In today’s gasification plants, real-time monitoring of synthesis gas—or syngas—is no longer optional; it’s essential. With carbonaceous feedstocks such as coal, biomass or waste, the gasifier produces a complex mixture of hydrogen (H₂), carbon monoxide (CO), carbon dioxide (CO₂) and other components. Accurate, continuous data allows engineers to keep the process on-track, safe and economical.

Yet the question remains: how does an online syngas analyzer stand up to the harsh conditions inside a gasifier? Think high temperature, dust, tar, rapid composition changes and a heavy background gas matrix. Measuring H₂, CO and CO₂ in that environment demands robustness, precision and smart engineering. By asking this question, we set the stage for bridge-building between instrumentation and process reality.

Why Does an Online Syngas Analyzer Need to Understand Syngas Composition?

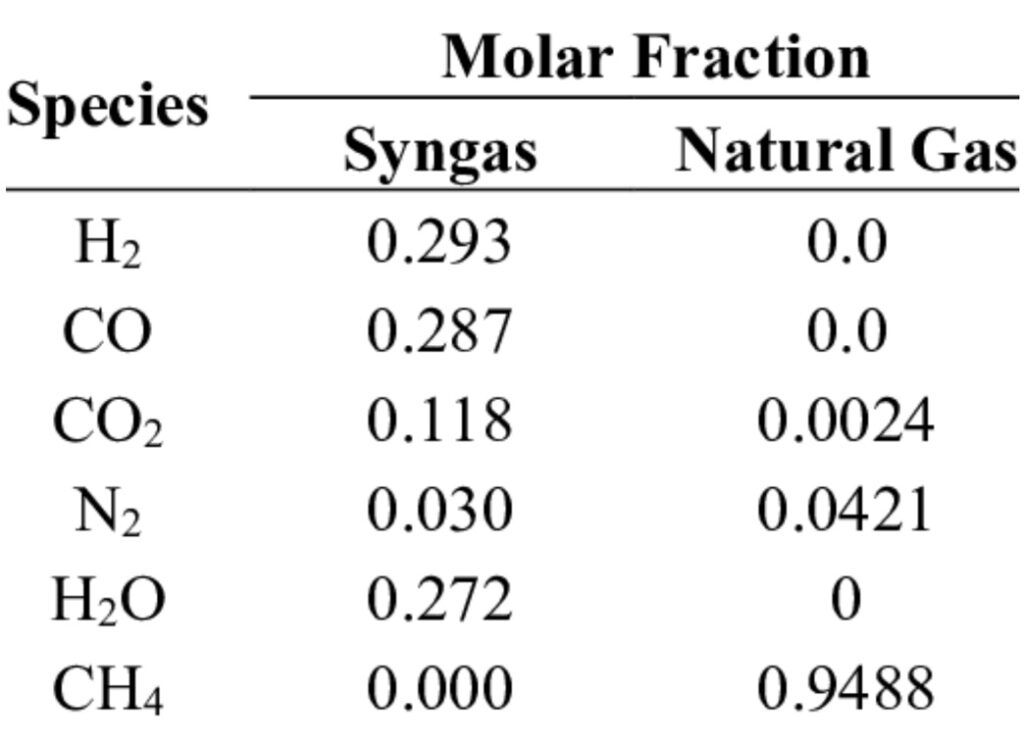

In the world of gasification, syngas (synthesis gas) refers to the mixture produced when carbon-rich feedstocks are converted under controlled conditions. Typically, syngas consists of major components like hydrogen (H₂), carbon monoxide (CO) and carbon dioxide (CO₂), with smaller amounts of methane (CH₄) and inert gases.

Each of these gases carries importance:

- H₂ provides high energy value and is critical for fuel or chemical synthesis applications.

- CO acts as both a fuel and a key reactant in downstream processes such as Fischer-Tropsch or methanol synthesis.

