Inconsistent ripening leads to massive post-harvest losses. Poor gas control in storage environments jeopardizes fruit quality and market readiness.

These sensors provide critical data that helps maintain optimal conditions, supporting uniform maturity and minimizing economic loss.

Modern storage demands smart control. Understanding the science behind gas monitoring empowers growers and distributors to maintain quality and meet consumer expectations.

Why Is Ethylene Monitoring Essential in Fruit Ripening?

Irregular ethylene levels lead to inconsistent ripening, color mismatch, and shortened shelf life.

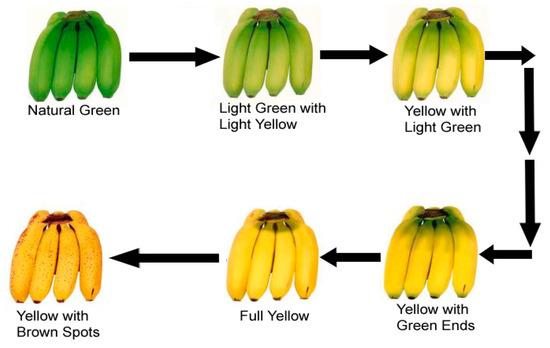

Ethylene (C₂H₄) is a naturally occurring plant hormone that triggers and regulates the ripening process in climacteric fruits such as bananas, avocados, mangoes, and tomatoes. Once released, ethylene accelerates cellular respiration, color development, softening, and sugar accumulation. However, excessive or uneven exposure to ethylene can result in over-ripened patches, textural imbalance, or internal spoilage before distribution.

For post-harvest managers, the challenge lies in maintaining ethylene at ideal concentrations, typically between 10–100 ppm depending on the fruit type and maturity stage. This control enables consistent ripening, allowing entire batches to reach optimal readiness for market delivery without wastage.

Real-time monitoring is crucial. Manual gas checks are often delayed and imprecise, leading to errors in ventilation or gas injection. This is where advanced gas analyzers like those from ESEGAS become indispensable. ESEGAS ethylene sensors use photoacoustic or electrochemical technologies to deliver precise, continuous data with fast response times. Their integration into ripening chambers ensures that ethylene stays within target thresholds, preventing uneven color or premature decay.

Moreover, in multi-fruit facilities, cross-contamination from high-ethylene emitters can damage sensitive produce. An integrated monitoring system alerts operators instantly, ensuring gas zoning and targeted airflow strategies are executed effectively.

By using ESEGAS solutions, producers not only ensure uniform ripening but also optimize operational efficiency, reduce manual intervention, and enhance the consistency of fruit presentation across supply chains.

What Role Does CO₂ Play in Ripening Control?

Neglecting CO₂ regulation leads to flavor degradation, decay acceleration, and reduced storage stability.

While ethylene is the primary ripening hormone, carbon dioxide (CO₂) plays a critical regulatory role in the ripening environment. High concentrations of CO₂ can inhibit ethylene action by reducing its binding affinity to receptor sites within the fruit. This means CO₂ can act as a natural brake, allowing ripening to be slowed or staggered—a key advantage in logistics and inventory coordination.

CO₂ also contributes to mold prevention and microbial control. In properly sealed ripening rooms, elevated CO₂levels (typically between 1%–5%) suppress the growth of spoilage organisms, extending the shelf life of high-value fruits. However, when CO₂ exceeds optimal thresholds or becomes trapped in low-ventilation zones, it can lead to anaerobic respiration. This results in off-odors, internal browning, and soft tissue breakdown.

Precise control of CO₂ levels is thus not optional—it’s essential. Conventional handheld CO₂ detectors often lack the sensitivity or responsiveness to track fast gas shifts in dynamic storage settings. This is why industrial-grade monitoring systems like those from ESEGAS are crucial. ESEGAS CO₂ sensors leverage non-dispersive infrared (NDIR) technology for high-accuracy, real-time monitoring. They are engineered for use in humid, chemically active environments typical of fruit ripening chambers.

With their low-drift performance and fast response time, ESEGAS CO₂ analyzers provide the actionable data needed to fine-tune ventilation, gas injection, and alarm settings. When integrated with automated control systems, they allow operators to maintain a stable and predictable ripening environment—protecting both fruit quality and operational efficiency.

In summary, while ethylene initiates the ripening process, CO₂ helps manage its pace and safety. Together, and when monitored with precision instruments like those from ESEGAS, they form the foundation of a controlled, high-yield fruit ripening strategy.

