With the continuous advancement of industrialization, environmental pollution problems are becoming increasingly serious, among which air pollution is particularly prominent. To effectively monitor and control air pollution, the flue gas online monitoring system came into being. In the flue gas online monitoring system, the dust monitor, as one of the key equipment, undertakes the important task of real-time monitoring of the concentration of particulate matter in the flue gas. This blog will introduce in detail the working principle, type, and selection points of dust meters to help users make reasonable choices in practical applications.

How Does the Dust Monitor Work?

Dust monitor are used to measure the concentration of suspended particles in the air. Common principles include light scattering, beta-ray absorption, charge, and optical particle counting.

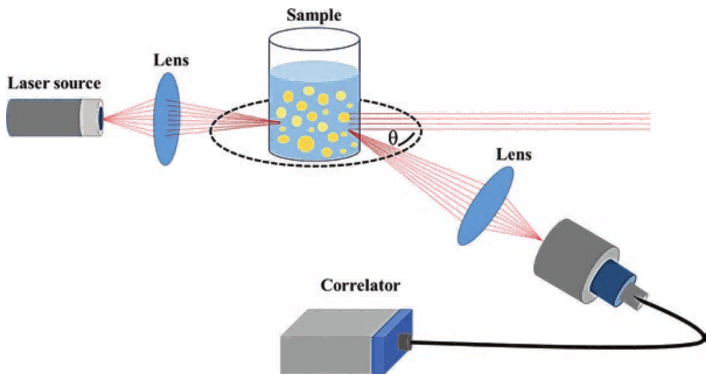

1. Principle of light scattering

When light shines on suspended particles in the air, scattered light is produced, and the intensity of the scattered light is proportional to the mass concentration of the particles. By measuring the intensity of scattered light and applying the mass concentration conversion formula, multiplying it by the K factor, and performing digital signal processing. In this way, the dust concentration signal can be converted into an electrical signal and received and analyzed by the corresponding equipment. (Adopted from Choudhary et al. 2017a)

- Laser backscattering: After the incident light passes through the dust particles in the flue, the light intensity weakens, and the dust particles reflect it in all directions. The part of the scattered light that is within a certain angle with the incident light is called backscattering. The signal intensity of scattered light changes positively with the concentration of dust particles. Based on this principle, the instrument passes through the flue through an embedded highly stable laser signal source, irradiates dust particles, and the optical receiver reflects the laser signal to calculate the dust concentration.

The optical part of the laser backscattering soot meter includes laser light source and power control, photoelectric sensing, and scattered light receiving parts. The principle is that the 650nm beam emitted by the laser enters the emission source (flue/chimney) at a slight angle. The laser beam interacts with the smoke particles to produce scattered light. The backscattered light enters the sensor through the receiving system and is converted into an electrical signal for processing. The circuit part realizes photoelectric conversion, laser beam modulation, signal amplification, demodulation, light source power control, and V/I conversion functions. The calibrator is used to generate a stable optical signal to perform zero and span calibration of the instrument.

- Laser forward scattering: After the laser light emitted by the laser is scattered by smoke and dust, its forward scattered light wave is reflected by the transmitting mirror at the middle projection edge converges into the optical fiber, and is finally detected by the detector. The light source used in the forward scattering method is a laser. The advantage is that the transmitting, receiving, and reflecting modules can be integrated, so the installation does not require optical path alignment. The instrument is simple to install and requires little maintenance. The detection concentration can reach 0 to 5mg/m3. Due to the short optical path design of the forward scattering method, in terms of sampling method, it can be approximated as point measurement. There are certain requirements for the straight pipe sections before and after the flue, which generally require a certain length. On the straight pipe section of the flue.

The laser forward scattering method uses a flue gas sampling design with extraction, heating, and return, and can be used in situations where the measured gas contains extremely high water mist or the particle concentration is too low.