- CO₂ often behaves as a diluent or indicator of incomplete conversion, reducing the fuel value of the syngas.

Because of this, understanding their proportions is vital for performance, safety and economics in gasification.

Moreover, the exact composition of syngas depends heavily on the type of feedstock (e.g., coal vs biomass vs waste) and operating conditions. For example:

- Coal gasification often results in a syngas composition of roughly 30-60 % CO, 25-30 % H₂, and 5-15 % CO₂.

- Biomass or waste feedstocks may yield higher H₂ relative to CO, or higher CO₂ and inert gases, due to higher oxygen/hydrogen content and moisture in the feed.

These differences affect downstream requirements: for example, a high H₂/CO ratio is preferred for hydrogen production, whereas other ratios might be targeted for fuel synthesis.

But it’s not just about meeting regulatory gas-composition targets. There are three further dimensions where measurement matters:

- Operational: Accurate composition data lets operators optimize feedstock rate, oxidant/steam input, temperature and pressure to maximize conversion and yield.

- Safety: Unexpected shifts in syngas composition may signal feedstock inconsistencies, tar or dust loads, or equipment fouling — each of which could escalate into safety risks.

- Commercial: The calorific value of the syngas, the viability of downstream synthesis, and the ability to switch feedstocks or enter new markets all depend on trusted composition data.

Hence, an online syngas analyzer is far more than a regulatory gadget—it is a core enabler of control, insight and value in modern gasification systems.

How Does an Online Syngas Analyzer Actually Measure H₂, CO and CO₂ in Real Time?

(ESEGAS Online syngas analyzer)

An online syngas analyzer operates in a way that is very different from offline lab testing. It pulls the sample continuously, conditions it, and pushes real-time readings back to the control room. This approach gives engineers steady insight into gasifier behavior rather than delayed snapshots. It also reduces guesswork when load changes, slagging risks, or air-fuel ratio shifts occur. Because the process never stops, the analyzer becomes part of the plant’s core instrumentation rather than a periodic testing tool.

Modern systems rely on several proven sensor technologies. NDIR modules track CO and CO₂ using stable infrared absorption paths that withstand harsh matrices. TCD sensors measure H₂ through thermal conductivity changes, which respond quickly even when gas composition swings. Some designs add paramagnetic or electrochemical sensors when O₂ or trace gases matter for process control. Systems such as the ESEGAS IR-GAS-600 combine these technologies so operators can read multiple components from one platform.

Each measurement principle tackles a different challenge inside the gasifier loop. High H₂ and CO concentrations can distort readings, so the analyzer uses selective filters and optimized optical paths to keep signals clean. Dust and tar often threaten sample integrity, so the system includes heated lines and filtration to keep the sample stable. Meanwhile, extreme temperatures and pressures require rugged sampling probes and pressure-regulated conditioning to avoid drift. These layers work together to ensure that harsh conditions do not overwhelm the sensors.

Accuracy depends on smart calibration and compensation. The analyzer applies zero and span checks to correct drift and uses temperature and pressure compensation to stabilize the output. It also monitors flow, sample integrity, and optical performance so the data remains trustworthy. With these safeguards in place, operators can rely on real-world measurements even when the gasifier runs at full variability.

How Should an Online Syngas Analyzer Be Strategically Placed and Integrated into Gasifier Systems?

Accurate measurement is worthless if the sample is bad. A typical gasification train involves the gasifier, followed by extensive syngas cleanup. This cleanup involves filtration, scrubbing, and cooling to remove dust, tars, and moisture.

The most crucial step is Sampling and Conditioning. The analyzer station must be placed after the cleanup system. Placing it too early introduces contaminants that quickly destroy the sensors and sampling lines. Placement must capture a gas that is representative of the entire stream before it is diluted or mixed.

Key conditioning requirements include:

- Filtration: Removing all particulate matter and fine dust.

- Cooling: Dropping the temperature to a stable level, usually below the dew point of water and other condensable.

