Struggling to monitor HCl emissions effectively? Choosing the wrong technology could lead to non-compliance and environmental harm.

Understanding these technologies is essential—not just knowing their names. If you’re selecting an HCl gas analyzer for your facility, here’s what you need to know.

Why Is It Crucial to Monitor HCl Gas?

Invisible but highly corrosive, HCl gas can quietly compromise your entire production line—causing safety incidents, equipment failure, and regulatory violations.

Hydrogen chloride (HCl) is a colorless gas with a sharp, pungent odor, widely produced in industrial processes such as PVC manufacturing, coal combustion, waste incineration, and metal refining. Despite its invisibility, HCl is far from harmless. It reacts aggressively with moisture in the air or in human tissue, forming hydrochloric acid, which leads to significant corrosion in pipelines, flue gas ducts, and sensitive electronic components.

Beyond equipment damage, exposure to HCl poses serious health risks. Inhalation can lead to respiratory distress, coughing, and chronic lung damage. For workers in enclosed or poorly ventilated areas, even small leaks can escalate into serious occupational hazards. These risks make proactive detection not just advisable but essential.

On the regulatory side, environmental protection agencies across the globe impose stringent emission limits for HCl. In regions with Waste Incineration Directive (WID) or Industrial Emissions Directive (IED) enforcement, exceeding these limits can result in hefty fines, operational shutdowns, or legal action. Furthermore, customers and stakeholders increasingly demand transparency and environmental accountability, especially from high-emission sectors.

Implementing a real-time, high-precision HCl gas analyzer empowers industrial operators to stay ahead of these challenges. Solutions from ESEGAS provide continuous monitoring with rapid response times, enabling early leak detection and process optimization. This not only helps prevent compliance violations but also reduces long-term maintenance costs and protects both workers and the environment.

In short, monitoring HCl isn’t just about compliance—it’s about safeguarding health, infrastructure, and your company’s reputation.

How Does TDLAS Technology Detect HCl with High Precision?

Traditional sensors struggle in harsh industrial environments—leaving critical gas leaks undetected and your operations exposed to risk.

Monitoring HCl gas in real-world industrial conditions presents unique challenges. High temperatures, moisture, particulate matter, and chemical interferences can all affect the accuracy and reliability of conventional detection methods. Electrochemical sensors, for example, are prone to drift and degradation, while chemical sampling techniques often lack real-time responsiveness and require frequent calibration.