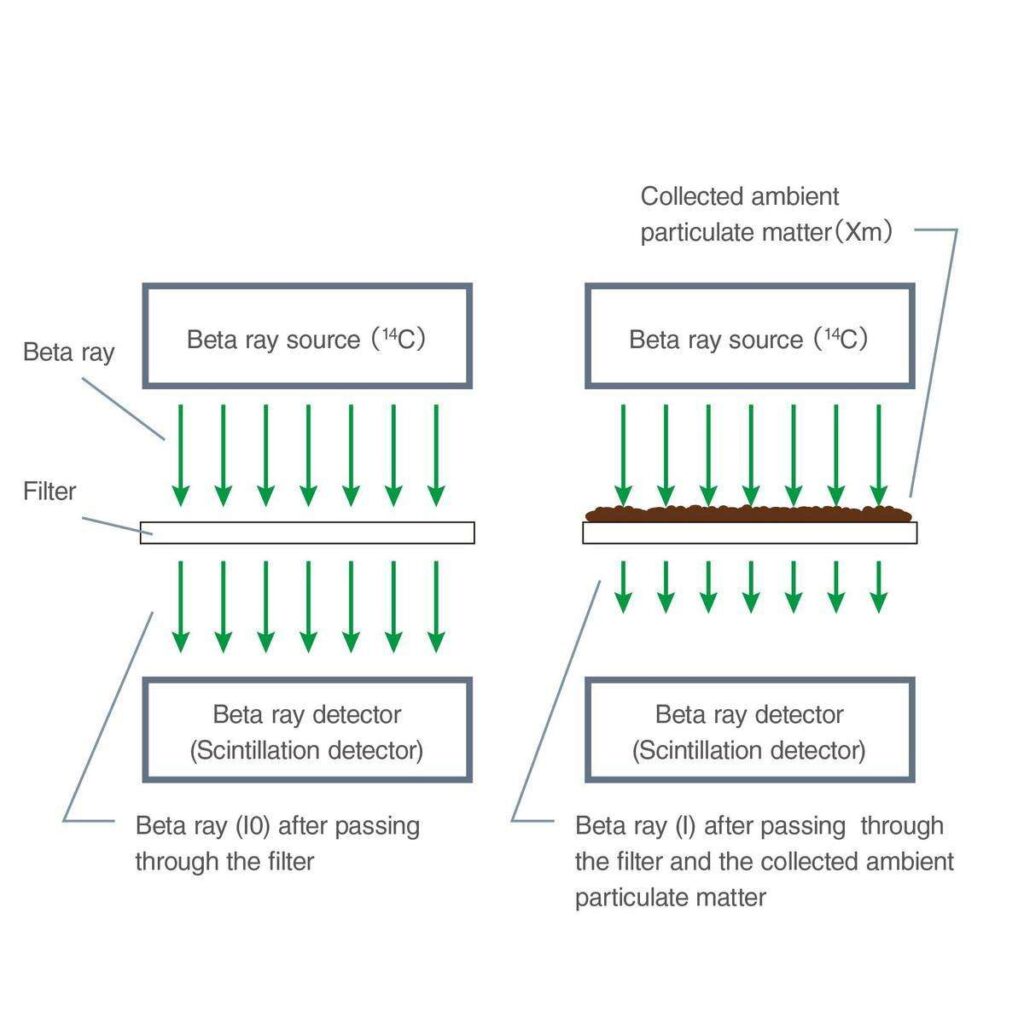

2. Principle of β-ray method

Beta rays are a type of ionizing radiation released by charged particles during their motion. Beta rays have low energy and can penetrate certain materials. When beta rays pass through a medium containing particulate matter, they will interact with the particulate matter and scatter or absorb the particulate matter, resulting in energy loss. Based on the interaction of beta rays with particulate matter, we can infer the presence and concentration of particulate matter by measuring the intensity of the scattered or absorbed rays. In the beta-ray method, a commonly used measuring device is a beta counter. It includes a radioactive source and a detector. The radioactive source emits beta rays which pass through the sample to be measured and are picked up by the detector.

When beta rays pass through particulate matter, they are scattered or absorbed. These scattered or absorbed rays can cause changes in current flow or counts in the detector. Based on these changes, we can calculate the concentration of particulate matter. Typically, measurement results are displayed and recorded on a display or computer.

