Struggling with inaccurate gas detection in your incineration plant? Traditional systems can’t keep up with evolving environmental demands — but FTIR CEMS from ESEGAS changes the game.

FTIR CEMS enables precise, multi-gas emissions monitoring in real time, even under complex, corrosive conditions found in waste incineration plants, ensuring full compliance with global emission regulations.

Already know FTIR CEMS helps you stay compliant? Keep reading to uncover why ESEGAS stands out and how it can transform your waste incineration monitoring strategy.

What Is FTIR CEMS and What Role Does It Play in Waste Incineration Plants?

Frustrated by blind spots in your emissions monitoring? Waste incineration generates a wide spectrum of pollutants, from acidic gases to organic compounds. Traditional Continuous Emission Monitoring Systems (CEMS) often fall short when faced with these challenges.

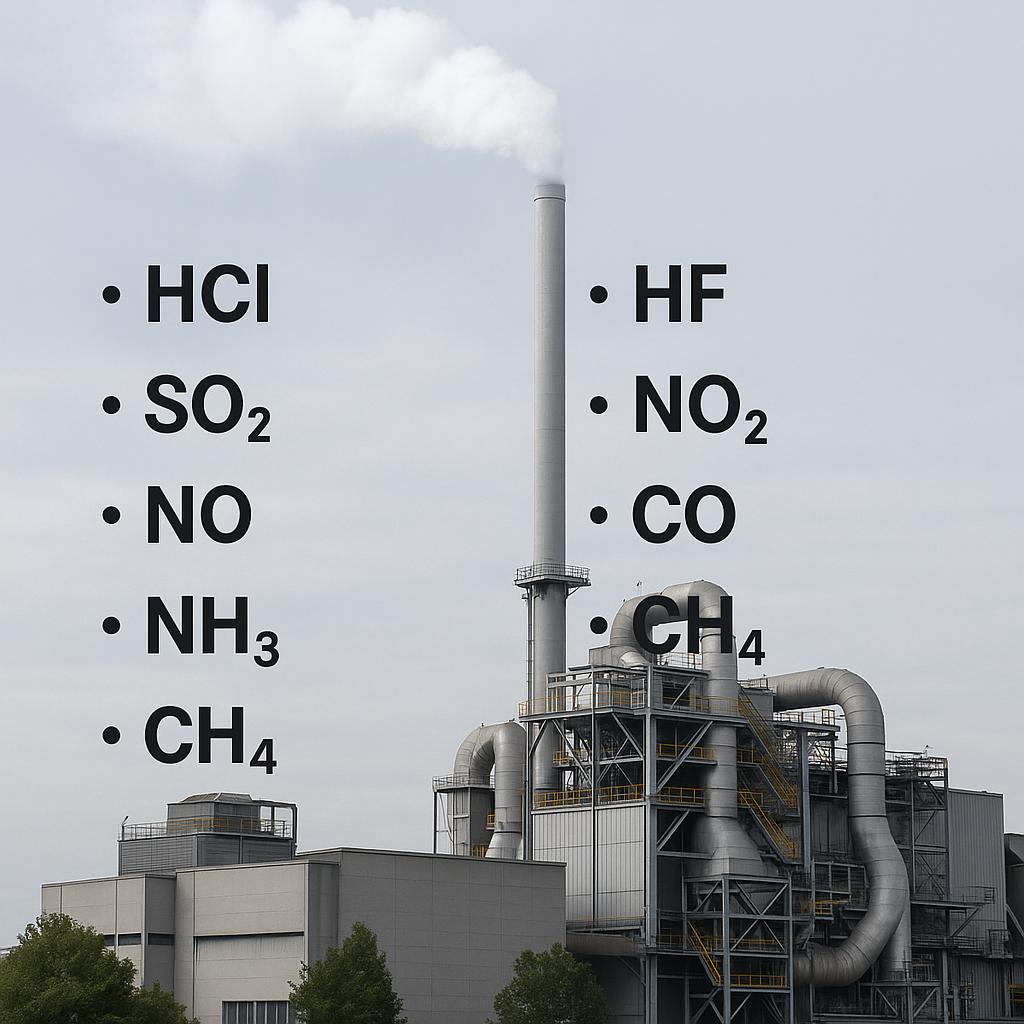

FTIR CEMS — Fourier Transform Infrared Continuous Emission Monitoring System — leverages advanced infrared spectroscopy to continuously measure multiple gas components simultaneously. Instead of relying on separate sensors for each gas, FTIR detects the unique infrared absorption spectra of various molecules. In waste incineration plants, where gas composition varies and includes harmful substances like HCl, SO₂, NOx, and VOCs, this technology provides unparalleled accuracy and speed.

