Volatile organic compounds (VOCs) refer to organic compounds that are easily volatile at room temperature and are widely used in industrial production, including solvent use, petrochemical industry, coatings, printing, and other fields. VOCs not only cause serious pollution to the atmospheric environment but also cause significant harm to human health. To reduce VOCs emissions, industrial companies need to use advanced monitoring technology to control their emission levels and ensure compliance with environmental regulations. As an efficient and accurate monitoring tool, gas analyzers play an important role in industrial VOCs emission control.

Sources and Hazards of VOCs

1. Main sources of VOCs

Volatile organic compounds (VOCs) are complex mixtures composed of various hydrocarbons and their derivatives, which are widely present in industrial production and daily life. The main sources of VOCs include the petrochemical industry, coatings and paints, the printing industry, and automobile exhaust. In the petrochemical industry, VOCs mainly come from leakage and volatilization of raw materials and products. Coatings and paints release large amounts of VOCs during use, and solvents and inks used in the printing industry also release large amounts of VOCs. In addition, automobile exhaust is also an important source of VOCs.(Image source: thepetrosolutions).

Petrochemical industry: In the process of petroleum refining and chemical production, VOCs mainly come from the leakage and volatilization of raw materials and products.

- Coatings and paints: Coatings, paints and their solvents release large amounts of VOCs during use.

- Printing industry: Solvents and inks used in the printing process also release large amounts of VOCs.

- Car exhaust: The exhaust gas emitted by vehicles contains higher concentrations of VOCs.

Other industries: industries such as electronic manufacturing, textiles, pharmaceuticals, etc. also produce VOCs.

2. Environmental and health hazards of VOCs

VOCs have significant harm to the environment and human health. In terms of environment, VOCs are important precursors to the formation of photochemical smog. Under sunlight, VOCs react photochemically with nitrogen oxides to generate ozone and secondary organic aerosols, causing air quality to deteriorate and affecting people’s quality of life. In terms of health, VOCs have certain toxicity, irritation, and carcinogenicity. Long-term exposure to high concentrations of VOCs may cause damage to the respiratory system, nervous system, and immune system, and even lead to cancer. Therefore, controlling the emission of VOCs is crucial to protecting the environment and public health.

Environmental hazards: VOCs are important precursors to the formation of photochemical smog. They react photochemically with nitrogen oxides under sunlight to generate ozone and secondary organic aerosols, leading to the deterioration of air quality.

Health hazards: VOCs are toxic, irritating, and carcinogenic to the human body. Long-term exposure to high concentrations of VOCs can cause damage to the respiratory system, nervous system, and immune system.

Application of Gas Analyzers in Industrial VOCs Emission Monitoring

Gas analyzers are widely and crucially used in industrial VOCs emission monitoring, especially in production processes and waste gas treatment systems. Through real-time and accurate monitoring, companies can effectively control and reduce VOCs emissions and meet the requirements of environmental regulations. The specific applications of gas analyzers in these aspects will be discussed in detail below.

1. VOCs monitoring in the production process

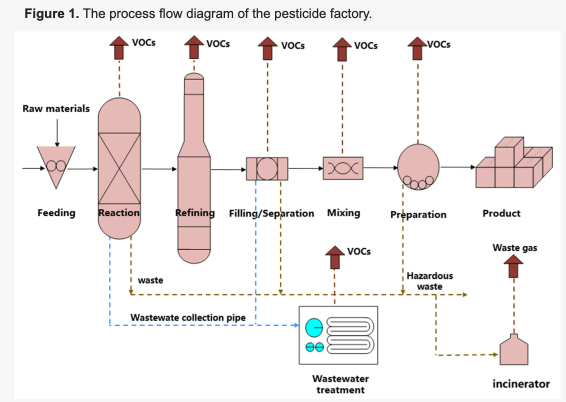

In the industrial production process, different process links (such as reaction, distillation, drying, mixing, etc.) may produce different types and concentrations of VOCs. Gas analyzers can monitor VOCs emissions in these links in real-time, helping companies promptly discover and solve pollution problems in production.