The beta ray method has the advantages of high measurement accuracy, fast response speed, and easy operation. Therefore, it has been widely used in fields such as air quality monitoring and industrial particulate matter emission control.

It should be noted that the beta-ray method may be interfered with by other factors in some special cases, such as other radiation sources present in the sample or background radiation in the measurement environment. Therefore, it is necessary to pay attention to calibration and accuracy verification when making measurements to ensure the reliability and accuracy of the measurement results.

3. Principle of dust sensor gravimetric method

The principle of the gravimetric method is to use a sampler with specific cutting characteristics to extract a certain volume of air sample at a constant speed and trap the particles in the sample gas on a filter membrane of known mass. By comparing the mass difference of the filter membrane before and after sampling and the sampling volume, the dust concentration can be calculated. It should be noted that when measuring particle concentration, the denominator volume in the unit “ug/m3” should be the volume under standard conditions (0°C, 101.3kPa). Therefore, the actual measured volume at temperature and pressure needs to be converted into the volume under standard conditions.

4. Principle of oscillating balance method

The micro-oscillating balance method uses an oscillating hollow conical tube inside the sensor, and a replaceable filter membrane is installed at the oscillating end. The oscillating frequency depends on the characteristics of the conical tube and its quality. When the sampled air flows through the filter membrane, the particles in it are deposited on the filter membrane. The change in the quality of the filter membrane leads to a change in the oscillation frequency. The mass of the particles deposited on the filter membrane is calculated through the change in the oscillation frequency. Then, the mass of the particles deposited on the filter membrane is calculated based on the flow rate, and on-site ambient temperature, and air pressure is used to calculate the mass concentration of particulate matter markers during that period.

The oscillating balance method is a method commonly used to measure the mass concentration of particulate matter. It uses the principle of an oscillating balance to obtain mass information of particulate matter. An oscillating balance is a precision balance instrument that infers the mass of particulate matter by measuring the change in its mass on a balance. In the oscillating balance method, the sample is usually placed in a container and then vibrated to evenly distribute the particles within the container. When the sample vibrates, the particles are subject to inertial forces, causing the sample mass on the balance to change. By measuring the size of this mass change, we can calculate the mass of the particle.

The measurement accuracy of the oscillating balance method is very high and it can quickly and accurately measure the mass concentration of particulate matter. In addition, the oscillating balance method also has the advantages of simple sample processing and controllable experimental processes.

It should be noted that when performing oscillating balance measurement, attention needs to be paid to the accumulation and dispersion of the sample to ensure that the particles are evenly distributed within the container. At the same time, for different types of particles and sample properties, different vibration parameters and experimental conditions may be required to obtain accurate and reliable measurement results.

The Types of Dust Monitor

In the flue gas online monitoring system, dust meters can be divided into fixed dust meters, portable dust meters and personal dust meters according to their uses and application scenarios. Each of these types of dust meters has its own characteristics and is suitable for different monitoring needs.

1. Fixed dust monitor

Fixed dust meters are usually installed in fixed locations in flue gas emission ducts or industrial sites for continuous, real-time dust monitoring. Fixed dust meters mainly use the following measurement principles:

- Light scattering dust monitor

The light-scattering dust meter uses a light beam emitted by a light source to pass through flue gas containing particulate matter. The particulate matter will cause the light beam to scatter. The intensity of scattered light is proportional to the concentration of particulate matter, and the concentration of particulate matter is calculated by detecting the intensity of scattered light. The light-scattering dust meter has the advantage of fast response and is suitable for real-time online monitoring.

- β-ray absorption dust monitor

The β-ray absorption dust meter determines the concentration of particulate matter by measuring the absorption of β-rays in particulate matter. As the flue gas passes through the sampling head, particulate matter is collected on the filter membrane. The rays emitted by the β-ray source pass through the filter and are received by the detector. By comparing the intensity of β-rays before and after filtering, the concentration of particulate matter is calculated. This method has high accuracy, but the response speed is relatively slow, so it is suitable for occasions where high-precision measurement is required.

