Syngas, a critical energy resource, requires precise compositional monitoring to maximize its industrial potential. Traditional gas analysis methods often struggle with accuracy and reliability. Why is Non-Dispersive Infrared (NDIR) technology emerging as the preferred solution? This article examines NDIR technology’s role in real-time syngas analysis, its operational advantages, and how it drives sustainable industrial practices. Let’s understand syngas first!

What Is Syngas and How Is It Produced?

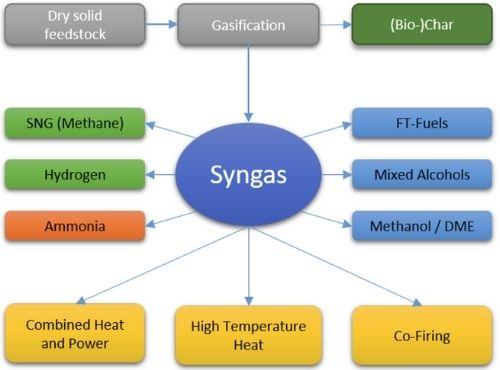

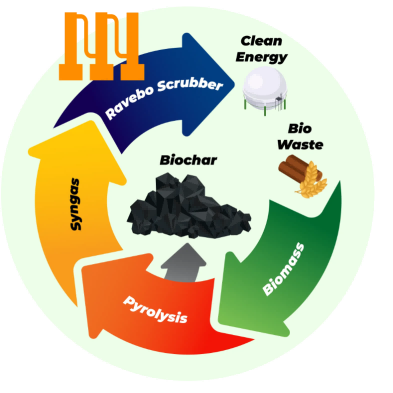

Syngas, or synthesis gas, serves as a critical fuel gas mixture containing hydrogen (H₂), carbon monoxide (CO), and carbon dioxide (CO₂). Primarily combines carbon monoxide (CO) and hydrogen (H₂) in its core formula (CO + H₂). Manufacturers produce it through gasification—a thermochemical process that converts carbon-rich materials like biomass, coal, or waste into energy-rich gases. By reacting feedstocks with controlled oxygen or steam at high temperatures, gasification efficiently breaks down complex hydrocarbons. This method not only diversifies energy sources but also aligns with circular economy principles by repurposing waste materials.

(gasification-converting-biomass-and-waste-into-syngas)

What Are Core Components and Their Role of Syngas?

The typical composition of syngas include:

—Hydrogen (20–40%): H2 serves as a high-energy carrier, critical for ammonia synthesis and fuel cells.

—Carbon monoxide (35–45%): CO acts as a reducing agent in metallurgy and a precursor for liquid fuels.

—Carbon dioxide (15–25%): CO2 influences reaction equilibria and requires monitoring to minimize carbon capture costs.

—Methane and other hydrocarbons (0–15%): CH4 and trace hydrocarbons affect combustion properties.

—Nitrogen (2–5%): N2 dilutes energy density but stabilizes flame temperatures.

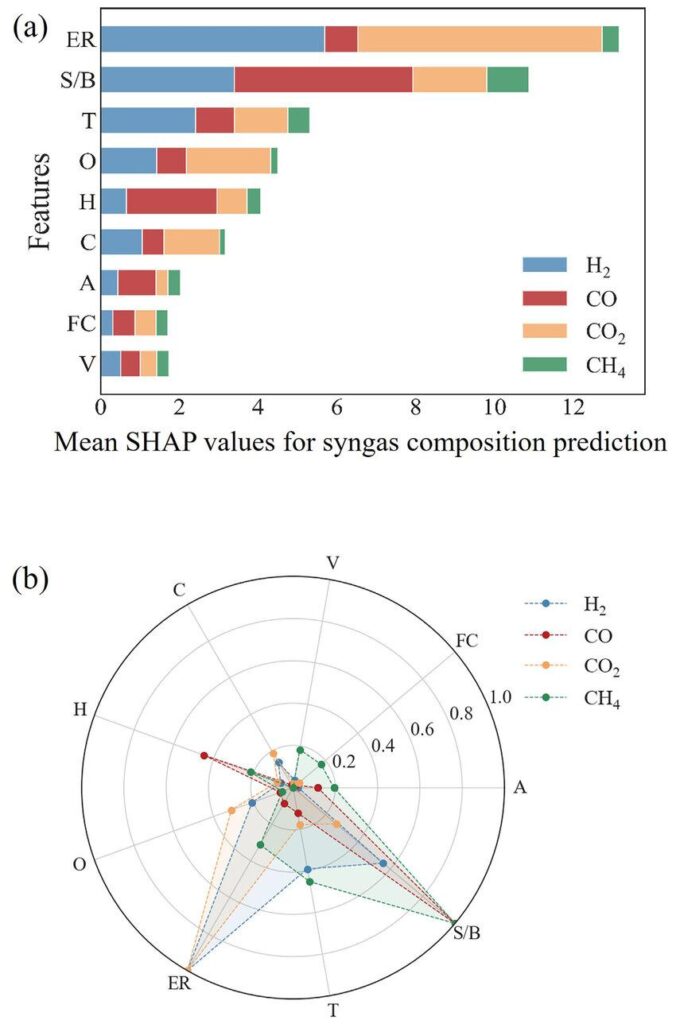

(Analysis-of-syngas-composition)

What Is the Applications of Syngas?

