Laboratory gas monitors and analyzers are essential for ensuring safety and precision in scientific inquiry, industrial creation, and patient care. These instruments play a critical role in detecting and measuring gas concentrations. This is vital for protecting personnel, maintaining air quality, and optimizing processes.

Why is Laboratory Gas Monitoring Important?

Labs can be risky places, what with the chance of encountering poisonous, flammable, or suffocating gases A leak or a simple mistake in handling these gases could lead to serious trouble. That’s why keeping a constant eye on gas levels is so important for spotting problems early and stopping them before they happen. Gas leaks or improper handling can lead to explosions, fires, or health complications. Therefore, continuous gas monitoring is crucial for early detection and prevention of such incidents. It helps ensure a safe and compliant workplace.

What Gases Do These Monitors Detect?

Common laboratory gases include nitrogen, oxygen, hydrogen, carbon dioxide, methane, and argon. These gases serve various purposes, such as creating inert atmospheres, supporting chemical reactions, or providing fuel sources. However, they can also pose risks if not properly monitored. For example, seemingly harmless gases like nitrogen and argon can cause asphyxiation in poorly ventilated areas .

How does ESEGAS Provide Tailored Solutions?

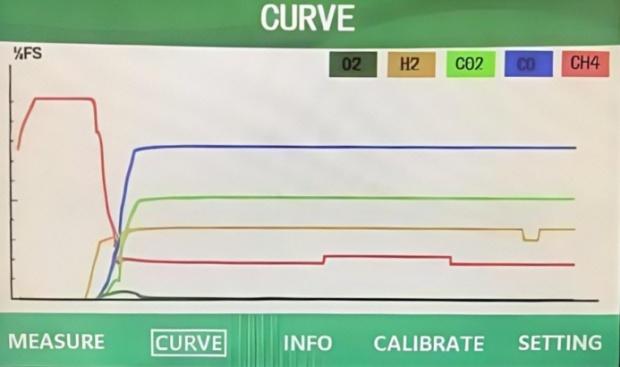

ESEGAS gas analyzers are designed for comprehensive gas analysis, such as ESEGAS IR-GAS-600. ESEGAS uses different technologies to measure various gases in a single analyzer. These include NDIR for Carbon Monoxide (CO), Carbon Dioxide (CO2), Methane (CH4), and Hydrocarbons (CnHm, optional). TCD for Hydrogen (H2), calculation technology for Nitrogen (N2), and ECD for Oxygen (O2).

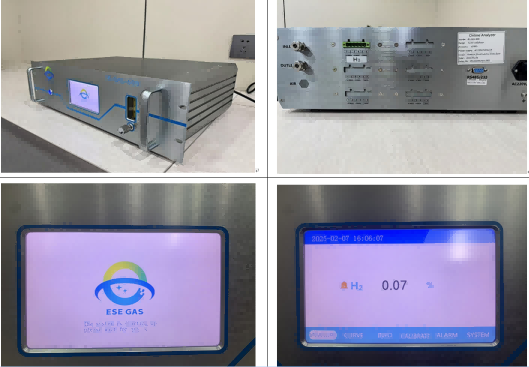

For simpler setups, ESEGAS also offer single-gas analyzers, for example recently ESEGAS update new version of Hydrogen(H2) analyzer IR-GAS-600.

(https://www.linkedin.com/feed/update/urn:li:activity:7294561224585789441/?actorCompanyId=96088958)

Regardless of your application, ESEGAS provides accurate, reliable, and safe gas analysis solutions. These solutions are customized to your exact needs. If you want to know more information, please visit our websites: https://esegas.com/ and https://gas-analyser.com/.

Fixed vs. Portable: Which is Best for You? Fixed gas analysis systems are installed in specific locations to continuously monitor gas levels. Mostly applied in industrial areas, these systems provide early warnings of gas leaks and ensure worker safety. For example, ESEGAS Gas analyzer system provides comprehensive monitoring in steel plant blast furnaces. This is essential for explosion prevention, worker safety during maintenance, and consistent process performance.

(https://esegas.com/)

Portable gas analyzers, such as IR-GAS-600P and ESE-FTIR-100P , are used for laboratory gas monitoring or spot-checking in different areas.

(https://esegas.com/product/portable-ftir-gas-analyzer/)

When it comes to monitoring gas in potentially dangerous lab environments, ESEGAS portable analyzers stand out for their reliability. These devices can adjust to varying concentration levels.

Are There Specific Safety Standards?

Certain laboratory gases present significant chemical hazards. Chlorine and Nitrogen Oxides are prime examples of toxic and corrosive substances. To maintain workplace safety and meet COSHH requirements, it’s essential to verify exposure limits using the HSE’s EH40 documentation (https://www.hse.gov.uk/pUbns/priced/eh40.pdf). Also, reference the relevant Material Safety Data Sheets. While commonly perceived as safe, even chemically inert gases such as Nitrogen and Argon can create dangerous conditions. This can happen through oxygen displacement. This is particularly true in confined or poorly ventilated areas. For comprehensive safety guidance, reference should be made to the Approved Codes of Practice issued by organizations like the British Compressed Gases Association.

What About Calibration and Maintenance?

The accuracy and reliability of gas monitors depend on two key processes: calibration and maintenance. Calibration adjusts the monitor against known gas concentrations. This ensures accurate readings. Maintenance includes sensor cleaning, parts replacement, and regular inspections. Check out ESEGAS’s YouTube channel for detailed video tutorials on performing manual calibration and maintenance. This is a great resource for hands-on learners!

How to Choose the Right Gas Analyzer?

Selecting the appropriate gas analyzer depends on the specific requirements of the laboratory or facility. Factors to consider include the types of gases being used, the required level of accuracy, and the environmental conditions. Consulting with environmental solution expert (ESEGAS) can help ensure the selection of suitable gas sensing solutions. If you want to know more, contact us please! ESEGAS’s websites: https://esegas.com/ and https://gas-analyser.com/. Our e-mail: [email protected].