Why Do Waste Incineration Facilities Require FTIR Gas Analyzers?

Worried that conventional sensors can’t keep up with complex flue gases? Waste incineration is notoriously unpredictable — the chemical composition of the emissions changes constantly depending on feedstock, temperature, and operating conditions.

Unlike traditional analyzers that monitor only a few gases at once, FTIR CEMS handles dozens of gas species with high specificity and sensitivity. This ensures facilities can detect not only regulated pollutants like CO, NOx, and SO₂, but also emerging contaminants such as NH₃, HF, and dioxins’ precursors. ESEGAS’s technology ensures real-time feedback and control, which is essential for process optimization and regulatory compliance under increasingly strict environmental legislation.

What Are the Key Advantages of ESEGAS FTIR CEMS?

Still using outdated analyzers that require frequent recalibration and maintenance? That’s both costly and risky for compliance.

ESEGAS’s FTIR CEMS stands out with a fully integrated optical system, automated calibration routines, and a built-in sample handling system designed for high-dust, high-humidity environments. Its modular design makes installation flexible and maintenance straightforward. The system offers high signal-to-noise ratio and low detection limits, while an intuitive user interface allows operators to view real-time trends and alerts.

What truly sets ESEGAS apart is its proprietary software and cloud compatibility, allowing for remote diagnostics, data reporting, and system management — reducing downtime and ensuring continuity.

Which Gases Can ESEGAS FTIR CEMS Accurately Monitor?

Not sure if your analyzer captures all critical emissions? Missing key pollutants could mean failed inspections or hefty fines.

ESEGAS FTIR CEMS is capable of simultaneously monitoring a wide range of gases including HCl, HF, SO₂, NO, NO₂, CO, CO₂, NH₃, CH₄, N₂O, and Total Organic Compounds (TOC). This comprehensive detection is possible because FTIR technology uses the entire mid-infrared spectrum to identify gas “fingerprints.” This capability ensures compliance with EN 14181 and US EPA standards while providing operators with actionable data for process control and environmental reporting.

How Can FTIR Systems Operate Reliably in Harsh Incineration Environments?

High humidity, dust, and corrosive gases destroying your equipment? These are the realities of waste incineration environments — and a major cause of sensor failures.

ESEGAS designs its FTIR CEMS with advanced gas conditioning systems that include heated sampling lines, filters, and corrosion-resistant materials. Its systems maintain sample temperatures above dew point to prevent condensation, and use high-durability alloys and coatings to withstand acid gases like HCl and SO₂. Automated self-check and purge functions further enhance longevity and reduce maintenance intervals, making ESEGAS’s solution both rugged and reliable.

What Are Some Real-World Applications of ESEGAS FTIR CEMS in Waste Incineration?

Curious how others have solved similar monitoring challenges? Many municipal and industrial incineration plants have already adopted ESEGAS’s solutions to meet stringent emission limits.

In a recent installation in a Southeast Asian municipal waste incinerator, ESEGAS deployed its FTIR CEMS to monitor 12 gas components continuously, with data logged in real time and transmitted to environmental authorities via API. The facility achieved 99.8% data availability over a 12-month period, reduced maintenance downtime by 40%, and successfully passed multiple third-party audits. Similar success stories span Europe and the Middle East, where ESEGAS has become a preferred choice for plants seeking a future-proof monitoring strategy.

Conclusion

FTIR CEMS has redefined emissions monitoring in waste incineration by offering unmatched accuracy, multi-gas capability, and reliability. ESEGAS leads this transformation with robust engineering, intelligent software, and proven field success — ensuring plants stay compliant, efficient, and environmentally responsible.