Inconsistent flow control can lead to waste, contamination, and serious quality risks in food production. For manufacturers aiming at high hygiene and precision, is there a better solution than the Ultrasonic Flow Meter?

The food industry’s demand for precision, hygiene, and efficiency has driven the widespread adoption of non-invasive, accurate technologies like the Ultrasonic Flow Meter. These instruments provide real-time flow data, reduce maintenance, and help producers meet safety and regulatory standards.

Accurate flow monitoring is central to modern food manufacturing. Whether it’s controlling milk dosing, measuring cleaning solutions, or monitoring cooling water, outdated mechanical meters often fall short. Ultrasonic Flow Metersoffer a smart, contactless alternative—enabling food producers to take full control of their production environment.

What Is an Ultrasonic Flow Meter and How Does It Work?

A High-Precision, Non-Invasive Flow Measurement Technology Designed for Demanding Applications

An Ultrasonic Flow Meter is an advanced instrument that measures the velocity of a fluid—liquid or gas—flowing through a pipe using ultrasonic sound waves. Unlike traditional mechanical meters, it does not rely on moving parts or direct contact with the process medium. This makes it especially suitable for industries like food and beverage, where hygiene, accuracy, and low maintenance are critical.

There are two main types of ultrasonic flow measurement technologies: Transit-Time and Doppler. In food industry applications, transit-time meters are the preferred choice due to their high accuracy and suitability for clean or mildly contaminated liquids.

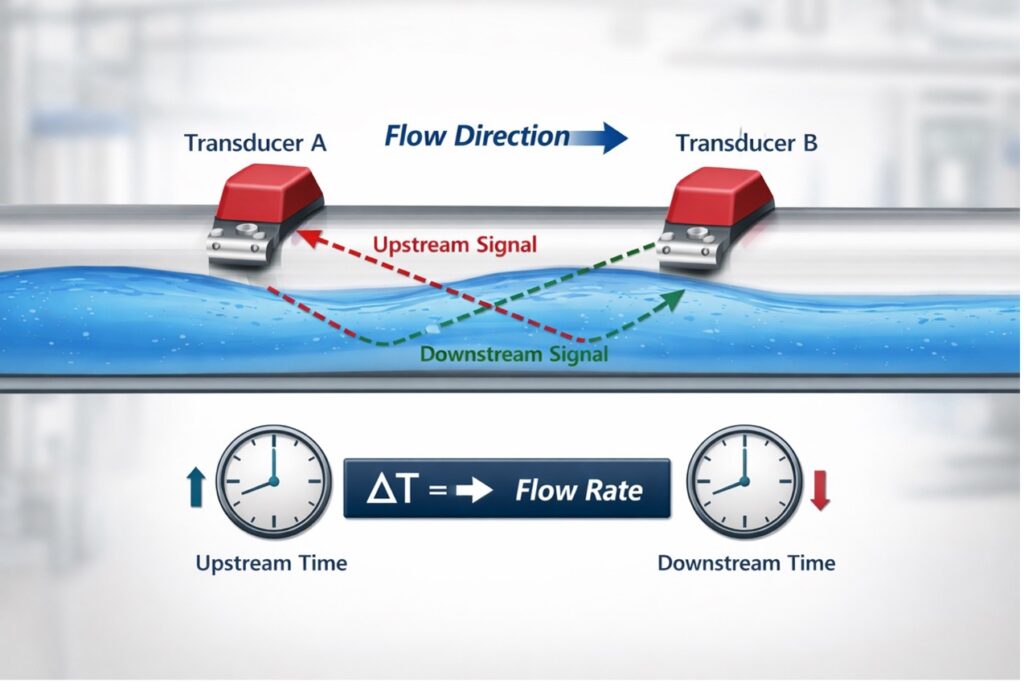

How Transit-Time Ultrasonic Flow Measurement Works

The ESEGAS Ultrasonic Flow Meter operates on the transit-time differential principle. Here’s how it works:

- Two transducers are installed either on the outside of the pipe (clamp-on type) or in direct contact with the fluid (inline type).