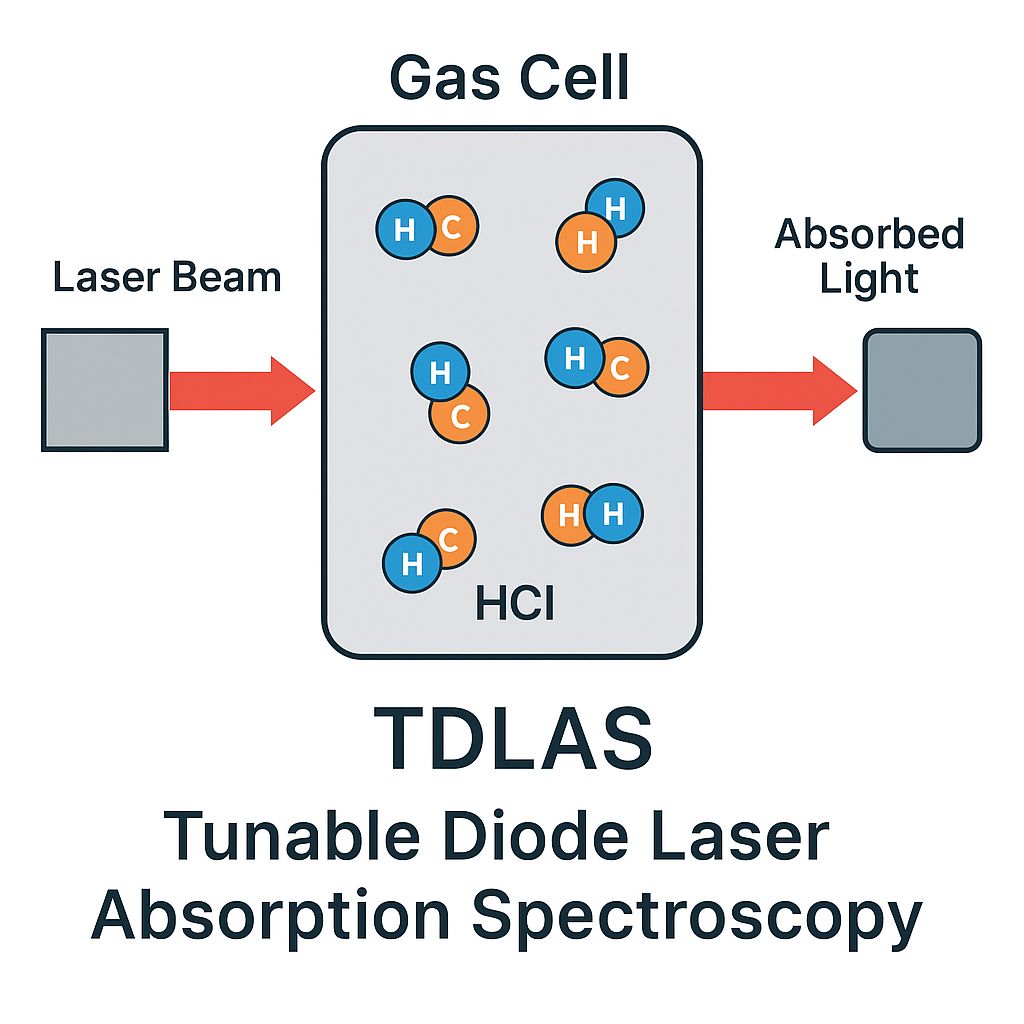

This is where Tunable Diode Laser Absorption Spectroscopy (TDLAS) excels. TDLAS is an optical gas sensing technology that leverages the principle of selective absorption: every gas molecule absorbs light at a unique wavelength. By tuning a diode laser to match the specific absorption wavelength of HCl—typically in the near-infrared range—the system can detect the presence and concentration of HCl molecules with extreme accuracy.

Here’s how it works: a laser beam passes through the gas sample or directly through the process duct (in situ), and a detector on the other side measures the amount of light absorbed at that precise wavelength. The more HCl molecules present, the greater the absorption. This relationship enables real-time, quantitative measurement of HCl concentrations, often down to the ppm or even ppb level.

TDLAS systems offer several advantages:

- High specificity: The laser targets only HCl, minimizing cross-sensitivity with other gases.

- Fast response time: Measurements are nearly instantaneous, ideal for dynamic processes.

- Low maintenance: With no moving parts or chemical consumables, TDLAS analyzers are extremely stable and require minimal upkeep.

- In situ or extractive installation options: Suitable for a variety of industrial layouts and emission points.

ESEGAS has developed a robust line of TDLAS-based HCl gas analyzers—such as the ESE-LASER-HCL-200 and ESE-LASER-HCL-700—specifically engineered to meet the demands of continuous emission monitoring (CEM) systems in incinerators, cement kilns, and chemical production plants. These systems can withstand extreme process conditions while maintaining the accuracy and sensitivity required for environmental compliance and process control.

By using ESEGAS’s TDLAS technology, industries gain not just a sensor, but a critical control point—ensuring that HCl emissions are continuously tracked, quickly addressed, and always under control.

Which HCl Analyzer Models Fit Specific Industry Needs?

Not all industries face the same HCl monitoring challenges—using a one-size-fits-all solution could lead to over-engineering or costly underperformance.

Different industrial sectors require different specifications when it comes to HCl gas analysis. Factors such as concentration range, installation type, environmental conditions, portability, and data integration all influence the ideal solution. Choosing the wrong model may result in excessive calibration effort, poor data accuracy, or even equipment damage.

To address these diverse demands, ESEGAS has developed a full line of HCl gas analyzers based on advanced TDLAS technology, each designed for specific operational scenarios:

1. ESE-LASER-HCL-200 – Standard Online TDL HCl Analyzer

Best for: General industrial applications requiring continuous monitoring

Industries: Waste incineration, coal power plants, fertilizer manufacturing

This is a robust, fixed-installation online analyzer designed for real-time, continuous monitoring of HCl in flue gases. It offers stable long-term performance, fast response time, and high measurement accuracy in harsh conditions such as high temperature or dust-laden exhaust streams. It’s widely used in emission control systems where compliance with environmental regulations is critical.

2. ESE-LASER-HCL-200P – Portable TDL HCl Analyzer

Best for: Field inspections, spot checks, emergency response

Industries: Environmental audits, third-party testing, stack testing services

Portability meets performance in this compact analyzer. It retains the high specificity of TDLAS while offering battery-powered operation and easy transport. The 200P is ideal for temporary monitoring, field verification of fixed systems, or use by regulatory bodies during inspections. Its plug-and-play design requires minimal setup time.

3. ESE-LASER-HCL-500 – High-Performance Online HCl Gas Analyzer

Best for: Harsh environments, higher accuracy requirements, large-scale systems

Industries: Cement kilns, chemical manufacturing, glass production

This model expands on the HCL-200 by incorporating advanced optical components and diagnostic functions. It’s designed for environments where gas composition or process dynamics vary significantly. Features include automatic baseline correction, system self-checks, and integration with SCADA or DCS systems.

4. ESE-LASER-HCL-700 – Trace-Level (ppb) HCl Analyzer

Best for: Ultra-low concentration monitoring, early leak detection

Industries: Semiconductor manufacturing, pharmaceutical facilities, cleanrooms

When even trace amounts of HCl can damage sensitive processes or violate purity standards, the HCL-700 delivers. It provides ultra-sensitive detection in the ppb range and is used for ambient air monitoring or enclosed space detection. This model offers precision control over gas purity in environments with zero-tolerance for contamination.

ESEGAS ensures that each of its analyzers is not only tailored to technical needs but also supports long-term operational efficiency—minimizing maintenance, downtime, and environmental impact.

Whether you need rugged in-situ monitoring for a cement kiln or handheld precision for a mobile test team, there’s an ESEGAS solution optimized for your use case.

Conclusion

Choosing the right HCl gas analyzer is critical for safe, compliant, and efficient operations. With advanced TDLAS-based solutions, ESEGAS offers trusted technology tailored to industrial needs.

if you have any questions, please contact us directly!