- Tar Removal: Eliminating sticky hydrocarbons that coat components.

A real-world pitfall is a non-representative sample point. Another is inadequate conditioning, which causes matrix shifts and clogs. Plant engineers must invest in robust sampling systems. They are as critical as the analyzer itself. A well-designed system ensures the gas reaching the sensors is clean, dry, and at a consistent pressure and temperature, guaranteeing data integrity.

What Actionable Insights Does Online Syngas Analyzer Data Provide for Operations?

The online syngas analyzer generates more than just data points. It provides real-time operational feedback.

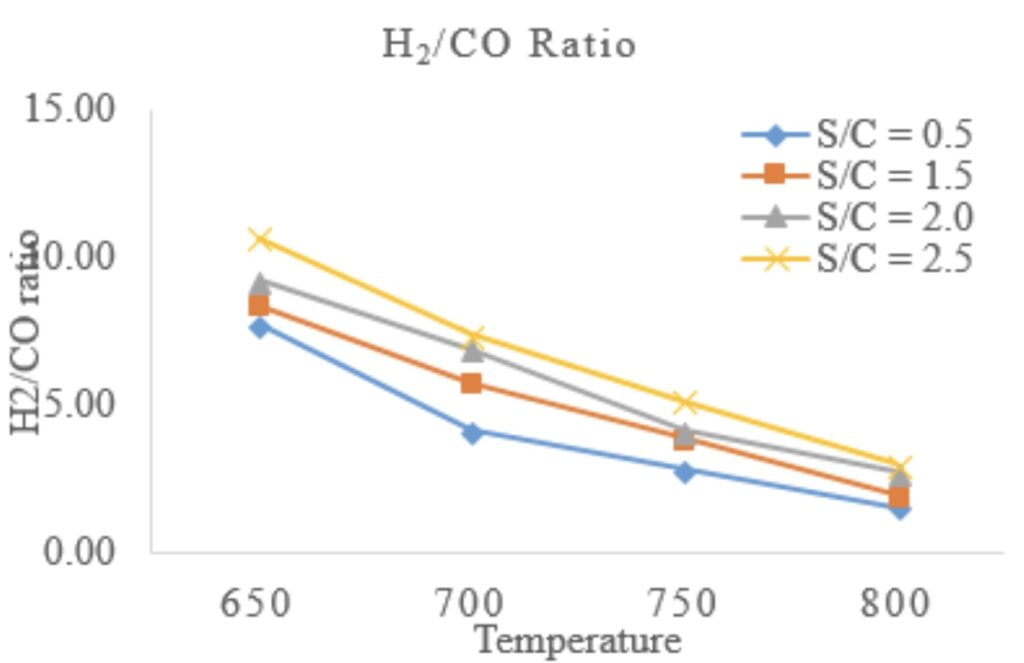

- Conversion Efficiency: A shift in the H2/CO ratio often signals a change in the gasifier’s conversion efficiency. A sudden drop in H2 might point to a problem with the feedstock moisture content or a temperature fluctuation.

- Dilution and Inserts: Elevated CO2 and nitrogen readings can indicate excessive air or steam injection. This lowers the gas’s calorific value and wastes energy.

- Safety and Emissions: Continuous monitoring provides early warnings for potential safety issues, such as dangerously high CO levels. It also helps control and verify emissions performance.

Engineers use these raw readings to move from reactive troubleshooting to predictive control. By tracking trends, they can optimize feedstock input, adjust the gasifier temperature, and fine-tune oxygen/steam delivery. This data integrity translates directly into an operational advantage, supporting optimized asset utilization and ensuring compliance with strict environmental standards.

Conclusion

In modern gasification plants, a high-quality online syngas analyzer is non-negotiable. The accurate, real-time measurement of H2, CO, and CO2 is essential. It underpins operational performance, ensures safety, and verifies regulatory compliance. The analyzer is the eyes and ears of the plant, linking complex chemistry to simple, actionable control decisions.