- Monitoring the production process

In the chemical and petrochemical industries, production processes are complex and involve a large number of chemical reactions and material transfers. Each process step may produce different levels of VOCs emissions. For example, during the distillation process, light components in the raw materials may volatilize, resulting in the emission of VOCs. By installing gas analyzers in key process links, companies can monitor VOCs emissions in real-time, adjust operating parameters promptly, and optimize production processes, thereby reducing VOCs emissions.

- Equipment leak monitoring

During long-term operation, industrial equipment may leak due to wear, aging, or improper operation, resulting in VOCs emissions. Gas analyzers can regularly test equipment and find potential leaks. By promptly repairing and replacing damaged parts, companies can effectively prevent the leakage of VOCs and reduce environmental pollution. For example, in petrochemical companies, pipeline valves, and joints are often prone to leaks. Gas analyzers can help detect the concentration of VOCs in these key parts, detect and repair leaks promptly, and ensure the safe operation of equipment and emission compliance.

2. Environmental monitoring and compliance

In addition to their use in production processes and exhaust gas treatment systems, gas analyzers also play an important role in environmental monitoring and compliance. By monitoring the concentration of VOCs in the environment inside and outside the factory in real-time, companies can ensure that emissions will not cause pollution to the surrounding environment and meet the requirements of environmental regulations.

- Factory boundary monitoring

Setting up a gas analyzer at the boundary of the factory can monitor the concentration of VOCs inside and outside the factory in real-time, and identify and solve potential pollution problems promptly. For example, in chemical parks and industrial clusters, companies can install factory boundary monitoring systems to monitor VOCs emissions in each factory in real-time and prevent environmental pollution incidents. The real-time data provided by the gas analyzer can help companies formulate scientific emergency plans and improve environmental management levels.

- Compliance monitoring

According to the requirements of environmental protection regulations, enterprises need to Regularly submit VOCs emission monitoring reports to the environmental protection department to prove that their emissions meet standards. The accurate data provided by gas analyzers can help companies achieve compliant emissions. By recording and analyzing VOCs emission data, companies can discover emission patterns and trends and take measures in advance to prevent excessive emissions.

3. VOCs monitoring in exhaust gas treatment systems

The exhaust gas treatment system is an important link for industrial enterprises to control VOCs emissions. By monitoring the exhaust gas treatment system, companies can evaluate the treatment effect, discover and solve existing problems, and ensure the efficient operation of the exhaust gas treatment system.

- Monitoring before and after exhaust gas treatment

Gas analyzers can be installed at the air inlet and outlet of the exhaust gas treatment system to monitor VOCs concentration changes before and after treatment in real-time. By comparing the VOCs concentration at the import and export, companies can evaluate the treatment effect of the exhaust gas treatment system. For example, in exhaust gas treatment processes such as catalytic combustion and adsorption and desorption, by monitoring the VOCs concentration at the inlet and outlet, the operating status of the treatment equipment can be judged, timely maintenance and optimization can be performed, and the exhaust gas treatment efficiency can be improved.

- Optimization of exhaust gas treatment systems

Through the analysis of gas analyzer monitoring data, weak links in the exhaust gas treatment system can be discovered and process optimization can be carried out. For example, in the activated carbon adsorption process, the activated carbon after adsorption saturation needs to be regenerated. Gas analyzers can help determine the optimal time for regeneration to prevent VOCs emissions from exceeding standards due to reduced adsorption capacity. Through long-term accumulation and analysis of monitoring data, companies can continuously optimize waste gas treatment processes, reduce VOCs emissions, and reduce operating costs.