Syngas composition directly impacts energy conversion efficiency and downstream applications. Feedstock variability (coal, biomass, or waste) and gasifier configurations primarily determine the H₂/CO ratio and impurity levels. Transitioning to applications, syngas demonstrates remarkable versatility across energy sectors. Common Applications in the Energy Industry Syngas serves as a crucial intermediary in various applications:

- Power Generation: Used as a fuel in internal combustion engines or gas turbines to produce electricity. Moreover, gas turbines burning syngas achieve 40-50% electrical efficiency while reducing particulate emissions versus direct coal combustion

- Chemical Synthesis: Acts as a building block for producing chemicals like methanol, ammonia, and synthetic hydrocarbons. Its tunable composition – methanol producers require specific H₂/CO ratios (2:1).

- Hydrogen Production: Serves as a source of hydrogen for fuel cells and industrial processes. Ammonia synthesis demands high-purity hydrogen extracted through pressure swing adsorption.

What’s the Difference between Syngas and Natural Gas?

While syngas and natural gas both serve as industrial fuels, their distinct compositions create critical differences in performance and applications. I will use a comparative table highlighting the differences between natural gas and syngas through several perspectives.

| Aspects | Natural Gas | Syngas |

| Composition | Methane (CH₄) dominates as the primary component (90-95%),optimized methane formulas integrate trace hydrocarbons—ethane (C₂H₆, 2-4%) and propane (C₃H₈, 1-3%) | Consists mainly of carbon monoxide (CO) and hydrogen (H₂), with varying amounts of carbon dioxide (CO₂) and methane (CH₄), depending on feedstock type and gasification parameters. |

| Energy Density | Methane delivers a compact energy yield of 50-55 MJ/kg, attributed to its unique molecular efficiency. | Generally lower, around 30% less than natural gas, variable feedstock sources. |

| Infrastructure Design | Higher energy density allows for streamlined delivery through narrower pipelines. | Requires wider pipes to increased volumetric throughput for equivalent energy transport, owing to reduced energy concentration per unit volume. |

| Feedstock Flexibility | Limited to natural gas reserves. | Diverse feedstocks convert underutilized resources, including coal, biomass, and waste materials |

| Environmental Considerations | Methane is a potent greenhouse gas; leaks pose significant climate risks. | While CO is toxic, syngas combustion can be environmentally-friendly, especially when derived from renewable sources, potentially lowering carbon footprint. |

| Detection & Monitoring | Focus on methane leak detection due to its high global warming potential. | Emphasis on monitoring CO levels to prevent hazards. |

What’s the Environmental Benefits of Syngas Utilization?

Syngas utilization delivers measurable ecological improvements through innovative waste-to-energy strategies.

1) Waste Reduction:

Syngas directly addresses global waste management challenges by converting non-recyclable materials—such as agricultural residues and municipal solid waste—into clean energy. This process minimizes landfill dependency and repurposes materials that would otherwise emit methane during decomposition. Industries adopting this approach not only reduce operational waste but also align with circular economy principles, creating value from discarded resources.

2) Lower emissions:

Syngas derived from biomass feedstocks supports carbon-neutral energy cycles. Unlike fossil fuels, biomass absorbs CO₂ during growth, offsetting emissions released during syngas combustion. For instance, gasification plants using forestry waste can achieve near-zero net emissions when paired with carbon capture systems. Furthermore, integrating NDIR (Non-Dispersive Infrared) technology enables precise monitoring of greenhouse gas outputs, ensuring compliance with emission reduction targets.

How Can NDIR Technology Enhance Syngas Production and Quality Control?

What is NDIR technology? Non-Dispersive Infrared (NDIR) technology operates by detecting gases through their unique absorption of infrared (IR) light at specific wavelengths.If you want to know more about NDIR technology, I have more information in blog post ‘Why do NDIR Gas Analyzers Dominate Greenhouse Gas Monitoring?’

How Can NDIR Technology Overcome Key Challenges in Syngas Analysis? Syngas analysis demands careful attention due to three critical factors that impact accuracy and safety. Understanding these challenges empowers operators to select optimal monitoring strategies. Let’s explore the obstacles and actionable solutions.

Syngas production relies on diverse feedstocks (biomass, coal, waste) and fluctuating gasification parameters, causing unpredictable variations in H₂, CO, and CH₄ ratios. Standardized testing protocols struggle to adapt, demanding real-time adaptive monitoring systems for reliable data.

Tar aerosols, sulfur derivatives (H₂S, COS), and fine particulates distort spectroscopic and chromatographic readings. Advanced filtration and laser-based sensors are emerging to isolate target gases and minimize false results.