We must ask ourselves: Is your current measurement setup providing the accuracy and data integrity that supports your performance, safety, and regulatory goals?

It’s time to evaluate your current system. Ask the right questions about the sensor technology, the robustness of your sampling system, and how that data integrates with your control room. Map out your next-generation analytics roadmap today to ensure your gasification process runs safely, efficiently, and profitably. Consult with our team!

FAQ: Online Syngas Analyzers in Gasification

1. Why is real-time analysis of H₂, CO and CO₂ in syngas crucial for gasifier operations?

Real-time analysis is crucial because H₂, CO and CO₂ define the syngas’s quality and energy content. Monitoring these components:

- Ensures Efficiency: Tracks the H₂/CO ratio, which signals gasifier conversion efficiency.

- Optimizes Performance: Allows immediate adjustments to feedstock or steam/oxygen injection.

- Guarantees Safety: Provides early warnings for potentially hazardous CO levels.

- Verifies Compliance: Confirms the final gas product meets commercial and environmental standards.

2. What specific sensor technologies does an online syngas analyzer use to measure H₂, CO and CO₂?

Online syngas analyzers employ a combination of proven technologies for high accuracy:

- CO and CO2: Typically measured using Non-Dispersive Infrared (NDIR) sensors. These rely on the principle that both gases absorb specific infrared wavelengths corresponding to their concentration.

- H₂ (Hydrogen): Usually measured with a Thermal Conductivity Detector (TCD). H₂’s uniquely high thermal conductivity causes a measurable change in the TCD sensor’s heat loss, indicating its concentration.

- Oxygen (O2): Sometimes included using electrochemical or paramagnetic sensors to track inert gas levels.

3. How do online syngas analyzers handle the harsh conditions (dust, tar, heat) of a gasifier environment?

The analyzer itself does not operate in the harsh environment. Accuracy is maintained through a dedicated Sampling and Conditioning System. This system performs several vital steps:

- Filtration: Removes all particulate matter and fine dust.

- Cooling: Reduces the gas temperature to a stable, consistent level, often condensing moisture.

- Tar Removal: Eliminates sticky hydrocarbons to prevent coating sensors and lines.

This process ensures that the gas reaching the sensors is clean, dry, and at a stable pressure, preventing sensor damage and matrix interference.

4. Where should the online syngas analyzer station be positioned in the gasification train for the most accurate data?

The analyzer station must be strategically placed after the main syngas cleanup system (e.g., after filters, scrubbers, and coolers).

- Why after cleanup? Placing it before cleanup would immediately foul the sensitive sensors and sample lines with dust and tar.

- Optimal Point: The ideal placement captures gas that is representative of the total production stream, typically before any downstream mixing or dilution with other process streams occurs.

5. How do engineers ensure the accuracy and data integrity of the online syngas analyzer readings over time?

Maintaining accuracy requires several integrated methods:

- Auto-Calibration: Systems regularly perform automated checks and calibration using certified span and zero gases to correct sensor drift.

- Compensation: Built-in algorithms automatically compensate for fluctuations in sample temperature and pressure, which otherwise affect the gas density and sensor readings.

- Data Validation: Engineers track trends and use the data to identify anomalies, ensuring the readings translate into reliable, actionable operational insights.

6. What is the operational impact of a sudden shift in the H₂/CO ratio reported by the online analyzer?

A significant shift in the H₂/CO ratio is an immediate signal of a change in the gasifier’s internal conversion chemistry.

- Ratio Drop: Often indicates issues like low gasifier temperature, excessive steam/air injection, or an increase in feedstock moisture content, leading to lower efficiency.

- Ratio Spike: Could indicate a need to adjust oxygen or steam inputs to maintain the desired synthesis gas composition for downstream processes (e.g., Fischer-Tropsch synthesis).