In natural gas operations, hydrogen sulfide (H₂S) is more than just a nuisance—it’s a corrosive, toxic, and economically damaging contaminant. Even trace levels can corrode pipelines, poison catalysts, and pose serious risks to worker safety. That’s why reliable H₂S monitoring is non-negotiable across the natural gas supply chain.

This is where TDLAS (Tunable Diode Laser Absorption Spectroscopy)-based H₂S analyzers come in. Compared to traditional methods, they deliver faster response, higher accuracy, and stronger resistance to interference. For engineers and process professionals, choosing the right H₂S analyzer can mean the difference between costly downtime and continuous, safe operations.

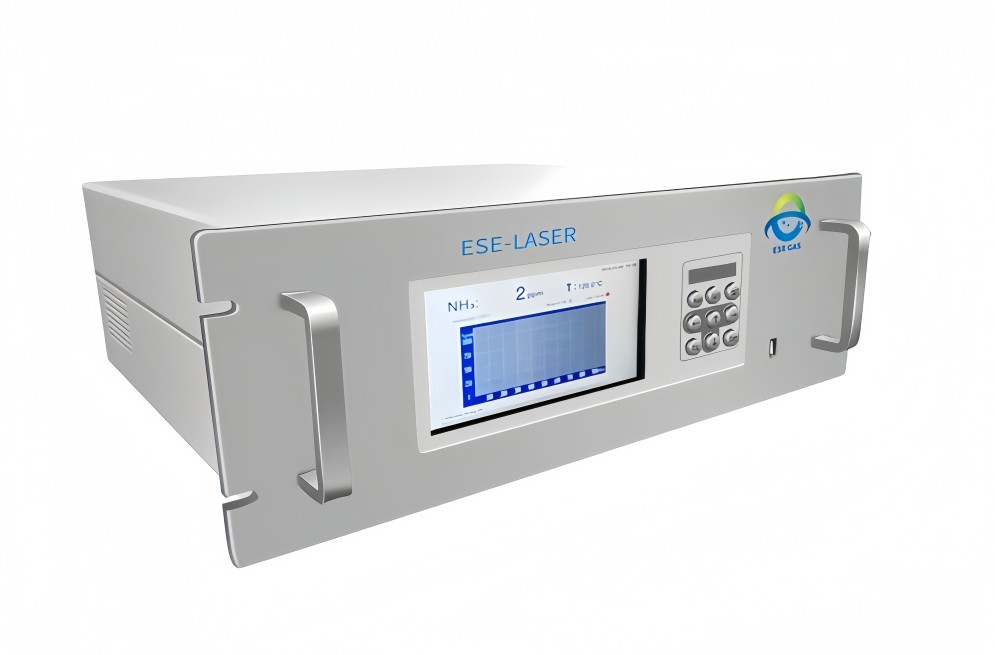

In this post, we explore the unique benefits of TDLAS technology—focusing on how the ESEGAS ESE-LASER-600 TDL online H₂S analyzer supports sour gas pipeline integrity and gas processing efficiency.

What Makes the H₂S Analyzer a Smart Choice for Sour Gas Applications?

(Sour natural gas treating facility)

The ESE-LASER-600 is not your average H₂S analyzer. It’s engineered with field realities in mind: fluctuating gas conditions, cross-sensitivity challenges, and tight compliance deadlines.

Let’s look at what sets this analyzer apart:

- Dual measurement range (0–500 ppm or 0–30%) allows flexible deployment across upstream, midstream, and downstream facilities.

- Ultra-low detection limit (customizable) in the parts-per-billion (ppb) range enables early warning and precision control.

- TDLAS core technology offers pinpoint selectivity to H₂S—minimizing false readings from CO₂, CH₄, or H₂O.

- Enhanced Heliotrope light cell design ensures stable performance, even in corrosive or variable environments.

- Half-year calibration intervals and no consumable parts reduce operating costs and downtime.

- Custom gas configurations and surface coatings minimize gas adsorption, ensuring accurate long-term monitoring.

This combination of precision, durability, and adaptability makes the ESE-LASER-600 ideal for sour gas pipelines, gas sweetening plants, amine treatment units, and more.

