Coal-fired power plants face two major pressures today: stricter emission limits and the need for smarter operations. Regulators now require real-time proof that plants stay within pollutant limits like NOx, CO, SO₂, and CO₂ — not occasional manual readings. Continuous Emission Monitoring Systems (CEMS), which include emission gas analyzers, deliver this real-time data to show compliance and avoid fines or permit losses.

Beyond compliance, operators also use emission gas analyzers to optimize combustion, reduce fuel use, and support predictive maintenance. Trends in O₂ and CO concentrations, for example, reveal combustion inefficiencies before they become costly failures.

This guide answers the core question: How do you choose the right emission gas analyzer for coal-fired plants? You’ll find a clear evaluation path, practical selection criteria (accuracy, reliability, durability), and guidance on matching technology to plant needs — from regulatory compliance to performance insight and integration strategy.

What Are the Core Concepts of Emission Gas Analyzer Use in Coal-Fired Plant Monitoring?

In coal-fired power plants, effective emission gas analyzers must track a range of key pollutants. These include nitrogen oxides (NOx), sulfur dioxide (SO₂), carbon monoxide (CO), carbon dioxide (CO₂), oxygen (O₂) and, increasingly, ammonia (NH₃). NOx and SO₂ drive air quality concerns and control technology decisions, while CO and O₂ reveal combustion health and efficiency. CO₂ helps quantify greenhouse gas emissions and energy performance. Collectively, these gases tell both environmental and operational stories about the boiler’s performance.

Regulatory frameworks shape what analyzers must measure. International and national standards (ISO, EN, local emission limits) define both pollutants and measurement quality. Continuous Emission Monitoring Systems (CEMS) provide real-time, automated data for compliance reporting. In contrast, spot or portable analyzers serve field diagnostics and short-term troubleshooting when certified CEMS isn’t required.

However, stack gas realities in coal plants challenge measurement. High temperature, heavy particulate loads and moisture can skew readings and damage sensors. That’s why sample conditioning — such as heated sampling and moisture removal — is essential before analysis. These steps ensure that the gas entering the analyzer reflects the true emissions, improving accuracy and reliability.

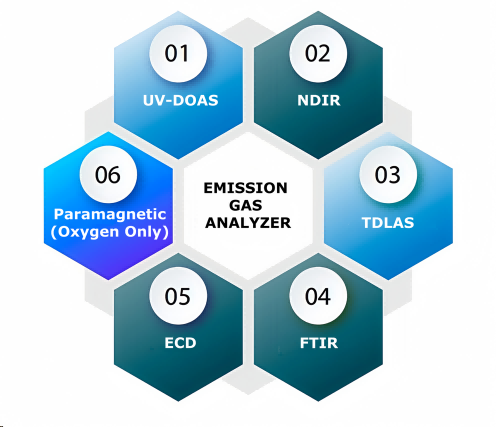

What Core Technology Options Does an Emission Gas Analyzer Use in Coal-Fired Plants?

When selecting an emission gas analyzer for a coal-fired plant, understanding the underlying technology matters. Every method has strengths, limits, and ideal use cases. This section breaks down the main analyzer technologies to help you choose with confidence.

A. Tunable Diode Laser Absorption Spectroscopy (TDLAS)

TDLAS uses a laser tuned to specific gas absorption lines to measure concentration. It excels at detecting low-level gases like ammonia or acid gases even in dusty, humid conditions, thanks to high selectivity and minimal cross-interference. This makes TDLAS ideal for demanding stacks where other methods struggle. However, most TDLAS units focus on one gas per module, so multi-component installations may require multiple lasers.

B. Non-Dispersive Infrared (NDIR)

NDIR is a widely used spectroscopic method for CO and CO₂. It relies on infrared absorption and offers stable, long-term performance with relatively low maintenance. NDIR analyzers remain a cost-effective baseline technology for core combustion gas measurement because of their reliability and simple optics.

C. Other Methods (UV-DOAS, FTIR, Paramagnetic, ECD)

- UV-DOAS (Ultraviolet Differential Optical Absorption Spectroscopy): Strong choice for NOx and SO₂ with good multi-component separation. It distinguishes overlapping spectra by fitting multiple ultraviolet absorption bands.

- FTIR (Fourier Transform Infrared): It measures many gases simultaneously but adds system complexity.

- Electrochemical cells (ECD): it suits low-range toxic gas detection or oxygen concentration (%).

