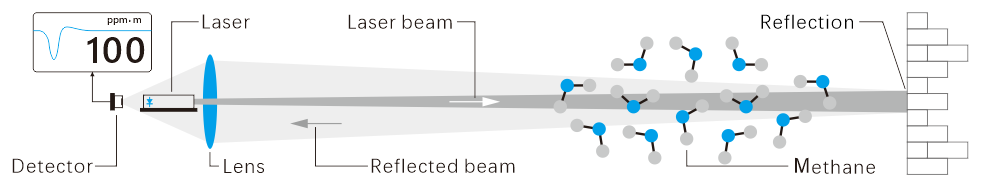

The vehicle-mounted laser gas detection system is mainly based on Laser Absorption Spectroscopy (LAS), which detects the type and concentration of gas by analyzing the absorption characteristics of gas molecules to lasers of specific wavelengths. This method has the characteristics of non-contact, high sensitivity, and real-time online monitoring, and is particularly suitable for rapid detection and response of gas leaks.

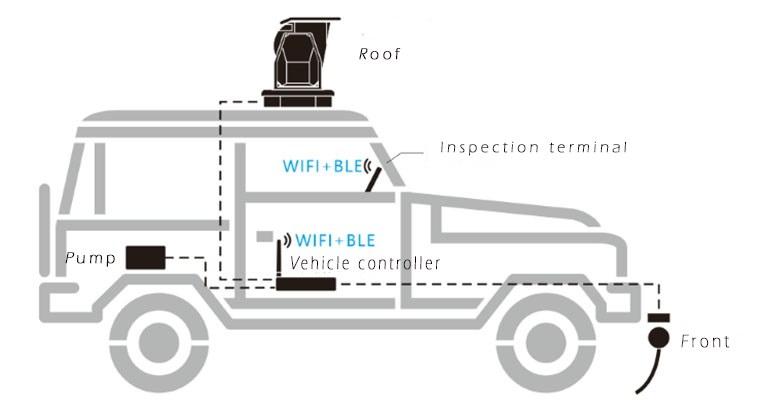

The vehicle-mounted laser methane leak detection system (Roof system) is a gas detection device used for the detection of urban long-distance natural gas pipelines. The device emits two lasers, a green indicator laser points to the detection area, accompanied by the invisible infrared laser that can measure the concentration per unit (ppm·m) of methane gas present at a long distance.

- How Laser Absorption Spectroscopy Works

Laser absorption spectroscopy relies on the unique absorption characteristics of gas molecules for lasers of specific wavelengths. When laser light passes through a certain gas, light of a specific wavelength will be absorbed by the gas, and the intensity of absorption is proportional to the concentration of the gas. By measuring the change in the intensity of the transmitted light, the concentration of the gas can be calculated. For vehicle-mounted systems, lasers and detectors are installed on the vehicle to scan the gas distribution of the surrounding environment in real-time. Once an abnormal concentration of a specific gas is detected, the presence and location of the leak can be inferred.

- How the in-car system works

The vehicle-mounted laser gas detection system generally consists of a laser, a spectral detector, a data processor, a positioning system, and an onboard control unit. As the vehicle travels along the pipeline route, the system continuously emits lasers and monitors the gas concentration in the surrounding air. Once an abnormal change in gas concentration is detected, the system automatically records the location and data, generates a leak warning, and notifies maintenance personnel for further investigation and repair.

According to the above physical principle, a beam of a specific wavelength can be used to penetrate the leading methane gas mass and the concentration of methane in the air mass that is passed through can be calculated by measuring its absorbance (Unique Selectivity).

In the test, after the emitted beam passes through the leaked methane-air mass, only the device can complete the measurement and output the unit concentration value if the beam is reflected by a reflecting surface and returned Due to the leaked methane-air mass may drift. it is constantly changing and unevenly distributed in both space and time scales. The distance from the device to the reflector is uncertain, so the thickness of the methane gas mass is also uncertain. to show the concentration values in this case, the concept of unit concentration (ppm) is commonly used in the industry, which is expressed as methane concentration (ppm)x standard thickness (1 m).

Technical advantages of vehicle-mounted laser gas detection system

Compared with traditional gas leak detection methods, such as handheld detectors, fixed detection stations, gas sniffers, etc., the vehicle-mounted laser gas detection system shows obvious technical advantages in many aspects:

- High sensitivity and precision

Laser absorption spectroscopy technology can achieve a sensitivity of one part per million (ppm) or even lower, which can quickly and accurately detect trace gas leaks, which is crucial for early detection of leaks and preventing further spread.