2. Portable dust monitor

Portable dust meters are suitable for on-site detection and environmental surveys. They are small in size, light in weight, and easy to carry. Common types of portable dust meters include the following:

- Light scattering portable dust meter

The light-scattering portable dust meter uses the principle of light scattering to measure and has the characteristics of simple structure, convenient operation, and fast response speed. It is suitable for industrial sites, indoor air quality testing, and other occasions that require quick response.

- Charge-type portable dust monitor

The charge-type portable dust meter charges the particles through a high-voltage electric field and calculates the concentration of the particles by measuring the current of the charged particles in the electric field. This method has a simple structure and low cost, and is suitable for the measurement of high-concentration dust.

3. Personal Dust Monitor

Personal dust meters are designed for personal protection and monitor the concentration of particulate matter in the air around the wearer. It is smaller in size and is usually worn on the chest or waist. It is mainly used in high-risk occupations such as miners and construction workers.

- Light scattering personal dust meter

The light-scattering personal dust meter directly detects the concentration of particulate matter through an optical sensor, which has the advantages of high precision and real-time monitoring. Suitable for working environments with high requirements on personal safety.

The online dust meter is installed on the pipeline of industrial emission sources and is suitable for continuous online monitoring. Its advantage is that it can monitor changes in dust concentration in real-time and provide data support for pollution control.

- Light transmittance method online dust monitor

The transmittance method online dust monitor calculates the concentration of particulate matter by measuring the change in light intensity after the light source passes through the flue gas. It is suitable for monitoring various industrial flue gas emissions and has the characteristics of simple installation and convenient maintenance.

Special dust meters are designed for specific environments or specific dust types, and usually have higher pertinence and measurement accuracy. For example, mine dust monitors, cement plant dust monitors, etc. These instruments are designed with the dust characteristics of specific scenarios in mind and can provide more accurate measurement results.

| Type of Dust Meter | Subtypes | Measurement Principle | Advantages | Typical Applications |

| Fixed Dust Meter | Light Scattering, Beta-ray Absorption | Measures light scattering or beta-ray absorption by particles | High stability, continuous monitoring, suitable for long-term use | Industrial emissions monitoring, long-term environmental monitoring |

| Portable Dust Meter | Light Scattering, Charge | Measures light scattering or particle charge in an electric field | Portable, easy to carry, fast response time | Field measurements, environmental surveys, industrial hygiene |

| Personal Dust Meter | Light Scattering | Measures light scattering | Compact, wearable, high precision for personal safety | Personal protection in high-risk jobs like mining and construction |

| Online Dust Meter | Light Transmittance | Measures light transmittance through smoke | Continuous real-time monitoring, easy installation and maintenance | Industrial emission sources, various industrial applications |

| Specialized Dust Meter | Designed for specific environments | Tailored for specific dust types and environments | High precision, tailored for specific needs | Mining, cement plants, and other specific industrial environments |

Choosing a suitable dust meter requires comprehensive consideration of many factors such as the measurement environment, accuracy requirements, response time, and maintenance needs. Different types of dust meters have their own advantages and disadvantages. Users should choose the most suitable type of dust meter based on specific application scenarios and needs to ensure the accuracy and reliability of monitoring data. Through scientific and reasonable selection and use of dust meters, accurate and reliable data support can be provided for environmental monitoring, effectively controlling and reducing air pollution, and protecting the ecological environment.

Key Points for Dust Monitor Selection

When choosing a suitable dust meter, you need to consider the following aspects:

1. Measurement range and accuracy

Choose the appropriate measurement range and accuracy based on monitoring needs. For high-concentration dust environments, a dust meter with a larger measurement range should be selected; for occasions with higher accuracy requirements, a dust meter with higher accuracy should be selected.

2. Response time

Response time refers to the reaction speed of the dust meter to changes in particle concentration. For occasions where real-time monitoring is required, a dust meter with a short response time should be selected, such as a light scattering dust meter.

3. Environmental adaptability

Dust meters need to work under different environmental conditions, including temperature, humidity, pressure, etc. When selecting a model, the environmental adaptability of the dust meter should be considered to ensure that it can work stably in actual applications.