4. Technical advantages and future development

The technical advantages of gas analyzers in industrial VOCs emission monitoring are mainly reflected in high sensitivity, high precision, real-time monitoring, simultaneous detection of multiple components, and remote monitoring and data transmission. Modern gas analyzers use advanced detection technology to detect extremely low concentrations of VOCs, ensuring high accuracy of monitoring results. At the same time, the gas analyzer can perform continuous real-time monitoring, record monitoring data, provide detailed emission curves, and provide a scientific basis for environmental management. In addition, modern gas analyzers can detect multiple VOCs components simultaneously, improving monitoring efficiency and meeting monitoring needs in complex environments. Through the Internet and IoT technology, gas analyzer emissions also comply with standards. Gas analyzers play a key role in this process, helping companies achieve compliance monitoring by providing accurate and real-time VOCs emission data.

- Collection and analysis of monitoring data

The gas analyzer can continuously monitor VOCs emissions at each key node in the production process and record the data. These data can help companies understand the dynamics of emissions and identify emission peaks and potential problems. For example, through data analysis, companies can identify weak links in the production process, optimize operating procedures, and reduce VOCs emissions. The monitoring report generated by the gas analyzer can be used as strong evidence of environmental compliance to ensure that the company successfully passes the environmental inspection.

- Data reporting and environmental communication

Environmental protection regulations require companies to submit regular emission reports and record VOCs emissions and monitoring data in detail. The detailed data provided by gas analyzers can help companies prepare compliance reports to ensure the accuracy and credibility of report content. In addition, the real-time monitoring function of the gas analyzer can also provide instant data during surprise inspections by the environmental protection department to prove that the company’s emission levels comply with standards. Through effective communication with environmental protection departments, companies can better understand and comply with environmental regulations and improve their environmental image.

Technical Advantages of Gas Analyzers in VOCs Monitoring

The technical advantages of gas analyzers in VOCs monitoring are significant, making them an indispensable tool in industrial emission monitoring.

- High sensitivity and precision

Modern gas analyzers use advanced detection technology to detect extremely low concentrations of VOCs, ensuring high accuracy of monitoring results. This is especially important for controlling strict environmental emission standards. For example, PID (Photoionization Detection) technology can detect VOCs concentrations at the ppb level (parts per billion), meeting the high standards of industrial and environmental monitoring.

- Real-time monitoring and data recording

The gas analyzer can perform continuous real-time monitoring, record monitoring data, and provide detailed emission curves. These data can not only help companies understand their emission status in real-time but also provide an important basis for subsequent environmental audits and process optimization. The real-time monitoring function can help companies take rapid response measures when emissions exceed standards to avoid environmental pollution incidents.

- Simultaneous detection of multiple components

Modern gas analyzers can detect multiple VOCs components at the same time, improve monitoring efficiency, and meet monitoring needs in complex environments. For example, in the petrochemical industry, a variety of VOCs may be produced during the production process. Through simultaneous detection of multiple components, companies can fully understand the emission situation and take corresponding control measures for different components.

- Remote monitoring and data transmission

Through the Internet and Internet of Things technology, gas analyzers can achieve remote monitoring and data transmission, making it convenient for enterprises and environmental protection departments to keep track of VOCs emissions at any time. For example, enterprises can view the VOCs concentration of each monitoring point in real time through the remote monitoring platform, and promptly discover and solve emission problems. Remote monitoring can also help enterprises reduce labor costs and improve the efficiency of environmental management.

Application Cases of Gas Analyzers in Industrial VOCs Emission Monitoring

Gas analyzers have been widely used in many industries to monitor VOCs emissions. Here are a few typical cases:

- VOCs emission control in petrochemical companies

A large petrochemical company installed multiple gas analyzers in key links and emission points of its production equipment to monitor VOCs emissions in real-time. Through the analysis of monitoring data, the company found that certain production processes had excessive VOCs emissions. By optimizing production processes and strengthening equipment maintenance, the company has significantly reduced VOCs emissions and met the requirements of environmental regulations. In addition, the company has installed gas analyzers at the inlet and outlet of the exhaust gas treatment system to monitor the exhaust gas treatment effect in real time. Through the evaluation of treatment effects and process optimization, the company improved the efficiency of waste gas treatment and ensured emission compliance.