- Real-time and fast response

The vehicle-mounted system can monitor the vehicle in real-time while it is moving, with a response speed of milliseconds. Traditional detection methods usually require a period to obtain results, while the vehicle-mounted laser gas detection system can provide accurate detection data within a few seconds.

- Wide area coverage and high efficiency

The vehicle-mounted system covers the monitoring area through the vehicle’s driving route and is suitable for long distances, complex terrain, and inaccessible pipeline areas. Compared with fixed detection stations, the vehicle-mounted system has greater flexibility and wider coverage, and can efficiently detect gas leaks in large-area pipeline networks.

- Contactless Detection and Security

The vehicle-mounted laser gas detection system does not require direct contact with the gas during the detection process, avoiding the risk of leaking gas and directly endangering the detection personnel. In addition, the system does not rely on the physical collection of samples, which also avoids sample contamination and errors.

- Intelligence and data analysis

Modern vehicle-mounted laser gas detection systems are equipped with advanced data processing algorithms and artificial intelligence technology, which can automatically identify leak patterns, analyze data trends, and generate real-time reports. It can also upload data to the cloud for remote monitoring and decision support.

Application scenarios of vehicle-mounted laser gas detection system

The vehicle-mounted laser gas detection system has significant technical advantages in pipeline gas leakage monitoring, so its application scenarios are very wide and cover multiple fields. The following is a detailed description of the application of the system in various scenarios:

1. Natural gas and oil pipeline leak detection

Application Background

Natural gas and oil pipelines are important infrastructures for energy transportation, usually spanning vast geographical areas, including wilderness, forests, farmland, and urban areas. As these pipelines are exposed to the natural environment for a long time, they are susceptible to corrosion, geological activities, external construction, and other factors, which can cause leaks. Natural gas leaks are particularly dangerous because natural gas is a flammable and explosive gas, and its leakage may cause serious accidents such as fires and explosions.

Application

The vehicle-mounted laser gas detection system can be installed on inspection vehicles that travel along the pipeline route while the system continuously scans the gas concentration in the surrounding air. When the system detects abnormal changes in gas concentration (such as methane, etc.), it will immediately generate an alarm message and record the specific geographic location and timestamp. In this way, the inspection team can respond quickly, locate the source of the leak, and make repairs.

Application Advantages

- Efficiently covers long distances: Vehicles can cover hundreds of kilometers of pipeline in a shorter period, which is faster and more comprehensive than manual inspections or fixed monitoring stations.

- Reduce labor costs and time: The automated inspection method reduces the reliance on a large number of manual labor, reduces labor costs, and can quickly detect problems.

- Improved security: Reduces the risk of manual inspectors being exposed to harmful gases and dangerous environments.

2. City gas pipeline monitoring

Application Background

Gas pipeline networks in cities are usually buried underground, and their safe operation is directly related to the safety of life and property of urban residents. Especially in old urban areas, gas pipelines are prone to aging, corrosion, mechanical damage, and other problems, and the probability of leakage is high. In addition, the densely populated and built buildings in urban environments mean that once a gas leak occurs, it may spread rapidly and cause a major safety accident.

Application

The vehicle-mounted laser gas detection system can be deployed on vehicles of gas companies or municipal management departments, and monitor the changes in gas concentration around gas pipelines in real time by patrolling on urban roads. When a gas leak (such as methane, ethane, etc.) is detected, the system will immediately issue an alarm and generate the specific location of the leak point, so that the maintenance team can take quick action.

Application Advantages

- Flexibility and mobility: The system can be flexibly deployed on different types of patrol vehicles to adapt to the complex road conditions and traffic conditions in the city.

- Real-time response and precise positioning: Real-time monitoring capability enables the system to quickly detect leaks, shorten the duration of leaks, and reduce the risk of accidents.

- Reduce maintenance costs: Routine inspections through the vehicle-mounted system can significantly reduce the maintenance cost of urban gas pipelines and improve overall operational efficiency.

3. Safety inspection of industrial parks and chemical plants

Application Background

Industrial parks and chemical plants usually have a large number of flammable, explosive, and toxic gas pipelines, and the safe operation of these pipelines is crucial to preventing accidents. The production process of chemical plants is often accompanied by high temperature and high-pressure environments, which increases the risk of pipeline leakage. In addition, the factory area is complex and the equipment is diverse, so traditional fixed monitoring methods are often difficult to fully cover.

Application

The vehicle-mounted laser gas detection system can be used for routine safety inspections and accident emergency response in industrial parks and chemical plants. The system is installed on patrol vehicles in the factory area and regularly drives along the main passages of the factory area to monitor the concentration of dangerous gases such as volatile organic compounds (VOCs), ammonia, and hydrogen sulfide in the air in real-time. When abnormal concentrations are found, the system will automatically alarm and generate a detailed detection report to help enterprise managers make quick decisions.