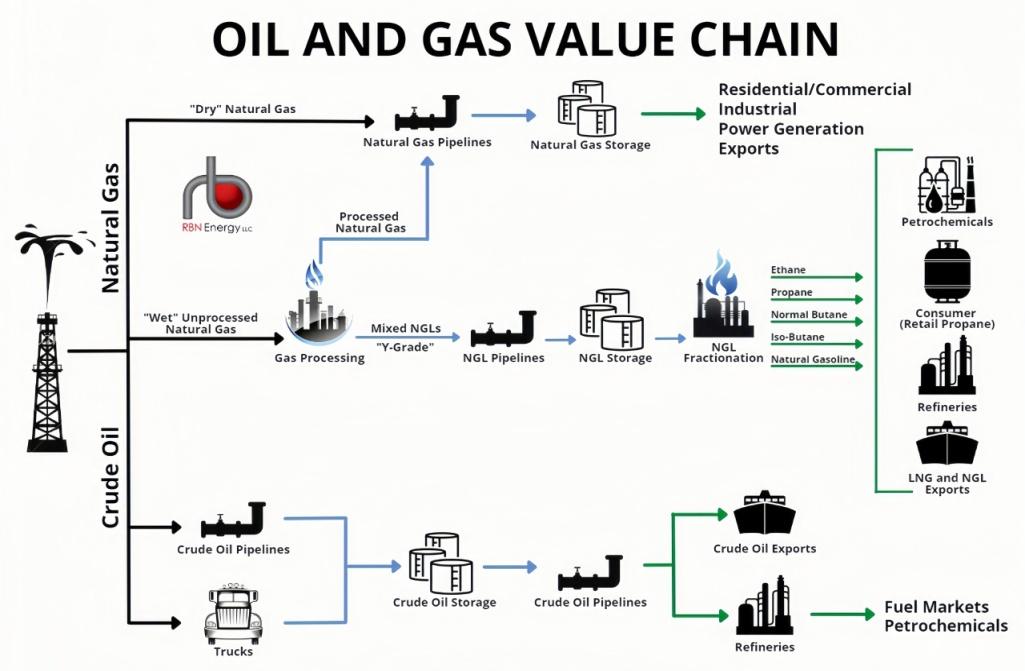

Where Does the H₂S Analyzer Fit in the Natural Gas Value Chain?

H₂S can appear in nearly every stage of natural gas production and distribution. Below are key locations where continuous H₂S monitoring matters—and how the ESE-LASER-600 supports each:

1. Upstream Gas Extraction

Raw gas from wells can contain high H₂S levels. TDLAS analyzers provide immediate feedback, helping field operators make real-time decisions about well output, separation, and conditioning.

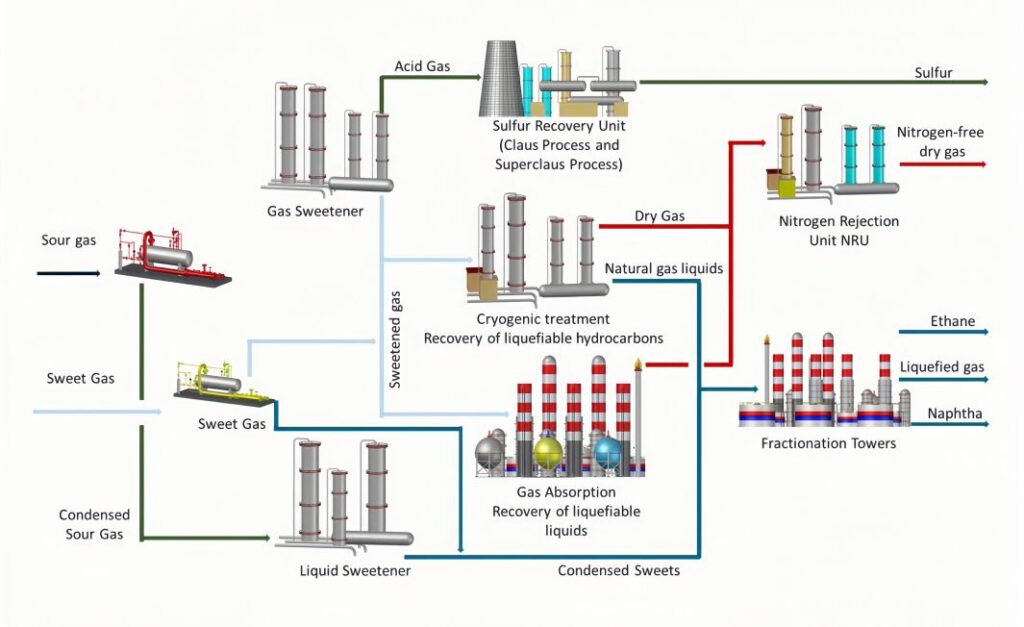

2. Gas Sweetening Units (Amine Systems)

Post-treatment monitoring is critical to ensure H₂S is removed effectively. The ESE-LASER-600 ensures sweet gas complies with sales gas specs (<4 ppm), reducing the risk of product rejection or pipeline corrosion.