- These transducers send and receive high-frequency sound pulses both upstream and downstream through the fluid.

- When fluid is stationary, the transit times in both directions are equal.

- When the fluid flows, the upstream pulse takes longer, and the downstream pulse is faster.

- The meter calculates the time difference between these signals, and based on the known distance between the transducers and the angle of transmission, it determines the flow velocity.

- By multiplying the velocity by the cross-sectional area of the pipe, the volumetric flow rate is calculated.

This method delivers extremely accurate readings—often within ±1% of the actual flow—even at low flow rates.

What Makes ESEGAS Ultrasonic Flow Meters Stand Out?

1. Non-Intrusive Design for Sanitary Food Operations

Unlike traditional meters, which contact the process media, Ultrasonic Flow Meters from ESEGAS are entirely external to the flow path. This design ensures compliance with food-grade sanitary requirements and reduces contamination risks to near zero—an essential advantage in dairy, beverage, and flavoring processes.

2. Minimal Maintenance and Downtime

ESEGAS Ultrasonic Flow Meters have no moving parts, meaning wear and tear is virtually eliminated. For food plants operating 24/7, this translates to fewer maintenance interventions, less downtime, and lower operational costs over time.

3. High Accuracy and Repeatability

Flow control is directly tied to product quality. In applications like ingredient mixing or syrup blending, even slight inaccuracies can result in off-spec batches. ESEGAS meters deliver precision within ±1%, ensuring consistent, repeatable results across every shift.