- Paramagnetic/Oxygen Methods: Rugged options for O₂ measurement, supporting combustion control and efficiency checks.

Each method balances cost, maintenance effort, and environment fit. For example, UV-DOAS may cost more than NDIR but reduces cross-interference for complex gas mixes.

D. In-situ vs Extractive Systems

- In-situ analyzers measure gas directly in the stack, reducing sample handling but requiring rugged optics and probes.

- Extractive systems draw a sample out of the flue gas, then condition it (e.g., remove moisture, filter particles) before analysis. This improves accuracy and protects sensors but adds sampling complexity and maintenance steps.

Choosing between these depends on plant conditions, required pollutants, and data quality needs.

Now that we’ve explored the strengths and limitations of key analyzer technologies, the next step is to understand how to evaluate and compare these options for real coal-fired plant needs.

What Selection Criteria Matter Most for an Emission Gas Analyzer in Coal-Fired Plants?

Choosing the right emission gas analyzer goes beyond picking a technology. To deliver reliable, compliant, and operationally useful data, you need a balanced evaluation of performance, site conditions, integration needs, long-term costs, and standards compliance. Below are the core criteria engineers and plant managers must weigh.

A. Measurement Performance

First, focus on accuracy and precision. An analyzer must deliver measurements traceable to regulatory reference methods and achieve low detection limits for key gases like NOx, SO₂, CO, CO₂, O₂, and others. Accuracy within a few percent of the reference value ensures your data withstands audits and informs decisions. Additionally, consider response time. Real-time systems (e.g., <10–30 s) provide actionable control loop data, while periodic sampling suits less dynamic compliance needs.

B. Environmental & Site Conditions

Coal plant stacks are harsh environments. High temperatures, moisture, and heavy particulate loads can bias readings or shorten sensor life. Prioritize analyzers with robust probes, heated sample lines, and effective filtration to shield sensitive optics and electronics. Rugged materials and corrosion-resistant components extend longevity and reduce unplanned downtime.

C. Integration & Compatibility

Modern emission gas analyzers must play well with existing plant systems. Ensure compatibility with SCADA/DCS via standard outputs like Modbus, 4-20 mA, or OPC UA. This enables real-time data flow into control strategies and facilitates remote diagnostics or cloud-based monitoring for future-proof oversight.

D. Total Cost of Ownership (TCO)

Don’t focus just on the upfront price. Consider installation, calibration gases, spare parts, maintenance labor, and energy draw over the analyzer’s lifetime. Well-designed systems with automated calibration and self-checks can cut long-term costs by reducing manual intervention and improving uptime.

E. Standards & Certifications

Finally, verify that the analyzer meets relevant standards and certifications. International and regional benchmarks (e.g., ISO, EN, EPA protocols) define acceptable measurement quality and data reporting formats. Certified products with validated performance and compliance documentation make regulatory reporting smoother and support audit readiness.

With these evaluation criteria in mind, the next step is to see how different emission gas analyzer types perform in real coal-fired plant scenarios and operational workflows.

How Do Emission Gas Analyzer Use Cases Differ in Coal-Fired Plant Scenarios?

Now that we understand what makes a high-quality emission gas analyzer, let’s explore how specific analyzer technologies apply to real use cases in coal-fired plants. In coal-fired plants, emission gas analyzers serve multiple purposes beyond simple compliance. Different analyzer types support distinct use cases, from meeting legal limits to improving combustion and spotting problems early. Below, we explore practical scenarios and match them with the right analyzer technologies.

A. TDLAS-Based Emission Gas Analyzer for Targeted Gases

TDLAS excels in monitoring single, difficult-to-measure gases such as ammonia (NH₃). Its high selectivity and fast response allow reliable detection of low-level NH₃ upstream or downstream of SCR/SNCR units. Tracking NH₃ slip is vital for ensuring selective catalytic reduction (SCR) systems operate efficiently without over-injecting reagent or harming catalysts. TDLAS gas analyzer also supports other trace gases, HCl and HF, with minimal interference, which helps with precise emissions control and optimization.