Application Advantages

- Multi-gas detection capability: The system can detect multiple gases at the same time, adapt to the complex and diverse types of gases in chemical plants, and provide comprehensive safety monitoring.

- Rapid emergency response: In emergencies (such as fire, equipment explosion, etc.), the onboard system can be deployed and responded to quickly, effectively reducing the scope of the accident.

- Improve production safety level: Continuous gas monitoring helps companies strengthen safety management and prevent safety accidents.

4. Leakage monitoring during pipeline construction and maintenance

Application Background

During pipeline construction and maintenance, improper operation or external damage (such as excavation and drilling) often leads to gas leakage risks. Especially for the construction or maintenance of underground pipelines, it is difficult to visually judge the leakage situation, and traditional detection methods are often not timely and accurate enough.

Application

The vehicle-mounted laser gas detection system can be used for real-time monitoring of pipeline construction and maintenance sites. The system is installed on the construction vehicle and can detect air quality at any time during the construction process. If an abnormal change in gas concentration is detected, the system will immediately sound an alarm to remind the construction team to stop work and conduct inspections in time to prevent accidents.

Application Advantages

- Dynamic monitoring capabilities: During the construction and maintenance process, the system can continuously monitor dynamically and detect potential leakage points in time.

- Construction safety assurance: Real-time monitoring helps construction teams prevent safety accidents and improve safety during the construction process.

- Improve efficiency: When a leak is found, the system can provide the leak location and gas type, helping the team to respond and make decisions quickly.

5. Greenhouse gas monitoring in agriculture and animal husbandry

Application Background

The production process of agriculture and animal husbandry releases a large amount of greenhouse gases (such as methane, carbon dioxide and nitrous oxide), which have a significant impact on global climate change. Therefore, monitoring and managing the emission of these greenhouse gases is crucial for environmental protection and sustainable agriculture.

Application

The vehicle-mounted laser gas detection system can be used in patrol vehicles in agricultural and livestock areas to monitor the concentration and distribution of greenhouse gases. The system can monitor livestock feeding areas, farmland and composting areas in real time, identify high-concentration greenhouse gas sources, and help farm managers optimize management measures.

Application Advantages

- Improve environmental protection: Accurately monitoring greenhouse gas emissions, can help agriculture and animal husbandry develop more environmentally friendly production methods.

- Helping achieve emission reduction targets: Provide governments and institutions with accurate data to support greenhouse gas emission reduction targets at the regional or national level.

- Real-time monitoring and feedback: The system can provide real-time monitoring data, allowing farmers to adjust production activities immediately and reduce greenhouse gas emissions.

Practical application cases of vehicle-mounted laser gas detection system

The following are some practical application cases of vehicle-mounted laser gas detection systems in pipeline gas leakage monitoring:

- North American Natural Gas Pipeline Inspection

North America has the world’s largest natural gas pipeline network, and regular inspections of these pipelines are essential to ensure the safety of energy transportation. In recent years, some energy companies have introduced vehicle-mounted laser gas detection systems. By installing laser gas detection equipment on inspection vehicles, they can efficiently and continuously monitor hundreds of kilometers of pipelines. According to statistics, the application of this system has increased the coverage of natural gas leak detection by more than 30%, while reducing the detection cost by nearly 40%.

- Safety Monitoring of Urban Gas Pipelines in Europe

In some old European cities, gas pipeline systems are prone to leaks, posing a threat to residents’ safety. To address this challenge, some cities have begun to use vehicle-mounted laser gas detection systems for daily patrols and monitoring. The system can not only accurately detect tiny leaks, but also generate map reports in real-time, providing gas companies with efficient maintenance and management support.

- Safety inspection of Asia’s largest chemical parks

A large chemical park in Asia has introduced a vehicle-mounted laser gas detection system as an important part of production safety monitoring. The system inspects the gas pipelines in the park every day, and can promptly detect and alarm potential gas leaks, helping the company avoid many possible safety accidents.

Conclusion

The vehicle-mounted laser gas detection system is becoming a revolutionary technology in the field of pipeline gas leakage monitoring due to its advantages of high sensitivity, real-time, and non-contact detection. It not only improves the efficiency and safety of gas leakage detection, but also provides important technical support for urban safety, energy transportation, and industrial production. With the continuous advancement of technology and the gradual promotion of its application, the vehicle-mounted laser gas detection system is expected to play a more important role in the future and provide strong protection for human safety and the environment.