3. Pipeline Transport

Even residual H₂S can cause internal corrosion or lead to environmental violations during venting or flaring. Continuous in-line measurement helps operators adjust injection rates or schedule pigging operations.

4. Gas Processing and Storage

From dehydration to LNG production, trace H₂S must be monitored to protect catalysts and preserve product quality. TDLAS technology’s fast response enables immediate corrective actions.

How Does the H₂S analyzer Help Operators Cut Costs and Improve Safety?

Beyond measurement accuracy, this analyzer adds real value to operations:

- Fewer shutdowns: Reliable H₂S alerts prevent corrosion failures and unplanned maintenance.

- Lower OPEX: With no consumables and only biannual calibration, operators save on labor and spare parts.

- Better compliance: Instant detection supports environmental reporting and health & safety standards (e.g., OSHA 10 ppm ceiling limit).

- Faster commissioning: The analyzer’s user-friendly interface and robust diagnostics simplify startup and integration.

For program engineers and maintenance teams, that means less firefighting and more confidence in the data. For EHS managers, it translates into reduced risk and peace of mind.

What Should You Consider Before Installing a H₂S Analyzer?

(Consider)

Before deploying a TDLAS system, ask yourself:

- What are your target H₂S ranges—trace, ppm, or percentage?

- Will the sensor face high dust, pressure, or moisture conditions?

- Do you need fast response or long-term trend data?

- How often can you perform calibration or maintenance?

The ESE-LASER-600 offers flexible customization to meet these needs—from fiber-coupled probes for high-pressure lines to anti-adsorption coatings for low-flow streams.

Whether you’re working offshore, on a gas gathering system, or in a refining complex, this system adapts to your process—not the other way around.

How to Implement a Online H₂S Analyzer in Sour Gas Pipelines and Supply Chains

Implementing a TDL online H₂S analyzer involves deliberate planning and precise execution. Below is a clear, step-by-step guide to help engineers and technical readers succeeding with real-world sour gas pipelines.

Step 1: Define Monitoring Strategy

- Identify sampling points: sour gas extraction, sweetening units, pipeline entry/exit, storage/processing lines.

- Choose desired H₂S range: trace ppb, ppm, or percent levels. Online analyzers support wide dual-range setups.

Step 2: Set Up Sampling System

- Install extraction probes in pipeline or gas line, followed by sample conditioning—including filters, knockout traps, and temperature control.

- Route the conditioned sample to a secure analyzer shelter or cabinet with climate control.

Step 3: Analyzer Installation & Calibration

- Calibrate analyzer twice a year or as required; remote diagnostics simplify scheduling.

- Implement auto-validation routines—some systems offer continuous device health checks and verification logging, ideal for custody transfer and specification compliance.

Step 4: Tuning for Specific Conditions

- Choose suitable coatings or purge controls to reduce adsorption of sticky H₂S on surfaces.

- Use enhanced optical cell designs (e.g., heliotrope or differential laser paths) to boost signal-to-noise, maintain ppb-level detection, and resist background gas interference.

Step 5: Integrate with Control Systems

- Stream measurement outputs (4–20 mA, RS-485, Modbus, Ethernet) to plant DCS or SCADA systems.

- Set alarm thresholds—for H₂S levels, calibration prompts, or sensor health signals.

- Configure multipoint sampling, linking several probe lines to one analyzer to economize instrumentation.

Step 6: Operational Validation & Support

- Use field-serviceable modules and replaceable components to minimize downtime.

- Perform routine visual inspections: clean optics quarterly, check alignment monthly, verify pump and flow rates.

- Keep training protocols updated so local engineers and technicians can manage commissioning, troubleshooting, and validation.

Deploying a TDL online H₂S analyzer offers significant operational and safety benefits for sour gas applications. By following these six steps, you create a system that delivers accurate, reliable data day after day.

Conclusion

If you’re running sour gas operations, precision matters. Small measurement errors can lead to big problems—whether in asset damage, regulatory fines, or safety risks.

With its advanced optical core, dual-range design, and nearly maintenance-free operation, the ESEGAS ESE-LASER-600 makes an excellent long-term investment. It’s not just an analyzer—it’s an insurance policy for your pipeline integrity and gas quality.

Looking for a reliable solution to monitor H₂S in complex gas streams? The TDLAS-based ESE-LASER-600 is ready to meet the challenge—fast, accurate, and built to last.