How to Choose the Right Ethylene and CO₂ Sensors for Fruit Storage?

Inaccurate sensor readings compromise ripening control, leading to quality loss and increased waste.

Selecting the right gas sensors is fundamental to ensuring effective fruit ripening. Ethylene and CO₂ concentrations must be maintained within narrow ranges to avoid under- or over-ripening. The wrong choice of sensor—whether due to poor sensitivity, slow response time, or instability in humid environments—can distort real-time data and cause delayed or incorrect decisions.

For ethylene monitoring, sensors must detect concentrations as low as 0.1 ppm to respond effectively to early-stage gas accumulation. Electrochemical and photoacoustic sensors are preferred for their high precision in low parts-per-million detection. For CO₂, non-dispersive infrared (NDIR) sensors are standard due to their stability, low drift, and ability to withstand fluctuating humidity and temperature conditions common in ripening chambers.

Durability and calibration frequency are equally important. Many fruit storage environments experience variable gas loads and high moisture, which can degrade lesser-grade sensors quickly. This is where ESEGAS sensors excel. ESEGAS offers a full range of gas analyzers with robust housings, moisture protection, and automatic calibration systems. Their sensors are purpose-built for post-harvest agriculture, ensuring sustained accuracy over long periods with minimal maintenance.

Integration capabilities are another key consideration. Sensors should easily connect to existing ripening room controllers, data loggers, or cloud-based platforms. ESEGAS devices are IoT-ready, featuring multiple output protocols (4–20 mA, RS485, Modbus) that facilitate seamless connectivity to any control infrastructure.

In essence, the ideal sensor must combine high accuracy, environmental resilience, long-term stability, and system compatibility. With ESEGAS, post-harvest managers gain a trusted partner in building a gas monitoring system that protects fruit quality from storage to market.

How Should Sensors Be Installed and Maintained in Ripening Chambers?

Improper sensor placement or neglected maintenance results in inaccurate data, threatening the entire ripening process.

To achieve precise gas monitoring, ethylene and CO₂ sensors must be installed and maintained according to strict industrial protocols. Fruit ripening chambers have unique environmental conditions—variable airflow, high humidity, and gas concentration gradients—that can easily distort measurements if sensors are not correctly managed.

Here are key guidelines for optimal sensor deployment and upkeep:

1. Sensor Placement Best Practices

- Install at fruit level: Sensors should be positioned where gas interaction is most active—typically at the height where fruit crates are stacked. Avoid placing sensors too high or near air vents.

- Avoid direct airflow: Sensors must not face strong fans or gas injectors directly, as this can cause erratic readings. Choose areas with stable air mixing for a representative sample.

- Multiple-point coverage: In large or multi-zone chambers, install multiple sensors to monitor gas stratification and detect localized concentration spikes.

2. Maintenance and Calibration Protocols

- Routine calibration: Sensor accuracy can drift over time due to exposure to moisture and contaminants. ESEGAS sensors support automated or manual calibration routines that can be scheduled based on usage intensity—typically monthly or quarterly.

- Filter checks and cleaning: Protective filters should be cleaned or replaced periodically, especially in dusty environments. Sensor heads should be wiped with a dry cloth or alcohol swab to remove residues.

- Firmware and diagnostics: ESEGAS offers smart diagnostics with real-time status indicators, self-check routines, and updateable firmware to ensure ongoing reliability.

3. Integration and Alarm Configuration

- Link to control systems: Sensors should be integrated into the chamber’s central control system. ESEGASdevices feature Modbus and analog outputs for easy connectivity.

- Set threshold alarms: Configure audible or SMS/email alerts for gas levels that exceed safe thresholds. This enables quick corrective action before ripening is compromised.

4. Environmental Considerations

- Humidity protection: Always choose sensors rated for high-humidity use. ESEGAS sensors include protective coatings and sealed enclosures to resist condensation.

- Temperature stability: Sensors must operate reliably across the chamber’s temperature range, typically 12–20°C for ripening environments.

By following these installation and maintenance standards—and leveraging advanced sensor technology from ESEGAS—operators can build a high-integrity monitoring system. This ensures that gas data remains accurate, actionable, and consistent across every ripening cycle.

Conclusion

Effective fruit ripening relies on precise gas control. With ESEGAS sensors, producers can achieve uniform ripening, extended shelf life, and smarter inventory decisions—all driven by accurate ethylene and CO₂ monitoring.