4. Maintenance and calibration

The dust monitor needs regular maintenance and calibration during use. Choosing a dust monitor that is easy to maintain and calibrate can reduce the cost of use and improve work efficiency.

5. Cost

Choose the right dust meter based on your budget. On the premise of meeting the measurement requirements, choose equipment with higher cost performance. For laboratories or special occasions, you can choose the high-precision optical particle counting method; for industrial sites, you can choose the economical and practical light scattering method or charge method.

Application of Dust Monitor in Flue Gas Online Monitoring System

Dust meters in flue gas online monitoring systems are important in various industrial and environmental monitoring fields. The following describes in detail the specific applications and importance of dust meters in different application scenarios.

1. Industrial emissions monitoring

In industrial emission monitoring, dust meters are used to monitor the concentration of particulate matter in flue gases emitted by factories and industrial facilities in real-time. By monitoring industrial emissions, we can ensure that emissions comply with national and local environmental regulations and standards and prevent harm to the surrounding environment and the health of residents.

Application

- Power plants: Power plants produce large amounts of smoke and particulate matter when they burn coal or other fuels. The dust meter can monitor the concentration of particulate matter in the exhaust gas to ensure that the emissions are within the range allowed by regulations.

- Cement factory: A large amount of dust will be generated during the cement production process. Real-time monitoring by dust meters can effectively control dust emissions and protect the surrounding environment.

- Metallurgical factory: High concentrations of dust will be generated during the metallurgical process. Through dust meter monitoring, timely measures can be taken to reduce dust emissions and protect the health of workers.

2. Occupational safety and health

In some high-risk occupations, high dust concentrations can have serious consequences for workers’ health. Dust meters are used to monitor the concentration of particulate matter in the working environment to ensure that workers are in a safe working environment.

Application

- Mining operations: Miners will be exposed to a large amount of dust when working underground. Through personal dust meter monitoring, the dust concentration in the working environment can be understood in real-time and the health of miners can be protected.

- Construction site: Construction workers will be exposed to a large amount of construction dust during the construction process. Through portable dust meters, protective measures can be taken in time to reduce the impact of dust on health.

- Manufacturing industry: A large amount of dust will be generated during the manufacturing process, especially when cutting, grinding, spraying, and other processes are involved. Monitoring by dust meters can ensure that workers are in a working environment that meets safety standards.

3. Research and Laboratories

In scientific research and laboratories, dust meters are used to accurately measure particulate matter in the air and provide reliable data support for research. Through the high-precision measurement of dust meters, scientific researchers can conduct in-depth research into the composition and sources of particulate matter and its impact on the environment and health.

Application

- Environmental science research: Study the sources of air pollution and their impact on ecosystems, and help scientists develop more effective pollution control strategies through data collected by dust meters.

- Public health research: Study the impact of particulate matter in the air on human health, and assess its impact on health problems such as respiratory diseases by monitoring particulate matter concentrations in different environments.

- Materials science research: In the process of studying the production of new materials, particulate matter in the production environment is monitored through dust meters to evaluate the impact of material production on the environment.

4. Environmental monitoring

Dust meters are used in environmental monitoring to measure the concentration of particulate matter in the air, providing data support for environmental protection and air quality assessment. By monitoring air quality, pollution sources can be discovered and controlled in time to protect public health.

Application

- Urban air quality monitoring: Placing dust monitor in urban areas can monitor the concentration of particulate matter such as PM2.5 and PM10 in the air in real-time, providing a basis for the government to formulate air pollution control measures.

- Road traffic monitoring: In areas with large traffic flow and dense vehicles, vehicle exhaust and road dust will cause air pollution. Through dust meter monitoring, the impact of traffic on air quality can be understood.

- Construction site environment monitoring: A large amount of dust will be generated during construction at the construction site. Through dust meter monitoring, the impact of construction on the surrounding environment can be understood in real time and corresponding dust reduction measures can be taken.

5. Agriculture

In the agricultural field, dust monitor are used to monitor particulate matter produced during agricultural production and provide farmers with guidance on environmental protection and health protection.