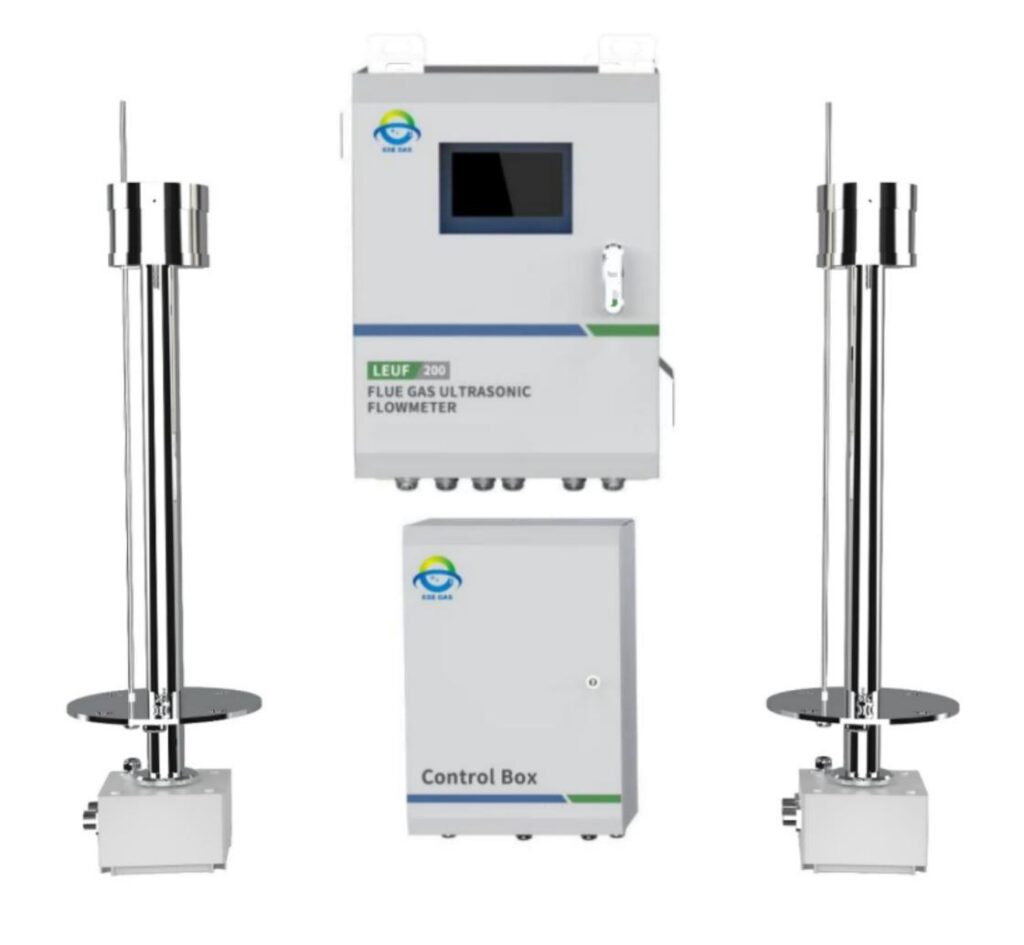

Meet the ESEGAS Ultrasonic Flow Meter: LEUF‑200

Precision Gas Flow Measurement for Specialized Food Applications

The LEUF‑200 is a flagship Ultrasonic Flow Meter by ESEGAS designed for highly accurate gas flow measurement in industries requiring strict process control, including sectors adjacent to food production like packaging gas injection and HVAC systems in food plants.

Key Benefits:

- Fully non-contact measurement

- Suitable for compressed air, CO₂, or nitrogen lines used in food packaging

- High sensitivity and ±1% accuracy

- Multiple output options for easy PLC/SCADA integration

- Durable performance in high-moisture environments

While the LEUF‑200 is primarily optimized for gas, the ESEGAS engineering platform offers the potential for customized liquid-based solutions tailored to CIP, ingredient dosing, and water management in food factories.

Explore the product: ESEGAS Ultrasonic Flow Meter – LEUF‑200

How Is the Ultrasonic Flow Meter Used in Food Manufacturing?

1. Ingredient Mixing and Batch Control

Problem: Manual or outdated flow monitoring systems can’t guarantee consistent ingredient ratios.

Solution: The Ultrasonic Flow Meter ensures real-time monitoring of liquids like oil, syrups, and flavorings. This helps standardize every batch and meet recipe requirements with precision.

2. CIP (Clean-In-Place) System Verification

Problem: Inefficient cleaning processes lead to hygiene risks and chemical waste.

Solution: ESEGAS meters monitor cleaning fluid flow, validating that tanks and pipelines receive the required volume. This supports audit compliance and improves sanitation protocols.

3. Cooling and Heating Water Monitoring

Problem: Heat exchange systems in pasteurization and sterilization rely on precise water flows.

Solution: An Ultrasonic Flow Meter measures both chilled and hot water flows, helping operators optimize energy use and protect product quality.

4. CO₂ and Nitrogen Flow in Packaging Lines

Problem: Modified atmosphere packaging (MAP) requires precise control over gas flows.

Solution: The LEUF‑200 accurately measures gas flow used to preserve food freshness, ensuring cost-effective and safe packaging.

Can Ultrasonic Flow Meters Integrate into Smart Factories?

Absolutely. ESEGAS Ultrasonic Flow Meters are built for Industry 4.0. They feature:

- Digital communication interfaces for PLC/SCADA systems

- Real-time remote diagnostics and monitoring

- Seamless integration with cloud-based data analysis

- Predictive maintenance alerts

This level of connectivity empowers food manufacturers to reduce manual oversight, improve traceability, and make faster, data-driven decisions.

Why Food Processors Trust ESEGAS

At ESEGAS, we don’t just sell flow meters—we engineer tailored measurement solutions that align with your specific production goals. With years of experience across diverse industries, including food, beverage, and gas systems, we offer:

- Expert application consulting

- On-site installation and training

- Long-term support and global logistics

- Custom integration into existing automation frameworks

Our commitment is not only to accuracy and reliability, but also to building lasting partnerships with manufacturers ready to scale their process capabilities.

Conclusion: Flow Measurement Is Food Safety, Quality, and Efficiency Combined

From maintaining hygiene to controlling recipes, Ultrasonic Flow Meters are no longer optional in the food industry—they’re essential. ESEGAS stands at the forefront, delivering advanced, cost-effective, and future-ready flow measurement technology.

When you choose an ESEGAS Ultrasonic Flow Meter, you’re not just measuring flow—you’re investing in process excellence.