Carbon monoxide concentrations frequently exceed 5,000 ppm in syngas streams – levels that pose immediate lethal risks. Conventional electrochemical sensors suffer from drift and slow response times during rapid concentration changes. This latency creates dangerous gaps in safety monitoring. NDIR (Non-Dispersive Infrared) technology detectors solve this by providing continuous, drift-resistant CO measurements with sub-10-second response times. Their cross-interference compensation algorithms maintain accuracy even when other infrared-active gases like CO₂ are present.

Non-Dispersive Infrared (NDIR) technology offers solutions to the above challenges:

- Precision-Targeted Gas Identification: sensors with NDIR technology leverage wavelength-specific absorption to isolate CO₂, CH₄, and CO molecules, eliminating cross-interference from complex gas mixtures. This accuracy ensures compliance with strict emission standards.

- Contaminant-Immune Performance: Unlike traditional catalytic bead sensors, NDIR technology remains unaffected by sensor poisoning, delivering stable readings even in high-particulate or corrosive syngas environments. Ideal for harsh industrial settings.

- Proactive Hazard Prevention: Real-time CO monitoring with NDIR technology mitigates explosion risks in biogas plants, coal gasification units, and chemical facilities—enabling swift response to unsafe thresholds.

By addressing syngas analysis challenges head-on, NDIR technology not only elevates process reliability but also aligns with industrial decarbonization goals.

Which Technology is Best for Syngas Analysis Comparing with NDIR Technology?

In syngas analysis, various technologies are employed to detect and quantify gas components such as carbon monoxide (CO), carbon dioxide (CO₂), and hydrogen (H₂).

Below is a comparative table highlighting the features of Non-Dispersive Infrared (NDIR) technology alongside other prevalent methods:

| Technology | Working Principles | Advantages | Disadvantages | Application Suitability in Syngas Analysis |

| NDIR (Non Dispersive Infrared) | Measures absorption of specific infrared wavelengths by gas molecules. | – High selectivity and sensitivity. – Non-contact measurement. – Low maintenance. | – Potential interference from other gases absorbing at similar wavelengths. – Requires precise optical alignment. | Ideal for continuous, on-site monitoring of key syngas components (e.g., CO, CO₂) in industrial settings. |

| Gas Chromatography (GC) | Separates gases based on their interaction with a stationary phase. | – Capable of analyzing multiple components simultaneously. -High-resolution separation. | – Complex and time-consuming sample preparation. – Requires skilled operation. | Best for laboratory-based, detailed compositional studies rather than continuous real-time monitoring. |

| Mass Spectrometry (MS) | Ionizes gas molecules and measures their mass-to-charge ratio. | – Provides detailed molecular information. – High sensitivity. | – Expensive equipment. – Requires high vacuum conditions. | Suited for specialized research applications and trace analysis, not typically for routine industrial monitoring. |

| Fourier Transform Infrared Spectroscopy (FTIR) | Measures absorption of infrared light across a broad spectrum. | – Simultaneous detection of multiple gases. -Non-destructive analysis. | – Sensitive to water vapor and other atmospheric components. – Requires complex data analysis. | Effective for comprehensive laboratory analyses but less optimized for rapid, on-site monitoring compared to NDIR. |

| Flame Ionization Detection (FID) | Detects ions produced during combustion of organic compounds. | – Sensitive to hydrocarbons. – Simple operation. | – Not suitable for inorganic gases like CO₂. – Requires hydrogen gas for the flame. | |

| Thermal Conductivity Detection (TCD) | Measures changes in thermal conductivity of the gas mixture. | – Universal detector for all gases. -Non-destructive. | – Less sensitive compared to other methods. – Requires calibration with known standards. | |

| Tunable Diode Laser Absorption Spectroscopy (TDLAS) | Utilizes tunable lasers to measure absorption at specific wavelengths. | – High precision and sensitivity. – Capable of detecting low concentrations. | – High equipment cost. – Sensitive to environmental conditions affecting laser performance. |

To choose the optimal syngas analysis tool, start by defining critical parameters: target gas concentrations, operating environment, and required measurement frequency. Always validate instrument compatibility with syngas matrices—especially when moisture or particulates are present.

How Does NDIR Technology Revolutionize Syngas Analysis for Cleaner Energy?

NDIR technology revolutionizes syngas analysis by merging precision engineering with environmental accountability. Its ability to isolate target gases like CO/CO₂ while resisting cross-interference positions it as a linchpin for industries navigating decarbonization mandates. Beyond lab applications, NDIR’s real-time adaptability empowers facilities to slash fuel waste and preempt costly miscalculations in carbon management. As industries pivot toward net-zero frameworks, integrating self-calibrating NDIR systems will likely become a benchmark—not just for compliance, but for redefining resource efficiency. Forward-thinking operators now leverage this synergy of accuracy and automation to future-proof processes while aligning with global sustainability metrics.