- Optimization of waste gas treatment in paint plants

A paint factory installed gas analyzers at the air inlet and outlet of the exhaust gas treatment system to monitor VOCs concentration changes before and after exhaust gas treatment. Through the analysis of monitoring data, the company found that there were problems in certain links in the exhaust gas treatment system, and the treatment effect was not ideal. After detailed analysis, the company decided to adjust the exhaust gas treatment process and introduced more advanced treatment equipment. By optimizing processes and upgrading equipment, the company has significantly improved waste gas treatment efficiency, reduced VOCs emissions, and met environmental protection standards.

- VOCs leakage monitoring in printing plants

A printing factory used a portable gas analyzer to conduct regular testing of equipment in the workshop and found small leaks in many equipment. By timely repairing and replacing damaged parts, the company effectively reduced the leakage of VOCs, improved the air quality in the workshop, and ensured the health of employees. In addition, the company has installed a fixed gas analyzer outside the workshop to monitor the concentration of VOCs outside the factory in real-time to prevent pollution to the surrounding environment.

Installation and Maintenance of Gas Analyzer

1. Installation Precautions

- Choose the appropriate location: When installing a gas analyzer, you should choose a location where VOCs emissions are concentrated, such as key nodes of the production device, the inlet and outlet of the emission pipeline, etc.

- Ensure good ventilation: The gas analyzer should be installed in a well-ventilated environment to avoid adverse conditions such as high temperature, high humidity, or strong magnetic fields from affecting equipment performance.

- Fix firmly: The equipment should be installed firmly to prevent vibration or movement from affecting the test results.

2. Routine maintenance

- Regular calibration: Gas analyzers should be calibrated regularly to ensure detection accuracy. The calibration frequency is determined based on the equipment instructions and actual usage.

- Cleaning and maintenance: The equipment should be kept clean, and the sensors and sampling pipes should be checked regularly to prevent dust and dirt from affecting the test results.

- Troubleshooting: If an equipment failure is discovered during use, the cause should be promptly investigated and repaired or damaged parts should be replaced to ensure normal operation of the equipment.

Prospects of Gas Analyzers in Future Industrial VOCs Emission Monitoring

1. Policy promotion and technological innovation

As global environmental regulations become increasingly stringent, companies’ demand for VOCs emission monitoring will continue to increase. As an important monitoring tool, gas analyzers will usher in wider applications and development. Technological innovation will further improve the detection accuracy, sensitivity and reliability of gas analyzers and provide strong support for industrial VOCs emission control.

2. Deepening and expansion of industry applications

The application of gas analyzers will gradually expand from traditional petrochemical, coating, printing and other industries to more emerging industries, such as electronic manufacturing, new energy, medicine, etc., providing effective solutions for environmental protection emission control in these industries.

3. Data-driven environmental management

With the development of big data and Internet of Things technology, gas analyzers will be deeply integrated with intelligent monitoring systems to achieve real-time data collection, analysis and management. Enterprises can optimize production processes, reduce pollution emissions, and improve environmental management levels through data-driven methods.

Conclusion

As an efficient and accurate VOCs emission monitoring tool, gas analyzers are increasingly used in industrial production. Through reasonable selection and scientific use of gas analyzers, companies can effectively monitor and control VOCs emissions, ensure environmental compliance, and protect the environment and employee health. At the same time, with the continuous advancement of technology and the promotion of policies, the application prospects of gas analyzers in industrial VOCs emission monitoring will be broader.

Through the detailed introduction in this article, I believe readers will have a deeper understanding of the application of gas analyzers in industrial VOCs emission monitoring. In practical applications, enterprises should select appropriate gas analyzers based on their own needs and specific conditions, and perform routine maintenance and data analysis to play their role in environmental management fully. if you want to learn more, please contact us!