Application

- Crop planting: During the crop planting process, fertilization, harvesting and other links will generate a large amount of dust. Through dust meter monitoring, timely measures can be taken to reduce the impact of dust on farmland and the surrounding environment.

- Livestock breeding: During the livestock breeding process, feed processing and livestock activities will generate dust. Monitoring by dust meters can protect the health of livestock and farm workers.

Dust meters are widely used in flue gas online monitoring systems, covering industrial emission monitoring, environmental monitoring, occupational safety and health, scientific research and laboratories, and agricultural fields. Through the scientific and reasonable application of dust meters, air pollution can be effectively controlled and reduced, and the ecological environment and public health can be protected. Choosing a suitable type of dust meter and conducting monitoring based on actual needs can provide strong data support for environmental protection work.

Q&A: Frequently asked questions about dust meters in flue gas online monitoring systems

Q1: What is a dust monitor?

A1: A dust monitor is an instrument used to measure the concentration of suspended particles in the air. It plays an important role in flue gas online monitoring systems, helping to monitor and control particulate matter concentrations in industrial emissions, ambient air quality, and occupational safety in real-time.

Q2: What is the main working principle of the dust monitor?

A2: The working principles of the dust monitor mainly include the light scattering method, β-ray absorption method, charge method and optical particle counting method. The light scattering method measures the concentration by detecting the degree of scattering of light by particulate matter; the β-ray absorption method determines the concentration by the absorption of β-rays by particulate matter; the charge method uses the charged characteristics of particles in an electric field to measure; the optical particle counting method passes Optical sensors count particles directly.

Q3: What types of dust monitor are there?

A3: There are mainly the following types of dust monitors:

Fixed dust monitor: installed in a fixed position, suitable for continuous online monitoring.

Portable dust monitor: easy to carry, suitable for on-site testing and environmental surveys.

Personal dust monitor: Worn on an individual, it monitors the concentration of particulate matter in the air around the individual.

Online dust monitor: Installed on the pipeline of industrial emission sources for real-time monitoring.

Special dust monitor: designed for specific environments or specific dust types, with high pertinence and measurement accuracy.

Q4: How to choose a suitable dust monitor?

A4: When choosing a dust monitor, the following factors should be considered:

Measurement range and accuracy: Choose the appropriate measurement range and accuracy according to monitoring needs.

Response time: When real-time monitoring is required, a dust meter with a shorter response time should be selected.

Environmental adaptability: Consider the environmental adaptability of the dust meter, such as temperature, humidity and pressure.

Maintenance and calibration: Choose a dust meter that is simple to maintain and easy to calibrate.

Cost: On the premise of meeting the measurement requirements, choose equipment with higher cost performance.

Q5: What are the applications of dust monitor in industrial emission monitoring?

A5: In industrial emission monitoring, dust monitor are used to monitor the concentration of particulate matter in flue gases emitted by factories and industrial facilities in real-time. For example:

Power plants: Monitor particulate matter concentrations in flue gases produced when coal or other fuels are burned.

Cement plants: Monitor dust emissions generated during cement production.

Metallurgical plants: Monitor high concentrations of dust generated during metallurgical processes.

Q6: What is the role of dust meter in environmental monitoring?

A6: In environmental monitoring, dust monitor are used to measure the concentration of particulate matter in the air to provide data support for environmental protection and air quality assessment. It is widely used in urban air quality monitoring, road traffic monitoring construction site environment monitoring, and other fields.

A7: Dust monitor are used in high-risk occupations to monitor the concentration of particulate matter in the working environment to ensure that workers are in a safe working environment. For example, in mining operations, construction sites and manufacturing industries, dust monitor can help promptly detect and control dust pollution and protect workers’ health.

Conclusion

The dust monitor plays an important role in the flue gas online monitoring system. Its working principle and selection are directly related to the accuracy and reliability of the monitoring data. By understanding the principles and characteristics of different types of dust meters and selecting the appropriate dust meter based on actual needs, the performance of the flue gas online monitoring system can be effectively improved, and environmental protection work can be assisted.more information pls visit us