B. UV-DOAS, NDIR, and ECD in Multi-Gas Emission Gas Analyzer

For broad-spectrum monitoring, combined technologies like UV-DOAS and NDIR make sense. The multi-gas analyzer can measure SO₂, NOx, CO₂, CO, and O₂ in one system. UV-DOAS handles gases with strong ultraviolet absorption (e.g., SO₂ and NO₂), while NDIR reliably measures infrared-active gases like CO, CO₂ and hydrocarbons. Electron capture detection (ECD) adds sensitivity for halogenated gases if needed. A multi-gas analyzer simplifies installation and data integration, helping with regulatory compliance and combustion tuning by tracking all key pollutants continuously.

C. FTIR Gas Analyzer

Fourier Transform Infrared (FTIR) analyzers, including models from leading suppliers, offer broad multi-gas coverage in a single system. FTIR’s strength lies in simultaneously quantifying a wide range of pollutants — from NOx and SO₂ to CO and volatile organic compounds — which makes it a strong candidate for comprehensive compliance monitoring and detailed emissions profiling.

D. Zirconia Oxygen Analyzer or Paramagnetic Oxygen Sensor

Oxygen measurement plays a unique role in combustion control. Zirconia oxygen analyzer and paramagnetic O₂ sensors deliver robust and real-time oxygen readings directly from the stack or flue gas. These readings guide air-to-fuel ratio adjustments, which can reduce unburned fuel, lower CO emissions, and boost thermal efficiency. Regular O₂ data also help operators spot inefficiencies and optimize boiler performance.

E. CEMS (Continuous Emission Monitoring Systems)

A full CEMS installation combines sample handling, conditioning, and multiple gas analyzers into a continuous monitoring framework. CEMS stream pollutant concentrations, flow rates, and derived emission factors to control systems and compliance reporting tools. With continuous data streaming, plants can:

- ensure regulatory limits are met in real time,

- optimize combustion efficiency by tuning fuel and air inputs,

- and enable predictive maintenance by spotting trends that foreshadow equipment issues.

Real-time compliance and data logging make CEMS essential for modern emission management and operational insight.

By aligning analyzer technology with specific use cases — “single-gas precision,” “multi-gas compliance,” “combustion control,” and “continuous oversight” — plants can extract more value from their emission gas analyzers and make smarter operational decisions.

Conclusion

As you wrap up the decision process, it helps to recap the essentials. First, align emission gas analyzer choices with your plant’s regulatory drivers, environmental conditions, and performance goals. A compliant system must measure required pollutants with consistent accuracy. At the same time, it should support combustion tuning and operational insights that improve efficiency and lower fuel costs.

Finally, engage suppliers with thoughtful questions about calibration plans, service support, warranty coverage, and documentation quality. A partner who supports training and upkeep can make a real difference in long-term performance and compliance readiness. Contact ESEGAS today to discuss your stack monitoring needs, request a tailored solution, or schedule a demo — and build an emissions strategy you can trust.

FAQs:

Q1: What does an emission gas analyzer measure in a coal-fired plant?

An emission gas analyzer tracks key pollutants such as NOx, SO₂, CO, CO₂, O₂ and trace gases like NH₃ to support compliance and combustion insights. These measurements help verify emissions limits and guide process control.

Q2: Why do coal plants use Continuous Emission Monitoring Systems (CEMS)?

CEMS provide real-time, continuous data on smoke stack emissions by sampling and analyzing multiple gases and stack parameters automatically. This supports regulatory reporting and reduces manual testing.

Q3: What’s the difference between continuous and spot analyzers?

CEMS automatically monitor emissions 24/7, while spot or portable analyzers are used for field checks, commissioning, or cross-validation of long-term systems.

Q4: How much does an emission gas analyzer or CEMS cost?

Prices vary widely based on gas count and performance. Basic online stack gas analyzers can start at a few thousand dollars, while multi-component CEMS solutions typically range from around $6,000 up to $60,000 or more for robust industrial units. Larger certified continuous systems can cost $120,000 to $250,000+ depending on configuration and stack requirements.

Q5: How do emission analyzers integrate with plant monitoring and reporting systems?

Modern emission gas analyzers offer standard outputs like Modbus, 4-20 mA, OPC UA, or Ethernet for SCADA/DCS integration. These interfaces support real-time control loops, compliance reporting, and long-term trending. Ask suppliers about remote diagnostics and cloud connectivity to future-proof your installation.

Q6: What’s a common cause of analyzer performance issues?

Stack sampling challenges like particulate build-up, moisture, or clogged sample lines often affect readings. Correct sample conditioning and maintenance reduce errors and downtime.